It is worth saying that hoppecke batteries should be installed as standard, but with a capacity of 80 Ah (C5).

The floor polisher is equipped with a built-in charger.

To see in which mode the floor polisher is REALLY operated, we installed a monitoring device for systems equipped with batteries - ABLogger.

ABLogger is a device that measures battery voltage and consumption / charge currents. The measured values with real time stamp are saved in the device memory. At the end of the monitoring, the device must be synchronized with the PC in order to evaluate the monitoring results in the form of current and voltage graphs.

Graphs of current and voltage changes over time give a complete picture of the operation of ANY vehicles or systems equipped with batteries.

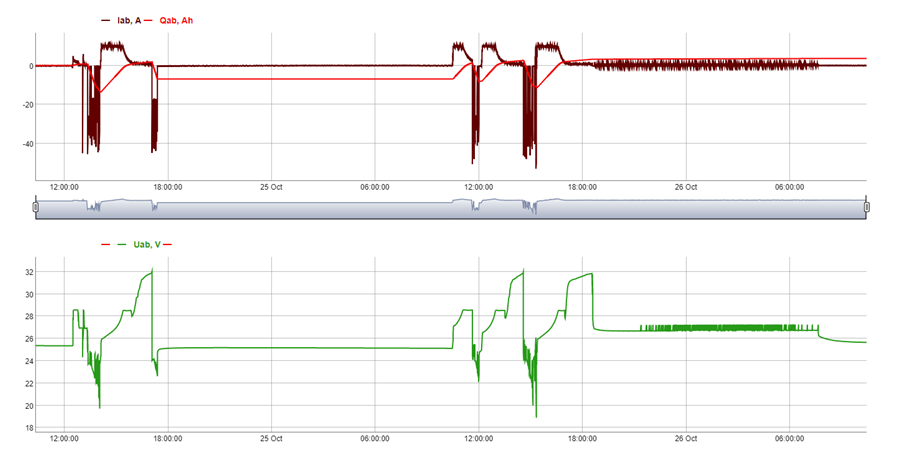

The monitoring was carried out for two days. The graphs of the current (top) and voltage (bottom) are presented in Figure 1:

Figure 1

Next, we will consider various sections of the graphs from Figure 1:

Consider the time interval from 12:28 to 13:21 on October 24 (Figure 2):

The graphs show that The battery was charged and then the floor polisher was started.

We analyze the graphs: first, the battery was charged (the voltage rises from 25.4 to 28.5 V). The charging current gradually decreases at an almost constant charge voltage of about 28.5 V. At about 13:03 the floor polisher is removed from the charge and used: at 13:03 it is clear that the current falls below zero (the logic is simple: if the current value is above zero, the battery is charged , below zero - the battery supplies the load). From 13:03 to 13:05 the floor polisher is intensively used - the voltage on the battery drops to 24.2 V.

After that, the floor polisher is put on charge again.

