Edward is from the countryside. All his life he was associated with agriculture. Graduated from the Moscow State Agro-Engineering University named after Goryachkin. After graduation, he worked in the field of agricultural machinery and precision farming. Now he is implementing robotic technology in Cognitive Pilot. He actively writes on Habré in his company's blog about the operation and technologies of agricultural machinery. His articles are steadily gaining high ratings and are included in the top articles of the year on Habré.

We share with you the transcript of the broadcast and the recording.

❒ Good afternoon, it's nice to see everyone here. Today, I would reveal such an interesting topic as digitalization - robotization in agriculture: what is there now, what are the problems we have, and what will be the future of agriculture - what will be in the future, what is humanity striving for.

My name is Eduard Abdulkin and I represent Cognitive Robotics . In general, I am a trainee, it is easier for me to work in the fields, as far from the office as possible.

❒ What is robotization in agriculture, and what is agriculture in general in the current realities?Technically, this is over 99% of what society around the world consumes. That is, everything that you buy in stores, what you eat - it often comes from agriculture. The general topic of robotization itself is huge, and it would not take us even a day to get acquainted with 10% of this topic, so now we will go over only the main aspects: what is, what will be. If you have any questions, ask in the comments, I’m here for that.

Agricultural robotization can be divided into two main areas:

- The first is crop production, the largest and most extensive area; we will touch on it a little later.

- And let's talk a little about animal husbandry.Livestock breeding includes poultry, pig and cattle - dairy production. Pig and poultry farming are narrowly focused specializations, not everyone, probably, will go there; We will not disassemble them so that there is no mess in our heads. And dairy production - here everyone, for sure, was in the villages and saw cows, everyone drinks milk, uses dairy products. This is a broad area that we will touch upon.

❒ Digital farm: what can it collect under it? This is what helps the dairy industry to develop, earn money, while investing less labor and human resources. Dairy production can be divided into areas:

- Automatic animal feeding

- Automatic milking

- Fully digital smart farm

Let's start with feeding.

❒ How are we used to seeing the process of how animals are fed? Hay, straw, grasses, silos, silage; grandmother brings hay to the cow.

But in large-scale dairy production there is a nuance: you need to constantly maintain a certain amount of milk, it is necessary that the animal does not experience stress and constantly receives the rate of feed that it should receive daily.

What is the so-called stress of an animal?when there is a change in feed, for example: a change in the feed base by 10% of the total feed (for example, we initially have 70% of silage, 10% of straw for holding the mass and 20% of additives, minerals, compound feed, etc.) leads to stress of the animal and reduces milk yield by 15-20% minimum. That is, you earn less money during this period, because the cows give less milk.

In order to avoid such situations, automatic feeding of animals was introduced. On the left in the picture is a feed room, there is a huge silo mixer in it, and feeds are supplied to it, which must be mixed in order to make a complete ration for the animals.

Feeding rates are programmed in advance, with certain types of feed. In autonomous mode, this huge crane loads in portions - depending on the size of the herd - the required amount of feed. The mixer in the left picture is mixing evenly so that each feed intake by the animals leads to the same nutrient intake.

In the right picture, you can see the dispenser robot - this system drives up to the mixer, the mass is automatically unloaded. It is pre-programmed in it, which herd and milking squad need to bring this or that ration - thus, the feed is distributed to the feed table for animals. As evenly as possible, so that each animal can come up and eat the rate that it needs.

A huge plus of this system is that everything is autonomous, everything is programmed, there is no human factor. Uncle Vasya will not be able to throw 50 kg of compound feed for 10 kg of silage. In addition, since the program is set in advance, you can take into account how much feed needs to be prepared in order to feed the herd for a whole year. We will analyze the cons later separately.

