Construction, installation, production, coordination and communication of participants from different countries - all this was quickly rebuilt as the situation changed, and as a result, the project's progress in 2020 was very impressive. The project was also lucky with funding, so, the main lagging behind - the United States, in 2020 financially increased injections into the project even higher than their direct obligations, covering the debts accumulated over previous years. All this has led to an impressive technical progress, which we will plunge into.

Construction

The “construction” heading used to occupy at least half of the entire annual text, but now its time is clearly running out, following the completion of the construction part of the project. At the end of 2020, 16 out of 18 buildings of the “start-up minimum of 2025” were commissioned and construction of 17 began - the control building, where the ITER MCC and IT infrastructure will be located. Nevertheless, the main event that took place in 2020 should be noted - the completion of the “tokamak building”.

January 8, 2020 - The builders are finishing the metal structures of the tokamak superstructure and start cladding. As a result, the gap from the 2015 schedule was ~ 6 months.

This building is the center of the entire complex, the heaviest and most complex facility built. 120x90 meters in plan, 7 floors vertically, ~ 300 thousand tons in weight, ~ 250 million euros worth, the construction of which took about 7 years.

December 2013 - the beginning of pouring the floor of the lower basement floor of the tokamak building complex.

The final metal structure covering the reactor hall and providing a pathway for the grandiose bridge cranes was assembled in just six months, and in February 2020, dismantling of the temporary wall between the pre-assembly hall and the tokamak building began. On March 30, a day before the deadline, a pair of overhead cranes with a lifting capacity of 1,500 tons entered the tokamak building, officially connecting it with a neighbor.

The cranes with ~ 1000 tons of test load are driven from the pre-assembly building into the reactor hall for the first time.

It should be noted that two wings are tightly attached to the tokamak building - a diagnostic building from the southwest and a tritium factory building from the northeast. The first was completed back in 2018 and has been settling in since then, but the tritium building froze at the floor level of the L2 floor at about the same time, in 2018. The reasons for this are not announced, but I suspect that another redesign of the systems is to blame. However, tritium in the ITER project will not be needed until 2030, so there is still time for completion.

Assembly and installation

In 2020, at the site in Cadarache, work on the assembly and installation of elements of the ITER systems has noticeably increased, from commonplace electrics to very specific parts of the future reactor - for example, cryo screens. But first things first.