Figure 2

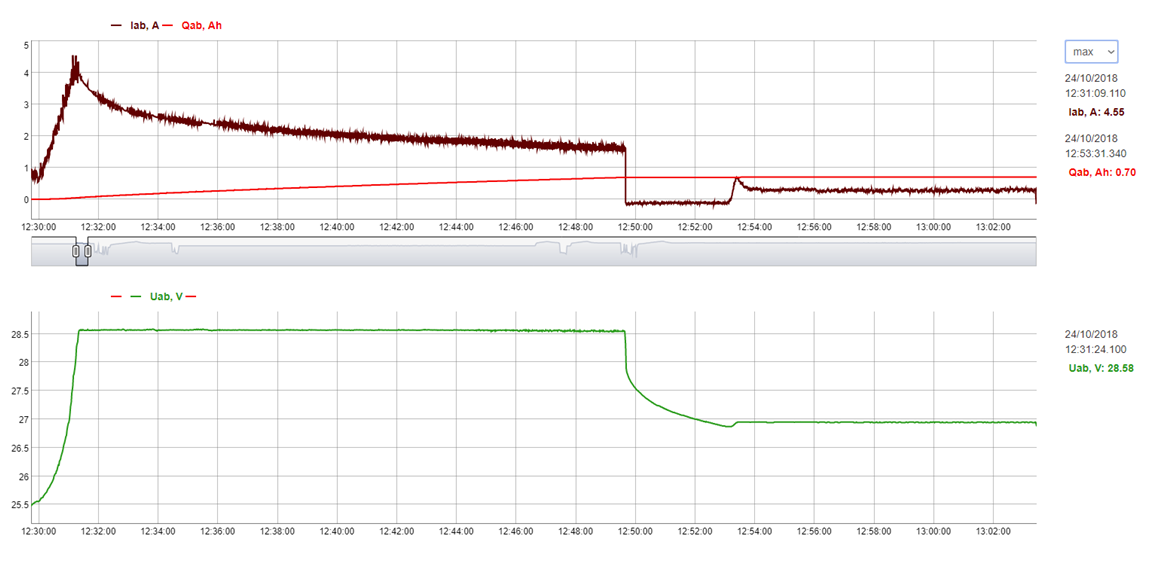

Let's consider the charging process in more detail (see Figure 3):

The maximum charging current was 4.55 A, the maximum charging voltage was 28.58 V. It can be seen that the voltage rises rapidly to 28.5 V and remains practically constant for about 18 minutes. In this case, the charging current gradually decreases to 2 A.

Then, at about 12:50, the charger turns off (the current drops to zero), and turns on again at 12:53 (seen by a small jump in the current and voltage on the battery).

Figure 3

After the worker took the floor polisher off the charge and checked its operation for about 30 seconds, then put the floor polisher back on the charge (see figure 4):

Figure 4

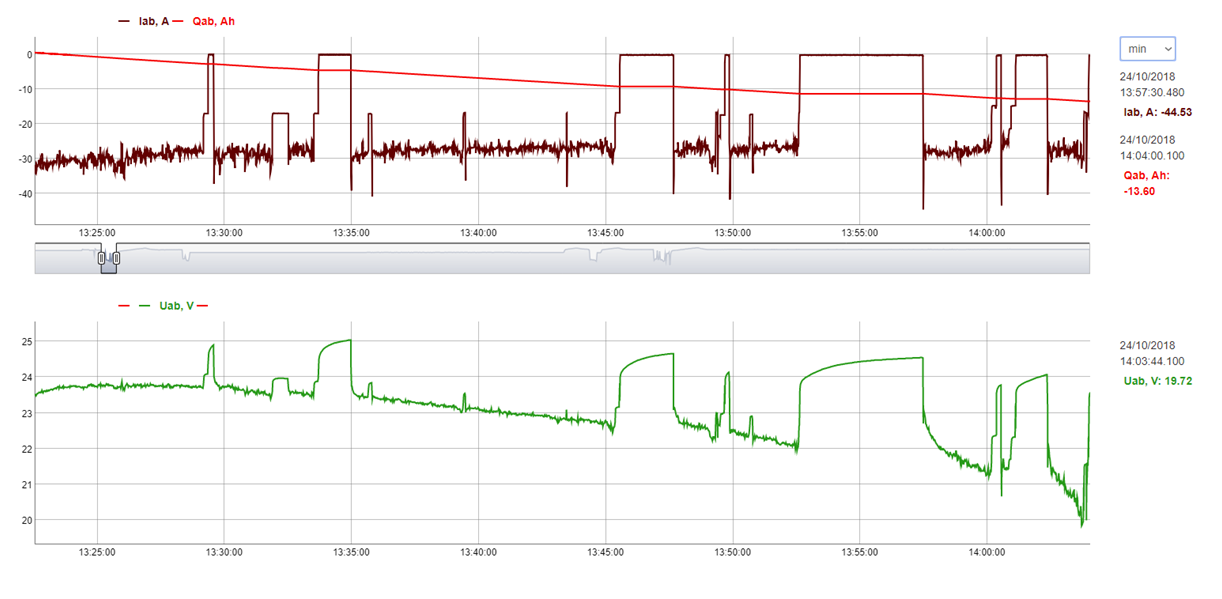

After the charge, the floor polisher was operated from 13:22 to 14:03 (see. Figure 5):

Maximum discharge current 44.53 A (minimum voltage19.72V ). In 41 minutes, the battery gave 13.6 Ah, it is easy to calculate that for an hour of operation in this mode, the battery would give about 20 Ah.

