Flipper Zero is a pocket multi-tool for hackers in the Tamagotchi form factor that we are developing. Previous Posts [ 1 ], [ 2 ], [ 3 ], [ 4 ], [ 5 ], [ 6 ], [ 7 ], [ 8 ], [ 9 ], [ 10 ]

The video shows a fresh sample of Flipper. This is a milled body, that is, cut from a piece of plastic and then painted. The final version will be molded under pressure with painting in bulk, that is, the color will be mixed into the plastic. But the final device looks exactly like this. The flipper is slightly larger due to two additional boards inside.

In this post we will tell you about the current status of the project, tasks and problems, upcoming production and access to the pledge manager.

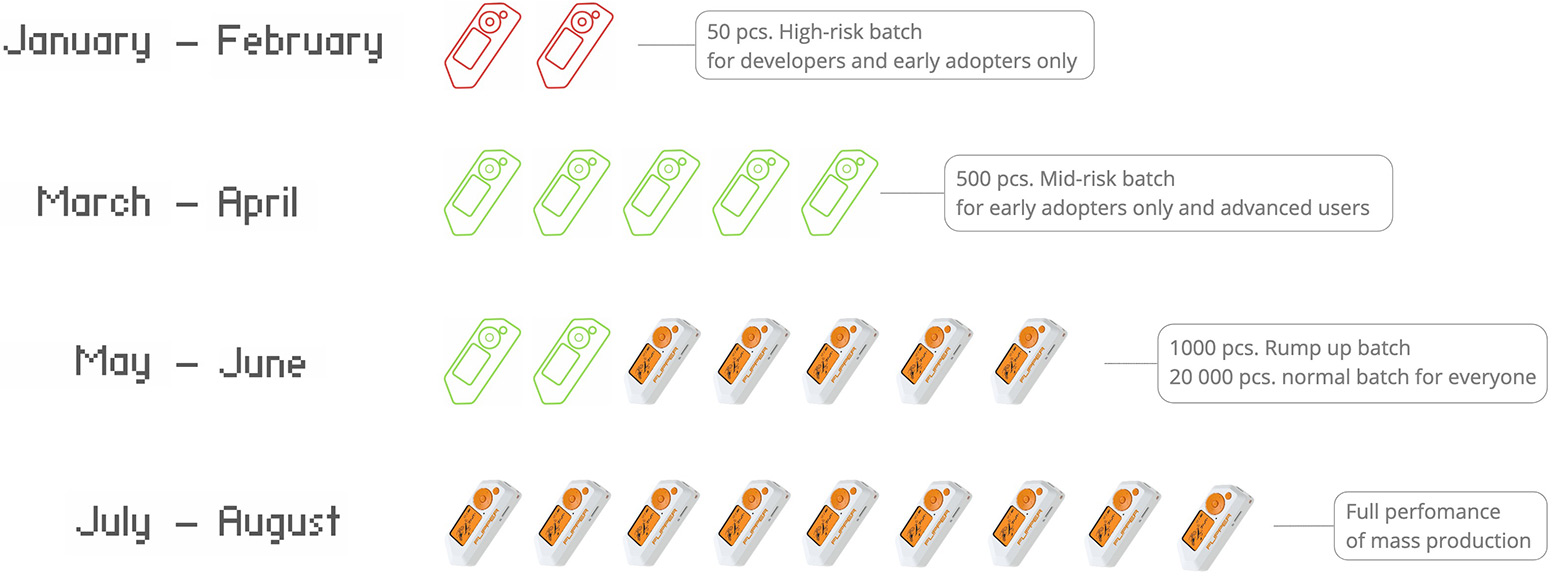

Production plan

: . , , . , . , , . , .

Given the huge expectations of our backers, we simply cannot afford to release a crooked device. We will gradually produce and send small batches to close developers and those who subscribe to the early adopters program. These people will act as beta testers, install new firmware versions, conduct field tests, and submit bug reports. But before you fit into early adopters, keep in mind that you might end up with a device that has serious bugs.

Flipper production plan

We expect that the first small batches will contain defects in mechanics and electronics, which will become apparent after a period of use. For example, conditionally, after a month of use, buttons on the joystick may start sticking, a USB port or, for example, pogo pins from iButton may break out. We will of course run automated tests, but they do not cover all potential problems that may arise. Therefore, we mark such parties as high risk. By the end of spring, we expect to have stable mass production.

Early Access Program

If you're willing to take the risk to get Flipper early, sign up for the Early Access program. But you should be aware that you may face marriage, mechanical flaws and other problems. You can apply for early access here (only available to Kickstarter backers) .

Keep in mind that the firmware is now very raw: it has many bugs, a lot has not been completed, the graphical interface for some functions is not ready, and they need to be launched from the console, without displaying them on the screen. Every day we release new firmware versions and all beta testers will have to constantly update and test.

Early Flippers will ship with raw firmware

The firmware repository on Github will be open by the time there are enough developers with Flippers on hand to contribute to the firmware code. We plan to intensively support the firmware for at least 2 years after the release of Flipper, so we prepare all backers in advance that at the moment you receive the device, not all functions may work there, and they will be added over time in firmware updates.