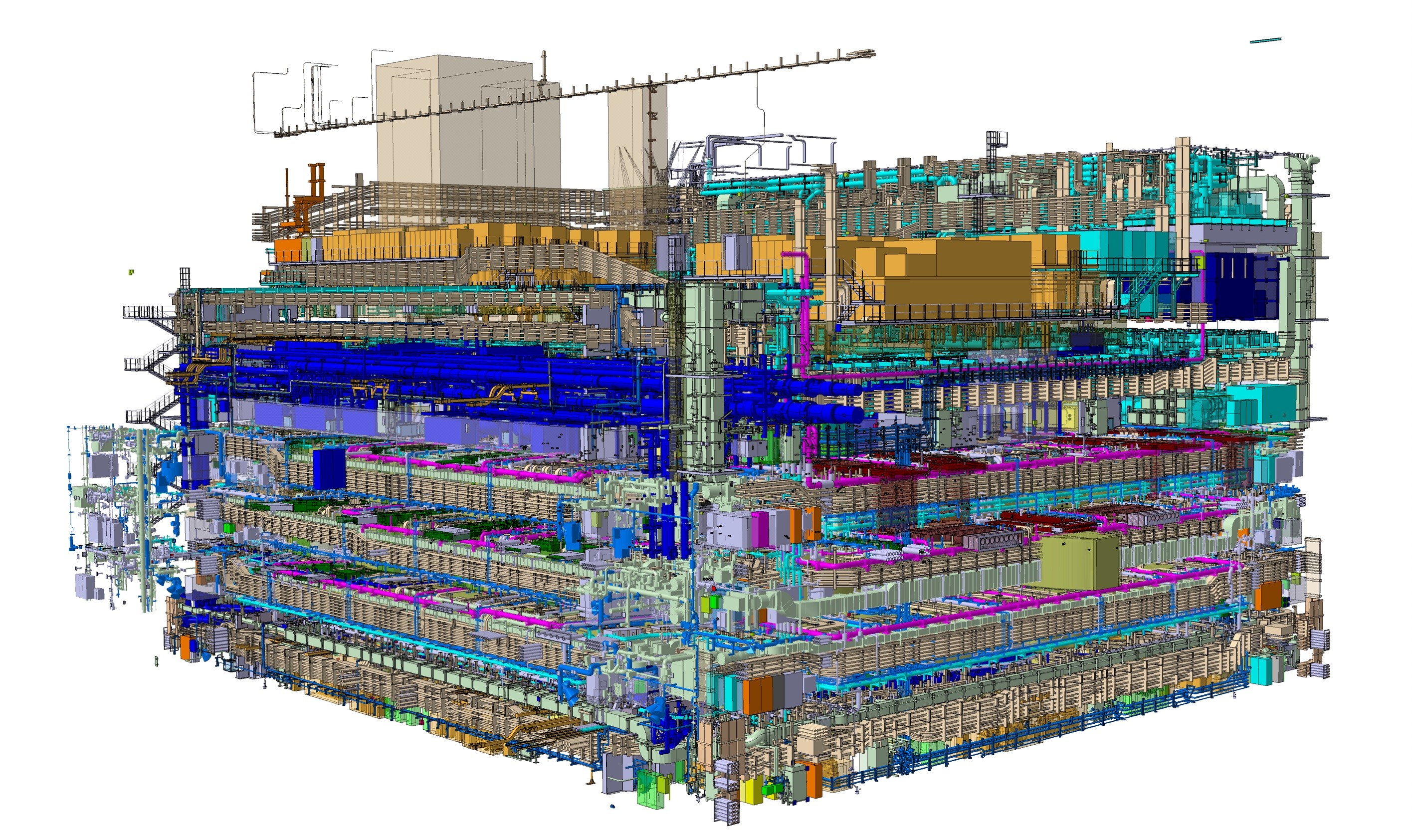

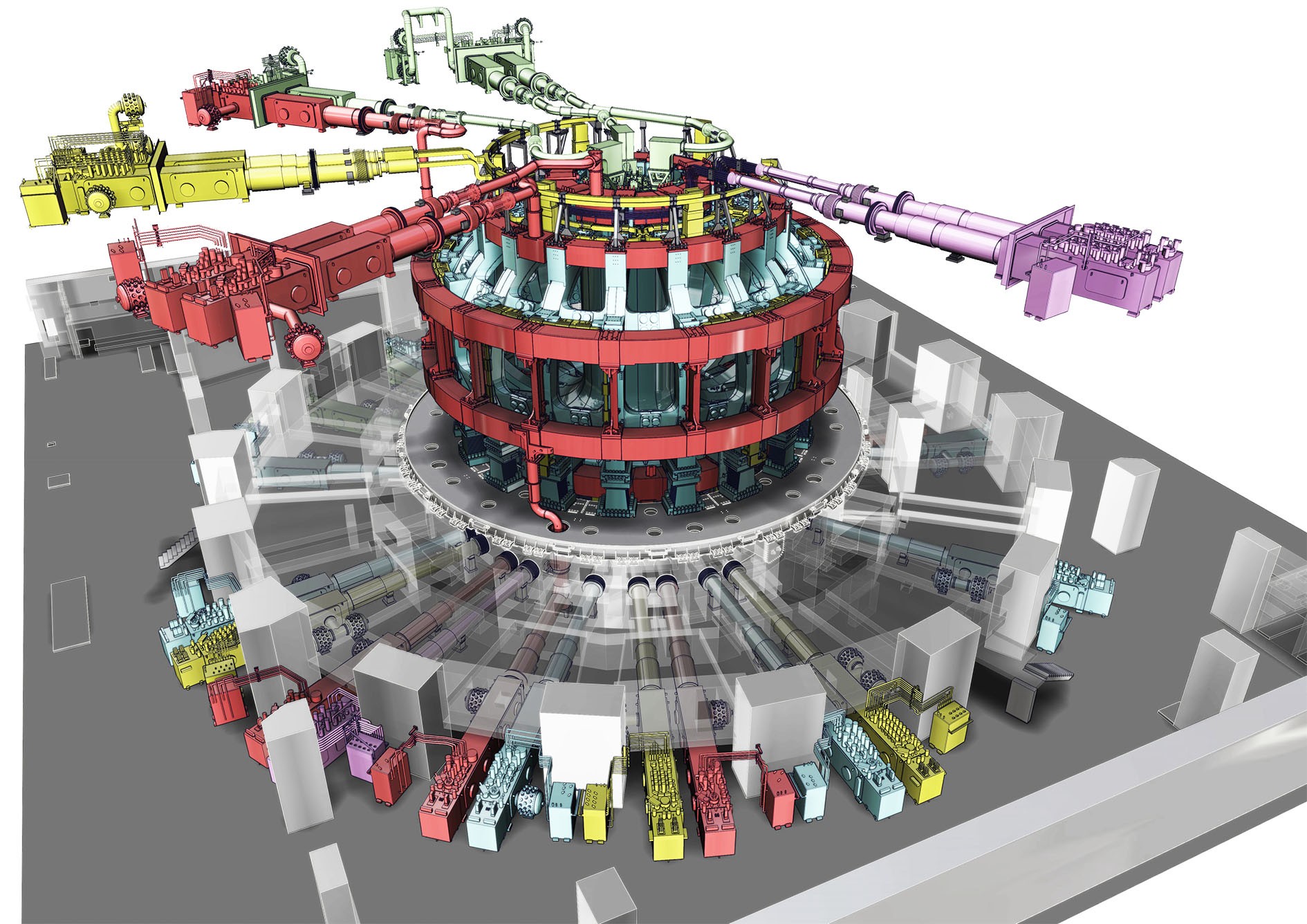

A render of a tokamak building with all (or most) of saturation. You can see beige lines of cable trays, yellow lines for busbars and switching, blue lines for cooling water, blue lines for cryogenics, pale green lines for ventilation, dark green lines for scientific equipment, red lines for heating systems, etc.

All specialized ITER systems, such as magnetic energy converters, microwave electron-cyclotron heating or diagnostic assemblies, depend on more basic service systems, of which four can be distinguished: power supply, heat removal, supply with cryo-fluids and vacuum. It is quite obvious that without the introduction of these subsystems, it is impossible to commission everything else. The most basic, obviously, is the power supply, without which neither heat removal, nor a cryo-plant, nor vacuum pumps will work. Back in 2019, a 22 kilovolt switchgear was put into operation, responsible for ~ 110 megawatts of consumers, mainly for service loads.

«» . () 400 , — 7 — 4 , 3 — . 22 , 66 — . — .

Load Center 14, 2020 .

In 2020, the creation of this subsystem continued with the construction and installation of load centers - local input switchgears located near the main consumers (cryocombine, heat release systems, RF heating and pre-assembly buildings). The tightening of consumer cables was also carried out.

A gloomy photo from an underground channel in which you can see a lot of laid 66 kilovolt cables going to consumers. In general, ITER has about 3 km of such underground galleries.

