Hello Habr! The first part is here . In this article, I continue to describe the refinement of the Y axis.

One of the messages of this part: learn to read drawings / sketches / pictures and pay attention to little things.

I quite admit that some terms, from the point of view of professional turners / milling machines / locksmiths, etc. not entirely correct, but I repeat, I describe my personal experience without any "check" on the internet (all of my brains, so to speak, a test :)) And I myself am an "amateur" in this regard.

In the first part, I did:

trimming profiles (and along the X axis too) and trimming them (by the way, I sawed off the excess with a hand hacksaw, and then finished it on the machine);

threading in profiles;

drilling holes in the front / rear strips;

assembly (and do not forget to put T nuts (12 pcs each) for the rails in the "middle" profiles, and nuts for fastening the standard X axis along the side profiles);

There shouldn't be any questions about the assembly.

Still, I will describe one nuance that will seem ridiculous, but two colleagues from different offices where I worked really called me, and they asked: “I am assembling a sofa / cabinet and there are two washers, one is some kind of curve and it is not solid, but the other normal, and I don't know what to put on the bolt first. " It's sad, but in their areas they "rummage" very well. We are of course talking about grover washers and ordinary ones.

: , , , :) !

, ( ).

:

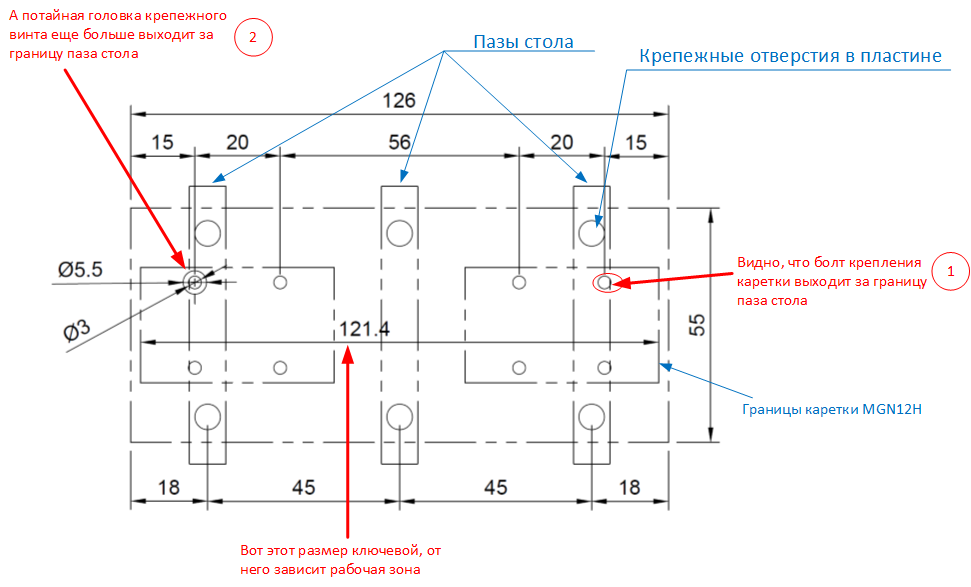

, 45.4x27.

, , 121.4 — , «» 300 — 121.4 = 178.6 , .. 1.4 ( 180 ) , 1 , — , , ( , ), ( , «» ), — .

:

120 , .

, , ?.

, ( , , , , , ), 10 . : 27 + 10 = 47 .

, .

6 = 11.5 . = 12 13 . : 27 + 13 + 13 = 53 . , 55 .

.

, «» , , 50 3 ( ). , , 50503 ( , , ..) , «» 47 ( ). .., , «». , ( ). , .. = 11 ( ).

.