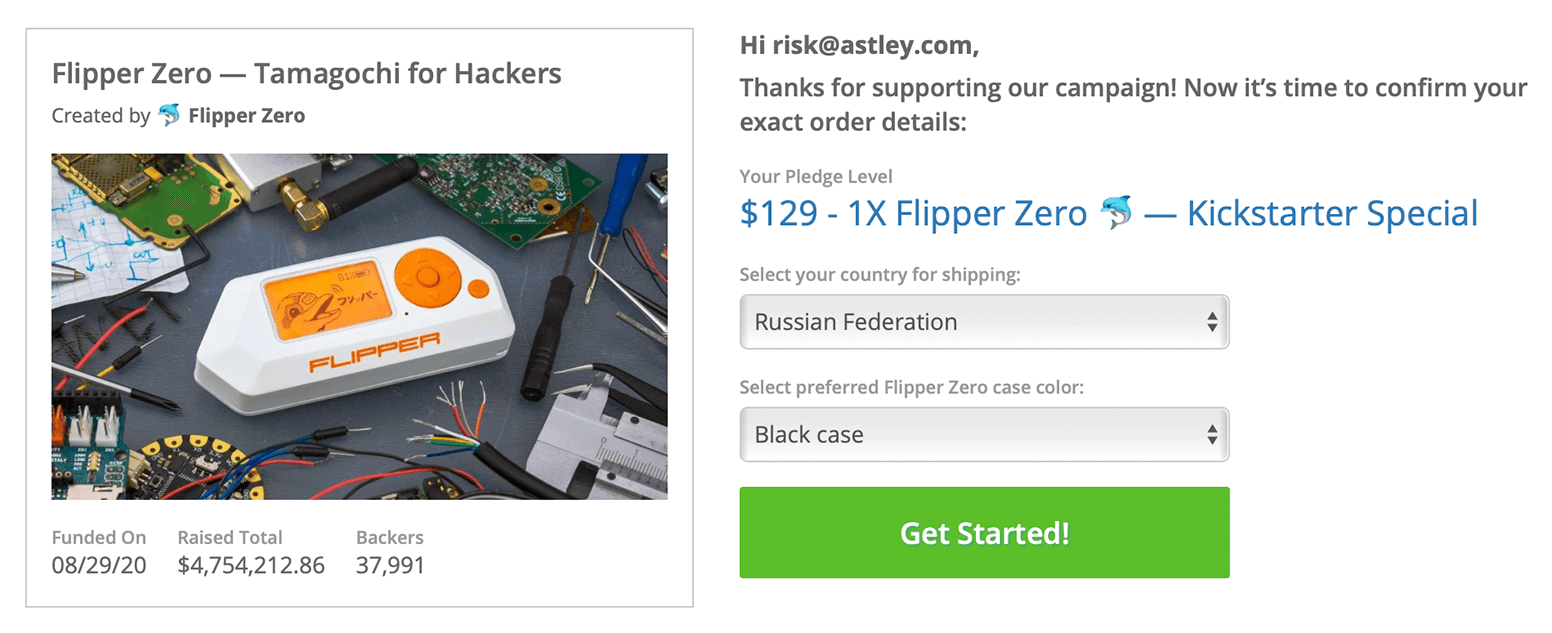

Launching the plage manager

Within a few days, we will open access to your personal account, where you can select the delivery address and pay for it, select the body color and add more Flippers to an existing order. It will also be possible to add a silicone case and development boards to the order. Now we are finishing screwing our shipping broker API to the pledge manager to automatically calculate taxes and shipping costs depending on the weight of the package. It will be ready in a few days.

Screenshot of the pledge manager page

An invite with access to the plage manager will come to your email address, which you indicated on the kickstarter and in your personal messages on the kickstarter. Do not be afraid to miss the letter, the system will remind you about it until you complete all the steps. Those backers who are not authorized in the pledge manager within a month will be notified separately.

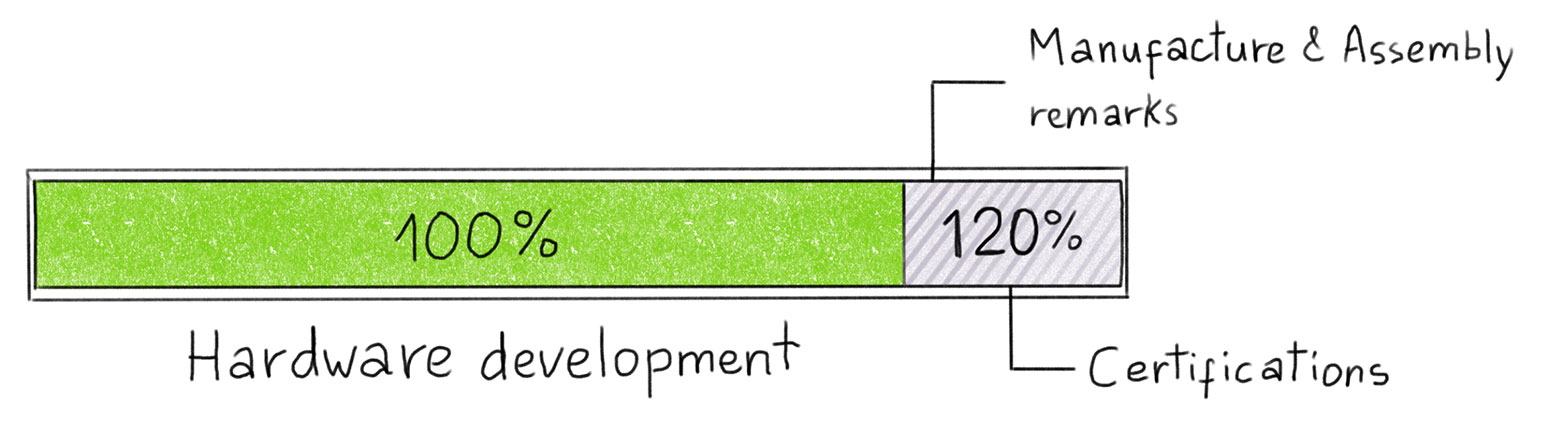

Current status

Hardware development was our top priority because hardware, unlike firmware, cannot be upgraded once released and shipped to users. Any flaw here would be fatal.

Now we are completing the fine tuning of the antennas, tweaking the component ratings and eliminating minor roughness. It remains to check for extreme conditions, temperature drops, vibration, shock, and more. In general, we can say that the hardware design is complete. Now we only make minor corrections that are sent by the certifying laboratory and factory.

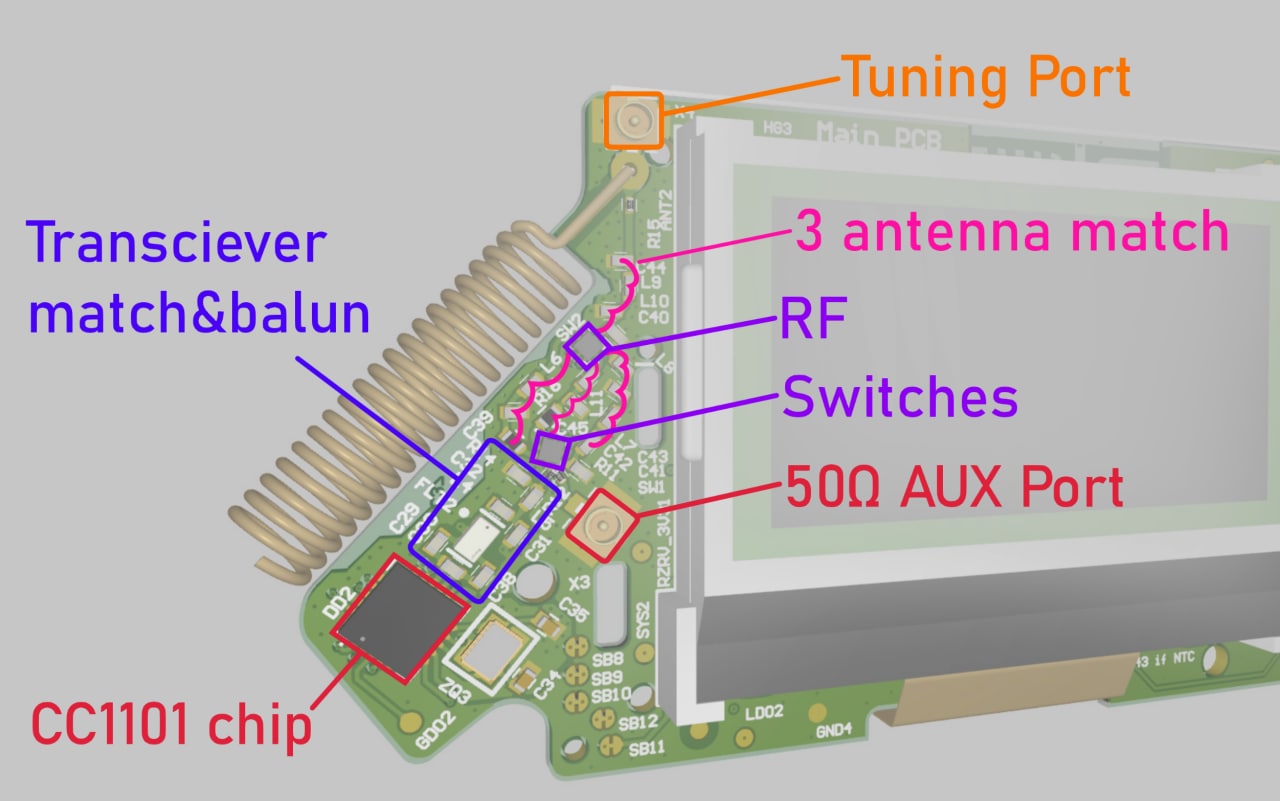

Supplementing broadband antenna Sub-1 GHz

Most of the difficulties now are with this subsystem. Simultaneous support of the ranges from 300 MHz to 900 MHz on a single transmit-receive path is a very difficult task. We use a circuit with three (!) Switching radio paths and our own antenna design. The difficulty of such a circuit is that it must pass all certification standards (FCC, EC and others), such as spurious harmonics, frequency deviations, etc.