❒ The following is also a rather extensive point. Are robotic milking machines (milking machines, robotic milking machines). They are of different production, different types. Their main task is to eliminate the human factor. There is a second nuance: in cattle - in this case, cows - life cycles are synchronized when the entire herd is milked at the same time. On the one hand, this is good, but on the other hand, it is bad, because it does not support the biology of the animal. Biologically, it is better to make it so that when an animal wants to milk, it can come up and milk. It should not be such that one cow is overweight, the other is undermatched, and this volume will be tolerated in the evening. The animal understands when it needs to surrender, and for this, automatic milking robots are made. They stand directly in the corral itself. That is, any animal can approach him,and in automatic mode, the milk will be removed. That is, the advantages of this system are not only the exclusion of the human factor, but also the maintenance of the biological component. How it works: A huge number of touch sensors, infrared sensors (NIR). The system sees how the animal comes up and gets up; the animal already understands where it needs to stand. In the autonomous mode, the search for the udder, the milking machine supply, the hook and the milk volume are removed. This is a huge plus, it is one of the most advanced dairy know-how.where he needs to stand. In the autonomous mode, the search for the udder, the milking machine supply, the hook and the milk volume are removed. This is a huge plus, it is one of the most advanced dairy know-how.where he needs to stand. In the autonomous mode, the search for the udder, the milking machine supply, the hook and the milk volume are removed. This is a huge plus, it is one of the most advanced dairy know-how.

❒ Next come “smart farms”.It is a unified system: animal feeding robots, animal milking robots. Plus, there are warehouses for storing feed, feed quality sensors, some leftovers, something that you can program in advance. Often, neural networks are used there, which warn the farmer, for example, that it is necessary to deliver a lot of silage - and he understands that the next day it is necessary to plan the delivery. What is a smart farm system for? As already mentioned, agriculture is a business. In business, you need to make money, you need each animal to give the right amount of milk every day. That is, it is necessary to exclude stress in animals, exclude temperature drops in the premises, exclude abrupt changes in the feed recipe. We need constant high yields every day - then the business will be able to earn.If you work "the old fashioned way" - everything is in manual mode, everything is on paper - then everything will be tightly tied to the human factor. A person today may forget, tomorrow he may not remember, and the day after tomorrow he may not notice. And then there will be no high milk yield. High yields happen when everything is synchronized, when there is a cohesive work of all mechanisms in one system - such a system is the "smart farm".

I will not dwell in detail on different types of animal husbandry; There is a lot of information here, nevertheless, it is not for nothing that agricultural universities have been created, in which people study for 5 years and then finish their studies. You can just mention that at any enterprise - poultry, pig, dairy - people always try to implement such a synchronized system so that all components work, to make it easier, to eliminate the human factor as much as possible. People don't want to hit record highs for one day - they want high figures to be achieved every day.

❒ Next comes a large, most developed direction - this is plant growing.Here I will dwell in more detail, and we will look at the advanced technologies that are currently being used. I will try to convey a piece of what you need to know and understand here.

Any crop production starts with soil. The soil is what ensures the very process of growing, ripening of plants, a lot depends on it. On the left in the picture you can see the mobile laboratories for chemical analysis of soil.

How it works: you have a device that can be installed on any type of equipment - an ATV, a car. It has a so-called syringe and chemical analyzers, and the vehicle must have an accurate GPS navigation system. You select the area of the field where you want to carry out the analysis, and send there a mobile laboratory - a vehicle with a chemical analyzer. You put the points at which you would like to conduct an analysis in order to understand the structure of your soil - what prevails in it, what chemical elements, what to add, what to remove. You understand that a certain crop will be grown in this field, and each of them requires a certain soil composition for better ripening of the mass. You want to balance the chemical composition of the soil as much as possible so that the plants are comfortable to ripen, ripen,give more harvest. You put GPS points on the field, the machine sees these points, moves along them and makes punctures at each point with the removal of chemical analyzes. All this is transported to the laboratory, which can also be mounted on the basis of a car, can be remote, or can simply be located at your enterprise. The lab technician performs a chemical analysis and you receive a map of the field. I did not include a field map in the presentation, but an example of a soil chemical composition map can be easily found on the Internet. It will contain data on various elements - nitrogen, phosphorus. You will find out what exactly is missing on the field, what needs to be added, what needs to be removed, what agrotechnical operations you will need to carry out.moves along them and makes punctures at each point with the removal of chemical analyzes. All this is transported to the laboratory, which can also be mounted on the basis of a car, can be remote, or can simply be located at your enterprise. The lab technician performs a chemical analysis and you receive a map of the field. I did not include a field map in the presentation, but an example of a soil chemical composition map can be easily found on the Internet. It will contain data on various elements - nitrogen, phosphorus. You will find out what exactly is missing on the field, what needs to be added, what needs to be removed, what agrotechnical operations you will need to carry out.moves along them and makes punctures at each point with the removal of chemical analyzes. All this is transported to the laboratory, which can also be mounted on the basis of a car, can be remote, or can simply be located at your enterprise. The lab technician performs a chemical analysis and you receive a map of the field. I did not include a field map in the presentation, but an example of a soil chemical composition map can be easily found on the Internet. It will contain data on various elements - nitrogen, phosphorus. You will find out what exactly is missing on the field, what needs to be added, what needs to be removed, what agrotechnical operations you will need to carry out.The lab technician performs a chemical analysis and you receive a map of the field. I did not include a field map in the presentation, but an example of a soil chemical composition map can be easily found on the Internet. It will contain data on various elements - nitrogen, phosphorus. You will find out what exactly is missing on the field, what needs to be added, what needs to be removed, what agrotechnical operations you will need to carry out.The lab technician performs a chemical analysis and you receive a map of the field. I did not include a field map in the presentation, but an example of a soil chemical composition map can be easily found on the Internet. It will contain data on various elements - nitrogen, phosphorus. You will find out what exactly is missing on the field, what needs to be added, what needs to be removed, what agrotechnical operations you will need to carry out.

