Hello ladies and gentlemen!

I will describe those. the process of finalizing the machine. I will also offer options (if possible) to simplify the revision.

The main message of this post is not to be afraid to work with your hands!

The rework technology is not mine, I focus on this.

When writing this article, I did not surf the Internet, checking the correctness of my thoughts.

All advice is based solely on my personal experience, which has been developed over the years.

If any advice seems strange or harmful to readers, please indicate it in the comments.

And the last thing. There will be videos in the article, but only when I cannot describe the current process in words or pictures.

Everything is stated here: Conversion of 3018 PRO to linear rails. Introduction and further on the links of the article.

If you read the articles from the link, then, in principle, everything is clear what and how, but the rework process itself is not described. Those. drawings are given, in the comments various options for improvements are given, but how it all happens is not described.

Disclaimer 1.

"" . ( ). - 150100 0.3. ( + ""). , - (, ). - (, , :) ). , , .

.

, . , Y, "", X - Z , Y - . ( ) Z X 0.8., ( , ) - 0.3 .

.

MGN12, 2040. Z. ( Y, Z).

2.

, : (). ... , , !. , , "" .

, ... 80 . , , , , , .. (, , :(( ). .. , "" .

3.

"" , ( ). , , / . .

, , .

(, ).

, Z ( ) ( ). , , (, ). , . ( , .., ), .

JUM-X2 . " ?". , , (, :( )

Y.

Y.

X . 2040, (. ) … :) Z. , . "", Y.

4.

, undo, .. ( " "). , X ( 90. ).

, .

cnc3018pro, . :

Y, ():

1. 360310 10. .. 290.

2. 380330 15. ( ). 300. ( ).

1, .. 290.

.. 300., , , :

1. 90.

2. .

.

- , ( , , , ).

, " ". . . , ( 0.5. ). , , ( "") - , , 0.2. - ( ).

:

, .

10. (, , , ).

, X . . , , ( ). ( 3 ). .

, , , , , (). "" (, , 0.01):

.

, , ... :

- , , ( );

- ( ) ;

- , , , , ( ...) - , ;

- ? ... ;

- ? ;

, /, , . , :(

, ( :) ) , .

:) .

.

5., 6.

.

: . .. 6 ( , 1.) 5., . , , .. ( ). 6, 4.8-4.9.

.

, - . .. - , , , 6 1, 6 2 - (1,2) , .. , . , , ( , , ). , :

, , - . , "". , . , 1. , 2. , , . , , ( , ).

, .. 1 2.

.

, ( , , ). "", "" .. , , , "" ( , ).

, .

.

, . , , 90 / ..

90.

, , . , , "". . : , ( , ).

. "", . / .

, , . - 20.

( ) - 10. .

Y.

X,Y . , .. . :)

/ ( , ):

:

/ ( ).

, - 6 . - ( ). - "" .

, :

, , . , .

.

, , . , , .. . , , ( , ) . : , .., . - . , , ( ), . .

- , ( , ). .

.

, :

X Y.

. - 4. ( "" ). , . - , : " "", - ! , , , . .... , , https://www.chipmaker.ru/ , , .

, .

.

, :

:

, ;

, , ( , - ) , ( ), ;

:

, , HDD.

, (, ).

, . - , - .

, , , (/ ), , ... 0.1-0.3 .. , .. , ... , .

, ?

( ) . , (.., "" - ).

, .

With an awl I outline future holes (since our material is not steel) and then with a screwdriver with a drill, with a diameter of about 2 mm. making a hole. And now an ambush :) You need to drill holes with a screwdriver / drill in two aligned strips perpendicularly. Handles will not work - the holes will be oval (or are there handles?).