Now we are adjusting the characteristics of the transmission path to the norms and standards of the certification laboratory. This is a time-consuming process.

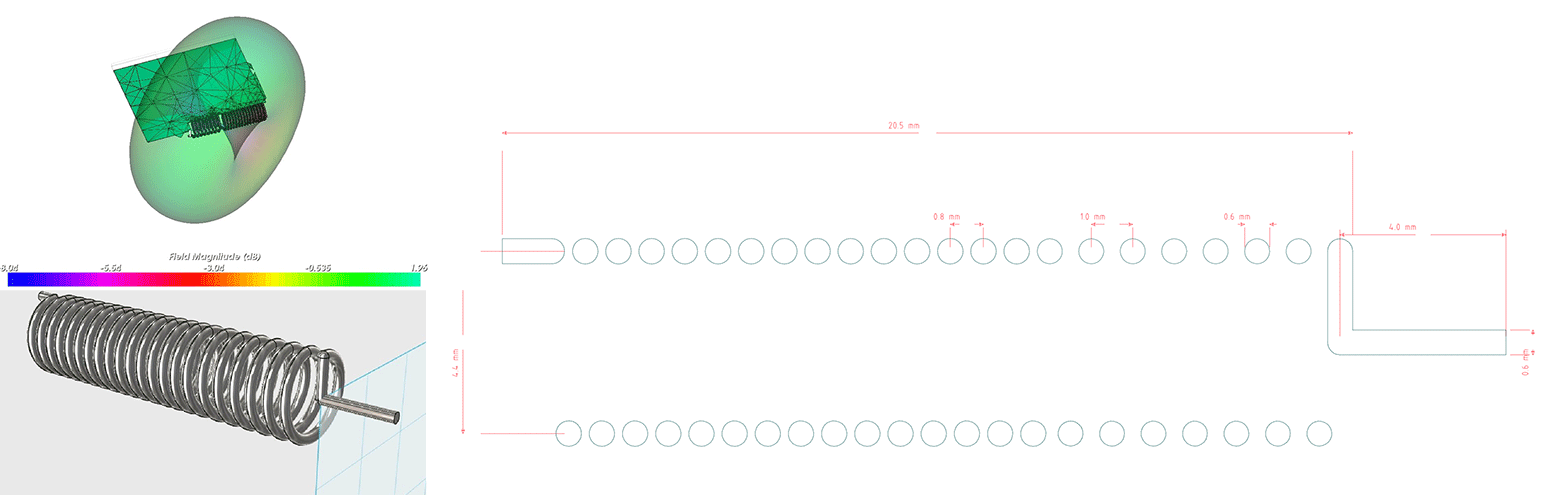

Elements of Sub-1 GHz module

Certification

In order to officially import the device into the EU and the US and sell it in stores like Amazon, we need to obtain a certificate of RF compliance in those countries. The fact is that for different countries these standards are different, and we need to make several different versions of devices that correspond to different standards. These are legal tasks that are far from development and production, but which we cannot avoid. They also complicate logistics as they spawn several different device versions with different SKUs. (

Regional differences in devices will only be at the firmware level )

In order to officially import the device into the EU and the US and sell it in stores like Amazon, we need to obtain a certificate of RF compliance in those countries. The fact is that for different countries these standards are different, and we need to make several different versions of devices that correspond to different standards. These are legal tasks that are far from development and production, but which we cannot avoid. They also complicate logistics as they spawn several different device versions with different SKUs. (

Regional differences in devices will only be at the firmware level )