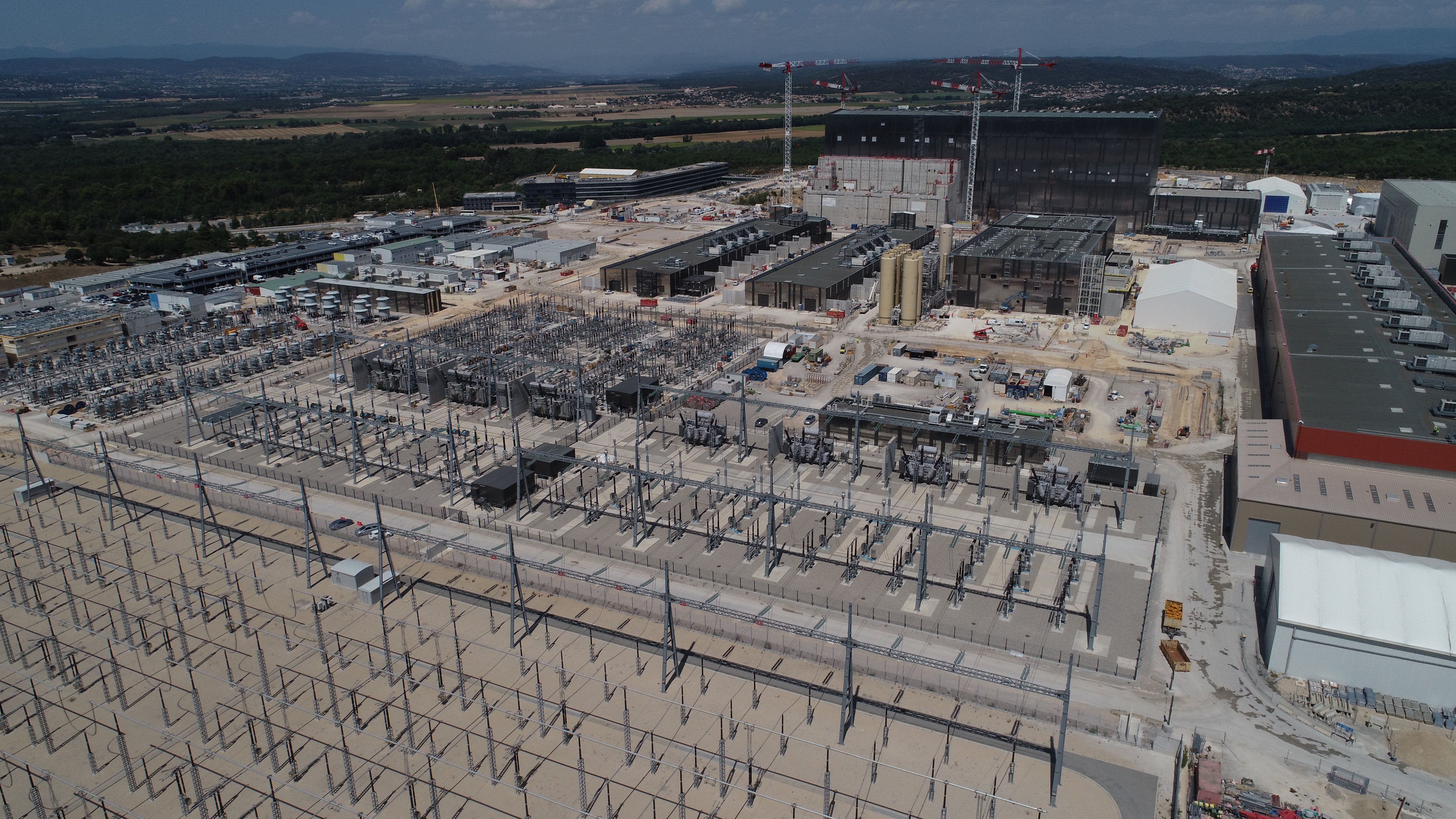

The second part of the power supply system is the “variable load power supply system” PPEN, which mainly includes heating and current control systems in magnets. At the moment of the plasma shot, this part will take up to 500 megawatts of power from the national network, while up to 2 gigawatts of instantaneous power will circulate inside the magnetic system. Here, in 2020, a large open switchgear of 66 kilovolts was installed, cables were pulled to the main consumers (magnetic converters and a radio-frequency heating building), and equipment for a reactive power control station was installed, in fact, a set of switched capacitors and inductors that will exchange energy with giant superconducting coils. ITER magnets, reducing the load on the French national grid.

Buildings of magnetic converters in the process of equipment installation.

Alley of measuring current transformers and capacitor assemblies of active filters of the reactive power compensation system.

The readiness of the power subsystem made it possible during 2020 to make significant progress in the installation of the largest consumer of electricity - the heat release system.

At the time of the most powerful thermonuclear experiments, this system will receive up to 1150 megawatts of both thermonuclear heat and the heat of mechanisms and systems. The heat will be dumped at a rate of 500-600 megawatts through 10 fan cooling towers, and the difference will be buffered in a hot and cold pool. Throughout the ITER site, pipes of three coolant loops have already been extended, providing about ~ 10 points of heat exchange with cold water.

