Recently I read a message that Moscow Mayor Sergei Sobyanin opened the Oil Museum on Sretensky Boulevard. “There are no oil rigs or oil fields in Moscow , but we have huge detachments of people who promote academic science, applied science, education, which largely works for the country's oil industry, making it an advanced one,” Moscow Mayor Sergei Sobyanin emphasized at the opening. ...

Well done, Sergey Semyonovich. And he did a good job - he opened the museum and said good words, but despite the fact that he worked for a long time in leading positions in oil-producing regions, he was a little mistaken with the terminology. There are no "oil rigs" not only in Moscow, they are not found anywhere in the world. There are oil rigs (see photo above), which are part of the drilling rigs, but there are no oil rigs. What then is there?

But about the methods and with the help of what equipment oil is produced in Russia and the world, I will try to tell and clearly show in my article in the most accessible language. (The photo above shows a drilling site in the vicinity of Naryan-Mar. The image is not very high-quality, since it was taken by the author through a helicopter window).

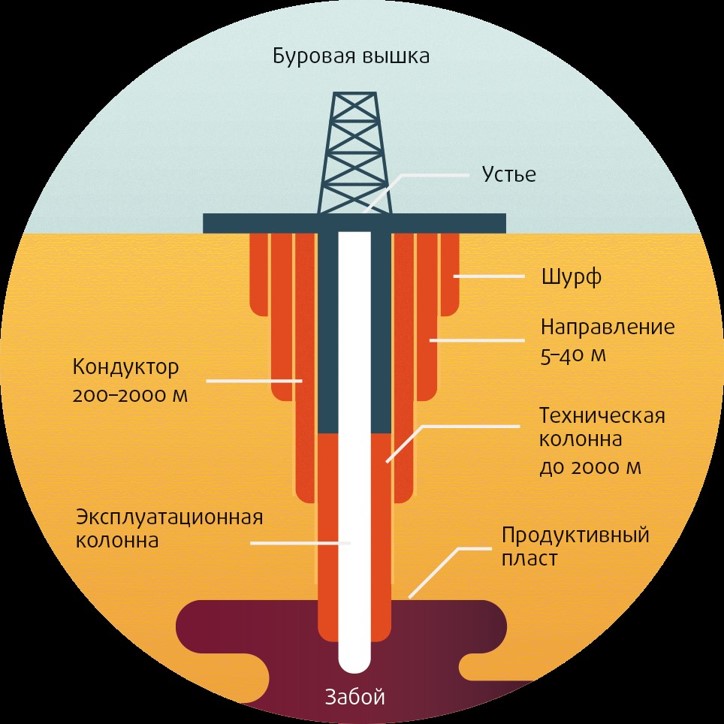

To begin with, oil is produced from wells. A well is a cylindrical mine (hole in the ground) of small diameter and great depth, designed to lift liquid (water, oil) or gas to the surface.

The diameter of oil wells, as a rule, decreases stepwise from the wellhead (well exit to the surface) to the bottom (well bottom). The borehole diameter starts from 40 mm and rarely exceeds 900 mm. The average depth of oil production wells in Russia is 2500 m. Special pipes, called casing pipes, are lowered into the wells to prevent the walls of the wells from collapsing.

