The Chinese company Hikvision is one of the leading suppliers of surveillance cameras in the global market, whose capitalization grew to $ 20 billion last year.

The demand for video surveillance systems has grown dramatically in the past few years both in China and around the world. The leaders of many regions and corporations believe that cameras are indispensable in the construction of so-called “smart cities” with widespread surveillance.

Hikvision's Thermal Camera released in 2016 caught the attention of System Plus Consulting for one simple reason: AI.

Hikvision has created the first camera with an integrated AI system, combining both software and hardware solutions in its product. This prompted System Plus Consulting, a division of Yole Développement, to look under the hood of this camera to understand "what technological solutions are behind it."

Most notably, this camera embodies the best of the worlds of the East and West - "Chinese microbolometer and processor" along with "non-Chinese analog components and devices for AI."

Among Hikvision's competitors in this specialty are Dahua and Uniview based in China, Bosch (Germany) and Axis (Sweden).

Hikvision differs from them in that "this company can design and manufacture its own products." The Chinese company has its own MEMS production line, is engaged in their packaging and testing, is engaged in surface mounting and performs the final assembly of components.

Intel, Hikvision, and Movidius (now Intel) supply three key components unique to the camera in question:

- Intel Peltier tunable module is responsible for digital signal processing after microbolometer reading and temperature control

- Hikvision itself has developed a chip for image signal processing, video encoding and encryption, and network functionality

- Movidius processor powers AI for image processing

Further in the text, specialists from System Plus Consulting will disassemble this camera and tell about it in detail.

Thermal chamber

A thermal camera is capable of detecting the heat generated by the human body and converting it into an image using a sophisticated signal analysis process. Images are reproduced by detecting and analyzing temperatures. In the last few years, thermal imaging has found its way into low-cost applications thanks to microbolometers.

Microbolometers are sensors that detect infrared radiation. They are made up of a network of sensing points (called "pixels") made up of different layers and different absorbent materials such as vanadium oxide or amorphous silicon (α-Si).

In a conversation with System Plus Consulting, we discussed the technical and structural aspects of the Hikvision DS-2TD2166-15 / V1 network thermal imaging camera. Technical specialists from System Plus Consulting spoke about the electronic and hardware structure of the system equipment, highlighting the various elements of which it consists.

The Hikvision DS-2TD2166-15 / V1 thermal network camera is equipped with an image sensor based on uncooled vanadium oxide focal plane arrays (Figure 1). It supports intelligent analysis algorithms for several critical infrastructures such as airports, railways, etc. This thermal imaging camera is based on several chipsets such as the RTD6171MR microbolometer with 640 × 512 pixels (17 μm pitch); FPGA Cyclone V 550MHz 224I / O (FBGA484); SDRAM 2 GB (128Mx16) 800 MHz 13.75 ns (TFBGA96); Temperature controller for Peltier module (TQFN48); System on a chip for professional HD IP cameras; Machine Vision Processor 2x32Bit RISC Proc. 4Gb LPDDR3; and DDR4 DRAM 8 GB (512Mx16) 2400 Mbps.

The technical and design features make this camera ideal for preventing fires and quickly detecting overheating and temperature changes in factories and manufacturing processes.

The image analysis techniques in this camera allow the detection of events in space and time from a continuous video stream. The camera has 4 types of rules for video content analysis (line crossing, intrusion, entering and exiting a region) and 4 more can be implemented.

The camera captures thermal images that enable users to detect people, objects and accidents in complete darkness and difficult conditions. Since the camera is only sensitive to infrared radiation emitted from bodies, its ability to view and record images is not affected by the light in the scene being recorded.

The camera can also measure the actual temperature of the monitored spot. The device gives an alarm when the temperature exceeds a threshold. Let's take a look at the hardware of this camera.

Figure 1: Hikvision DS-2TD2166-15 / V1.