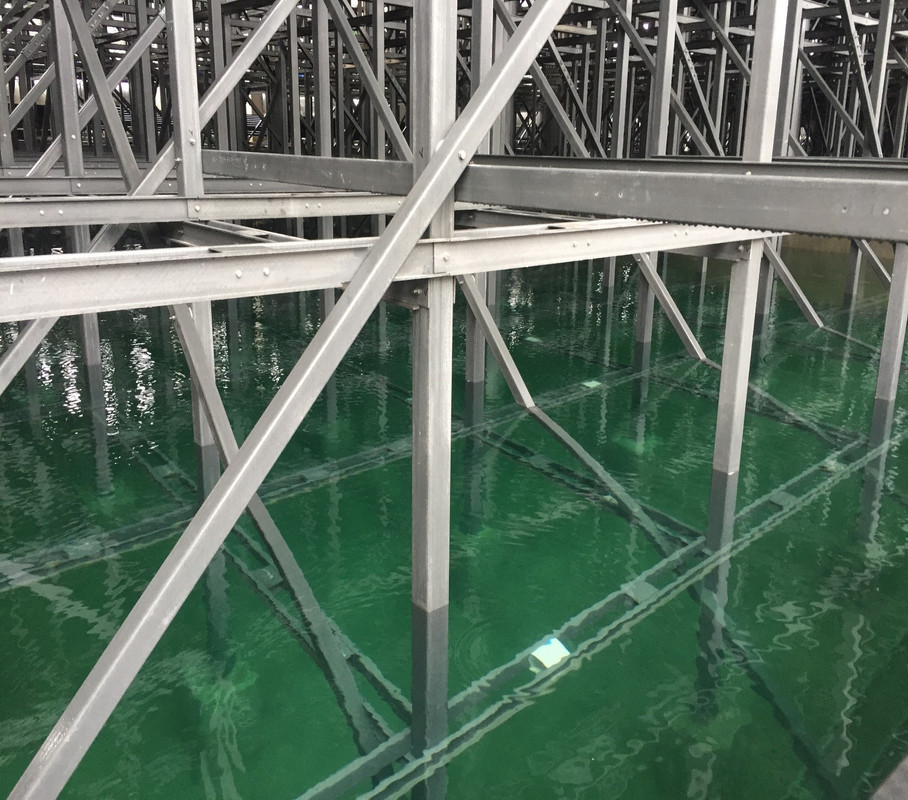

As a year ago, photographs of the first units of installed equipment were very pleasing, at the end of the year the eyes are delighted with the functional tests of this equipment. The photo shows a cold water pool under the cooling towers.

In November, water basins were successfully checked for leaks, and in December, commissioning of a rather complex complex of 27 pumps, 20 heat exchangers, a water treatment system, hundreds of sensors, dozens of valve drives with a total consumption of up to 67 megawatts began. It is expected that in the 1st half of 2021 this system will be ready to serve some consumers, in particular the cryocombine, another important service system of ITER.

The ITER cryocombinant will be the largest lumped cryo-plant in the world (the LHC cryosystem is even larger, but it is divided into several blocks). It consists of a park of gas holders and cryoliquid tanks, a nitrogen generator, 2 nitrogen compressors, 2 nitrogen liquefaction columns, 18 helium compressors organized in 3 lines, helium purification systems from oil and water and, as the pinnacle of all this, three vacuum boxes for helium liquefaction.

2 out of 4 "cold boxes" of the cryocombine - vacuum vessels with equipment for liquefying helium located inside - heat exchangers, circulators, evaporators, turbo expanders, etc.

From one listing of the main blocks, it becomes clear that the number of connecting pipelines will go off scale, and commissioning will not be quick. In particular, in 2020, installers installed ~ 800 sections of cryogenic pipelines only in the cryocombine (there is no exact information for “warm” pipelines, but I think there are no less of them). Also in 2020 there was a tightening of power and control cables, the installation of power electronics. In the second half of 2021, the start-up of the cryocombine can be expected - just at the moment when the heat release system will be able to receive heat from operating compressors (up to 30 megawatts at peak).

An interesting detail is in the foreground 5 electric heaters with a total capacity of 800 kilowatts, which are needed to quickly warm the superconducting magnets to room temperature when the installation is stopped for maintenance.

There is one thing, though, - between the cryo-processing plant and the tokamak building, an overpass must be laid, where pipelines with cryo-heat carriers will pass. But its construction has not even begun yet, and there are no consumers in the tokamak building yet. So, before ~ 2023, we will not see any benefit from the cryocombine.

Despite the seemingly prohibitive complexity - the entire cryocombine is assembled from already industrially ready systems, i.e. there is just a LOT of everything, but at least not on the verge of fantasy.

One of the key consumers of cryotemperatures will be the ITER vacuum system. This is the fourth “service” whale on which the tokamak functions. For example, the complex acceptance of superconducting magnets and all reactor equipment will begin with evacuation. Unfortunately, at the end of 2020, it was the most lagging system in terms of installation. In the fall of 2020, fitting installations of vacuum pipelines have just begun, but basically all its elements are at different stages of production. In particular, pipelines, gate valves, valves are actively being produced, junction boxes and cabinets, part of standard vacuum pumps have been ordered. The production of non-standard pumps is also underway - first-line cryosorption pumps, cryocondensation pumps that will separate hydrogen and helium isotopes.A critical control and leak detection system is being developed, for which IDOM, 40-30 and Gutmar received a contract in 2020

A set of gas analyzers for residual gases of a vacuum volume and external sources of helium / inside - helium detectors should detect and localize vacuum leaks.