| A country | Frequencies allowed (MHz) | Power |

|---|---|---|

| EU / England | 433.040 - 434.790 MHz | 10 mW |

| 865 - 868 MHz | 25 mW | |

| USA | 315 MHz | 75.62 dBuV / m |

| 433 MHz | 80.79 dBuV / m | |

| Japan | 312 - 315.25 MHz | 25 uW |

| Russia | 433.075 — 434.79 MHz

866 — 868, 868.15 — 868.55, 868.7 — 869.2 MHz |

10 mW |

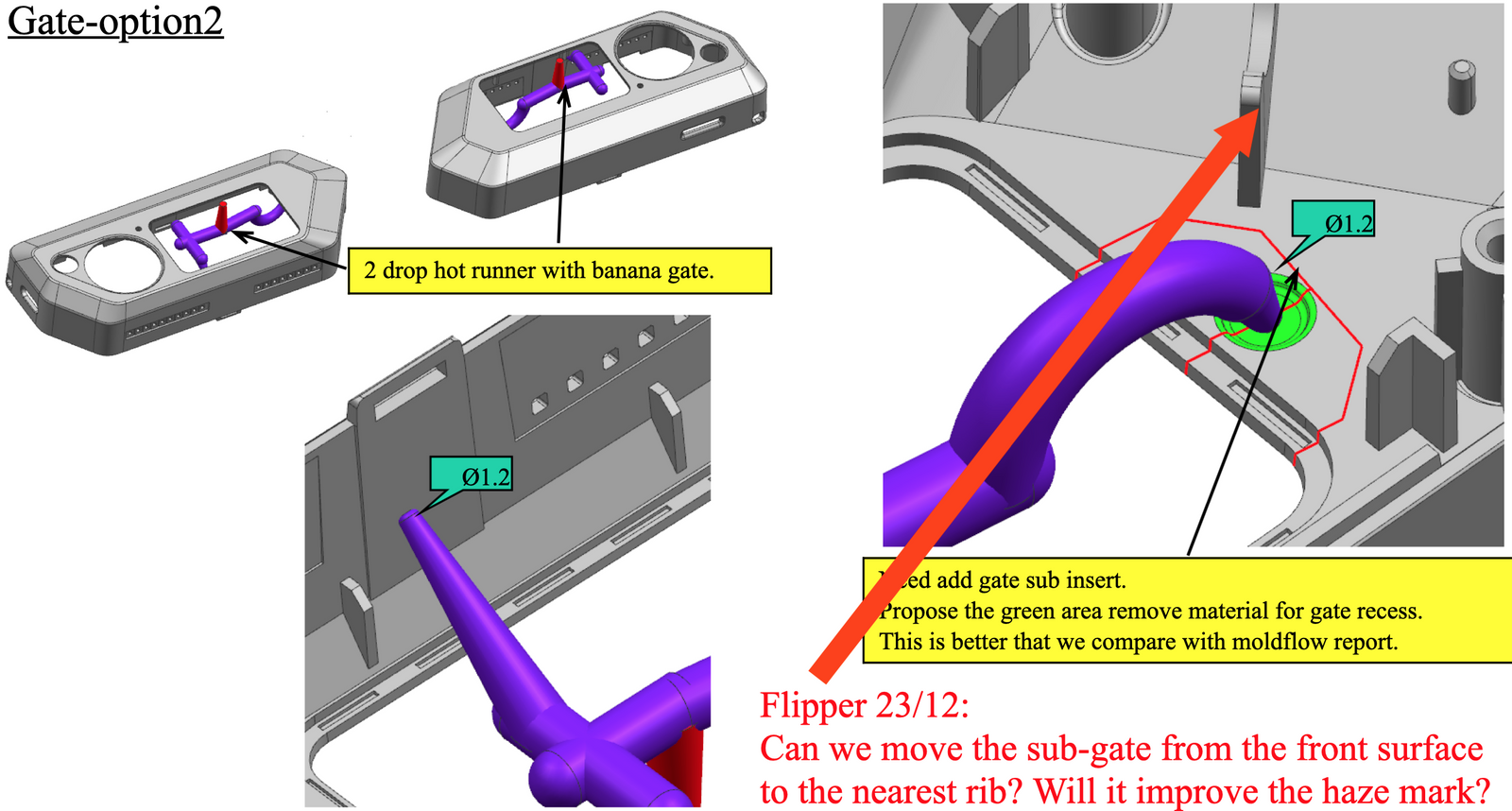

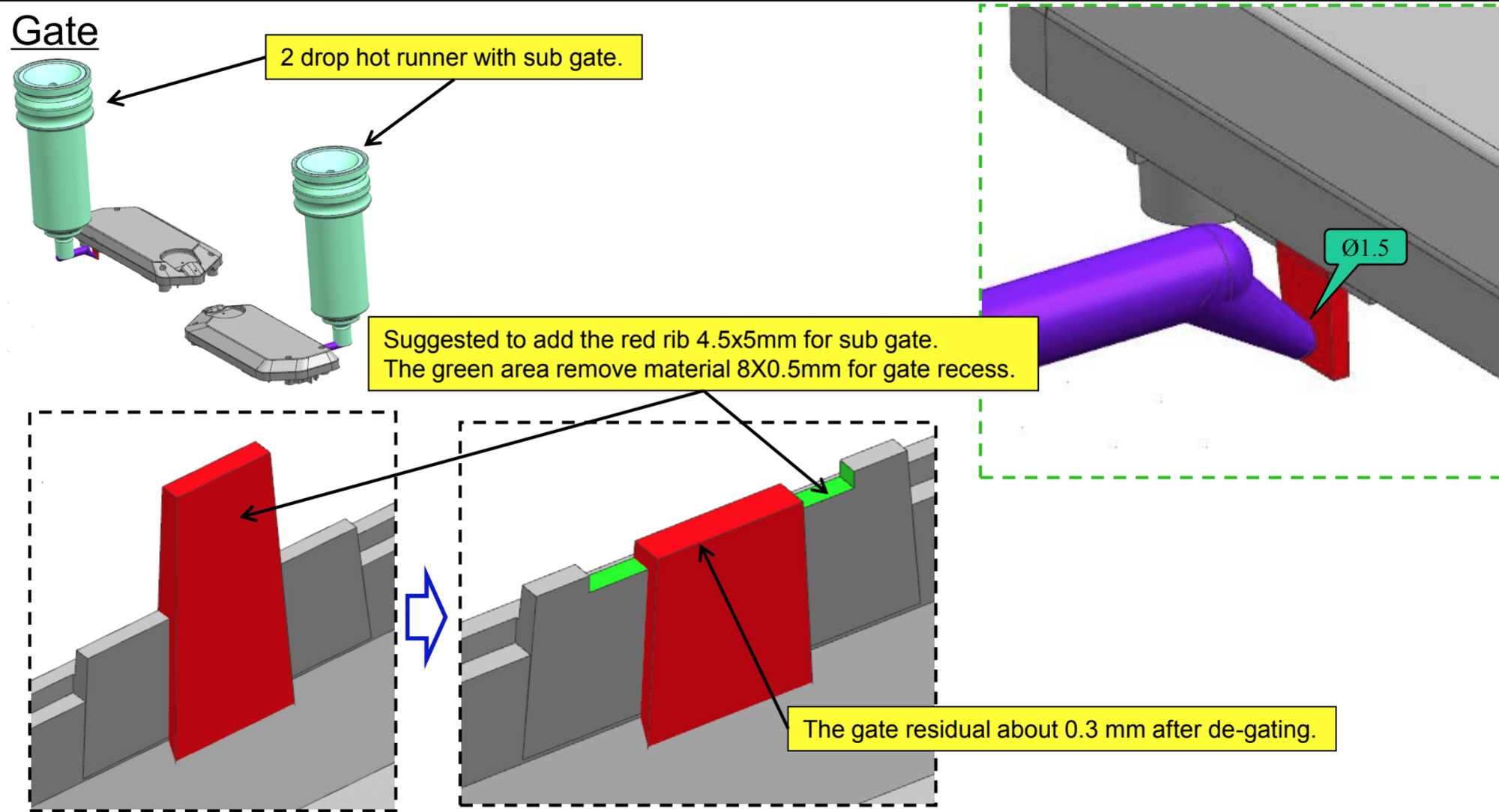

The preparation for body casting and assembly consists of dozens of very small fixes. Now we are in a state of coordination with the factory on all production details. It is necessary to consider how the part will be removed from the casting mold, where the injection points of the plastic will be and what type of casting is optimal for each part.

Example of corrections sent by a foundry The factory

makes corrections, calculates stresses, cooling rate, sprue position, etc. The difficulty with this process is that any rework of the mechanics involves redefining the position of the electronics inside and affects the assembly process. Therefore, even a 0.1mm displacement of the stiffeners can often lead to changes in the board outline. This is a time-consuming process as it requires the participation of all teams at once.

Three factories are involved in production, and each of them sets its own requirements. Now we are setting up the assembly and testing process at every stage.

Build process

The entire cycle from pre-assembly of each part to testing must fit into strict time intervals. If there is a deviation from this time, it will not be possible to manage to produce tens of thousands of devices. Now the assembly of one Flipper along with testing and firmware should be within 420 seconds!