Hikvision hardware

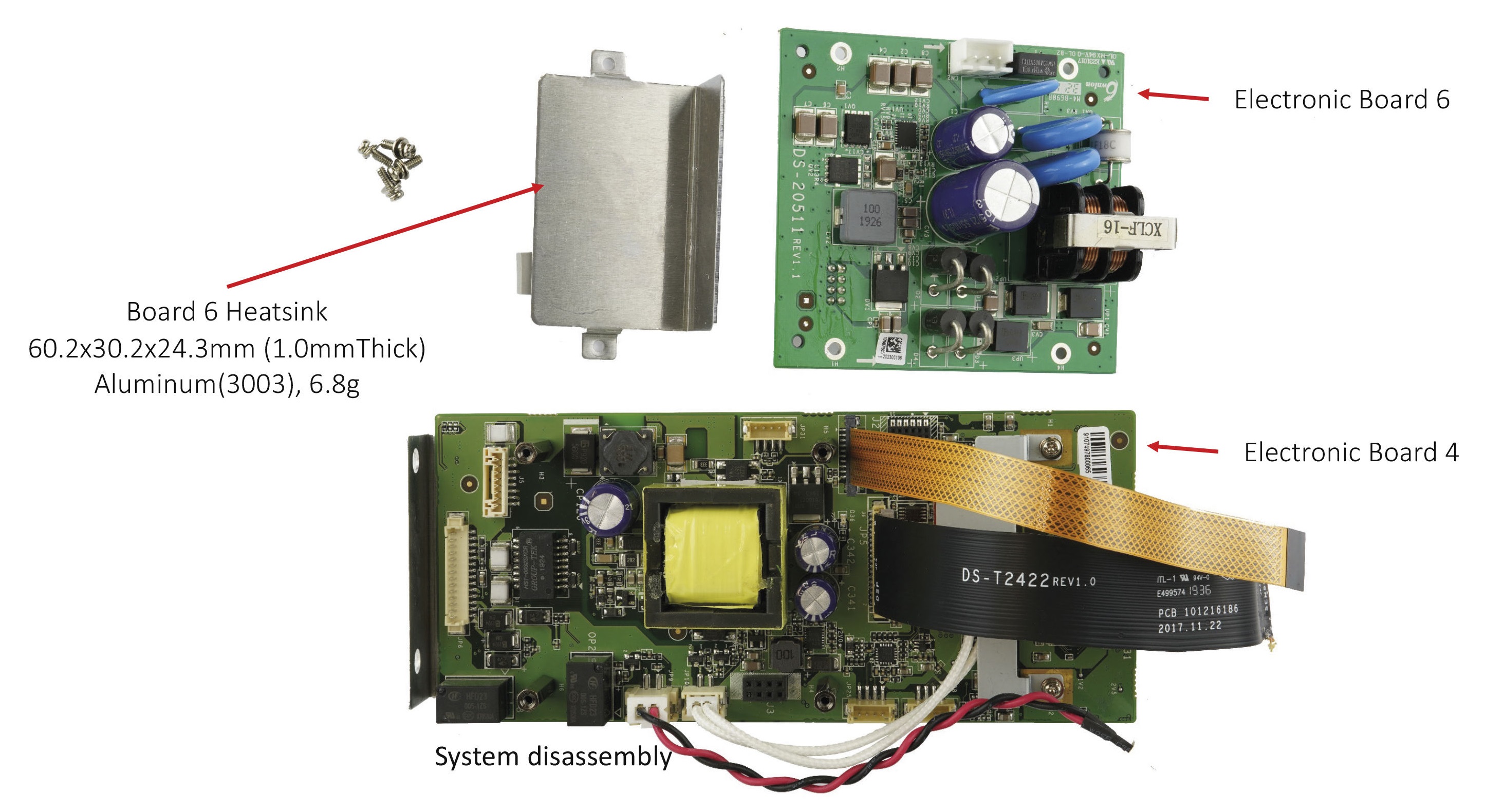

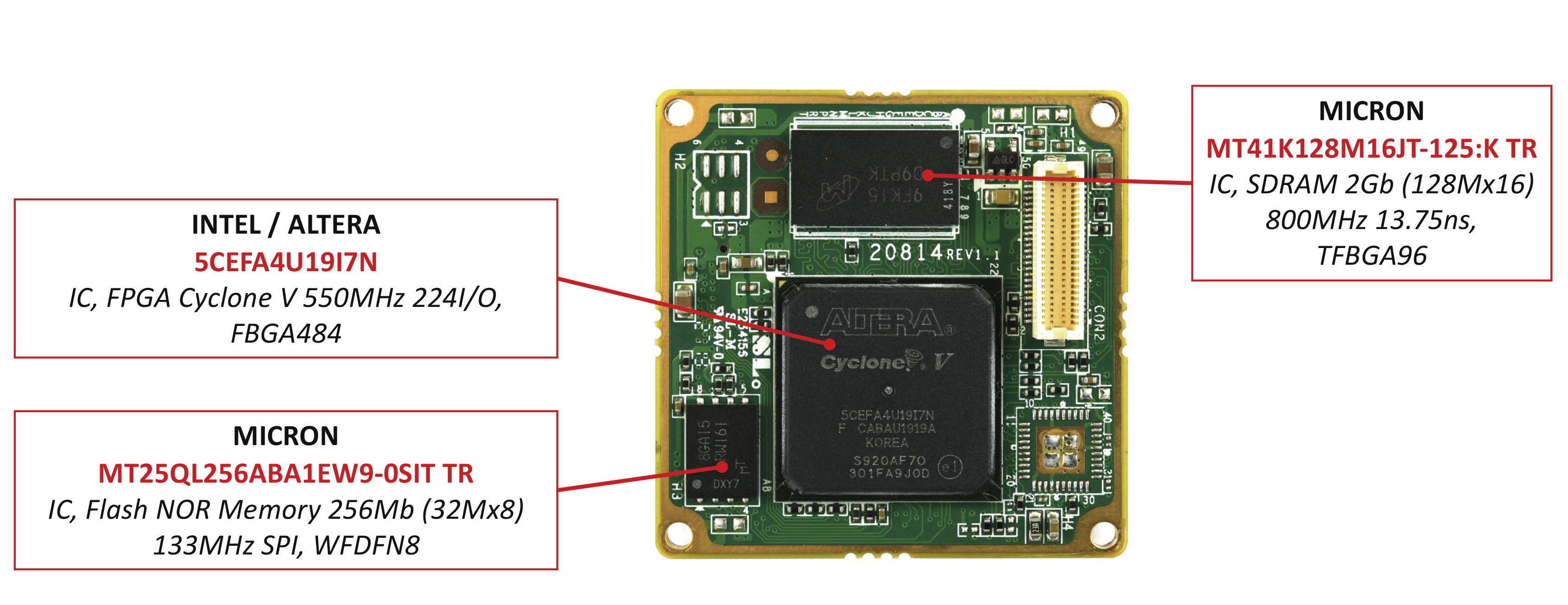

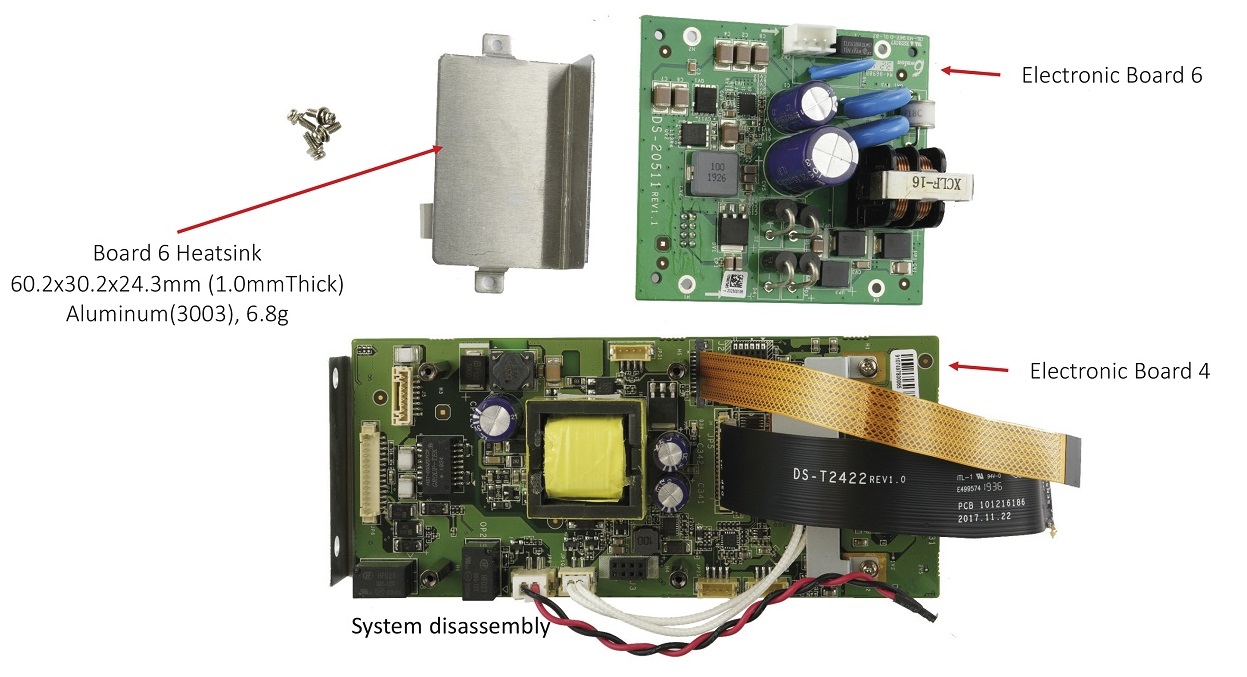

The thermal imager consists of 6 boards, each of which is designed for a specific purpose. Let's look at some parts (Figures 2 and 3). FPGA Cyclone V SoC built on TSMC's 28nm low power (28LP) process technology; It consists of a dual-core ARM Cortex-A9 MPCore processor, a variety of peripherals and a multiport SDRAM controller. The use of this scheme provides power savings and supports peak throughput of over 100 Gbps and data transfer negotiation between the processor and FPGA.

Figure 2: Some boards from Hikvision.

Figure 3: Hikvision PCB 2.

