I have a friend who says that if you count the number of hours spent on the manufacture of this device, then it is cheaper to buy the most expensive one. Of course, I disagree with him, but I will not dwell on this provocative topic for a long time. Let me just say that in time, the development and manufacture of this device took about 30 hours. I used the parts that I had in stock, including the humidity sensor, only the battery was purchased. For me, such projects are needed in order to improve skills, learn something new, and get a device to my taste.

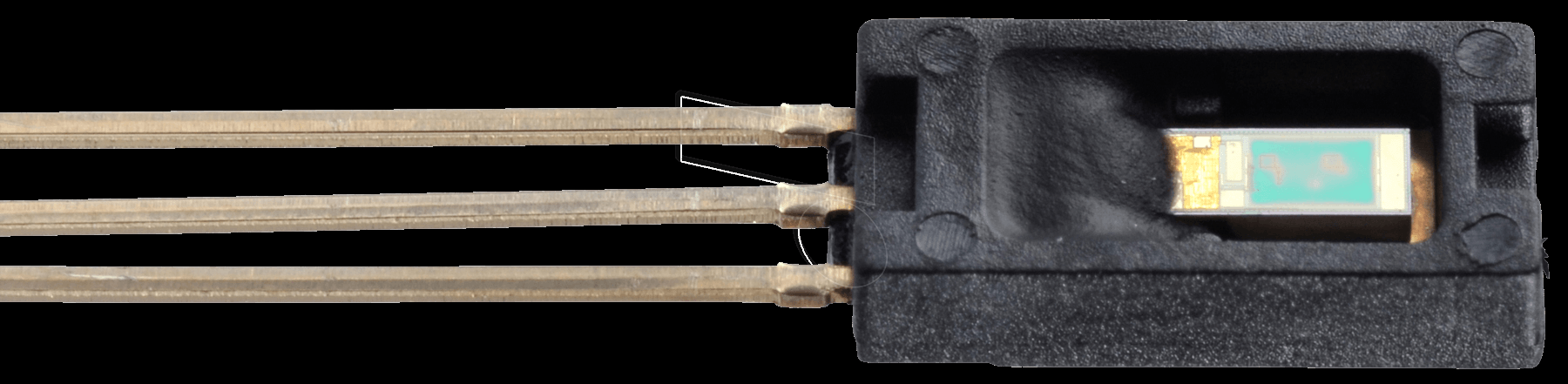

, 12 . USB-> -> +5 . 5 , , (HIH-4010-004), 5 . , RH% , ±3.5%.

- . , , . HIH-4010-004 datasheet , 90% 3% . HDC2080 TI , , 20% 80% 0° 60°. , , .