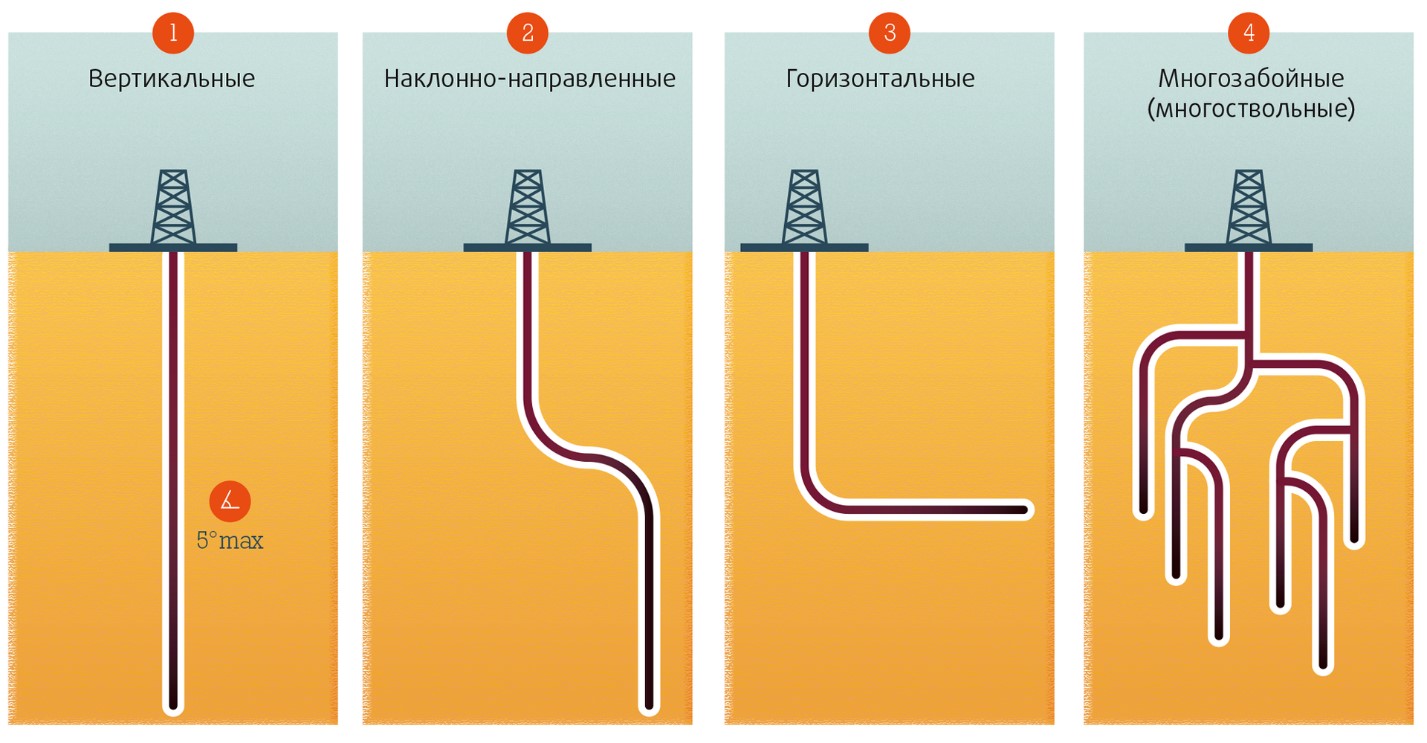

Depending on the geological conditions of the oil field, various types of wells are drilled:

The length of the well is the distance between the wellhead and the bottom, measured along the axis of the wellbore. Depth is the projection of the borehole length onto its vertical axis. For vertical wells, these values are the same, but for deviated and horizontal wells they are different.

Oil wells are drilled both onshore and offshore, but today we will not touch on drilling, but go straight to the methods of oil production or, as the oil producers say, to the methods of operating wells.

Currently, only two main methods of well operation are used :

- gushing (when oil is self- flowing out of the well) and

- mechanized (which, in turn, is subdivided into gas-lift and pumping ).

The choice of a method for operating oil wells, first of all, depends on the magnitude of the reservoir pressure and the depth of occurrence of the productive (i.e., oil-bearing) formation. In addition, the choice of the operating method can be influenced by the composition of the oil, the degree of its water cut (i.e.,% water content), the fluid pressure in the wellbore, and a number of other factors.

Fountain method of oil production

This method is used at high reservoir pressure. In this case, oil gushes, rising to the surface through the tubing (tubing) due to the energy of the reservoir. Gushing can occur due to the hydrostatic head (very rarely) or due to the energy of the expanding gas (in most cases, since the gas with the oil in the reservoir plays a major role in the well flowing).

