Active metasurfaces, the optical properties of which can be adjusted after fabrication, have become an area of interest in recent years. However, efforts to date still face severe performance limitations in tuning range, optical quality, and efficiency, especially for non-mechanical devices.

Engineers at the Massachusetts Institute of Technology have developed adaptive "metal lenses" that can provide more efficient focusing of the lenses of cameras, microscopes, telescopes and other imaging systems without the use of bulky drive mechanisms.

Transparent glass with two light-refracting polished surfaces has been the basis of most optical systems for many centuries. The degree of concavity or convexity of the lens surfaces allows you to see all sorts of objects, from a tiny cell to a distant, distant galaxy. However, to obtain a clear image of objects of any scale, one has to resort to physical movement of the lens using additional mechanisms that take up a lot of space and make the device heavier, be it a camera, a microscope or a telescope.

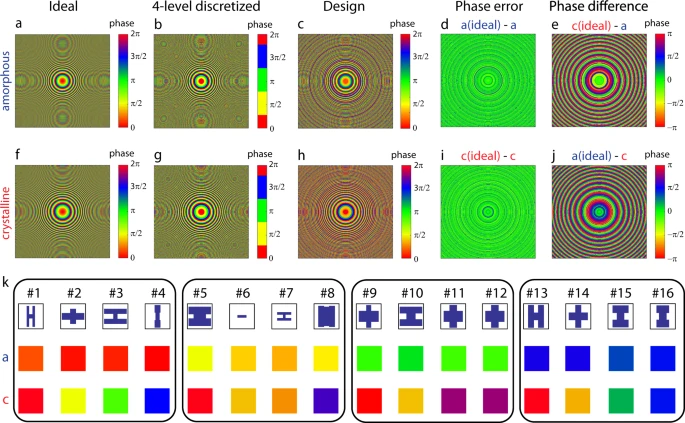

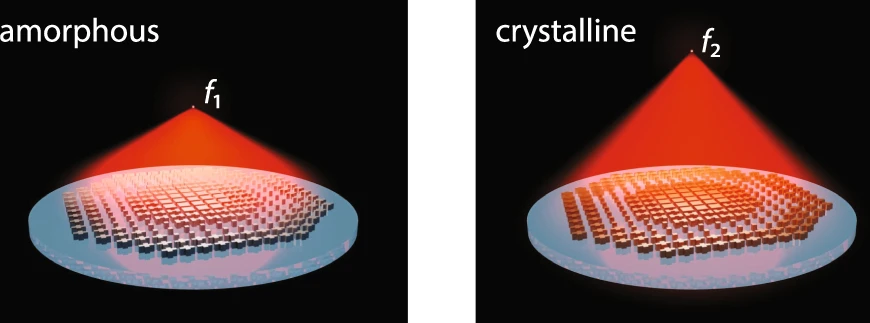

The researchers engraved the surface of the material with tiny, precisely patterned structures that work together as a metasurface, refracting or reflecting light in a unique way. When material properties change, the optical function of the metasurface changes accordingly. In this case, when the material is at room temperature, the metasurface focuses the light to create a clear image of the object at a certain distance. After heating the material, its atomic structure changes, and in response, the metasurface redirects light to focus on a more distant object.

Thus, the new active metal lens can adjust focus without the need for bulky mechanical elements. The new design, which currently allows for infrared imaging, could allow for more flexible optical devices such as miniature thermal imaging cameras for drones, ultra-compact thermal imaging cameras for mobile phones and low-profile night vision goggles.

Phase transitions

The new lens is made from a phase change material that the team made by customizing the material commonly used in CD and DVD rewritable discs. Called GST, it is composed of germanium, antimony and tellurium, and its internal structure changes from crystalline to amorphous, from transparent to opaque when heated by laser pulses. It is these phase transitions that make it possible to create reversible optical recording media. This mechanism allows you to write, erase and overwrite data stored on CDs.