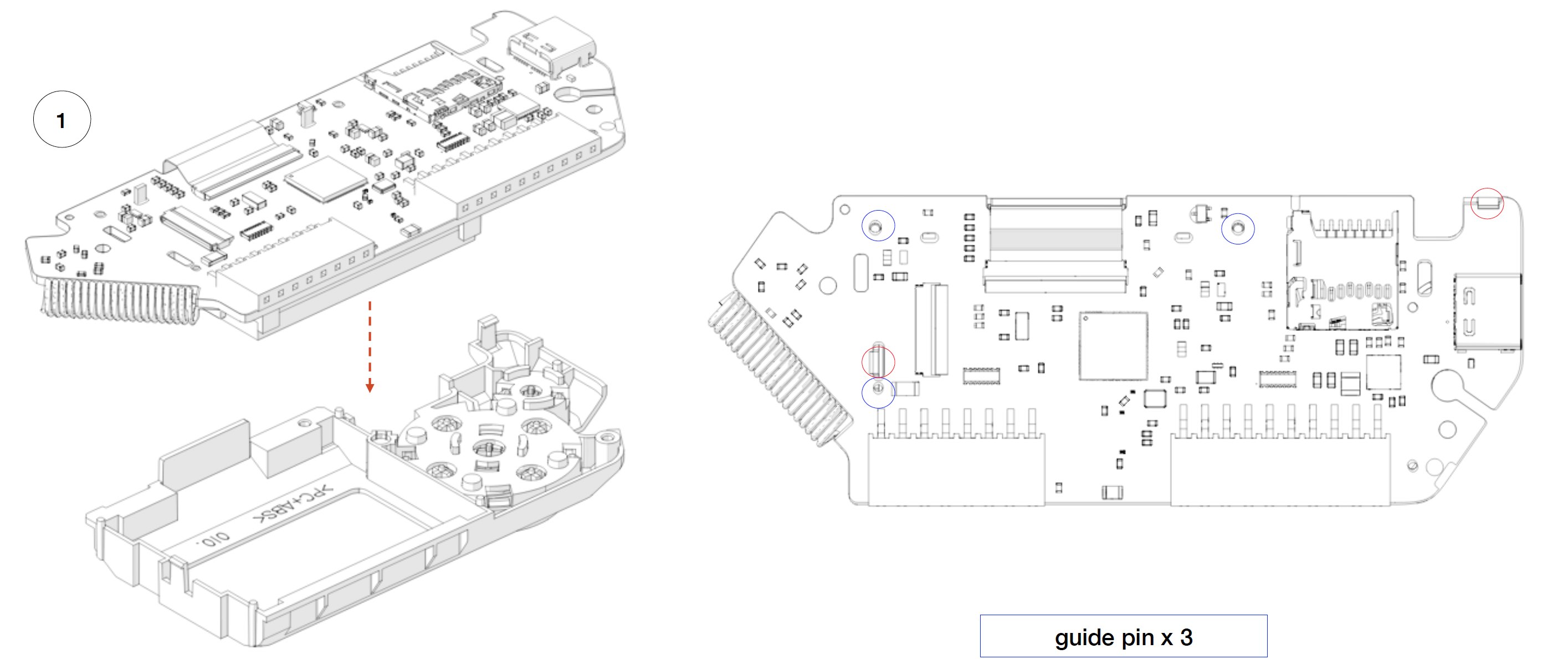

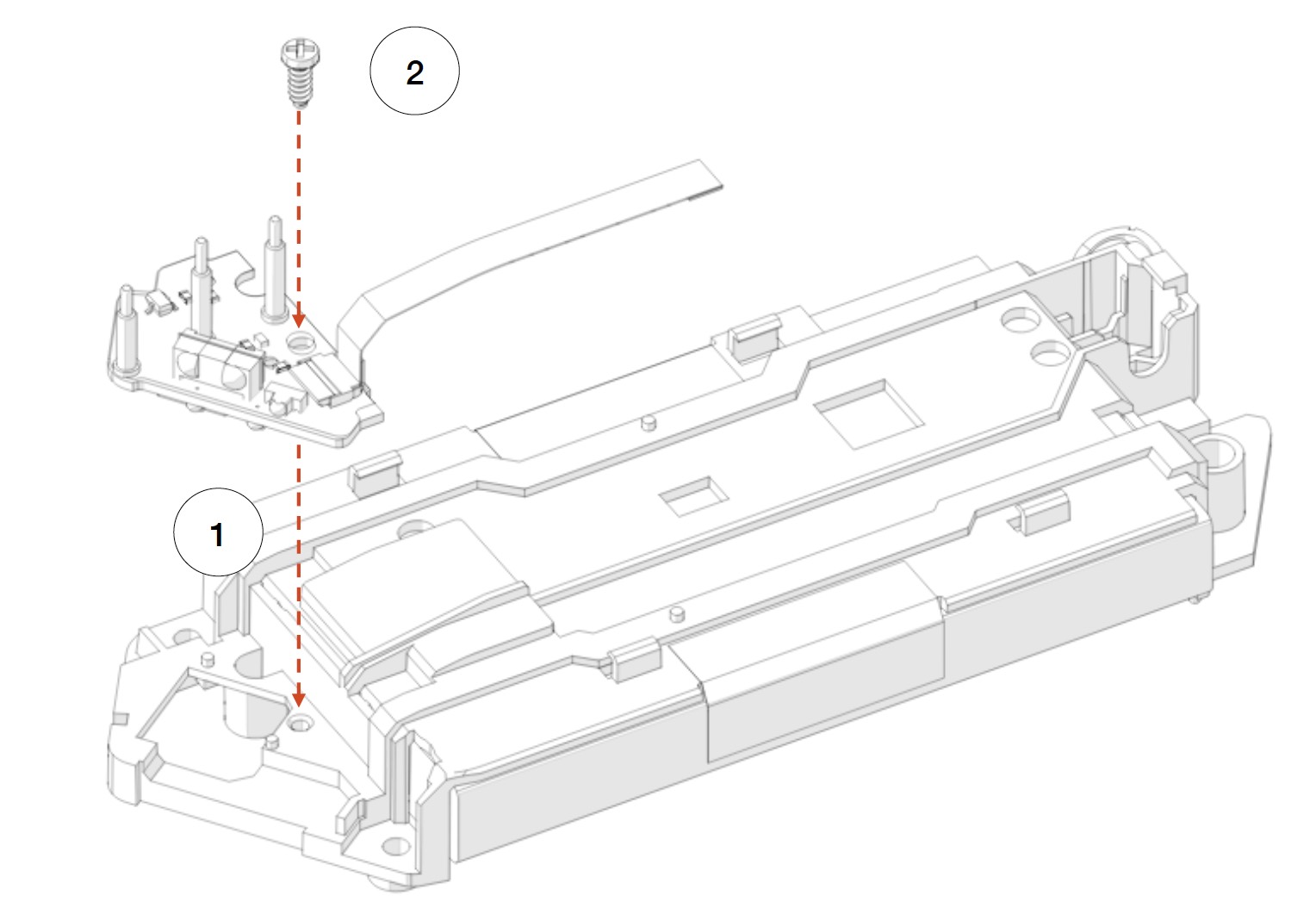

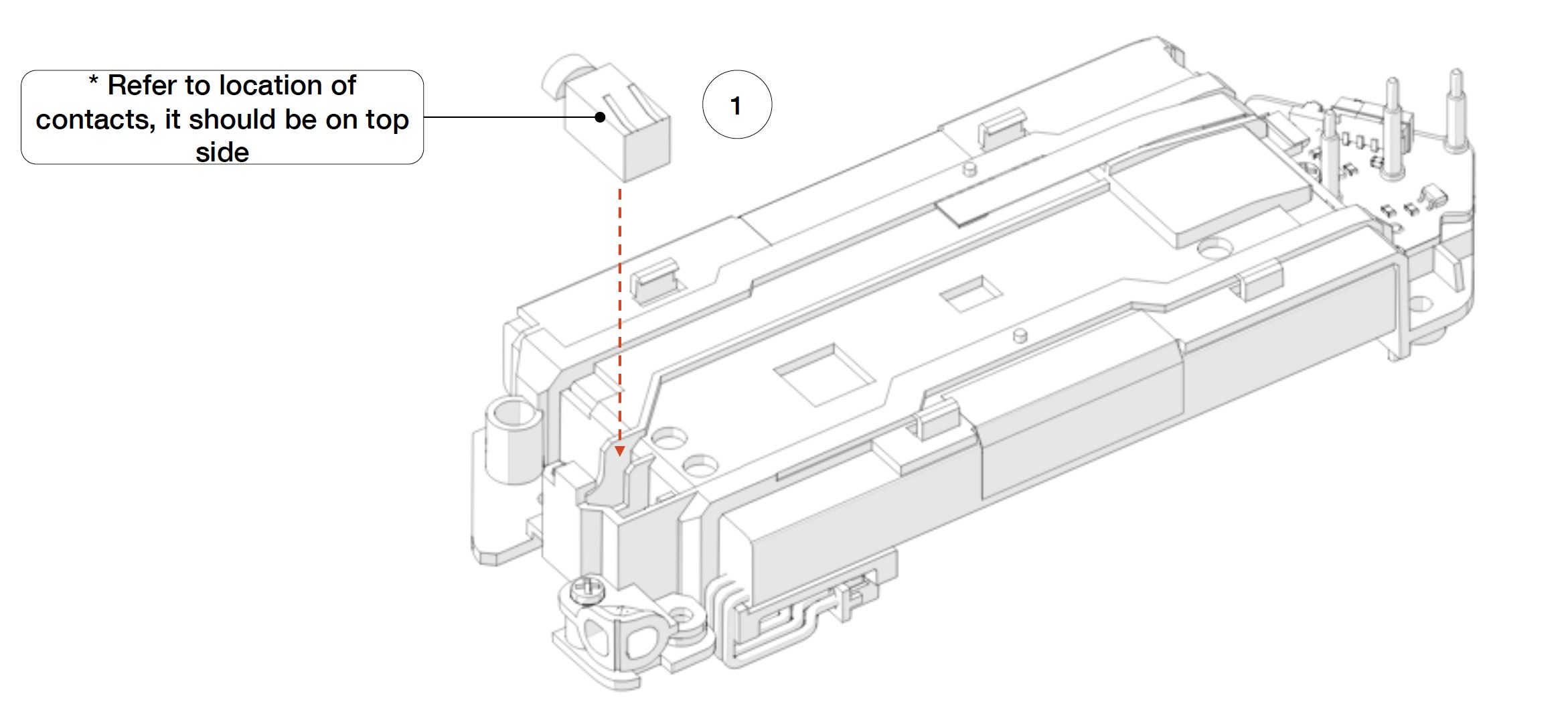

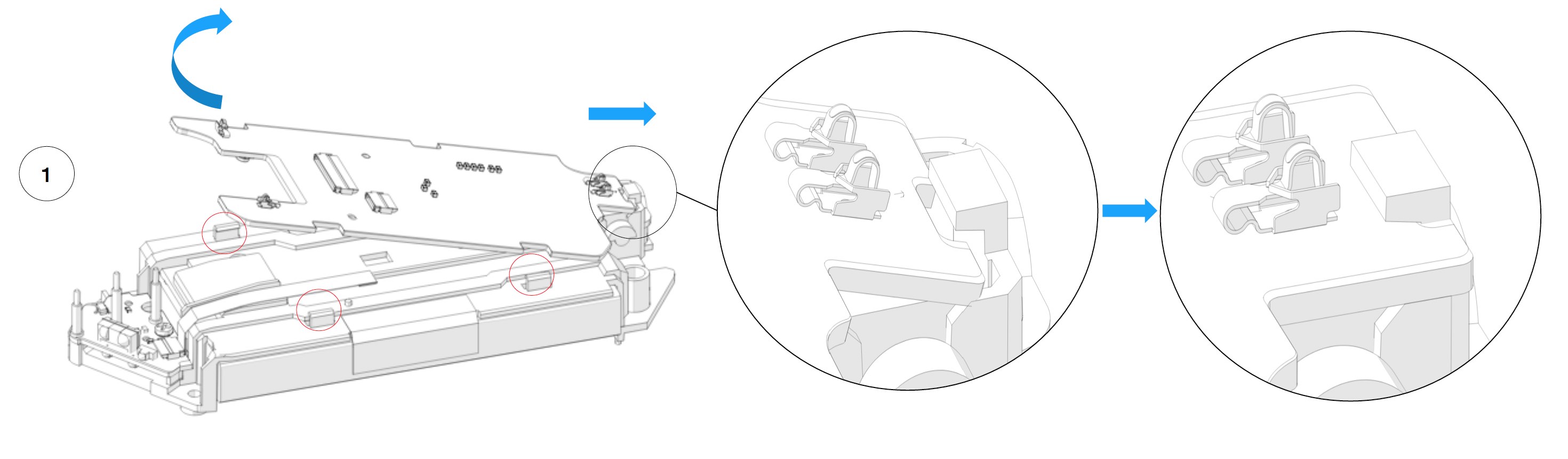

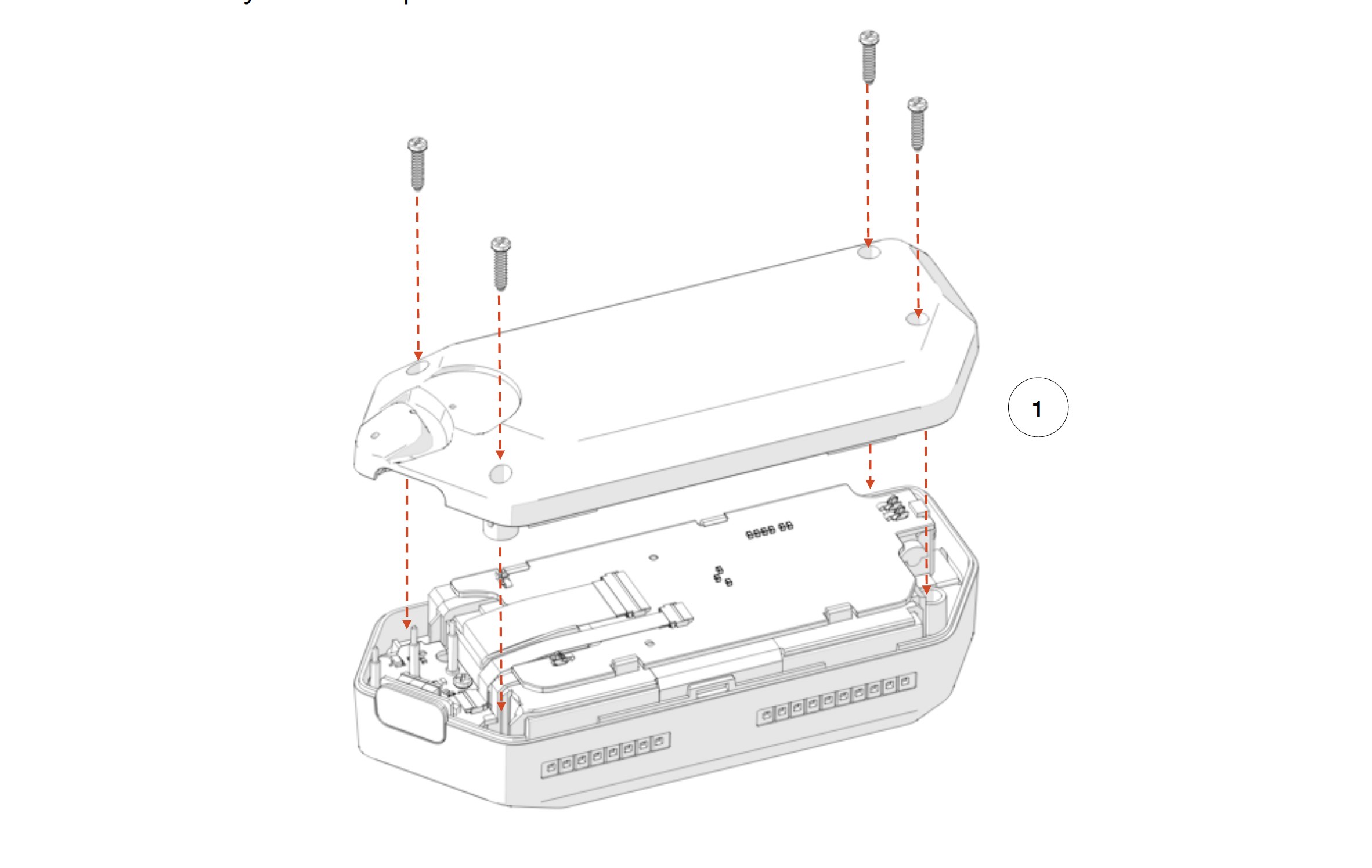

