You will learn:

why did we need it at all

is it possible to work with domestic manufacturers without fear and reproach

why you shouldn't skimp on parts for products (spoiler: if you have iron nerves, then you can)

how not to slip into despair, but to learn how to manage risks.

Developer - it sounds proud

How many people think: you come up with an idea, develop a product, make millions. How it really is: to build a robot, you need to think like a human. Thinking like a person with well-oiled processes in his head, aware of the risks, counting time, money and nerves, both his own and the team's, and of course, the customer's.

What is a histological processor for?

In dockyard times, namely at the beginning of 2018, our team launched an engineering startup Nextelligence and started a project to create a vacuum processor for histological laboratories.

In short, this is a device into which special perforated plastic cassettes with materials of human origin (alive or not) are placed, so that later a morphologist (histologist / pathologist) can look at a microscope under a microscope and make a histological conclusion.

The first and most time-consuming of the 5 stages of histological sample preparation is to replace the water present in the material with a paraffin mixture. The process of replacing water with paraffin is called histological tracing or simply tracing. It was this process that had to be automated, that is, to create a device that, in an automatic mode, sequentially fills the material under study with different reagents. At the same time, it was important to reduce the risk of loss of the test material to a minimum - according to statistics, almost every fifth sample is lost in laboratories.

Concept development

, « – – », . , (, ) , , , , , .

, , , , . - , « » .

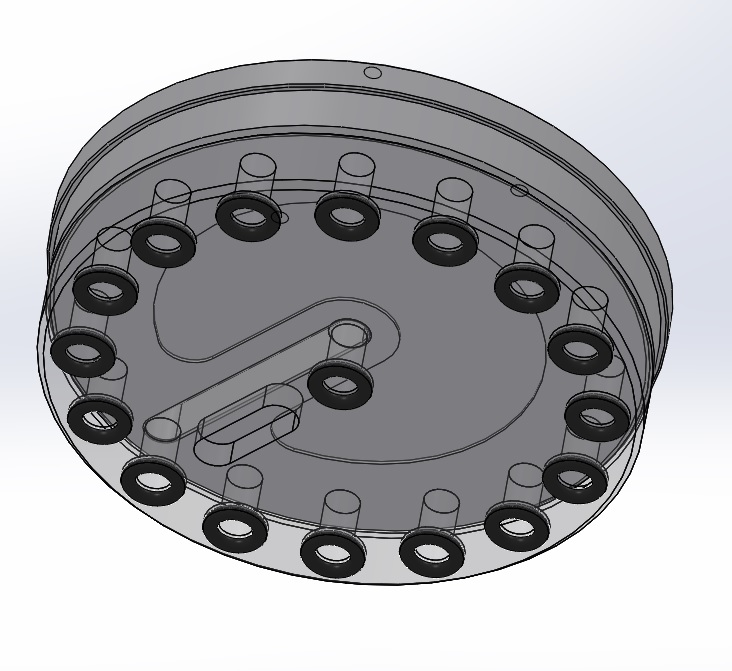

: 2 , , , (. 1), , – (. 2).

,

. , , . , , . , , , 2 , , , .

, , Medica/Compamed . , , .

-,

, ( ) . 9 10 , , , .

. .

3 , . , -, , - .. , , : « , ». , , . , . - , , . , , , .

, «» . …

, , . , . .

—

, , (!), - , , … , , .

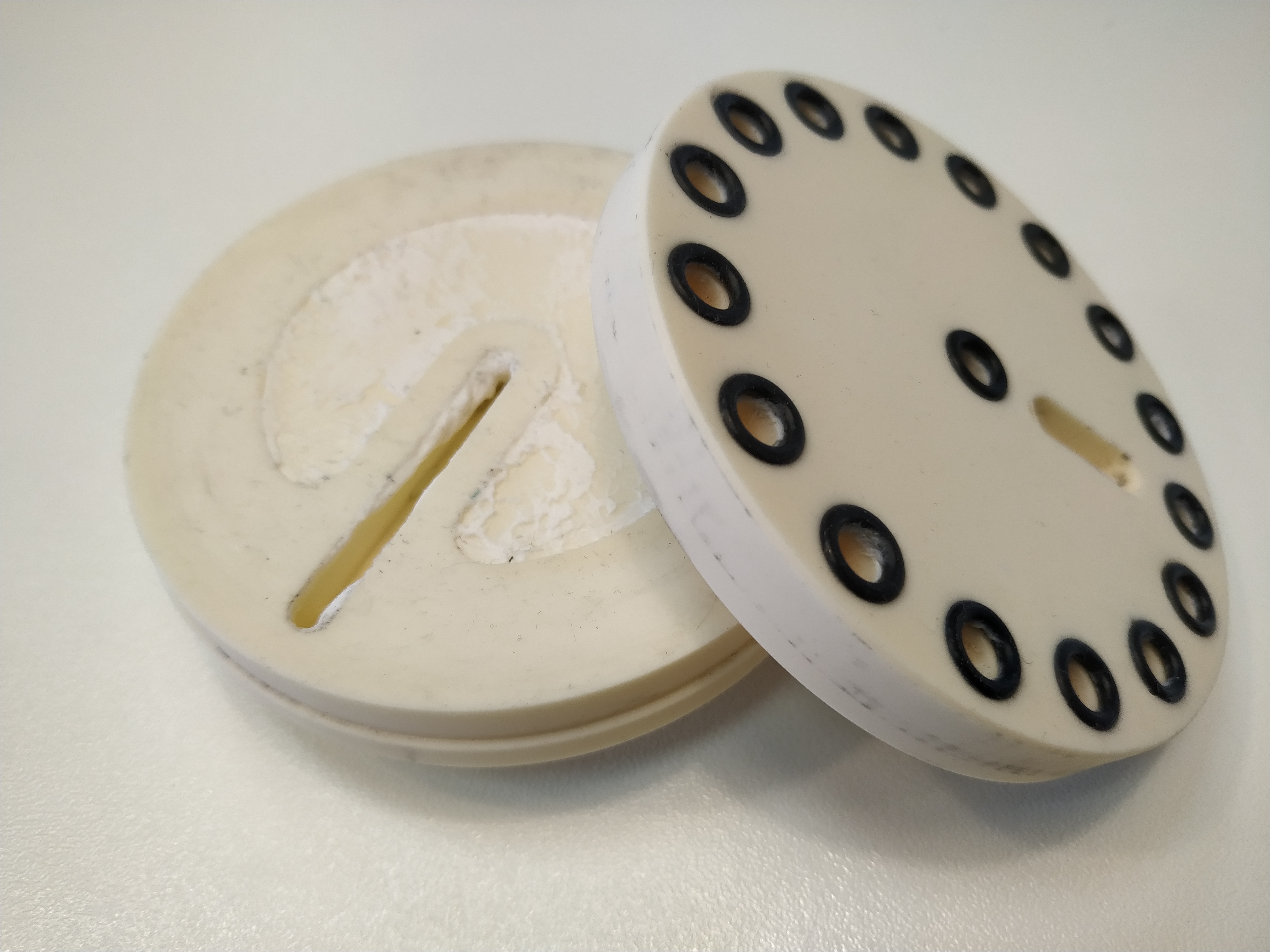

. - NBR FKM/FPM/Viton, , . — , . , , Viton - .

. , ( FFKM, Kalrez), , — - , .

- - , . , , .

- -:

. , . = , .

, . , .

If you decide on point 2, write more fines in the contract, so the contractor will have more incentives to hand over what you want when you want.

In general, manage your risk. ISO 14971 to help you.