The signal shaping / amplification component consists of various microcircuits, in particular the general-purpose amplifier AD8605ARTZ-REEL, the LT6203IMS8 100 MHz dual amplifier and the LT1994IMS8 70 MHz differential amplifier. The AD8605ARTZ features very low offset voltage, low input voltage and noise, and high bandwidth. It uses the patented Analog Devices, Inc. a DigiTrim trim technique that adjusts circuit performance by programming current sources.

The LT6202 has a noise voltage of 1.9nV / √Hz and only draws 2.5mA per amplifier. This amplifier combines low noise and current draw with a 100 MHz gain bandwidth, 25 V / μs slew rate, and is optimized for systems with low input shaping. Harmonic distortion is less than -80 dBc at 1 MHz, making these amplifiers suitable for use in low power acquisition systems such as this thermal chamber.

The LT1994 is ideal for level shifted signals to drive differential input and single-supply ADCs. The LT1994's common-mode output voltage is voltage independent and is regulated by applying voltage to the VOCM pin as described in its datasheet.

The 16-bit ADCs ADS1112IDGSR and LT3042IDD support consistent communication with FPGAs. The DS1112 is designed for high resolution measurement applications where memory and power consumption must be considered. The LT3042IDD is a linear, low dropout voltage regulator designed for powering noise-sensitive RF applications. There are other ICs on Boards 3 and 1 to support power supply to their respective integrated subsystems such as linear regulators and buck converters.

The main detail that determines 80% of the cost is a microbolometer (vanadium oxide). It is supported by a Peltier component with a temperature control circuit.