Further, there are various possible operations. I presented the simplest one in the picture on the right - a mineral fertilizer spreader is visible there. Conventional mineral fertilizers: nitrogen, phosphorus, potash; the spreader can deliver just the right amount. But this structure does not stand still: now the same spreaders are equipped with rather sophisticated computerized systems with GPS-navigation, and also hydraulically driven discs are installed on them for differentiated fertilization. What is the diffusion: you throw more fertilizers on the part of the field where the substances are needed, and on the part where they are not needed, you do not throw anything. That is, the spreader keeps track of which part of the field it is moving on and understands the task: whether it is necessary or not to throw. If necessary, it turns on the drives, opens the gate valves,fertilizer is coming. If it is not necessary, it does nothing. That is, everything does not stand still. We got the opportunity to work at the edges of the field without clogging up the environment next to the field with fertilizers - that is, without burning wild plants that do not need to be burned. This leads to both environmental protection and fertilizer savings. Without such modern technologies, you simply scatter fertilizers throughout the field in full, despite the fact that in most of the field they may not be needed, that is, they will not work there. Processing only those areas where fertilizers are really needed may require several times less amount of fertilizers. This leads to a reduction in the cost of work and to savings in production. Housekeeping really saves a lot of money.We got the opportunity to work at the edges of the field without clogging up the environment next to the field with fertilizers - that is, without burning wild plants that do not need to be burned. This leads to both environmental protection and fertilizer savings. Without such modern technologies, you simply scatter fertilizers all over the field in full, despite the fact that in most of the field they may not be needed, that is, they will not work there. Processing only those areas where fertilizers are really needed may require several times less amount of fertilizers. This leads to a reduction in the cost of work and to savings in production. Housekeeping really saves a lot of money.We got the opportunity to work at the edges of the field without clogging up the environment next to the field with fertilizers - that is, without burning wild plants that do not need to be burned. This leads to both environmental protection and fertilizer savings. Without such modern technologies, you simply scatter fertilizers all over the field in full, despite the fact that in most of the field they may not be needed, that is, they will not work there. Processing only those areas where fertilizers are really needed may require several times less amount of fertilizers. This leads to a reduction in the cost of work and to savings in production. Housekeeping really saves a lot of money.and to save fertilizers. Without such modern technologies, you simply scatter fertilizers all over the field in full, despite the fact that in most of the field they may not be needed, that is, they will not work there. Processing only those areas where fertilizers are really needed may require several times less amount of fertilizers. This leads to a reduction in the cost of work and to savings in production. Housekeeping really saves a lot of money.and to save fertilizers. Without such modern technologies, you simply scatter fertilizers all over the field in full, despite the fact that in most of the field they may not be needed, that is, they will not work there. Processing only those areas where fertilizers are really needed may require several times less amount of fertilizers. This leads to a reduction in the cost of work and to savings in production. Housekeeping really saves a lot of money.Housekeeping really saves a lot of money.Housekeeping really saves a lot of money.