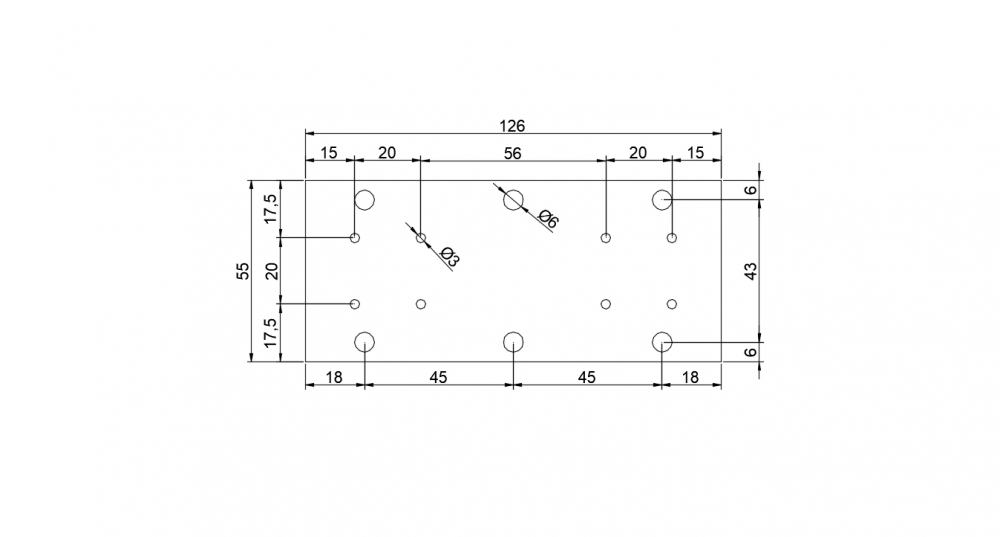

126553. , , .. 13060 ( «» ). … , , 3 . 1.65 3 6 .

.

… M3 20 , 1.65 — — , . , , , .

, , «» , , 1 — , , «» . , : « » ( , 90 , ) . 3 ( 2.9 ). , , . 3 6 6, .

, , .

300 , 290 ?

.

, . 300 . : ( — ), , . , , , , .

( 1 , 14 , .. , , .. ):

, ( ), . .

. , «» — («» — ).

, ( , ), . , . ( ), «». : . , ( , ), , , .

X/Y , - e , .. , .

, ( ). ( , , ). , — .

.

( ), — , ( ... «» ). , .

, . , , — ( , ). , .. .

:

;

;

«» ;

:(

:

«» , «» — , . , «» , . , ( ).

, . :

, .

, / — ..! , ( , ). , , ! :(. .

.

, , «/ » ( ), . 0.3 ( ). :

, , (- «») «» (, .., ). (, ), .

, , . , ( ). ( , ). ( , ) , .

, .

, ( , ), / 1-1.5 . 90 ., .. ( ). .. , , — . — 1-1.5 , . , ( ). «» ( «» , , ), , , ( , ):

.

, , ( ). .

.

, , 3 , , 6 , «» 4.5 , 6 ( 3 ).

, . , «»: 3 6.5 , 6 10 ( «»), — .

, .

, , , , :

, , ( , .. ). , , (, ).

? .

, .

, . ( 2) 3 , «» , ( , . 8:37):

, .. — . :)

«» .

.

3 , . , , , , . , , , , , ( , — ). :

( ):

:

, , , «» , .

, , , ( , : « ..» — :) ) . : , , , , ... 1.65 . , , !

8 ( ). .

/ , ( , — ).

:

.

, , «». 403 1. ( , ) :

, . ( , — ). , , . , pdf.

, .. .

, .

, X ( 2040). , . :