However, enough about the banal. Let's take a look at some more unique things. In 2020, the installation of busbars for the power supply system for superconducting magnets began. These are aluminum busbars with a cross-section from 100x160 to 400x700 mm with active water cooling, from just two buildings of magnetic conversion to the tokamak inputs, 24 double busbar lines must be extended. It should be noted that these bus ducts, their connections and supports, switching equipment are manufactured in Russia as part of a contribution to the project. It is gratifying to see "live" hardware, and even so visual :)

The last three photos are busbar lines in the basement of the diagnostic building (annex to the tokamak building), where some of the switching equipment will be located.

In 2020, the installation of busbars in the converter building and on the lower floor of the tokamak building was almost completed. Ahead is the installation of vertical sections in the shafts of the tokamak building, on the top floor and on two bridges that will connect everything together.

And this is how the busbar lines begin in the magnetic conversion building - from the converters (only decoupling inductors and an active jumper are visible) and across the bridge to the diagnostic building.

In addition, in 2020, in the building of the tokamak, the installation of cryoline, ventilation and air conditioning sections, water cooling pipes, cable trays and hundreds of supports for all this was underway. In general, the installation of systems in the tokamak building has officially started.

Without ventilation and air conditioning, it will not be possible to start at least the control electronics cabinets, so the installation of this system in advance pleases.

Another small but important milestone was the handover to ITER of a fully functioning auxiliary workshop (Building B61). There are systems for the preparation of demineralized water, compressed air and nitrogen, chillers delivering water with a temperature of 10 degrees, etc. This building was the first completed on the site (back in 2016), it was also the first in which all the systems were installed (at the beginning of 2019), and now it has been fully commissioned.

B61 in the upper left corner of the frame. And on the right in the center you can see an extension “tritium building” that has not been completed on 4 floors.

And finally - to the main “editing event of 2020”. Of course, we are talking about the beginning of the assembly of the reactor itself in its shaft. Watch this video, which shows the main stages of assembly of the ITER tokamak:

On May 25-26, after ~ a month of preparation, the heaviest part of the reactor - the base of the cryostat (1250 tons!) Was moved into the shaft and lowered to the pre-design position, on jacks.

In mid-April, the base of the cryostat was pulled into the pre-assembly building.

Then the real geometry of the gap was measured to the concrete base and ~ 100 spacers were made to level the base with an accuracy of 2 mm from the horizon. And finally, in June, the first part of the official reactor part was installed in place - supports that will perceive vertical, horizontal and tangential loads to the circle, which the electromagnetic part of the reactor will generously share.

It is interesting that the assembly of the part, which is heavy by all the world canons, was managed by engineers from the Chinese "Rosatom" company CNNC, who in cooperation with the Europeans received a contract for the assembly of the ITER reactor section.