❒ So, you worked with the soil , carried out a chemical analysis, applied the necessary fertilizers, worked out the field according to flow charts. The field is ready, you have sowed it, it has begun to grow. All is well - but the work does not end there. Progress does not stand still. In certain phases of the growing season, the plant must be fed in order for it to yield more yield. And we are aimed specifically at increasing yields while reducing production costs.

On the left in the picture is a very interesting machine - a spreader with nitrogen spectral sensors. The sensors are just the "horns" in the front. Any plant during its life produces nitrogen into the environment, and with the help of a sensor, you can see how much is released in a particular area of the field. This is an indicator: the more nitrogen is released, the better the development of plants is - and vice versa. If a plant emits little nitrogen, then either it is sick or it lacks nutrition - most often, in 99% of cases, it just lacks nutrition. We put nitrogen sensors on the machines, we put nitrogen fertilizer spreaders behind them. In real time, we drive across the field, see the volumes of nitrogen released and apply nitrogen fertilizers where they are needed. This, again,leads to an increase in yields and at the same time to savings by reducing the cost of applying mineral fertilizers. This is very important - over the past 3 years, fertilizers have risen in price by 2-3 times, at least. As a result, this technology helps the farm to earn more money and develop further.

❒ The second nuance is satellite images.As you know, now there are a huge number of different satellites operating in different spectra, and there is an opportunity to acquire images from them. They are made at regular intervals, and you can track which plants are developing. Especially if you cannot place NIR sensors on the entire volume of fields, carry out chemical analysis of soil and nitrogen spectrum everywhere. Satellite imagery helps to identify the so-called critical points of the field - they will be marked in red. On such an area, plants may starve - that is, there is empty soil, and the plants do not develop. A critical point may also indicate a plant disease - this is especially true in the production of sugar beets. Various nuances can be seen from the satellite. Your contractor company will give you a statement showing the critical points,and you will be able to send your agronomist to them - to inspect these areas already in manual mode, to determine what the problem is. Thus, you will work out the critical point in the early stages of plant development. This will lead to the fact that you can reduce losses from crop shortages and get more benefits.