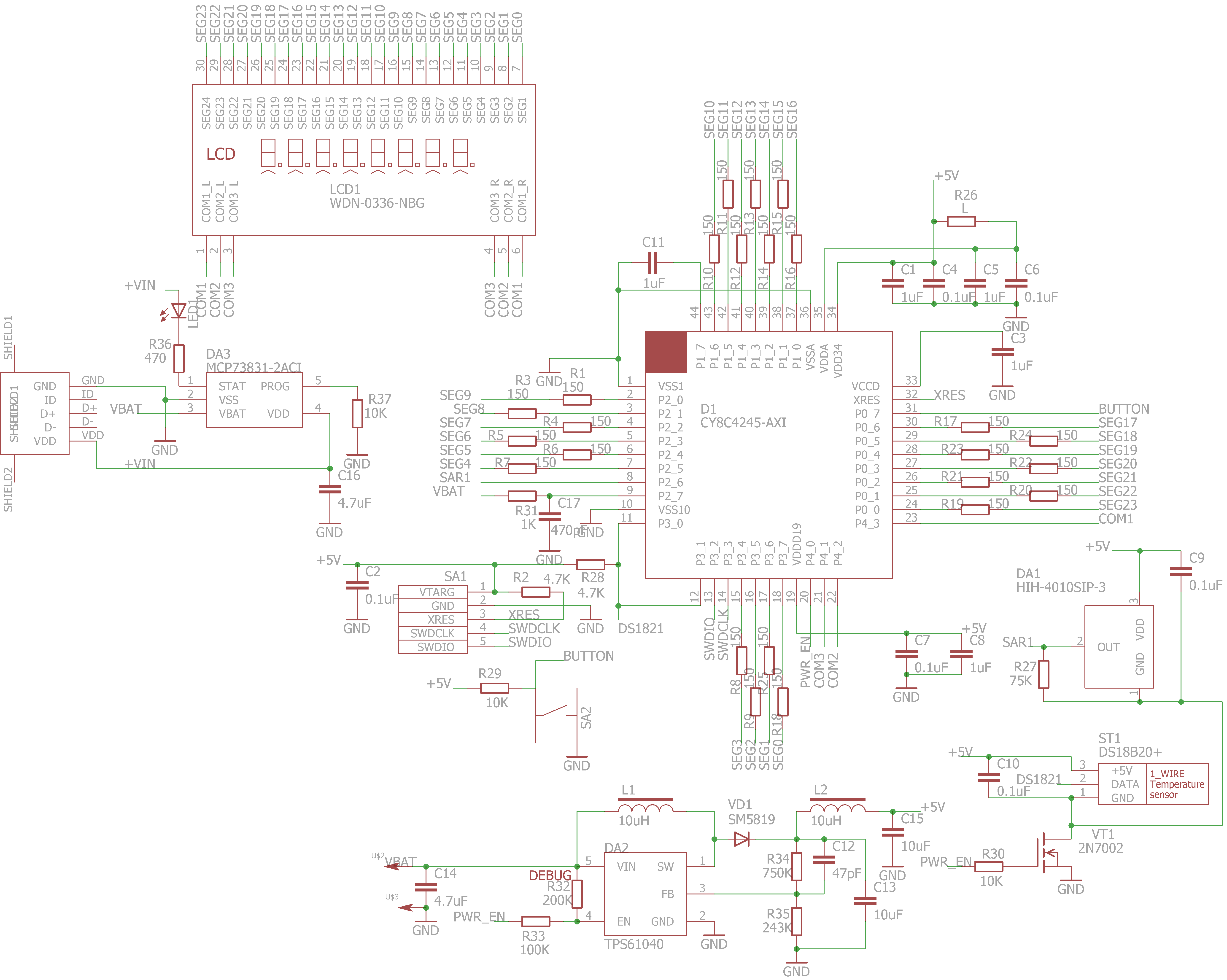

2014 Cypress , . PSOC 4200 $1 , . QFP SSOP.

, Cortex-M0, 32KB EEPROM 4K RAM, UDB ( ), PLD (Programmable Logic Device) 8 ALU 8 , 48 . , UDB .

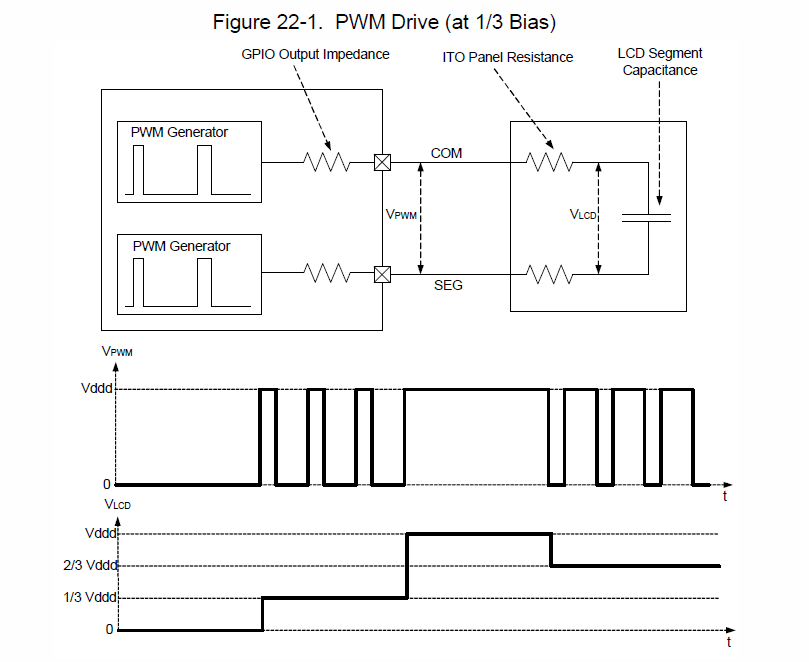

LCD, LCD , , , . LCD 4 .

, . . 3 , 0°, 0° 30° 30°.

Eagle. , .

, DS18B20 UART , 24 , 9600 115200. 6 24 - 4 . , , .

RH% , . 5.16 . , , HIH-4010-004 , Git . PSOC Creator , GCC , .

, , DS18B20 . , UART Watch Dog .

, 3 - 4.2 0.15 .

, , , , . , , , 60 .

60 , «STOP» . «STOP» 80 . «STOP» «» , LCD , ENABLE 0, .

.

, , . , - LCD , HDC2080, , , . . . - ( ). DS18B20, , .

3D 3D . , , .

Drilling of the board on a CNC machine, programs for drilling and milling are made in FlatCam from Gerber files generated by Eagle. The photomask was printed on a laser printer, soaked in acetone vapor for 20 minutes, after which it became black enough to make a printed circuit board using a photoresist.

In general, the topic of home-made is not very relevant now, but when you need to make one simple board, and you don't want to wait for a parcel from China, this skill helps a lot. I have worked out the method for years, I do it casually, doing other things in parallel, if there is interest, write in the comments, I will write a separate article on this topic.

Files with sources on GitHub