Figure 5

After intensive use, the floor polisher is put on charge from 14:04 to 17:04 (see Figure 6):

As can be seen from the graphs, the maximum voltage on the battery during charging is 32.02 V, and the maximum charging current is 10.41 A. At 16:28, an equalizing charge begins, during which, apparently, due to electrolysis, the battery loses water. This water loss must be compensated for by adding distilled water at least once every six months.

The capacitance is also calculated from the current values (red curve in the top graph in Figure 6). The capacity taken by the battery during charging is easy to calculate if you subtract the calculated value of the capacity at the beginning of the charge from the value at the end.

So, during the charge, the battery took a capacity of 15.44 Ah. This is enough to compensate for the capacity released during the operation of the polisher.

Figure 6

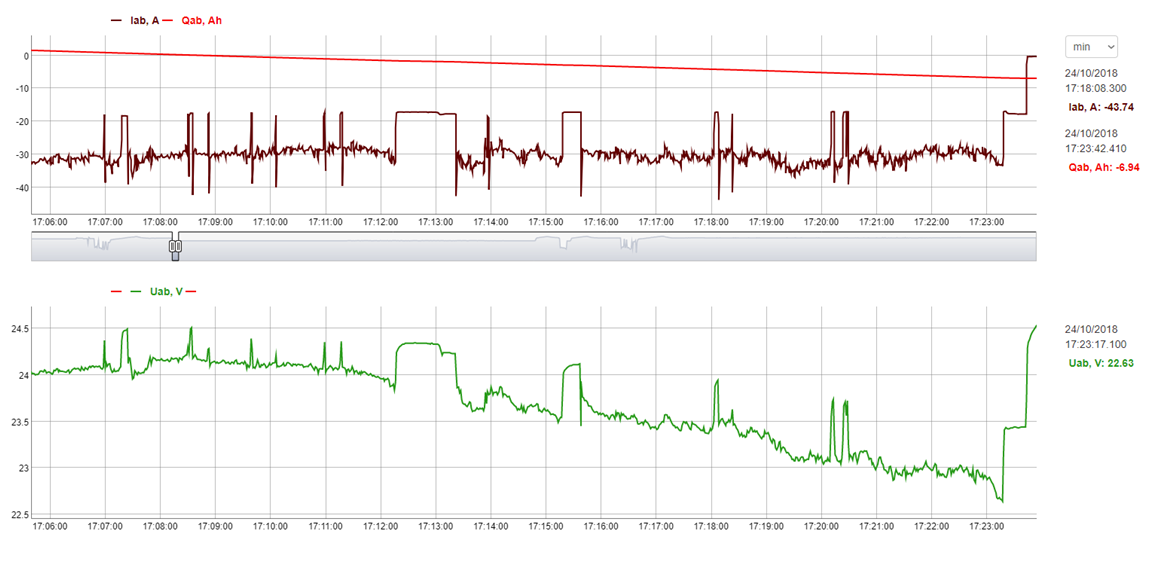

After charging, the floor polisher is operated again between 17:05 and 17:23 (see Figure 7):

As can be seen from the graphs, the maximum discharge current is 43.74 A (minimum voltage 22.63 V). In 18 minutes, the battery delivered 8.78 Ah, which corresponds to 29.2 Ah per hour.

Figure 7 The

working day on October 24 ended , but the operator forgot to put the polisher on charge. As a result, the floor polisher is put on charge only the next day at 10:27 (Figure 8):

Figure 8

Due to the operator's mistake, who forgot to charge the floor polisher at the end of the working day, there is no time left for a full charge. As a result, the floor polisher is on charge from 10:27 am to 11:38 am (71 minutes) , and then they start to operate it again.