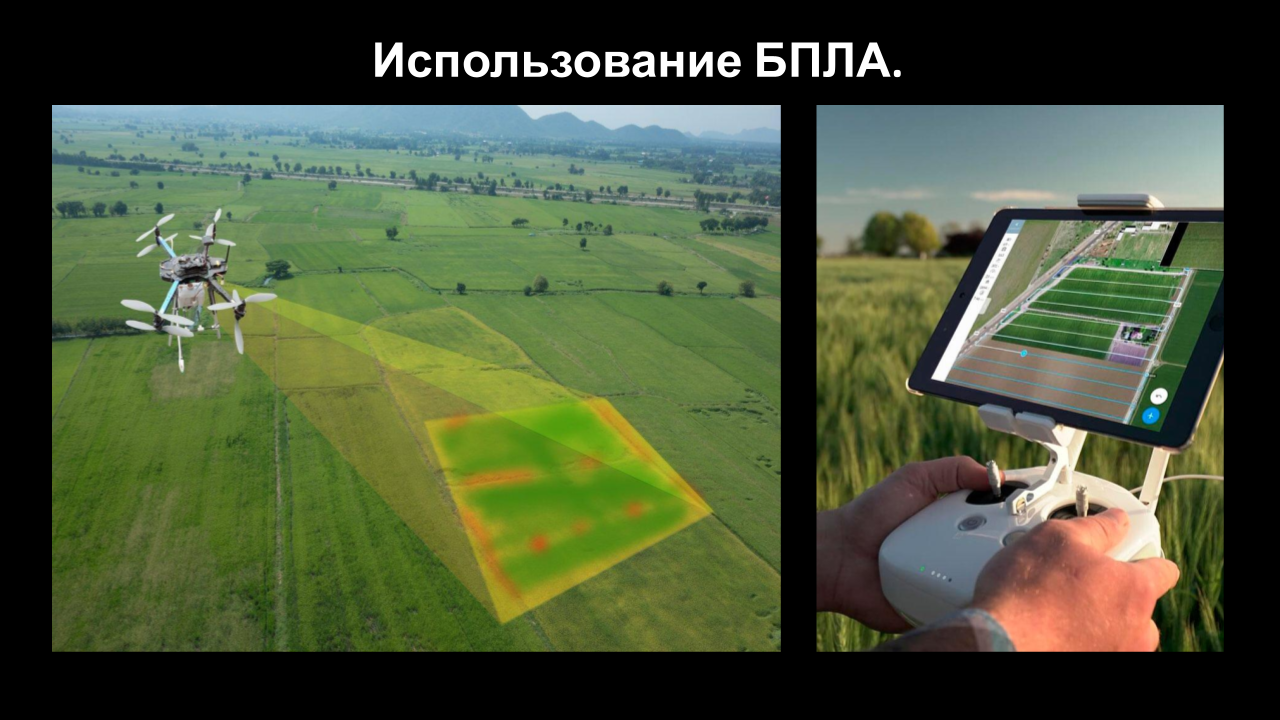

❒ There are more interesting options.Everyone has seen flying drones - they also developed in agriculture. If you have a large area of fields, then physically you will not be able to go around them all; also, again, if the contour of the field is large, then you can come and see what is on the edge of the field, but you will not see what is happening in the middle. For this, agrodrons are used. You can place an order with a contractor that will survey your fields from drones, or purchase drones for yourself and include in your staff a person who will conduct field analysis with their help. Their advantages are autonomy, ease of use, inspection not only of the edges, but also of the middle of the field. They will allow, again, to notice critical points and work them out in time - to understand what the problems are (starvation of plants, parasites, waterlogging of territories) and to quickly solve them,thereby leveling the shortage of the harvest during the year. In any case, you will increase your yield, the profitability of your farm. This is a huge plus.

Especially I will not introduce further, because there are really a lot of technologies. There are different types of drones, and different autonomous modes of their operation - just now it is impossible to describe everything. But the technologies that I have just described are the basis that is already being applied en masse. People and farms are striving for this now, I see this when I visit farms and communicate with production workers

❒ Let's move on to the next important aspect, which gives a huge plus.We are not standing still, many advanced farms have already renewed their fleet of equipment by 90%. And equipment manufacturers are also moving forward. They introduce various new gadgets, functions, technologies, and this is reflected in the functionality of tractors and other agricultural equipment. Each manufacturer has a huge amount of technology - CCI, Greenstar, navigation systems, Topcon, and so on. A huge amount of information. At the moment, the equipment is very high. Now you get into a new tractor and feel like a fighter pilot. At least 4-5 monitors, a huge number of buttons responsible for this or that functionality. This pulls us forward, all these functions work and are used.

Everything I have already said is good. We are striving for this, everything is moving towards this. But we must not forget that it is not for nothing that we in Russia have such proverbs - "until the thunder breaks out, the peasant does not cross himself", or "to be afraid of wolves - do not go to the forest." When operating all these systems in real conditions, certain problems arise. What is now visible in the picture is a snapshot from Bashkiria, a person worked on a modern powerful tractor equipped with a huge number of electronic "assistants", but ... it did not work out. What leads to such problems?