We prepare the process and pre-assembled parts of the device to meet this time. This is what the assembly instructions look like.

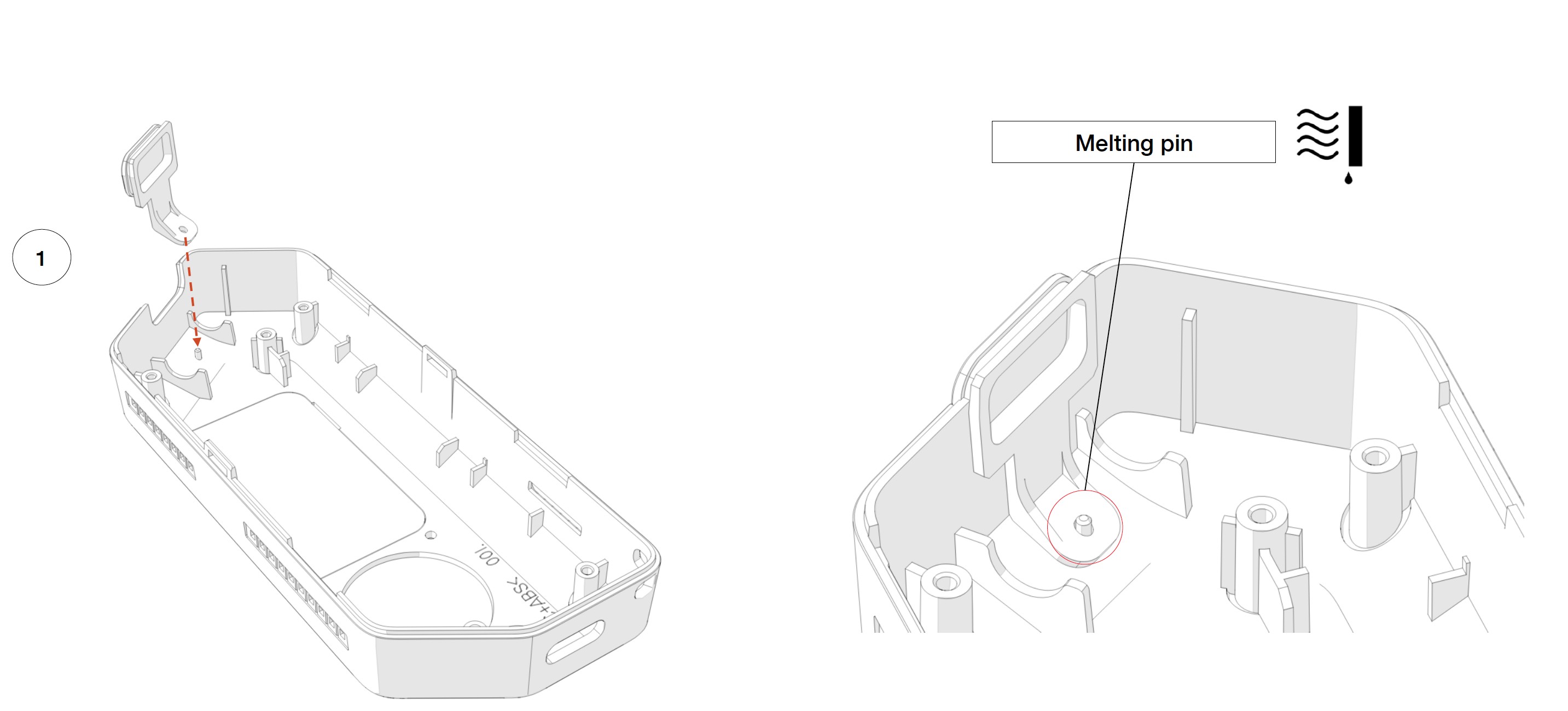

First, there is an intermediate assembly of individual modules, for example, an infrared window is soldered to the top cover of the case, for this a plastic pin is melted with a special soldering iron.