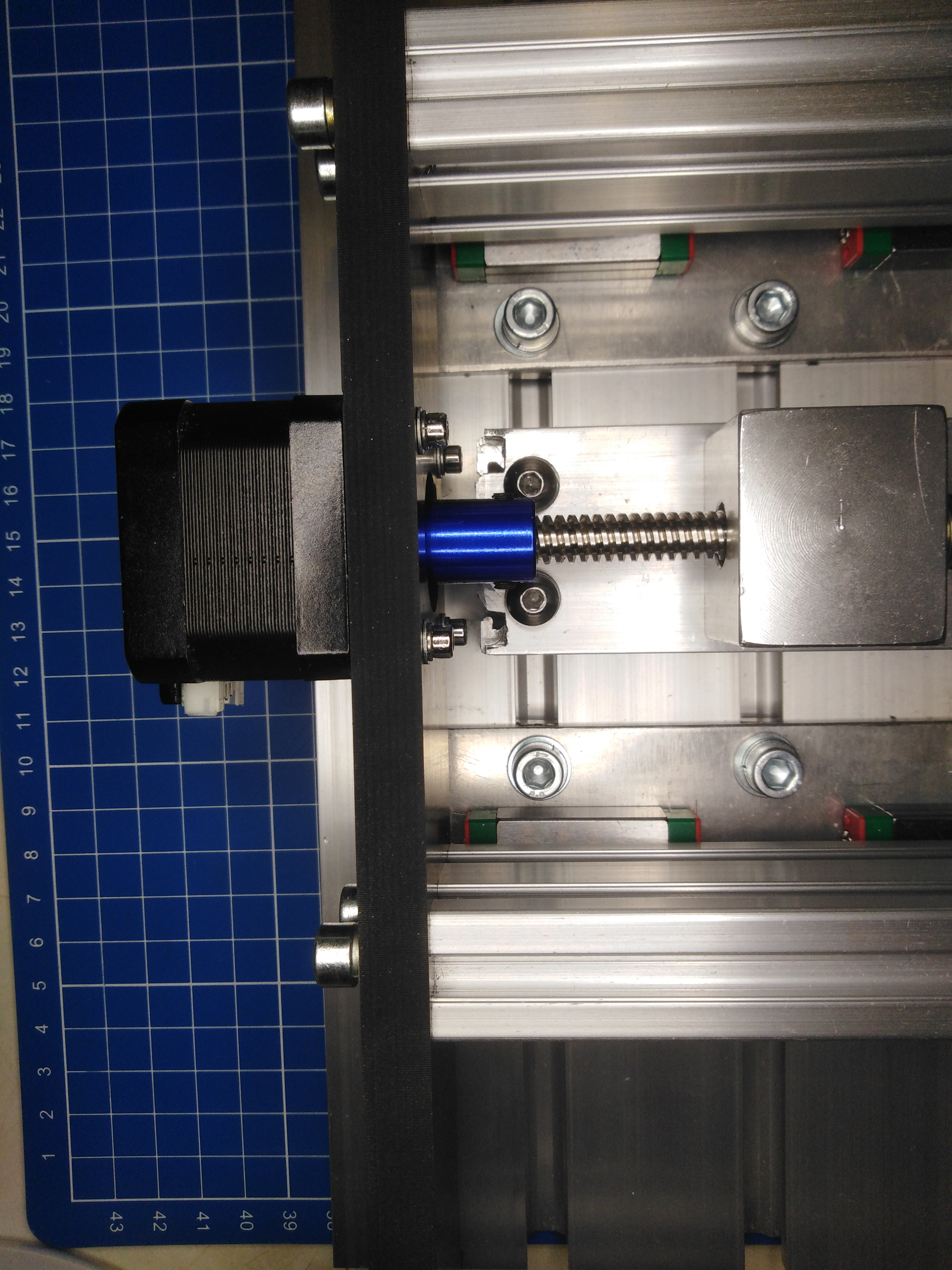

You see the spacers between the plate and the profile ... I stepped with the size. I had to do this. Although there are options, offhand:

there are aluminum square rods 16 mm + you need about 2 mm or more for the spacer;

stupid bolts with nuts;

I don't write the real height, because here in place you need to pick up.

And on one edge of the plate there are cutouts for the screws that secure the shagovik (yes, with a file, and it turned out collectively):

As a result, it turned out like this:

I will allow myself to post two videos where you can see / hear how the nut loosens in extreme positions. This means that the height of the center plate is adjusted, which is great!

It remains to adjust the table itself, and this is already a separate article (to adjust curly ....). And you need to think about the nut.

Thanks to all!