❒ The main thing you need at the moment- this is a high digital equipment of the farm. The farm must come to this, the farm must understand that it wants this. And before introducing new technologies, they must carry out some work on mistakes on their land, modernize one or another technique, and train personnel. And, just starting from the staff - we are Russian people, we love to relax. From the top of a large farm there may be many assignments, initiatives, there may be movement forward, but the machine operator-milker-mechanic himself must be ready to work for this. The main thing is to convey to them the idea that new technologies are not for keeping track of them and pulling them off. These are helpers for them, and with their help they will be able to work better and earn more. This is the most important thing to get across. Although not too often, I see the following picture on farms:the management introduced a "digital revolution" in the economy, bought a huge amount of modern technology, carried out preparatory measures - and none of this works "at the bottom". There, as they worked in the old-fashioned way, they still work, and the management does not see any steps forward - neither in the economy, nor in the quality of processing operations. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.bought a huge amount of modern technology, carried out preparatory measures - and "at the bottom" none of this works. There, as they worked in the old-fashioned way, they still work, and the management does not see any steps forward - neither in the economy, nor in the quality of processing operations. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.bought a huge amount of modern technology, carried out preparatory measures - and "at the bottom" none of this works. There, as they worked in the old-fashioned way, they still work, and the management does not see any steps forward - neither in the economy, nor in the quality of processing operations. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.carried out preparatory measures - and "on the bottom" none of this works. There, as they worked in the old-fashioned way, they still work, and the management does not see any steps forward - neither in the economy, nor in the quality of processing operations. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.carried out preparatory measures - and "on the bottom" none of this works. There, as they worked in the old-fashioned way, they still work, and the management does not see any steps forward - neither in the economy, nor in the quality of processing operations. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.and management does not see any steps forward - neither in the economy, nor in the quality of transaction processing. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.and management does not see any steps forward - neither in the economy, nor in the quality of transaction processing. The main thing is to inculcate the desire to work at the bottom, and people need to be prepared for this. Nobody gives them a "stick" - they are only given a "carrot": they will be able to work more efficiently, easier, they will not have to give a huge amount of energy and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.they will not have to give a huge amount of strength and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.they will not have to give a huge amount of strength and health to work. They will have enough energy and time for family life - a person will be able to finish work earlier, devote more time to his family. Look at the photo on the left - if you introduce digital economy here, you know, nothing will happen.

We need to prepare for this, strive and go for it. This does not happen in one year; this is a difficult job, although it is fruitful and will give in the end a huge plus - in money. But this will require 5-6 years of preparation in a normal mode. You can, of course, do everything in an intensive mode, in 2-3 years, but it is very difficult. 5-6 years is the average time for the transition from an "analog" economy to a digital one. It should settle in the heads of both the management and the working staff - this is the most important thing.

❒ Next item.As I said, the technique is equipped with a huge number of components. This includes the so-called "blind" systems - these are all GPS navigation systems. How they work: equipment is put on the tractor - a receiver, a tablet, a steering system. There is a signal from the navigation satellite, there is a drawing of points that the system installed on the tractor understands, and along which it seeks to drive this machine. This achieves a fairly good accuracy; if there is a correction signal, a very accurate guidance of the vehicle is obtained. But there is a huge disadvantage here: the car does not see anything in front of it, it is rigidly attached to the person. A person is obliged to monitor what is happening in front of the car. The field has ended - the satellite does not see it, it operates with dots. If a person falls asleep in the cab, for example, then the car can drive into the ditch.This is at its best. If another car drives into the field, or someone runs out, the system will not see this either, and anything can happen. The picture shows a case when the tractor drove onto the road - apparently due to the distracted tractor driver - and there was a collision between the trailed implement of the tractor and the machine, and nothing was left of the machine.

Who will be responsible for this? Probably, in this case, everything will be hanged on the tractor driver. In less serious cases, the management of the farm will be responsible to the traffic police and then reprimand the tractor driver.

❒ Imagine that you are working - you have a planting season, for example.And one of the tractors goes to the ditch. This is a minimum of two weeks of repair. And sowing should take, on average, no more than 10 days - for winter crops, spring crops, corn, this is the optimal period. Anything less is better not, it is then reflected not in the best way. And so, you lose the tractor for two weeks. You have not sowed enough, you will have a shift in terms, the yield will fall. And if two tractors collide - this is already lost, you will have to look for a contractor that will quickly arrive and perform the work for a fee. And if there were some other road users in the accident, you will have even more wasted time and nerves; in general, it will not have the best effect on working conditions.

❒ Where is the future of agricultural production heading?

I will try to move a little further into the scientific spectrum. Recently I read an article in an American magazine - I don't remember which one, you can search the Internet - that, on average, by 2050 the world's population will increase to 19 billion people. Whatever one may say, all these people will need to be fed. We, in Russia, have a fairly large agricultural stratum, we have rich lands, we do not have some kind of crisis in agricultural production, in water supply. That is, in any case, we will need to feed a significant part of the world. The export of agricultural products is growing every year - every year at the end of summer, during the harvest, you read in the news that the export volume has increased to such and such a value. Agricultural production must continue to grow with the population - if it stumbles at some point, it will be a disaster. Human life is the most precious thing that can be.

