Several printers printed this house from local soil in 200 hours. As a result, there is no waste and no need to deliver building materials.

Mario Cucinella Architects have partnered with Wasp, Italy's leading 3D printing company, to complete the first clay house. This process, called Tecla (technology and clay), is environmentally sustainable and environmentally friendly, as the production leaves no waste and does not require the delivery of materials to the construction site. It took several industrial printers just 200 hours to build this 60 sqm prototype in Ravenna, Italy.

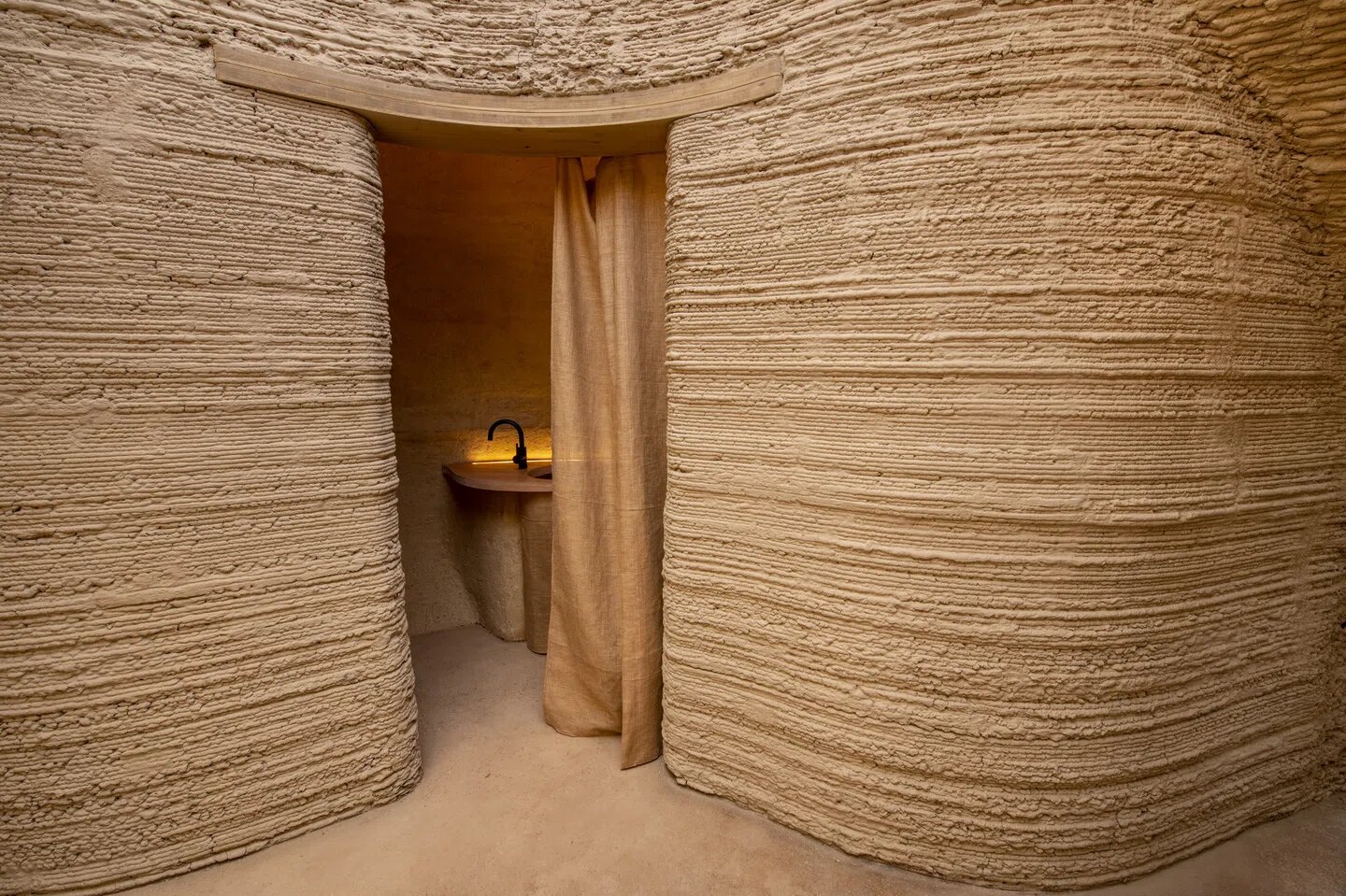

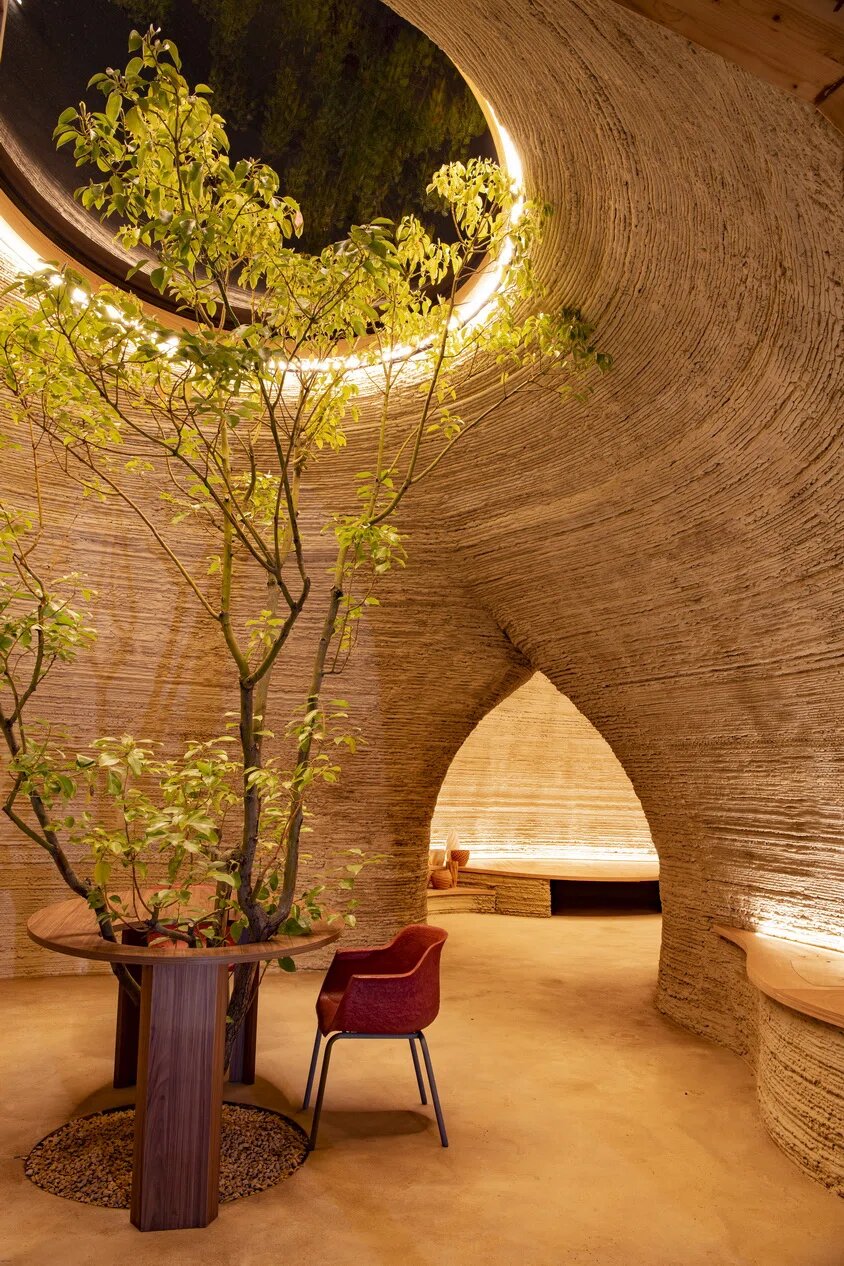

In terms of design, the house is an organic cave-like shape that looks like an ancient creation, created by nature itself, looking at which you would never think that there is high technology behind it. This is a natural feature of the "humanistic" architecture of Mario Cucinella, which arises at the intersection of the world of simplicity with the world of high-tech. "The aesthetics of this house was born from technical and material efforts." - says Mario - "Moreover, the approach was based not only on aesthetics, but also included the openness and sincerity of the form."

The project began with a design that Cucinella and Wasp founder Massimo Moretti started with the School of Sustainability, an organization that is exploring the possibility of building sustainable homes with minimal environmental impact - that is, using local materials without having to supply them to the building site. The result is Tecla's technology, which is a process with virtually zero emissions and low carbon consumption. "Tecla shows that a beautiful, healthy and sustainable home can be built with a machine." - adds Moretti.

The architect studied how the shape of the building can affect its efficiency depending on the climate and geographical latitude, and also implemented the composition of the material, taking into account insulation and ventilation. At the same time, the shape and external protrusions of the house additionally ensure its stability.

Inside there is a living space, a kitchen and a bedroom. Some of the furniture is integrated into the structure, while the rest of the freestanding items are designed for further processing and reuse. The house was built from 350 layers, 12mm thick, which took 60 cubic meters of natural materials. The average power consumption was less than 6 kW.

Photographer Iago Corazza