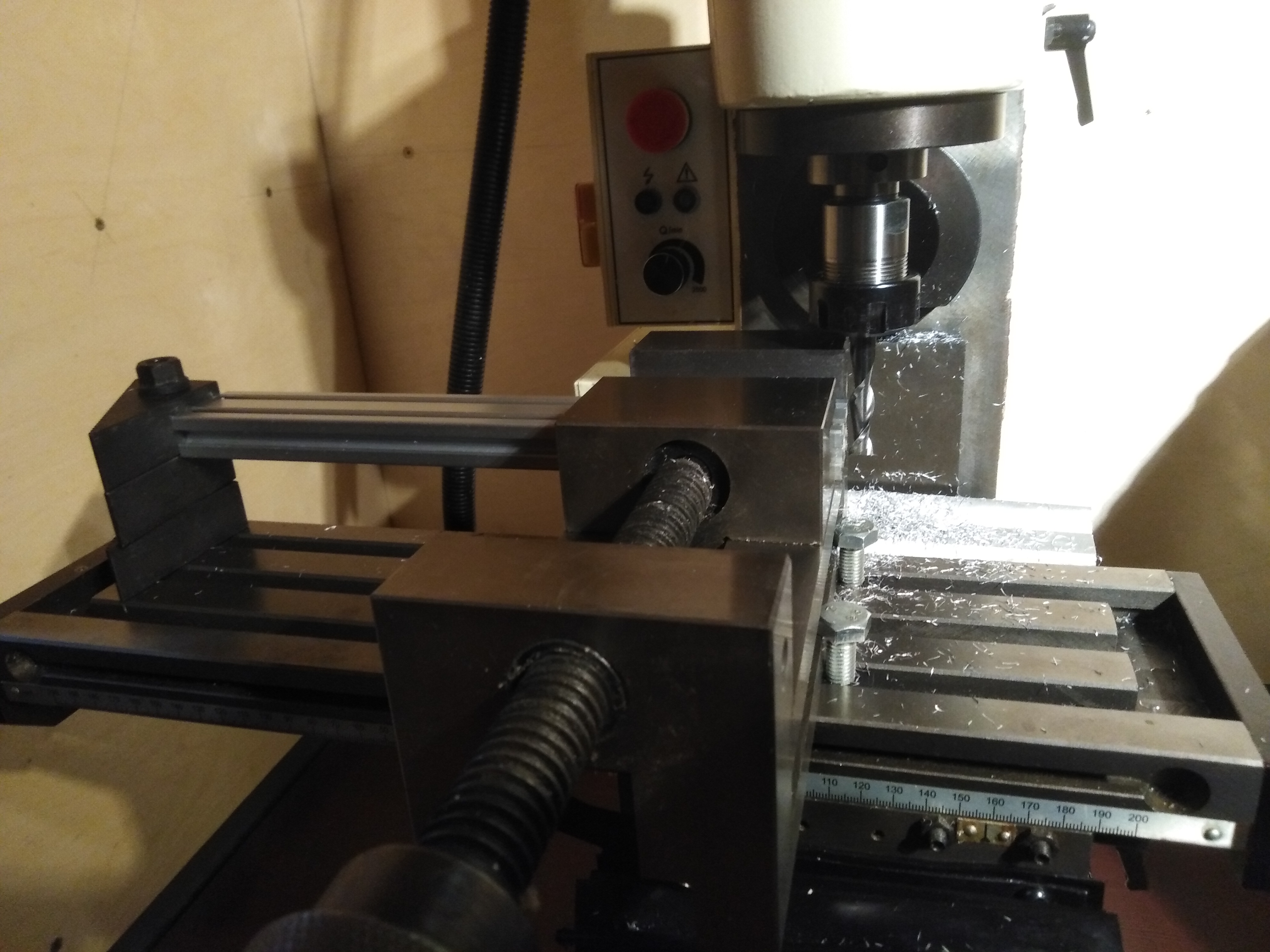

I am using a conductor like this:

There are clearly other conductors.

As a result, we get perpendicular holes.

