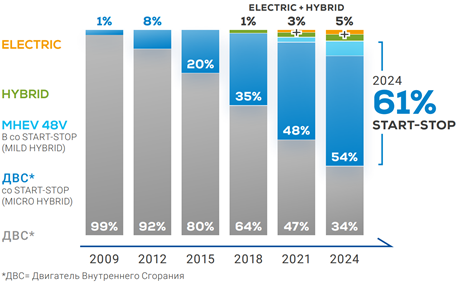

Already almost half of the new cars produced in the European Union are micro-hybrids.

Amid a heap of news about the deployment of infrastructure for new electric vehicles and disputes over charging standards, many may have missed the reincarnation of the old approach, which is now called Start-Stop technology. This is a great option not to waste energy on increasing the entropy of the Universe while you are just standing in traffic. If you stand for more than a couple of seconds, the engine automatically shuts off and does not eat idle fuel. Now I'll tell you in more detail how it works and why conventional batteries will die very quickly in this mode. As a former service center engineer, I have seen many batteries die due to inappropriate loads.

I want a lot of horses from a tiny motor

Photochemical smog in Beijing.

There are several trends in the modern car industry, albeit, perhaps, not everyone is happy about them.

First, it is an honest or near-honest effort by automakers to comply with regulatory requirements to create cleaner cars. Unfortunately, environmental standards are poorly combined with the wishes of buyers in terms of acceleration dynamics and engine power. As a result, “diesel gates” emerge , but overall progress in this area is very noticeable, which is critical for large cities. The photochemical smog situation is gradually improving, unless, of course, the city uses coal-fired power plants.

Secondly, there is a downward trend in prices. The consumer wants to get more "horses" for the same money. If earlier, one and a half liter engines of 50–70 hp were considered normal. with., now the same engine often produces 120, or even 150 horsepower. Obviously, nothing is given just like that. As a result, the motors require the installation of turbines, better fuel, precise injection control and become practically unrepairable.

On the other hand, the reduction in the vehicle renewal cycle leads to a kind of transition to CICD in the automotive industry. Whereas earlier the new technology was almost invisible against the background of a large fleet of old cars, now the rotation is faster. ABS, ESP and VSC systems are now gradually becoming the standard for any car, including budget cars. Actually, the classic internal combustion engine is no longer the same internal combustion engine as it was before. Yes, he refuses to drive on corn oil and incomprehensible fuel from a dirty canister. But on average, it has become significantly more powerful and more economical, albeit at the cost of durability. But the old elements had to be significantly modified.

We stand at the traffic light

This is a typical charge-discharge chart when driving a car with a start-stop system. Conventional batteries are killed at an alarming rate.

The most unpleasant part of the urban cycle is the constant twitching in an endless line when you are in a traffic jam. To save fuel, a start-stop system was developed to turn off the engine during forced pauses. Moreover, they are installed not only on classic hybrids, where an electric drive and an internal combustion engine are combined, but also on purely gasoline engines. The savings are quite substantial: 3-10% with a ceiling around 12%.

The first system of this kind was installed on the Toyota Crown back in 1974, but since then a lot has changed in the operation of the engine and other systems. The driving pattern has changed a lot. Previously, there was almost no system when it was necessary to start the engine while it was still running. Now, given the short cycles of traffic in traffic, this happens several times a day. This required the development of a more sophisticated starter with a tandem solenoid , which allowed the engine to restart while the crankshaft was still rotating. But getting it to start properly in sync is only part of the problem. Let's try to look at the modern implementation in numerous hybrids.