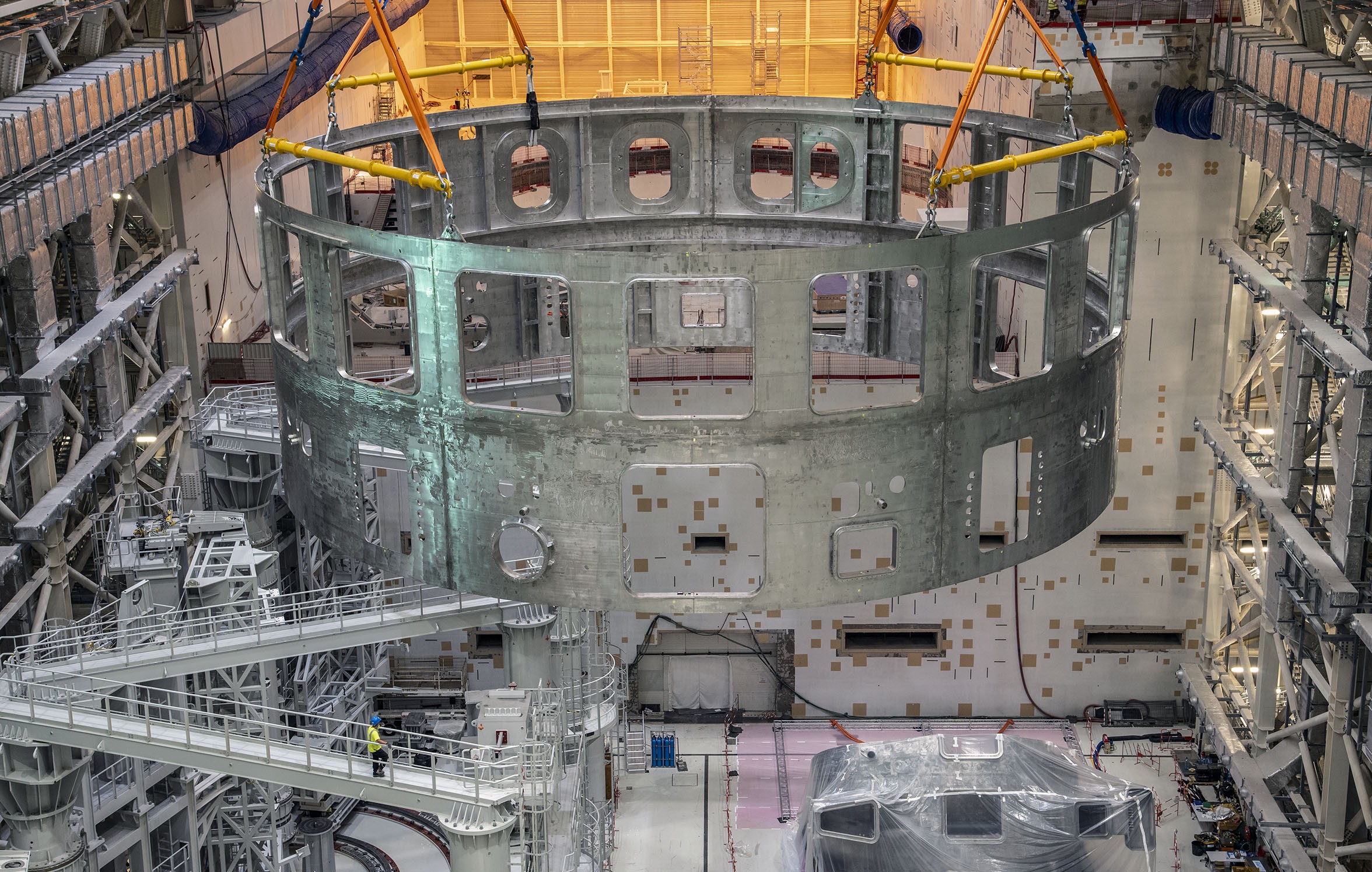

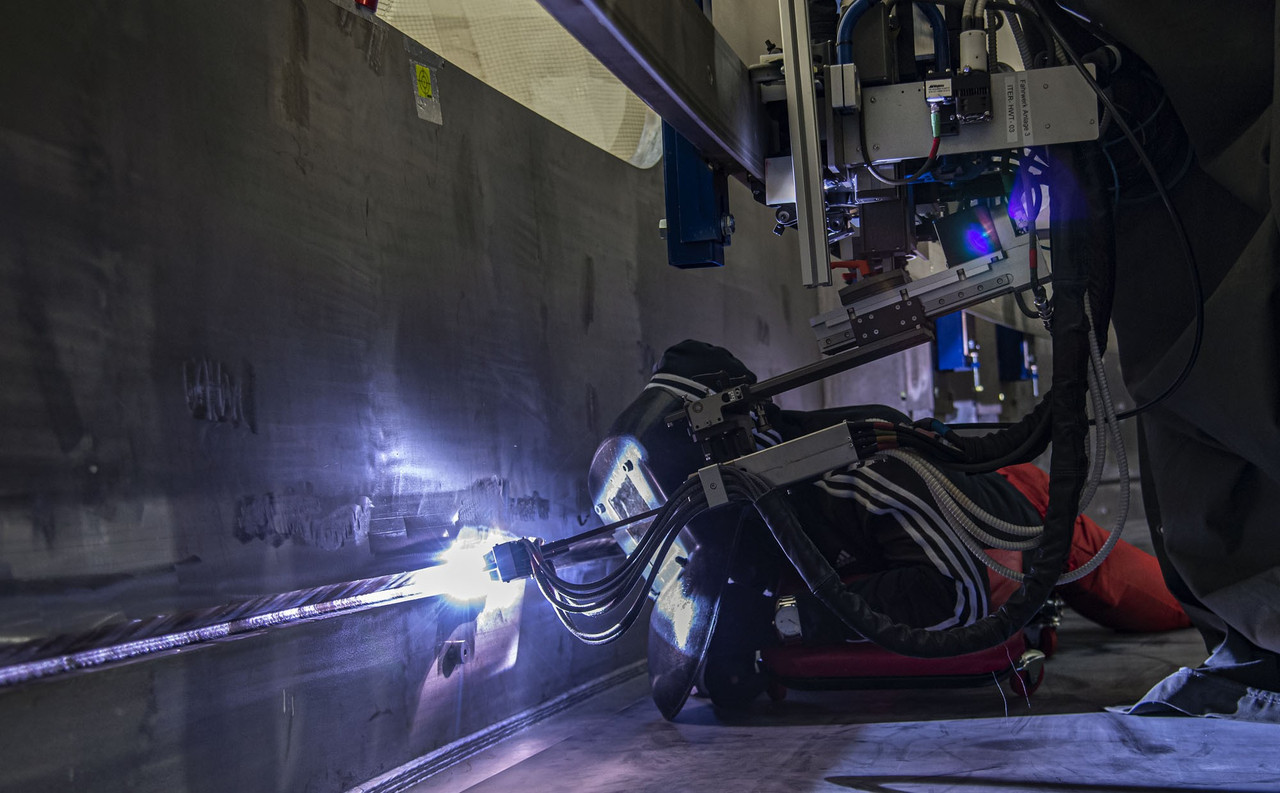

On August 31, the operation of transferring and installing the lower cylinder of the cryostat took place, and in October 2 “parts” of the cryostat began to be welded together with a 90-meter seam with a cross-section of 60 mm.

Meanwhile, in the preliminary assembly hall, the activity on the preparation of the next elements of the tokamak was growing. In September, the first of the 9 sectors of the vacuum chamber was installed for preparation. Until the end of 2020, work was underway to remove the precision geometry of the sector, re-check it for vacuum density, weld the supports of hundreds of sensors for technical and scientific diagnostics systems, and install the sensors themselves and their cables.

In early 2020, it is planned to tilt the sector (weighing 440 tons) to a vertical position and install it on an assembly stand, where it will be surrounded by vacuum cryoscreens and then connected to two toroidal coils.

Oh yes! Cryo screens. If they were not in the ITER project, it would be worthwhile to come up with something like that. Huge silvered structures with mysterious drawings on them - what better illustration of a grandiose sci-fi project?

Lower cylindrical section of the external cryoscreen. On the right, you can see the collectors from which helium is distributed and collected at a temperature of 80K.

Cryoscreen element separating the hot vacuum chamber from the cold magnet

In 2020, 2 of the four sections of the cryo-screen of the vacuum chamber were prepared (and installed on the assembly stand) and the lower cylindrical assembly was almost completed, which will stand inside the base of the cryostat and will shield the superconducting magnets from the heat of the outside world. At the beginning of 2021, this cylindrical section should be installed inside the cryostat, for which the equipment has already been installed in it.