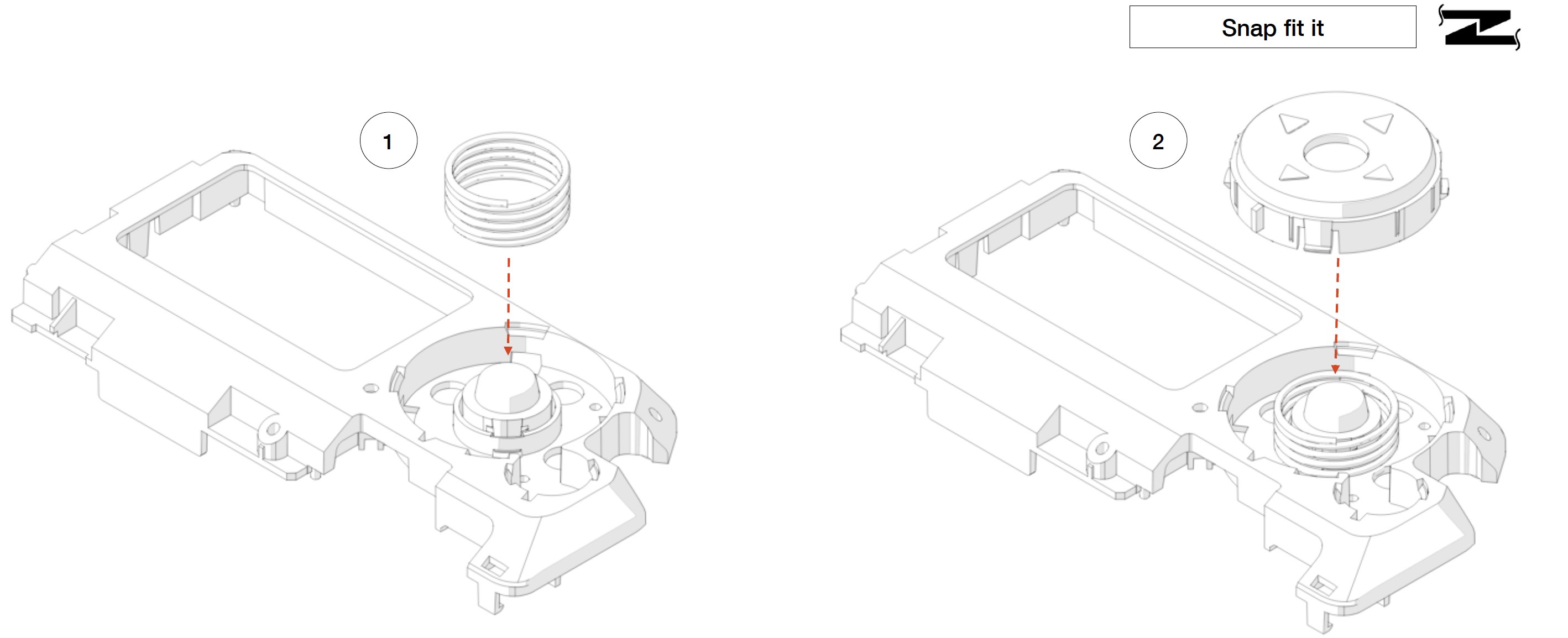

The springs and joystick buttons are installed in the screen overlay. This element consists of 8 parts: a snap, 3 springs, 3 buttons (center, large circle, back button), status LED light.

Maine board connects with snap and joystick. The plastic cover is fixed with latches for the board and forms a ready-made module, which is transferred for final assembly.

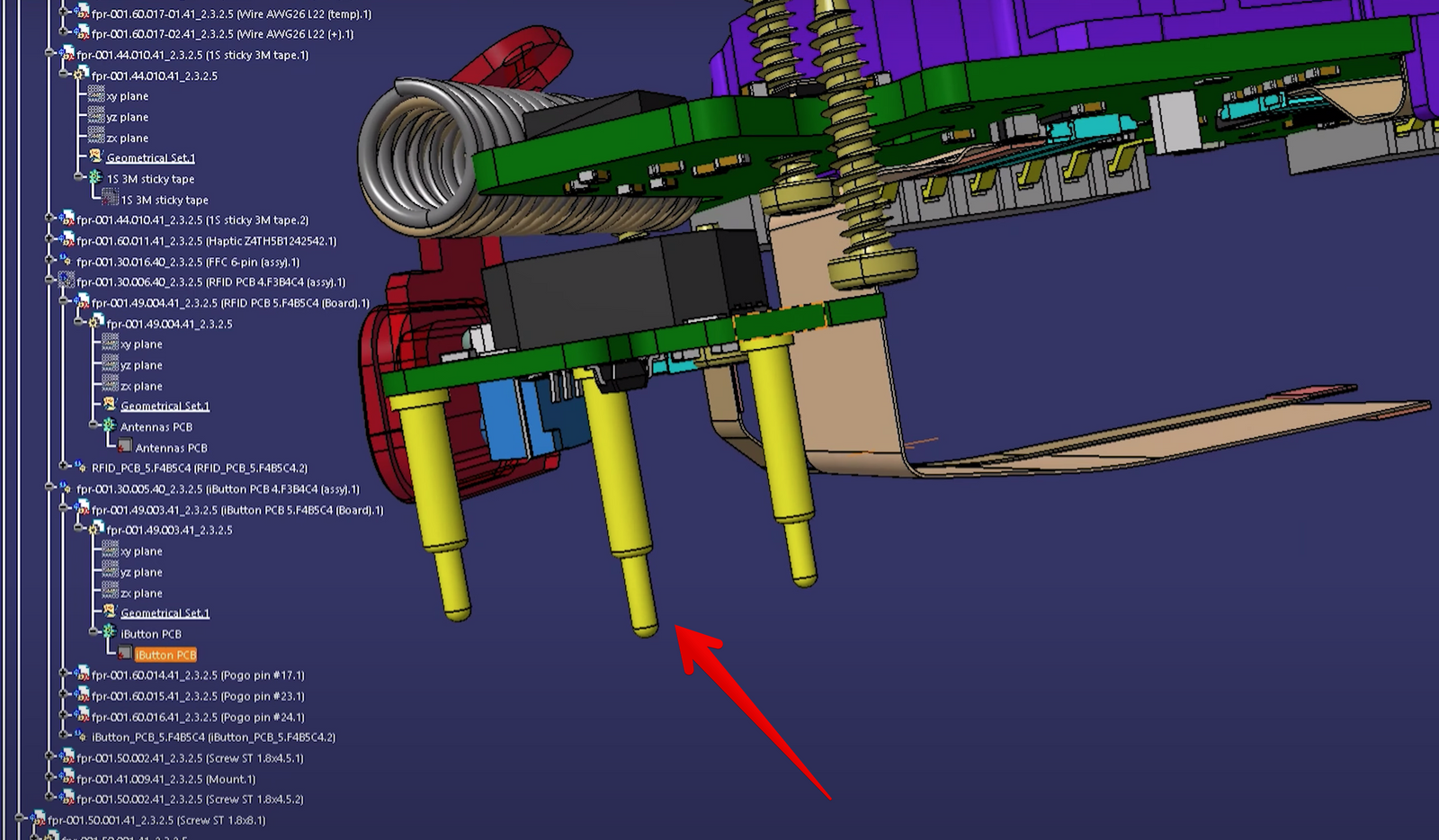

An ibutton board, a battery, a vibration motor are installed in the frame.

The NFC board is fixed to the frame and secured with latches.

In general, the assembly consists of 20 steps, which in the final end with the installation of the bottom cover. Then the device is sent for firmware and testing.

Unique components

Most of the parts from which Flipper is made are serial components that are ordered from suppliers. But there are several electronic components that are custom made specifically for Flipper. This requires placing an order for the production of each component with the correct manufacturer and agreeing on all the details.

Multiband Sub-1 GHz antenna

The antenna we need cannot simply be bought, so we order the winding of this wire antenna specially according to our drawings. It should simultaneously work well on the ranges from 300 to 900 MHz and at the same time fit into our case. Now we are checking that the manufactured antennas really meet our requirements.

IButton pogo pin

For the iButton pad, we use a pin of a non-standard length, so we had to order its production separately.

10-pin GPIO comb

This component is also non-standard and is produced for us. For prototypes, we used an assembly of two combs with 8 pins and 2 pins, which is not suitable for the final device. Finding a manufacturer of quality dies was not easy.

Two-piece comb - prototype crutch

PS

We are very concerned about the postponement of the dispatch date, but we hope for your understanding. For many of us, this is the most important project of a lifetime, which is why we try our best to meet your expectations. The fear of releasing a bad product and disappointing you is our main driver now.

Our social networks

All characteristics of Flipper Zero on the official website .

Our English-language blog .