As can be seen from Figure 9, the charge simply does not have time to reach the equalization stage. Based on the graphs in Figure 6, it can be assumed that it is necessary for the battery to be continuously charged for approximately 2 hours for the charger to switch to equalization charge.

The maximum voltage on the battery during charging 28.59V (maximum charging current 10.34 A) - 8.26 Ah was taken during battery charging.

Figure 9

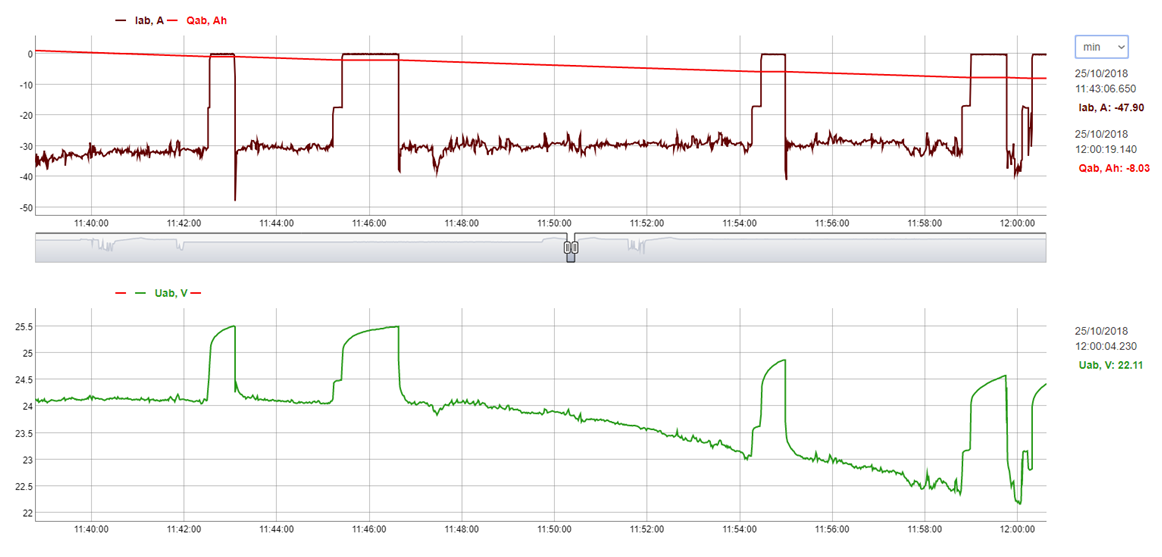

After charging, the floor polisher is operated again from 11:38 to 12:00 (Figure 10):

Maximum discharge current 47.9 A (minimum voltage 22.11 V). In 22 minutes, the battery delivered 9.35 Ah, which corresponds to 25.5 Ah per hour.