Hybrids, micro-hybrids and all the rest

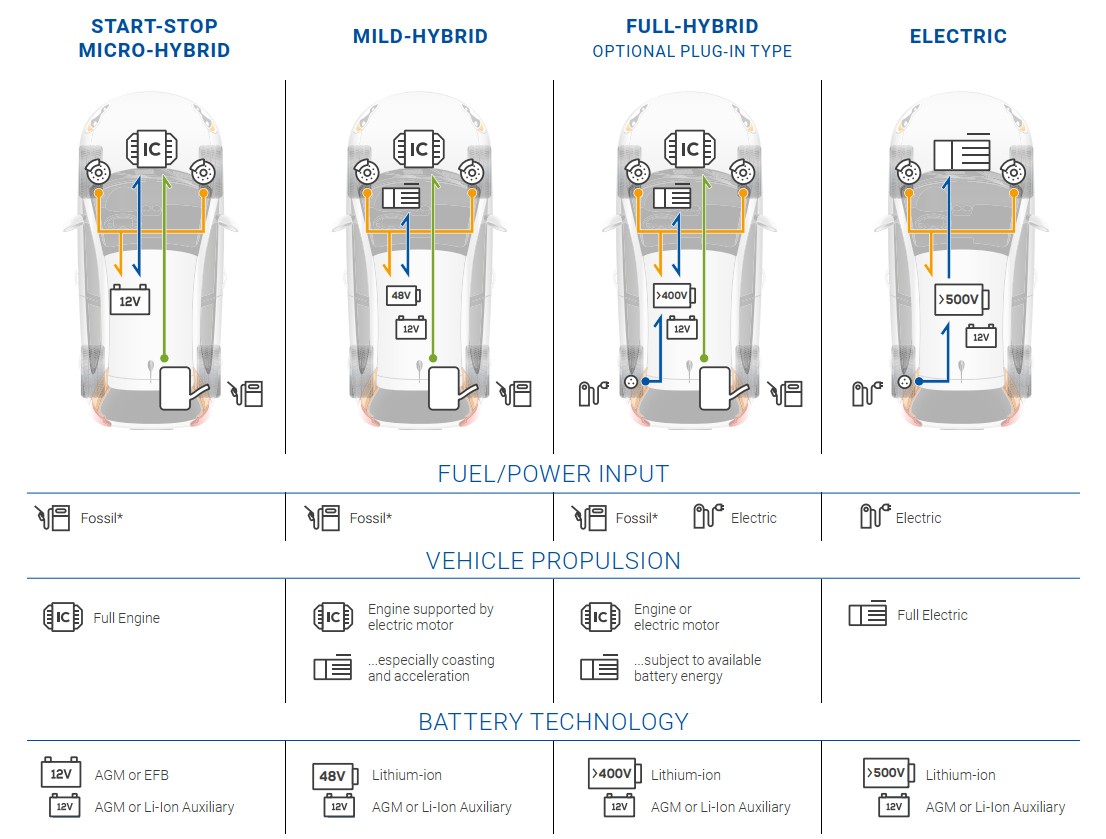

The current market has led to the fact that between a fully electric car and the usual ICE variant, several intermediate classes have formed.

Traditional internal combustion engines are almost all budget lines of cars: classic transmission, engine displacement is small to meet modern environmental standards. The engine is started using a conventional 12V lead-acid battery.

Microhybrids are all the same internal combustion engines, but with a start-stop system. The very first Toyota Crown formally belongs to this class. The key difference is in the starter we talked about earlier. For correct operation, it must have a power of the order of 3-5 kW. An ordinary battery will not be able to serve for a long time in a torn mode of operation of constant charges-discharges and repeated engine starts with high currents. Therefore, only AGM and EFB batteries are suitable for this type of vehicle. Inside the AGM is not a traditional liquid sulfuric acid, but a special absorbed electrolyte in the form of impregnated porous glass fiber structures. This allows it to withstand such operating conditions. And EFB has thicker plates, special pribluds in the active mass, and a special separator,and on the Exide, on top of this very confused active mass, they also smear a fiberglass mesh for stability.

Mini-hybrids: A new 48-volt electrical system and a small electric motor are added to the traditional 12V line. It is low-powered, but it is enough to ride a couple of meters in a deadlock and not pull the main internal combustion engine with constant starts. It is usually powered by a 48 volt lithium battery. A lead-acid battery is still used in the circuit to start the engine in a cold state and in case the electrical circuit suddenly fails to cope with it.

Full hybrid: in this scheme, purely electric drive over short distances is rather possible. Most often it is possible to recharge the traction lithium battery from the charger directly. The braking recuperation system is actively used. In general, a car is much closer in structure to an electric car. For example, the same internal combustion engine is often of a simplified design, often operating not within the framework of the classical Otto cycle, but on the basis of Miller and Atkinson cycles. The electrical stage accounts for the main, the most ineffective part for the internal combustion engine - crawling through traffic jams at a speed of 5-10 km / h, when the first gear is on and the gas pedal is not pressed.

, 47 % — , 48 % — , -, 1 %. .

AGM- EFB-

, .