The wrapped section of the cryoscreen on the assembly stand, with the help of which it will be put on the sector of the vacuum chamber. In addition to this part, there will also be an inner section of the screen and two of the same on the left.

At the end of 2020, the installation of cryofeders of the magnetic system also began - multi-meter products through which current, coolants, measuring and control signals are injected into a vacuum-cryogenic environment.

ITER cryofeder system on render

AND the feeder element in reality.

Finally, I want to add a little fly in the ointment to this pool of honey. Already with the naked eye, one can see the lag behind the plans. So, initially, by the end of 2020, it was planned to install 18 supports of toroidal magnets (like everything else in ITER - complex devices with active cooling and a clever stiffness characteristic) of Chinese production.

Toroidal support near the reactor shaft during a leak test.

Back in 2019, the Chinese made 6 first supports and promised to send 12 remaining ones by the beginning of 2020. However, now this deadline has shifted to February 2021 and already directly affects the installation schedule.

The PF5 coil, which has been produced at the ITER site in a special plant since 2017, also lags behind. In December 2020, a cryogenic test bench was just installed, which means that we will not see it in the design position before May 2021, with the initial date in February.

Installation of PF5 in a cryostat, early December 2020. An interesting detail for me is a whole cabinet of various electrical connections to PF5, which is used for the test.

So while the installation is going better than pessimistic expectations, but worse than optimistic ones, and the date of the first plasma in December 2025 remains elusive.

Continuation about the production of components and R&D in the second part.