Figure 10

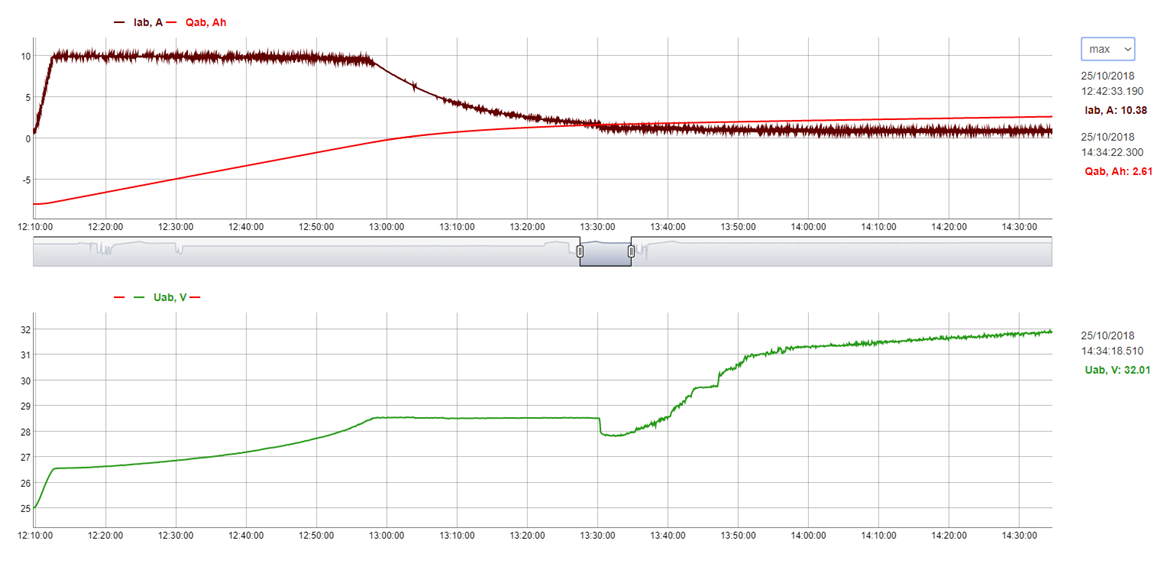

Then the floor polisher is charging again in the period from 12:09 to 14:34 (Figure 11):

Maximum battery voltage during charging 32.01 V (maximum charging current 10.38A) - from 13:57 on equalizing charge water is lost due to electrolysis.

During charging, the battery took 10.64 Ah.

Figure 11

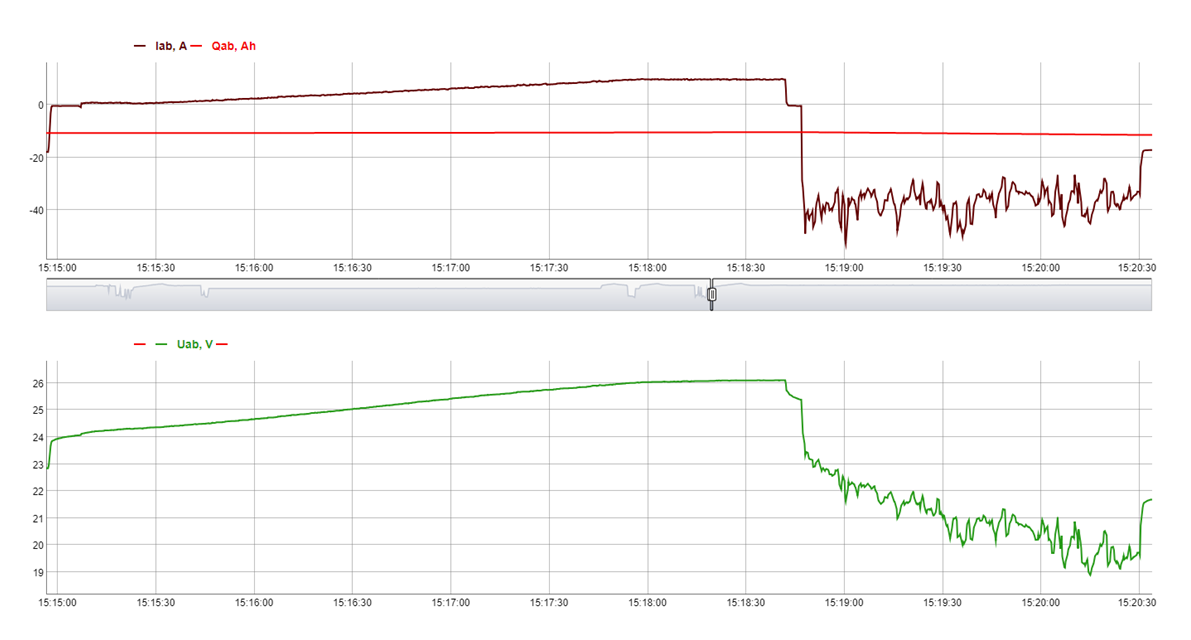

The floor polisher is then operated again from 14:36 to 15:21 .

