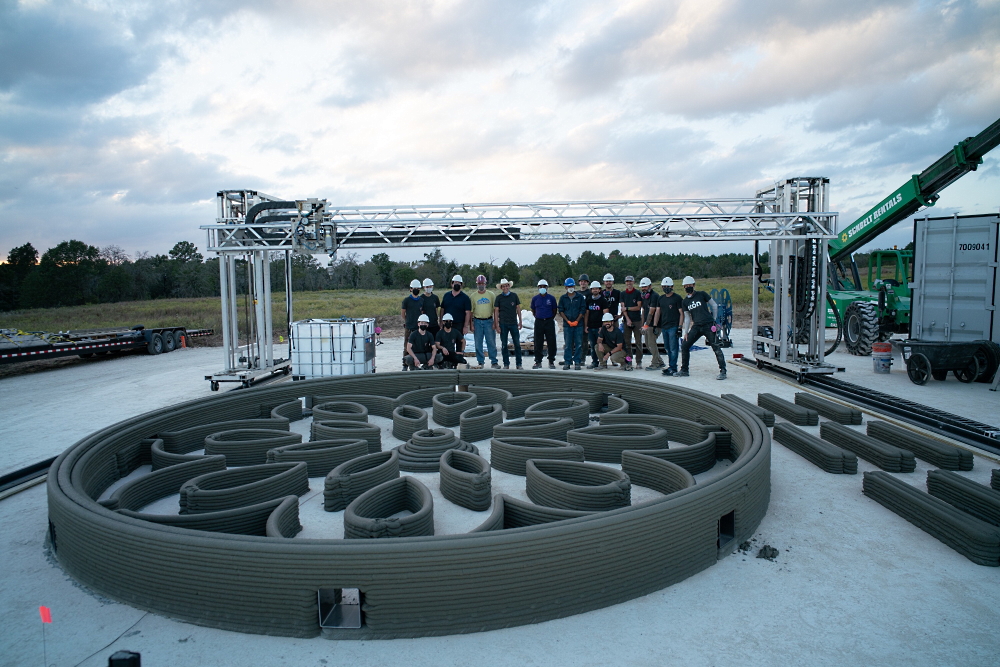

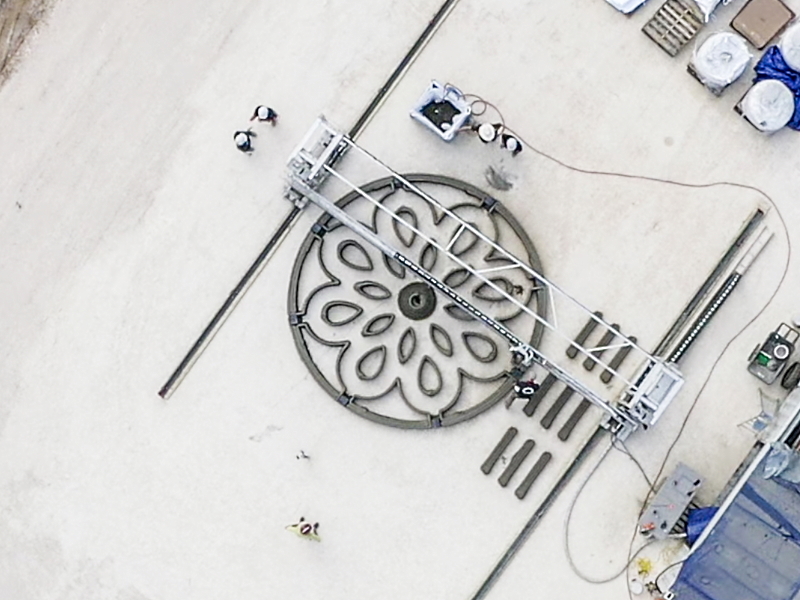

It is almost impossible to imagine space exploration without the use of local resources. Lunar base projects were buried under the surface , covered with soil, or surrounded by printed walls. But less attention was paid to the structures of the lunar spaceport - at best, flat areas are drawn in the illustrations. They will have a minus - engine exhaust will corrode the surface and raise dust. To address these potential challenges, a team of students from ten American universities and colleges supported by NASA and ICON, a 3D printing company, designed, built and successfully tested a large-scale prototype of the Lunar PAD runway.

2019 NASA L'SPACE 12- NASA NPWEE . L'SPACE NPWEE , NASA. 2020 . , NASA, - . () .

, Dust Devil (" "), Lunar Plume Alleviation Device (" ") , , Lunar PAD ( , "pad" " /"). Lunar PAD : .

. 3D-. 3D- , , , .

. , . , , , .

, . A&M . , , . - Lunar PAD /, .

It is also interesting to note that ICON, which provided the gantry 3D printer for the project, is engaged in 3D printing of houses and other structures. The company also received a contract from NASA last fall to research and develop a construction system that could be used on the Moon. A special division of the company has been created under this contract and, potentially, other space projects. The project was named "Olympus". And it's time to redo the freshly drawn renders - thanks to the efforts of the students who created the Lunar PAD, the depicted landing pads already look outdated.