Lenses

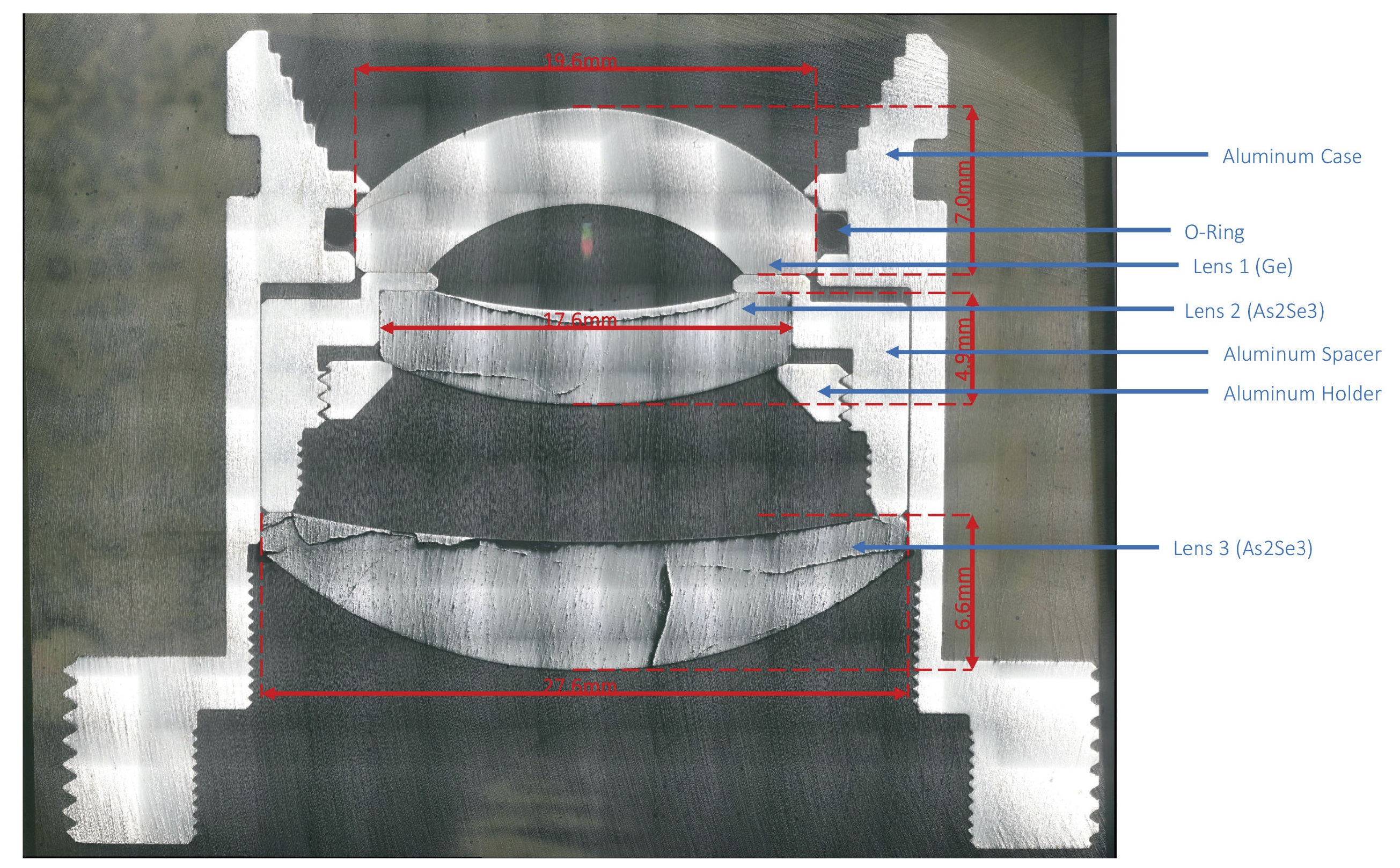

The main module supporting the microbolometer consists of various lenses to optimize the infrared rays on the sensors. In Figures 4 and 5, we see a germanium lens with a diameter of 19.6 mm and two lenses made of arsenic triselenide (As2Se3) of different diameters - 17.6 mm and 27.6 mm.

Figure 4: Camera module.

Figure 5: Lens module.

In optics, there is such a thing as the f-number (sometimes called the focal ratio or relative aperture), which expresses the area of perception of light. That is, the focal length divided by the diameter of the aperture.