However, at 15:14 the operator decides to put the floor polisher on charge. The polisher is charged for only 4 minutes, after which it is again removed from the charge and continues to be used. The battery voltage drops to 18.89 V. At this voltage level, the batteries wear out very quickly.

See the graphs in Figure 12:

Figure 12

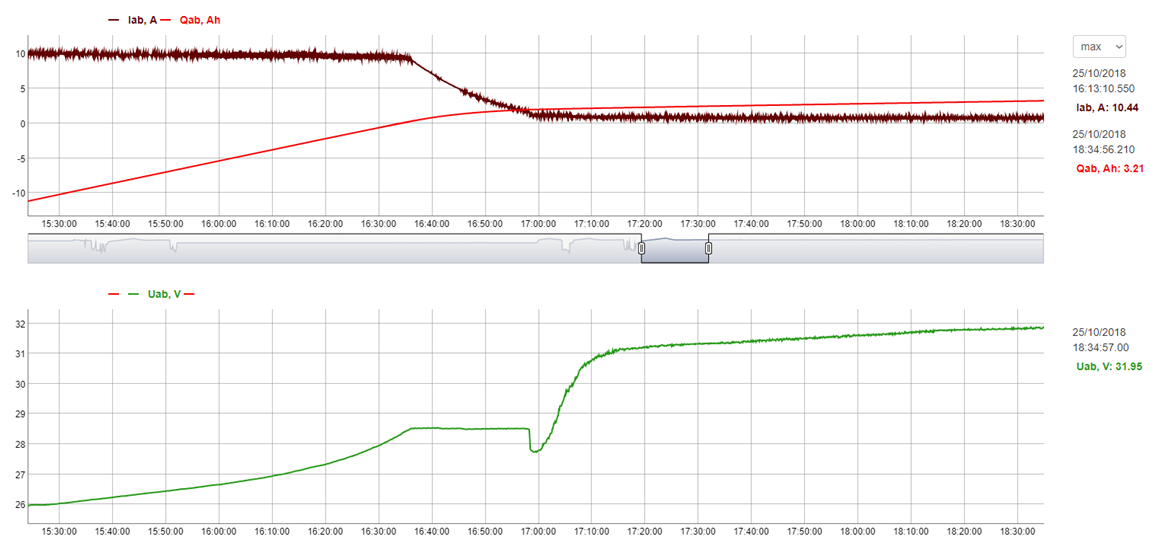

After such an execution, the battery is put on charge again. The battery is charged from 15:24 to 18:35 (Figure 13):

as you can see, with this charging time (3 hours 11 minutes), the charge has time to reach the equalization stage.

During charging, the battery took 14.68 Ah.

Figure 13

It is obvious that the battery is worn out - the voltage drops to about 11 V per battery with a real capacity consumption of only 10-15 Ah. And this despite the fact that the declared capacity of the battery is 60 Ah. The maximum possible cleaning time is thus limited to 30-40 minutes. It is not surprising, especially considering that no one refills the battery with water, while the charger performs equalization EVERY time if the batteries are on charge for at least 2 hours. And workers sometimes forget to put the floor polisher on charge, leaving the battery almost completely discharged. The fact that the floor polisher with this operating mode is generally able to work at least half an hour is already a miracle.