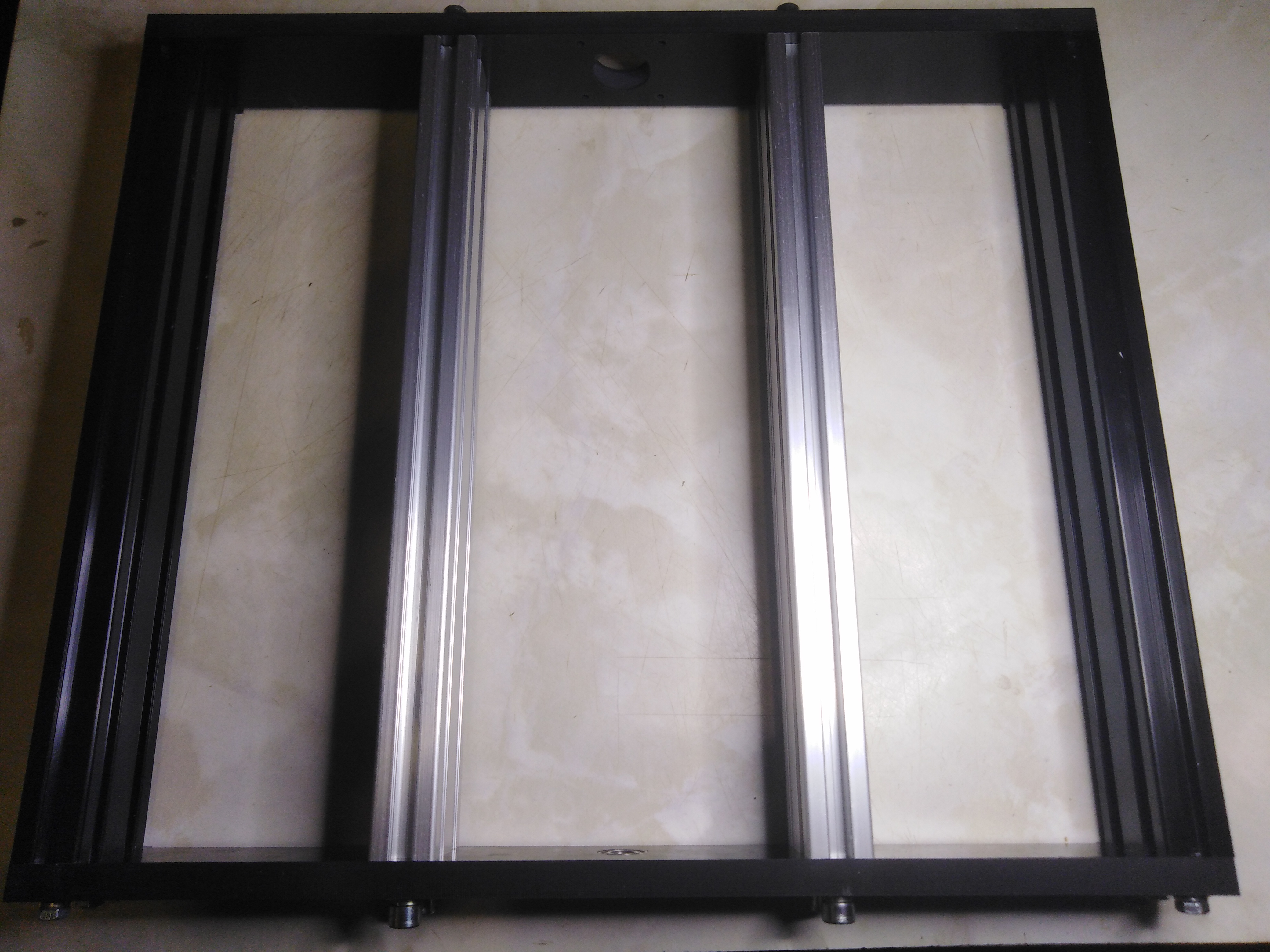

Everything, with the front / back planks finished, we fasten them with profiles. It turned out like this:

Further, the manufacture of plates, fastening the carriages of the rail to the table, but this will already be in the next article, unless of course the readers, with their pluses / minuses and comments, express their opinions on the first part.

Thanks!