The author of the column is the scientific advisor of RUTAS Sergey Vasilievich Kuzmin.

The more factories are built and the larger the city is, the more energy is required. It is logical that power supply systems should become more efficient, reliable and safe. And, of course, it is necessary to strive to reduce emergency situations.

But the accident rate is the scourge of modern networks. For example, in urban networks, for example, in the Far East, there are more than 3000 emergency outages per year. But the scale of these networks is not large, in most regions of the Russian Federation the networks are much larger. Why is everything so difficult?

The fact is that in many cities the basis of power supply is the networks that were laid back in the USSR, based on the needs of that time. Since the 2000s, many modern household appliances began to appear in homes: microwave ovens, refrigerators, televisions, washing machines and, of course, air conditioners. All this increased the load on the network. Yes, they are being modernized, but not at all as quickly as we would like.

As a result, energy losses in the system are increased, voltage surges occur, which often disable the very same household appliances, electronics, plus from time to time the networks themselves turn off due to overload, and various negative physical processes occurring in them.

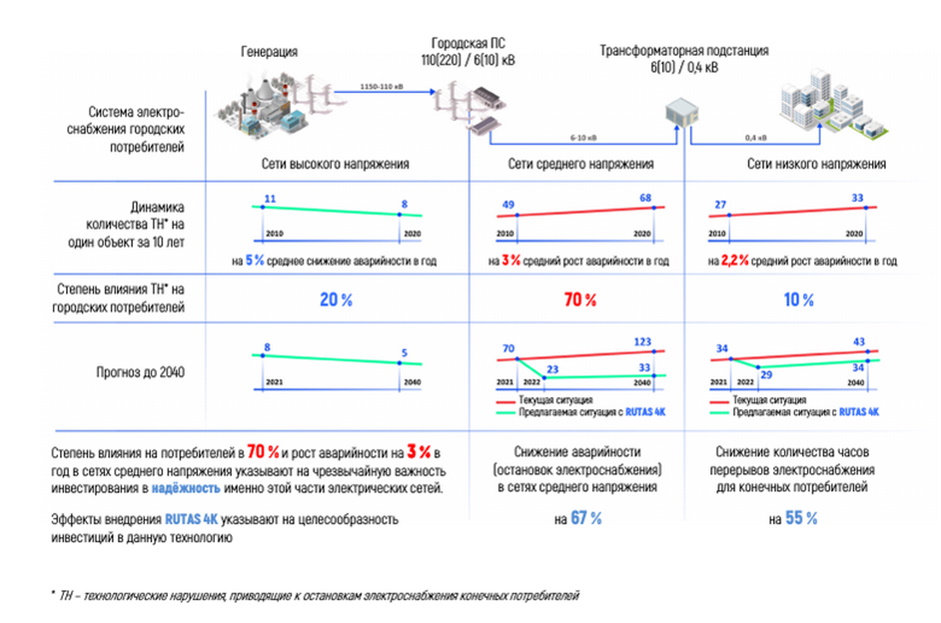

It is also worth separating the accident rate in high voltage networks, which falls by 5% per year, and medium voltage - here it grows by 3% per year. At the same time, the impact of problems in networks of the first type on the household consumer is about 10%, but in networks of the second type - about 70%.

What is it all about?

We will tell you about ourselves and our technologies, which can largely solve the problems mentioned above.

We are the RUTAS company, which since the 90s has been helping to bring the electric power systems of industrial enterprises and cities to a new level of reliability. Here are the main areas of work:

- Reduction of technical losses of electricity.

- Reduced downtime of energy consumers.

- Reducing accidents and increasing the efficiency of electric power systems

- Reducing the number of breakdowns in the insulation of cable lines, electric motors and transformers.

We use the results of modern scientific research in this work. New data and developments make it possible to increase the reliability of power supply systems by 67%, extend the service life of cable lines, couplings, electric motors and transformers by an average of 16 years, and reduce power shortages and emergency costs.

Our technology is called RUTAS 4K and is applicable to both metro and industrial networks. By the way, the problems and characteristics of the networks of cities and industrial enterprises are practically the same at the level of the ongoing physical processes, at the level of the elements used (all the same cable lines, transformers, electric motors connecting couplings). The only thing that industrial enterprises usually have more protection, they are more attentive to this. The only difference is in one additional component for metro networks (K4S).

What does technology achieve for cities?

There are several main points here:

- Reduce the number of hours of power interruption to end consumers by 55%.

- Reduce technical losses of electricity to a level not exceeding 7.5%,

- 30 80% ( 1,5-2,5 ).

- ,

- 20% . ( ) , , 4, 5 . — , . , .

?

For 26 years of our team's activity, more than 420 scientific studies of emergency modes, power consumption and operation of electrical receivers in power supply systems of 3, 6, 10 kV of large industrial enterprises and cities have been carried out. Scientific research has made it possible to study previously unexplored negative physical processes, to identify the main negative physical processes that accelerate the aging process of insulation and lead to breakdowns in the insulation of cable lines, electrical equipment and electrical receivers.

On the basis of scientific research, special devices have been developed, the introduction of which makes it possible to increase reliability, reduce the accident rate and the risks of failure of the electric power infrastructure. On the basis of the developed devices and methods, a four-component technology for reducing accidents and increasing the efficiency of electric power systems "RUTAS 4K" was formed.

Technology components:

- 1 ( 6-10 ) 6-10 . 2,0÷2,1 , 50%, , , 73%. .

- , , () , 97%, 98%, 100% , 8%.

- 2 «-» , (, ) , 1,76-1,78 , 22%, 12%. - , , .

- 3 «RC-» , 1,5-1,68 , 71%, 18%. RC- , .

- 4 «RC-K4» . , 4 8%. . .

First, a comprehensive survey of network objects is carried out. Based on the surveys, technical solutions are developed. This is the introduction of our technology, setting the basic parameters of the protection to improve their performance. In addition, we implement specialized devices for specific tasks.

It is very good when companies agree to train their employees on the latest scientific discoveries of the Rutas team. Then courses of different duration are organized. For example, in June of this year, a three-day course was held for managers of ISO Rusal (engineering construction services) responsible for the power industry of Rusal enterprises.

After agreeing on technical solutions, implementation projects are developed directly "on the ground", taking into account the specifics of installation. Production starts in parallel. After agreeing on all projects, ready-made technical solutions are delivered and installed and adjusted. By the way, this paragraph is also relevant for production facilities.

What about ROI?

As always, it all depends on the industry - from a few months to five years. Here are the main components of ROI:

- . , ( ). — . “ — ”. , — , , . . . , .

- 25%. .

- .

- .

- , , 16 .

Below is an illustration of the ROI for urban networks.

At those enterprises where our technologies have been introduced, the electrical injuries of employees have decreased by about 88%. The technology ensures the full performance of the protections, reduces the number of single-phase ground faults by 71%, the number of short circuits by 60%, the number of group outages of power supply lines by 97%, and the number of emergency outages by 67%. The results are quite visible and tangible - a reduction in the number of visits of repair crews, a simplification of working conditions. This means increased safety and reduced electrical injuries to employees.

In general, this is all that we wanted to tell today (more precisely, not all, but it turned out that way too much). If you need more information, you can get it on our website...