In any case, agricultural production is a very promising direction. This is where you need to move, this is what will be in the future. Maybe in the future we will not need gasoline or gold so much, but bread will only become more needed. In parallel, we are seeing a fairly large volume of urbanization around the world. That is, cities are growing - and strongly, and this growth is due to the rural population. Still, if you look at the Russian regions, you will see that the village is dying; people are trying to leave the village. To live in a village, you need to be a morally stable person, love to work, preferably - to be born there in order to love these places. Most of the people go to the city - there is more entertainment in the city, there is the same urbanization. There is a decrease in the number of people who can be attracted, and fewer young people are involved,comes to work on tractors and in dairy complexes, for example. More and more honored workers of the village go on a well-deserved rest, giving their strength and energy to agriculture. It is important not to cross the line when there will be no one to work in the countryside, but at the same time the city will demand more and more products. If this happens, it will be very difficult for the whole world.

No matter how we twist, everything goes to the fact that instead of a man in the fields, automatic systems will work. What is the big plus of the field - there is no heavy traffic, and the robot can be limited to a certain area, the area of the field, on which it will spin. In addition, six drones can be monitored by one person who can be paid a large salary. This is where everything goes. It is not for nothing that drones are now appearing on the roads. But in agriculture it is very important, it is precisely one of the leading directions. Many manufacturers of agricultural machinery go to autopilot and robotization. The picture shows the Case tractor, which does not have a cab at all. Other agricultural machinery manufacturers are striving for just that.

❒ I will also say about our company... We also do not stand still, and in the agroindustry we can be called leaders. We are the first to integrate vision-based piloting systems into agriculture; so far no one is doing this seriously. There are prerequisites, many manufacturers of agricultural machinery are experimenting with this, but we were the first to launch a fully working technology on the mass market - Cognitive Robotics with the AgroPilot product. Detailed information can be read, viewed on our website, but I will briefly list the features of the Pilot.

We are not tied to any GPS satellite system. The Pilot will not go into a ditch or crash into anything, nor does it require corrective signals, which currently cost $ 1000 per car. It is completely autonomous. We help to exclude the human factor from the driving mode as much as possible; Our combine operator is really an operator, not a driver, and he just sits and monitors the operation of the systems. In a modern harvester, you already feel like an airplane pilot: a huge number of sensors, multimedia, keys, levers, and all this must be controlled.

We conducted a study and realized that during harvesting, a person has to devote 85% of the time to pointing the header to the edge, and he has only 15% left on the other devices of the combine. Although the main thing for the combine is not even the header. The main thing is the separating apparatus: you need to monitor how it works, how it threshes, whether it is ground or not, it needs to be controlled. But a person often cannot do this - he constantly brings the header to the edge, holds the combine, and cannot take his attention away from it. Because if the harvester is wobbling, then the next harvester will also wedge into the wedge, and at the end of the field you will get a "navel", which you will then have to spend time on (and get it from the agronomist). Our system completely takes over the guidance of the harvester header, and the person switches to the rest of the functionality of the machine and can control it qualitatively.

We also have interesting ideas for tractors, forage harvesters. We have a huge amount of testing planned for this year, and I hope that we will gradually announce it all.

Q: marking, beacons on animals when grazing in pastures - what are the trends?What it is: there is an "electronic shepherd" system mode. Second, animals have beacons. It is more customary for us to use the “electronic shepherd” system; for those who don’t know, it’s just the posts, two wires with a weak current are stretched between them. As soon as the animal approaches the fence, it hits it slightly, and it understands that it is better not to go there. And he develops such a conditioned instinct. Everything related to pasture beacons is more likely in Austria, Switzerland, for example. They have very dense forests there, in which animals physically do not go. And it is beneficial to use it when there are only 5-6 heads in the herd, and you know about each animal what it eats, what its name is, when it calved, and so on. And you can manually approach, watch, control everyone.Therefore, in Russia there is a greater tendency towards "electronic shepherd", and in mountainous Europe - towards beacons.

The marking is placed in livestock complexes and helps zootechnicians more in combining groups of animals. That is, the groups are high-yielding, low-yielding, medium-yielding, for example, and high-yielding groups can be divided into several more subgroups. Both markings and beacons - for animals located directly in the dairy complex - help zootechnicians work with these animals, divide them into smaller subgroups and pay more attention to each subgroup. For example, it can be super-high-yielding animals, just high-yielding, less high-yielding. But this is more a question for zootechnicians - I am a mechanical engineer myself, I only talked with zootechnicians.