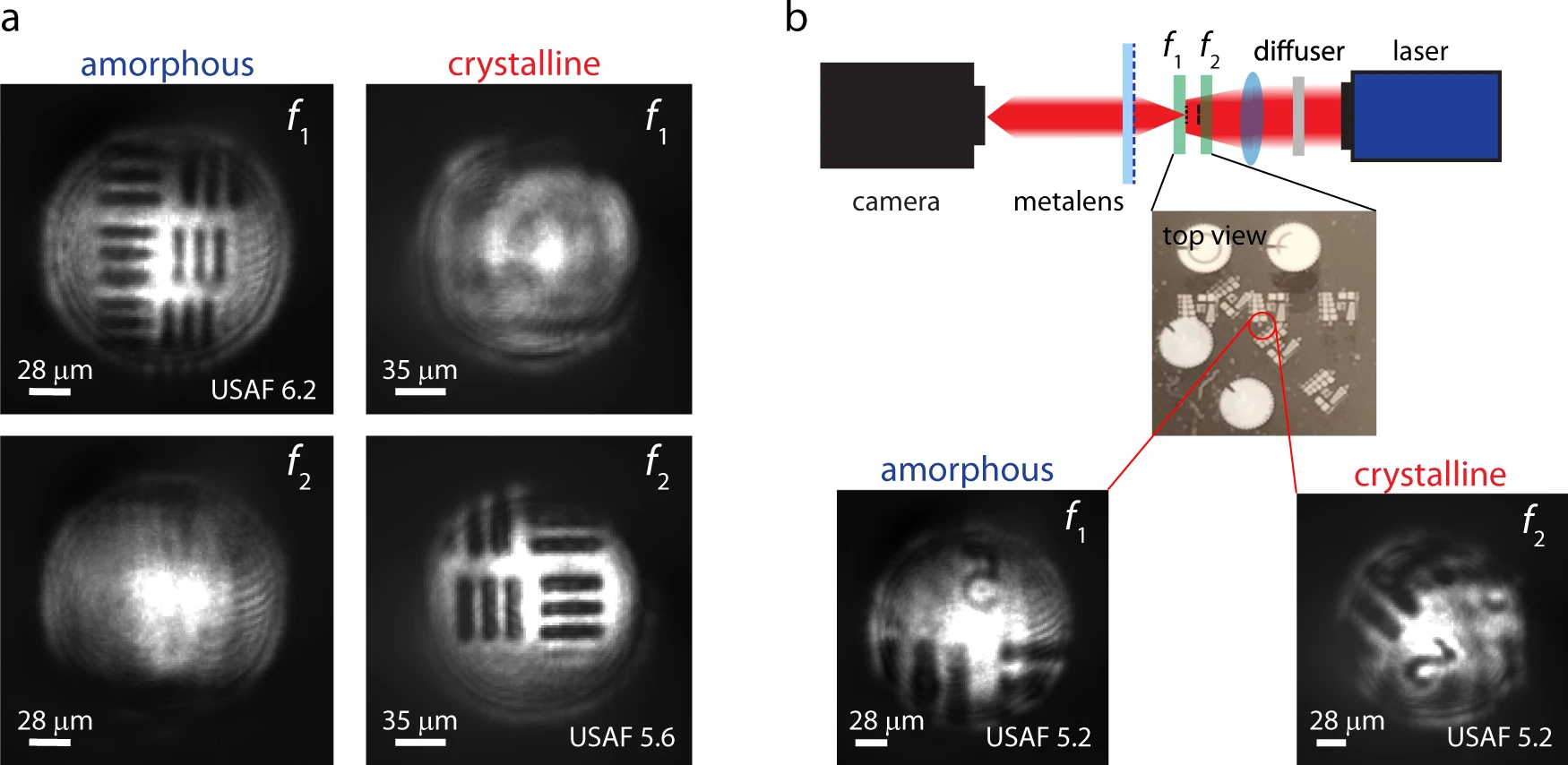

Change in focal length in the amorphous and crystalline state of the material

The engineers then added selenium to the structure of the GST, resulting in the GSST. In the updated version, the phase transition also influenced the interaction of the metamaterial with infrared light, transforming its reflective power with minimal impact on the transparency of the surface. Observing the unusual properties of GSST, the researchers thought it could be adapted to create an active "metalens" that can adapt its focal length depending on the phase.

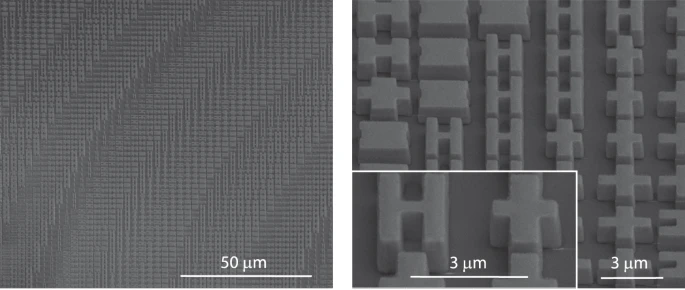

GSST under the microscope

In laboratory tests, engineers produced a layer of GSST just 1 micron thick and experimented with different forms of the material to find the most optimal variant that could change the way it interacts with light depending on the temperature. GSST's metal lenses were placed on a test rig, aiming at them the beams of a laser tuned to emit light in the infrared range. At some distance from the installation, engineers placed transparent plates with horizontal and vertical high-contrast strokes applied to them - the so-called test objects for assessing the resolution of digital optoelectronic systems.

In the initial amorphous state, the "metalens" easily focused on the nearest plate. The scientists then heated the metamaterial so that it acquired a clear crystalline structure and focused on a more distant test object. So far, the unusual material demonstrates the ability to capture crisp images at two levels of depth of field without the use of mechanical drives. In the future, the researchers plan to expand the range of phases of the GSST material in order to increase the focusing capabilities of the "metalens". One of the engineers compared the process of changing the phases in similar materials to the preparation of a steak. Meat can be not only raw or fried: there are many intermediate states - you just need to find a way to achieve them and fix the result.

Experiments show that the metal lens can actively change focus without any mechanical movement. The researchers say the metal lens could potentially be made with built-in micro-heaters to quickly heat the material in short millisecond pulses. By changing the heating conditions, they can also tune in to intermediate states of other materials, providing continuous focus adjustment.

More details: www.nature.com/articles/s41467-021-21440-9