AGM (Absorbent Glass Mat) is a technology for the manufacture of lead-acid batteries, in which the electrolyte does not splash freely inside, but is fixed on special glass fiber sponges. At the same time, thin glass fibers do not react with sulfuric acid at all, and due to their fibrous structure, they are practically insensitive to vibrations and mechanical damage. That is, even if the case is damaged, the acid will not flow in all directions, as in a classic battery, but will remain absorbed in fiberglass, like a diaper works. Glass only. Just don't disassemble and check them yourself. It's still very dangerous. Some of the micropores remain free of electrolyte. This is necessary to create a free space for gas recombination.

Inside, everything is formed in the form of a package of plates, which can have different thicknesses and areas of the active surface of this very active mass. If we need a battery with a large capacity and low currents, we increase the thickness, reduce the area. In the automotive application of AGM, the opposite option is more relevant - an increase in the area of the plates with a decrease in their thickness. Such batteries can deliver more current and charge faster, but have a smaller capacity. The plates in the blocks are pressed much more tightly together, which helps to better hold the active mass than conventional batteries. Also, an even tighter packing can be used not in plates, but in tightly rolled cylindrical lead rolls with a fiberglass spacer-separator.

Due to their structure, such batteries have several advantages:

- . - ;

- - ;

- , -;

- , , ;

- , ;

- , . .

The key difference from AGM EFBs is that EFBs are simpler and cheaper to manufacture. In them, the electrolyte is not bound, as in AGM, but is in free form. But unlike classic lead acid batteries, they have thicker lead plates. Their positive plates are stacked in fiberglass fleece, which prevents the active substance from shedding. Therefore, although they have a lower charge-discharge current compared to AGM, they can withstand about twice as many charging cycles as compared to classic batteries. In short, it is such an intermediate product in terms of its characteristics, which costs less than AGM.

However, they all have the same difficulties in common with classical lead-acid batteries. At high temperatures, their self-discharge increases, and in frosts, their capacity decreases. Therefore, if you have minus 30 overboard, then you should think about a heated parking lot. The capacity has already dropped due to the supercooled electrolyte, so the ice engine with thick oil also requires more revolutions to start.

What is interesting with us

I will tell you a little about our company. At Exide we manufacture a lot of batteries just for micro-hybrids - now it is about 30-40% of the entire European vehicle fleet. It is the battery of our production that most often gets into new cars. Now about 70% of European car brands put our lines, but with their own branding.

We have several types of batteries: AGM, EFB, Premium, Excell and Classic. The last three are classic. Excell is a basic reliable option with a good price.

Excell has a higher starting current, which is especially felt in winter. The current is about 15% higher than the Classic. And CLassic is for those who have a simpler car, no bells and whistles, and the price matters.

Premium will have the highest cold cranking currents - about 30% higher than Classic. In addition, the charging speed is higher due to our Carbon Boost 2.0 technology. A special carbon additive is introduced into the active mass of the negative plates, which also makes it possible to increase the chargeability, especially from the state of deep discharge, by about two times. Initially, they were developed specifically for start-stop systems, but later they were included in the classic line.

All Classic Series batteries have a sticker warning that they will not be suitable for start-stop systems. The cycle of operation typical of micro-hybrids will quickly destroy them, just like other conventional batteries. For such systems, we suggest installing AGM or EFB. These two types are almost identical in their parameters, but in the AGM the electrolyte is completely immobilized by impregnating special glass fiber structures, while in the EFB it is liquid. Actually, the EFB is rather an intermediate option between the classic lead-acid battery and the more expensive AGM.

By the way, if there is anything to be used as a source of backup power, then these are start-stop batteries, and not ordinary ones, which fail faster due to the smaller number of possible charge-discharge cycles.

The funeral is temporarily postponed

We will move towards a complete replacement of cars with internal combustion engines with electric vehicles for a long time: there is more than enough lithium on our planet. But only a small part of its deposits are commercially viable. At the same time, electric cars already account for about 50% of total demand, with a growth trend of up to 75% in the next 10 years. And also funny problems with dedicated lines from power plants to gas stations, where each charge can consume up to 150 kW.

Most likely, in the near future we will see the flourishing of intermediate hybrid solutions that will extend the life of both lead-acid batteries in new effective forms and internal combustion engines. And there, perhaps, in general, we will switch to hydrogen elements instead of lithium.