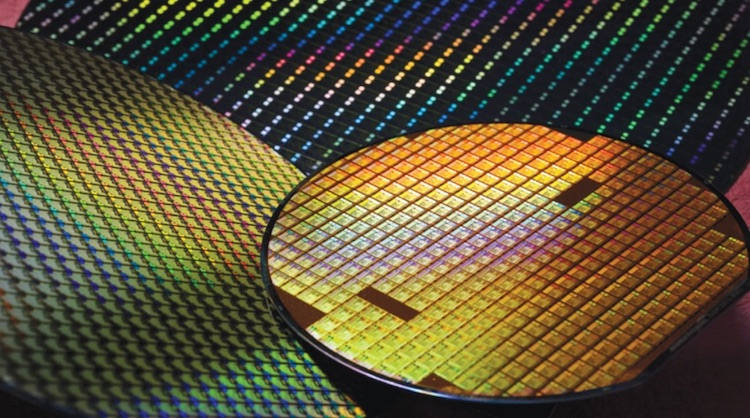

In late December, Apple placed its first order for 3nm chips from TSMC. The company uses these chips in new devices due out in 2022.

But the other day it became known that the development of the technical process is under threat - both Samsung and TSMC have problems with the new chips. We are talking about the production of FinFET GAA 3nm microcircuits.

What happened?

The Chinese edition of IT Home said both companies will postpone the commercial launch of the new chips. The site received this information from analysts of the Taiwanese Digitimes.

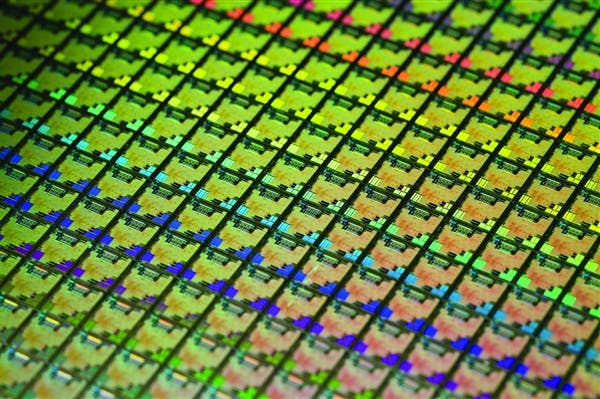

According to new information, the problem arose at the stage of refining the technology of multi-gate field-effect transistors (fin field-effect transistor, FinFET) to the new technology with ring gates (Gate-All-Around, FinFET GAA). It is key in the transition from 5nm to 3nm process technology. This technology has become a bottleneck for the entire process of manufacturing new chips.

According to experts, these difficulties give Intel a chance, which will have time to switch to a new technical process. The company is now working with 10nm chips, and now it has time to produce 5nm, and then possibly 3nm.

What was the plan?

If it had not been for the problem, TSMC would have completed the certification of the new technical process and launched test production by the end of 2021. The chip was supposed to go to the masses starting in the second half of 2022. It is reported that the chips were planned to be produced on the Phase 3 production lines at Fab 18. In addition, the company was going to introduce 4nm chips.

As for Samsung, the South Korean company was going to start the process of developing 3nm chips immediately after the release of 5nm elements. The new technical process makes it possible to ensure an increase in the performance of chips by 10-15% with a simultaneous increase in energy efficiency by 20-25%. Plans have been pushed back from 2021 to 2022 due to the coronavirus pandemic.

Both companies were going to complete scientific and technical research, certify the technology and start the process of commercial production of chips without any problems. At the same time, a huge amount of money has been invested in the development of the technical process. The same TSMC, according to the head of the company Liu Deyin, has invested several tens of billions of US dollars.

As for the 5nm process technology, everything is fine here. The same TMSC even builds a chip factory in the United States. It is planned to send 300 qualified engineers there for further training.

Customers will have problems too

Apple, which was mentioned above, placed orders a couple of weeks ago for the production of processors of the A and M series according to the 3nm process technology. TSMC was going to transfer to 3nm processors, which are intended for the most expensive and productive Apple computers. After the launch of production, TSMC planned to produce up to 600 thousand 3nm chips per year.

If plans have to be postponed, then Apple will postpone the launch of new devices - tablets and laptops. In addition to Apple, TSMC's customers include Chinese Huawei and MediaTek and American AMD, which do not have their own factories, not to mention Qualcomm.

But there is also a 2-nm process technology

Yes, companies that make chips are developing different technologies in parallel. The same TSMC is now working on 4nm, 3nm and 2nm process technology.

TSMC announced the launch of a functional circuit for the production of transistors using GAAFET technology back in mid-2020. True, now work is being done only on chip elements. Full production, if no problems arise during the work, will be launched between 2023 and 2024.

GAAFET technology is precisely the bottleneck in the plans. Currently used "fin" type field-effect transistors with vertically arranged channels. GAAFET is a horizontal field-effect transistor with a circular gate.

The gate encircled the channel on all sides, whereas in prior technology, the gate surrounded the channel on three out of four sides, which led to an increase in leakage currents. GAAFET doesn't have such a problem.

Not only technology, but also personnel

As reported in the fall, TSMC has more than technological problems. China is on the hunt for qualified specialists, experts in the chip development industry. That is, the Celestial Empire lures engineers to itself, offering them salaries increased by 2-3 times.

Two Chinese companies are currently on the hunt for talent: Quanxin Integrated Circuit Manufacturing (QXIC) and Wuhan Hongxin Semiconductor Manufacturing Co (HSMC). They have already managed to lure over a hundred employees by making them an offer that they do not refuse.

In general, hunting and enticing specialists is a common practice in the IT industry. But for TSMC, this is a problem, since the company employs not many professionals capable of developing new chips. Yes, TSMC employs about 6,000 engineers, but only 150 of them are PhD. And in just a week, the Chinese lured two-thirds of valuable personnel from TSMC.

The leadership of the Taiwanese chip manufacturer understands well what all this threatens the company, so TSMC is taking urgent measures to eliminate the threat. In particular, equipment suppliers were prohibited from sharing technological solutions with Chinese partners that were developed by the order of the company. Also, they began to raise wages to engineers so that the conditions in China were not too attractive for them.

Are these measures helpful? Unknown. But it may well be that the delay with the 3nm process technology is caused precisely by the problem with the frames. The probability of this is far from zero.