The advantages of this method include its high efficiency, since lifting occurs naturally, which does not require the use of expensive oil-producing equipment, thereby saving both its cost and maintenance.

The equipment of any well, including the flowing one, must ensure the production of products in a given mode and the safe conduct of all necessary technological operations. It is subdivided into borehole (underground) and wellhead (surface).

For the flowing method of oil production, technologically simple surface and underground equipment is required.

From the underground equipment, tubing is run into the well with a funnel at the end for the convenience of lowering and lifting research instruments. The tubing string consists of seamless steel pipes 5-10 m long, interconnected by threaded couplings. The tubing diameter varies from 27 mm to 114 mm, wall thickness from 3 mm to 7 mm. Tubing is the main working tool during well operation. The production casing, as a rule, is run into the well, cemented from bottomhole to wellhead, and no longer rises to the surface, therefore all underground operations are performed using tubing: lifting wellbore fluid to the surface, repair and flushing work, etc.

Well design

Christmas tree (FA) is installed as surface equipment at the wellhead. FA is designed to suspend the tubing string, seal the annular space, for operation, regulation of the operating mode and workover of the well, as well as for directing the production of the well into the flow line (i.e., the pipe through which oil flows from the well to the metering unit).

Fountain fittings

The wells are serviced by oil and gas production operators The

fountain method of oil well operation is used at the initial stage of field development. Upon completion of the flowing process, artificial lift methods are applied to the well.

Gas-lift method of oil production

Gaslift is one of the mechanized methods of oil production and a logical continuation of the flowing method and, in principle, is not much different from it. When it is used, oil rises from the bottomhole due to the energy of gas injected from the wellhead. They switch to this method when the energy of the formation becomes insufficient to push the oil, therefore, it begins to rise by pumping compressed gas into the formation.

High pressure compressors are used to compress the gas. This method is called compressor. The non-compressor gas lift method is carried out by supplying gas that is already under high pressure to the formation. Such gas is supplied from the nearest field.

Despite the fact that this method is distinguished by the simplicity of well maintenance, and it is most convenient for lifting large volumes of oil with a high gas content, it is becoming less and less popular due to the fact that it requires high costs for the construction of compressor stations and high-pressure gas pipelines. Currently, no more than 5% of oil in Russia is produced by the gas lift method.

This video (4 minutes) from Weatherford company very clearly (and, most importantly, without a single word) shows the technologies used in gas-lift oil production:

Pumping methods for oil production

Pumping methods of mechanized oil production include, as you might guess, oil production using various types of pumping units. Please note that we are talking specifically about "installations", since in addition to the pump itself, other submersible (ie, installed in a well) and surface equipment are needed.

Currently, various borehole pumping units are used for oil production:

- installation of a sucker rod pump (USHGN) or a sucker rod pumping unit (SSHNU)

- installation of an electric centrifugal pump (ESP)

- installation of an electrically driven screw pump (UEVN)

- installation of an electric driven vane pump (UELN)

- various types of downhole hydraulic piston pumping units (GPNA):

- inkjet

- hydraulic impulse

- turbopump

- vibrating.

Within the framework of this article, we will consider only the first three, as the most common.

Oil production using a sucker rod pump (sucker rod pump)

Yes Yes Yes. This is exactly the well-known "rocking chair", the photograph of which is most often used when talking about oil production. This is due, on the one hand, to the fact that the SRP is the oldest and most widespread type of mechanized operation of oil wells in the world, and, on the other hand, to the fact that it is the most "textured" oil production equipment.

To understand the prevalence. There are now about 2 million oil wells in operation around the world. Supershock pumping units are equipped with approximately 750,000 of more than 1 million wells, where one or another artificial lift method is used.