This division, broken down into subgroups, is more likely to occur in ordinary farms. In mass farms, where there are more than 5 thousand heads, this is rather irrelevant - they are divided only into large groups. But in dairy complexes with 2.5-3 thousand heads, the breakdown into subgroups is being actively implemented, with separate rations for each subgroup.

Q: tell us, what's happening in the software world? Mobile solutions are more interestingIf you get involved in this, this is a huge amount of information. For example, there is software for autonomous watering of plants - this is important, for example, for vegetable growers or those with dry weather. A person can buy a Valley or TL, or a circle - a pivot irrigation system and in the mobile mode adjust the start time, the volume of water; if there is a running bar, then determine the squares that must be passed. All this can be programmed from anywhere, even from a resort, and the system will start working at a given time.

For tractors - for example, our systems have GSM modules. A person can give a command through a Telegram bot, from anywhere in the world, and he will be given the entire layout for the car - how it worked, where, what was the positioning. You can request photos, and the system will transmit them - of course, not in super-quality, but at least in the form of a slideshow to see what is happening around the car in the field. And for feeding systems, for example, you can see how much leftovers are left. All this is through mobile applications. This is a big market.

If we take Europe, they now have very relevant contracting organizations. Farmers unite, order the execution of work using heavy, powerful equipment, which the farmers themselves do not have - they have small tractors. And the land must be cultivated. Contractors often use their own software, create their own applications. Through them, a farmer can online order a particular operation for a particular field. And the next day, a technician will arrive there, carry out the work, and according to the results of the work, it is through this application that a report will be sent - how much diesel fuel was spent, for example, how much should be reimbursed, how much was done in terms of area, what operation was performed. And that's all in the mobile app. This is a huge market, and there is nothing narrowly focused there.

Q: : / ()? ? — ..?As for the fog: in the fog, after all, no one picks up the grain. There is a moisture coefficient, above which it is impossible to harvest - otherwise, there will be paste instead of grain in the bins. As for the lack of light, we carried out a number of tests last year. What we got: It all depends on the head lighting of the combine. There was a test on the Rostselmash Akros 580 grain, if I'm not mistaken - it has a rather weak head lighting, and because of this, the system got confused, gave an error and asked a person to take control. A little later, they tested it on a John Deere S670 combine, in corn harvesting - it had the most powerful head lighting, and there were no problems with it. You can go to our YouTube channel and watch it - there is a separate video there.

As for the dustiness, there were minor problems, when the cars went back to back, right in a row. When harvesting the so-called "dirty crops" - peas, soybeans, barley - there were problems, the system malfunctioned and asked to take control. But at the same time, we gave a recommendation to make more distance between the cars, and the problem disappeared. In principle, the system works when a person can see himself, because we work in the visual spectrum. If a person cannot see anything, the system itself will not see anything either. We do not put lidars and sensor sensors on the reapers, we have gone away from this, this will not be in our system.

About whether the antenna system is implemented. We set a condition for ourselves: our system should be completely autonomous, we should not be tied to GPS, so we abandoned GPS receivers. We work entirely on video cameras.

The accuracy of the work depends on the machine. We carried out tests on old cars - TORUM and Akrosa the same, 10+ years, and on them the error was greater, from 12 to 18 cm.The problem was in the steering - in such cars there were already beaten pivots, couplings, there was a backlash on wheels. This gave an error. The system tries to bring the edge of the header as close to the edge of the cut as possible. But modern TORUM, Lexion, RSM-161, John Deere give an error of 7-10 cm, and it is constant. That is, on modern machines, the shortage does not happen more than these 7-10 cm.

Write in the comments and ask additional questions, I am always interested in discussing - especially with knowledgeable people; in a dispute, after all, truth is born. Contact us, we will be glad to hear from you. Later we will try to conduct more detailed lectures on the same platform.

Thank you all very much, goodbye.

The previous transcript of our broadcast can be viewed here , even more of our speakers using the hashtag # ruvds_decoding