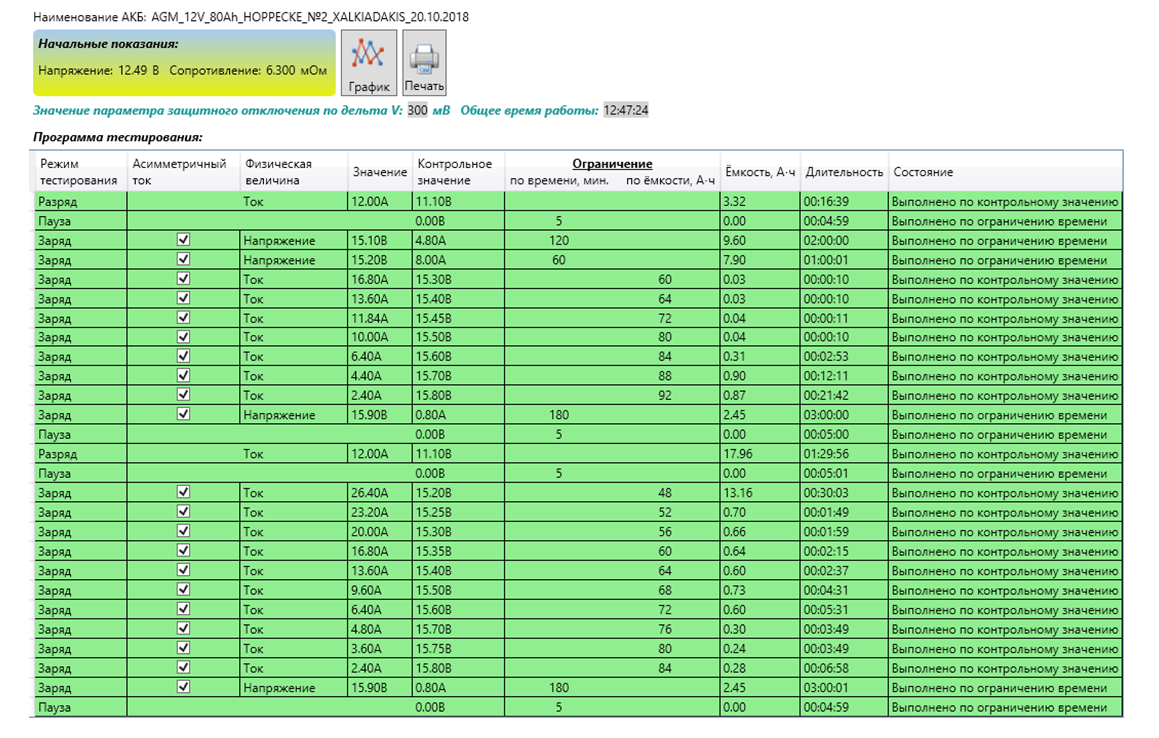

Given the state of the battery, we decided not to rely on the standard charger, but to try to restore the batteries using professional equipment - AEAC-12V Activator. See Figure 14 for the steps of the maintenance program:

Figure 14

We decided to start with a discharge - after all, I wonder what the real capacity of the battery is. In general, according to IEC 60095-1: 2006, in order to determine the reserve capacity, it is necessary to discharge the battery to a voltage of 10.5 V. However, given that the batteries are bad, we decided to limit ourselves to discharges up to a voltage of 11.1 V. As can be seen from the results of a completely completed maintenance program , reserve capacity was only 18 minutes prior to service. After service - already 97 minutes. It should be noted that, ideally, such a battery should have a reserve capacity of 240 minutes.

Let's deal with the second battery (see Figure 15):

Figure 15

As you can see at the end of the maintenance program, it showed itself a little worse - 16 minutes of reserve capacity for the first discharge and 87 minutes after maintenance.

Recommendations

1) Taking into account the peculiarity of the charger in the form of an equalizing charge EVERY time when the battery is on charge for at least 2 hours, it is necessary to compensate for the loss of water by adding distilled water at least once every six months. It is also advisable to sometimes carry out control training cycles.

2) Never leave the batteries discharged. After using the floor polisher, ALWAYS put it on charge.

3) Tune the charger by limiting the equalization voltage

to 31.2 V.

Outputs

- It cannot be said that “the floor polisher used to work poorly, but now the floor polisher works well” - even though the reserve capacity of the battery after servicing has increased 5.5 times. It is necessary to conduct an explanatory conversation with the workers operating the floor polisher, during which they explain how to properly operate such equipment.

- Replacing regular batteries by unknown "Kulibins" with similar, but smaller capacity, was not a good idea. It is better to operate the floor polisher with standard batteries of a larger capacity.