The sucker rod pump operates on the principle of a piston device: by means of the reciprocating movements of the ground drive through the sucker rod string, the deep pump lifts the oil to the surface. The rocking machine is driven by an electric motor through a V-belt transmission. Other types of drives for sucker-rod pumps are also used: chain drive, hydraulic drive, long-stroke drive, but all have the same purpose - to set in motion the rod string, ensuring the operation of the deep pump.

Of all the videos I watched on youtube about the principle of operation of the SRP (in Russian), this one seemed to me the most preferable from the point of view of accessibility, completeness of presentation, visualization and duration (5 minutes):

Oil production using the installation of an electric centrifugal pump (ESP)

The photo above shows the Christmas tree of a well equipped with an ESP. First, I will explain why ESPs are needed, if there are “rocking chairs”. The fact is that the USHGN (SSHNU) has many disadvantages that the ESP lacks, namely:

- the impossibility of operating high-rate wells, i.e. wells producing large volumes of oil;

- low efficiency of oil production with high water content;

- bulky and metal-consuming ground equipment;

- high probability of sucker rod breakage (especially in deviated and horizontal wells).

According to statistics, the share of wells in Russia equipped with sucker rod pumps is 34%. ESPs account for 63% of wells, while 82% of oil in the country is produced with the help of ESPs, which indicates the greater efficiency of this particular method.

The main components of the ESP :

- electric centrifugal pump (ESP)

- submersible motor

- water protection (protector)

- gas separator (optional)

- cable line

- ground control station (GC)

A submersible electric centrifugal pump is no different from a pipe externally, but the inner cavity of such a pipe (i.e. the pump body) contains a large number of parts that are difficult to manufacture. (See the picture below. Image taken from the Novomet website )

The ESP is driven by an electric motor located in the well (which is why it is called "submersible"). Electricity is supplied to it via a submersible armored cable. The electric motor can be asynchronous (the magnetic field is created by the stator of the motor) or valve (the magnetic field is created by permanent magnets located in the rotor of the motor), which has a higher efficiency. The submersible installation is controlled through a control station (CS). Direct start control systems are used, as well as control systems with the ability to control the speed of the submersible electric motor.

In this short (1 minute) video from Weatherford company, very clearly (and, most importantly, without a single word), the principle of operation of the ESP is shown:

For your convenience, here is the translation of the terms used in the video:

Electric Submersible Pumping System - installation of an electric centrifugal pump (ESP)

Motor - submersible electric motor

Seal - hydraulic protection

Gas Separator - gas separator

Submersible Pump - submersible electric centrifugal pump (ESP)

Gas - gas

Oil - oil

Oil production using the installation of an electric drive screw pump (UEVN)

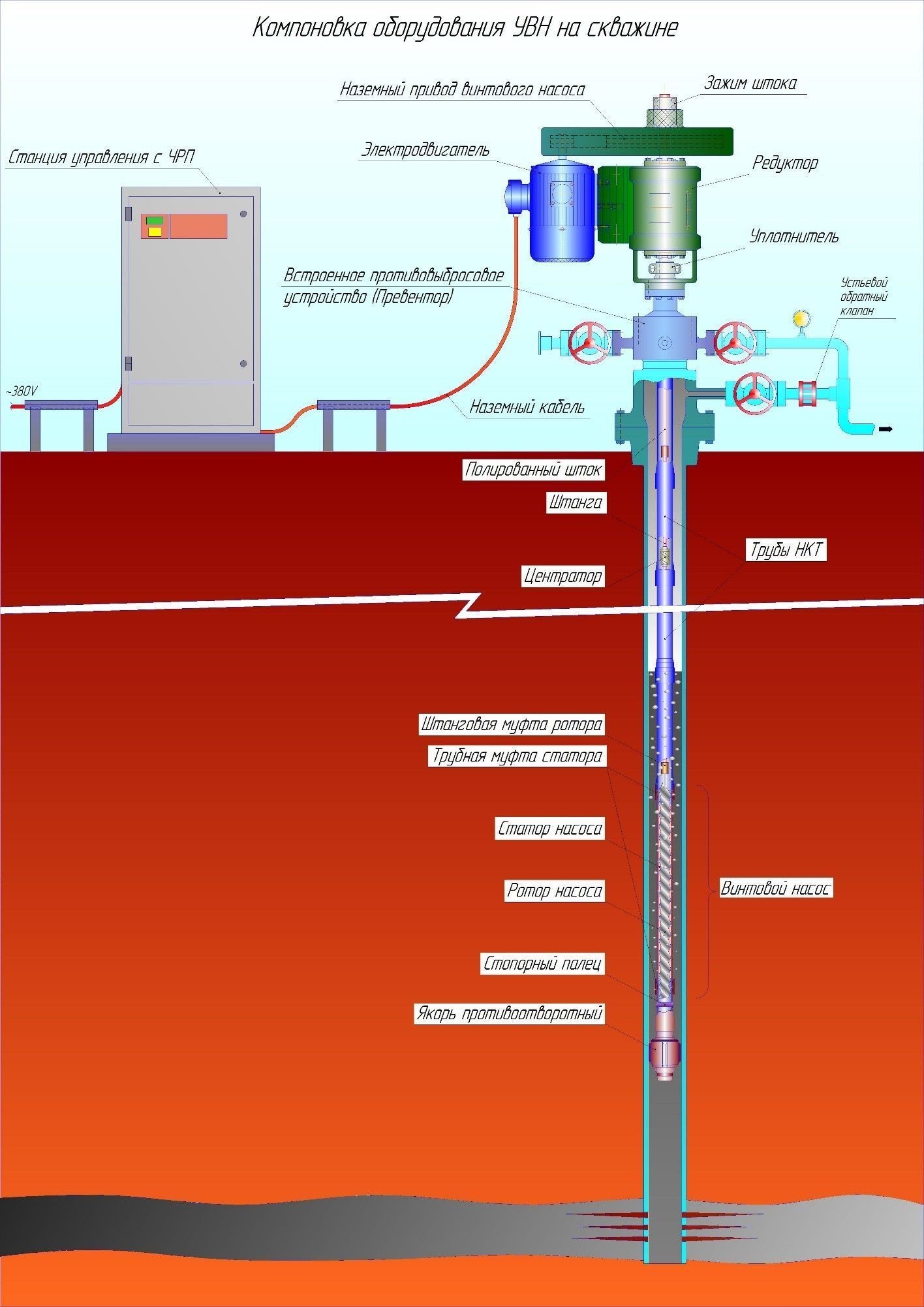

A screw pump is a positive displacement pump, the flow rate of which is directly proportional to the rotational speed of a special screw. When rotating, the screw (rotor) and its cage (stator) form a series of closed cavities along the entire length, which move from the pump intake to its discharge. Together with them, the pumped liquid moves.

There are two options for using PCPs for oil production.

In the first (as in the picture above), which is most widespread, the electric motor and the gearbox are mounted at the wellhead and connected by a belt drive. The cage of the screw pump is lowered into the well on the tubing, and the screw is attached to the rods, which are rotated by an electric motor through a gearbox.

In the second option (gaining popularity), the installation diagram of the ESP is similar to the ESP, i.e. The screw pump is driven by a submersible electric motor, which transmits torque directly to the screw pump shaft through a protector. Due to the drive from a submersible electric motor, this installation does not use sucker rods and a gearbox, which is the most unreliable and expensive component of a traditional UEVN.

UEVN are mainly used in wells with high-viscosity oil.

This video from the Weatherford company "Progressing Cavity Pumping System" shows the principle of operation of the UEVN (just watch the first 2 minutes):

Each of the oil production technologies described above has its pros and cons, and the choice of one or another production method depends mainly on the geological conditions of a particular field, and, of course, on economic parameters.