A lens with a larger aperture diameter allows more light or infrared radiation to pass through. Consequently, more infrared radiation improves measurements in terms of signal-to-noise ratio. The parameter that determines the quality of the measurement is called "NETD" or "Noise Equivalent Temperature Difference". It is usually expressed in milli-Kelvin (mK) and expresses how well the thermal image detector can distinguish between small differences in the thermal image. Typical values for uncooled thermal imaging cameras with microbolometers are in the order of 45 mK.

Microbolometer

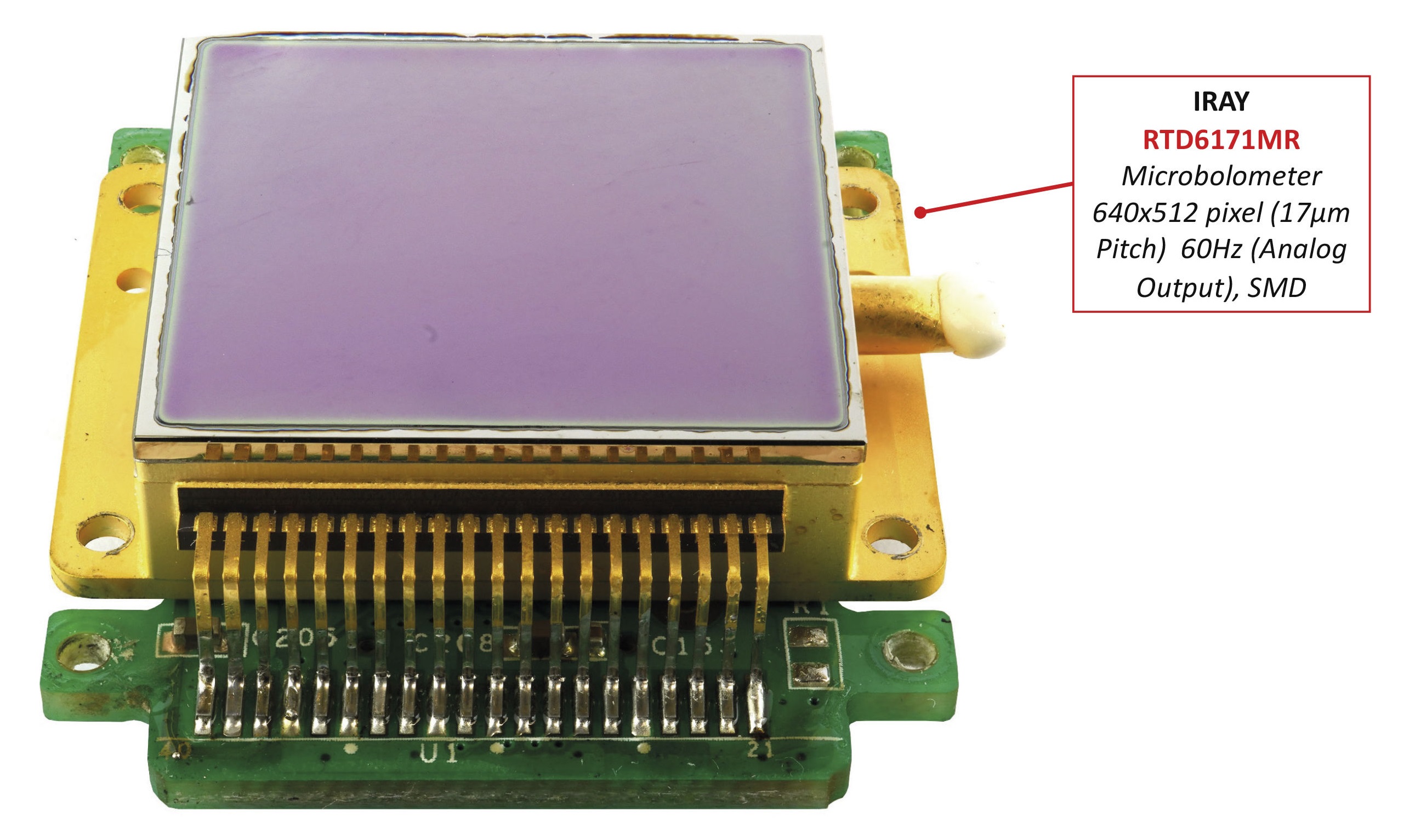

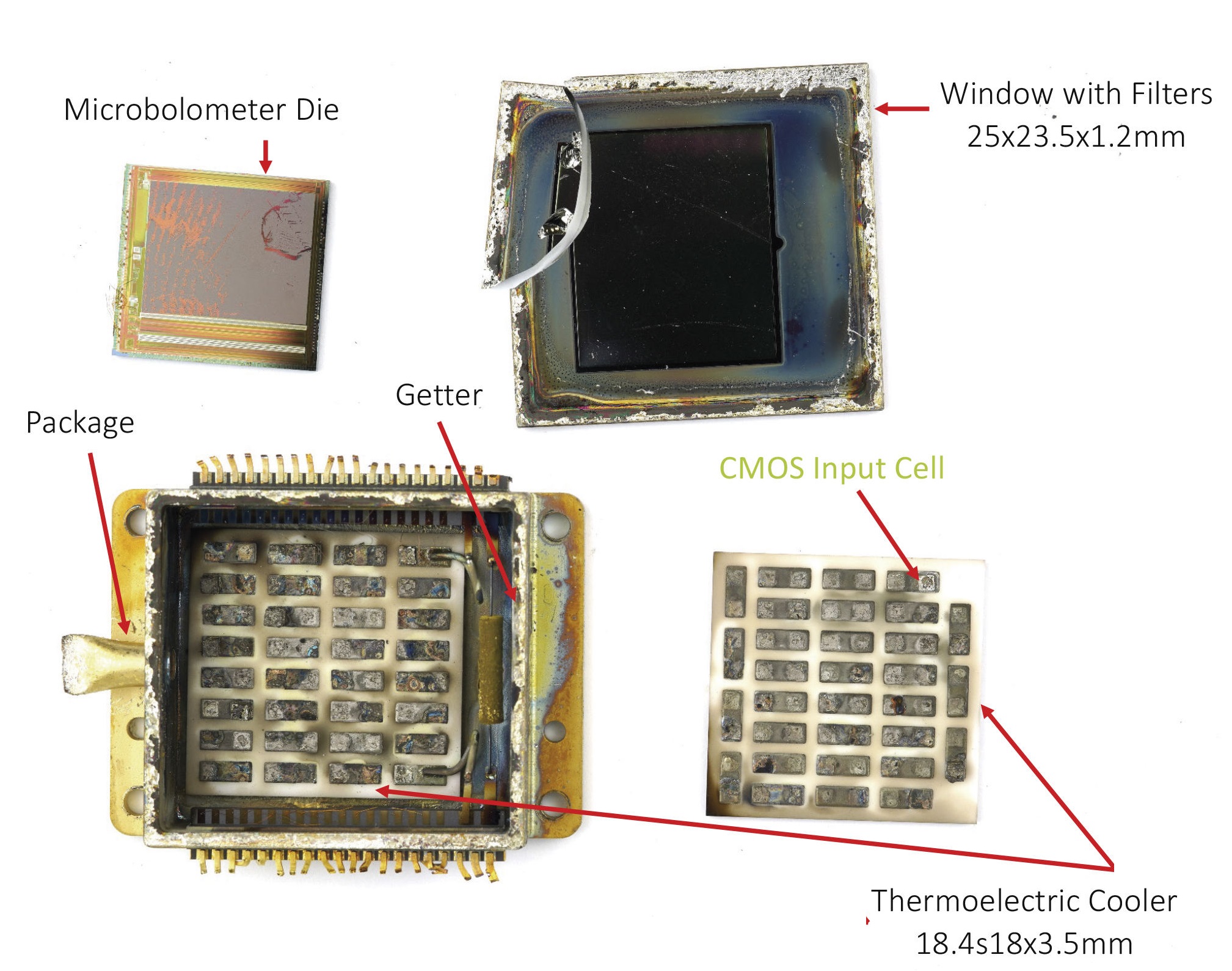

The pixel resistor grids form uncooled sensors. Such sensors are called microbolometers. Any radiation entering the absorber raises its temperature above the resistor temperature. The higher the power consumption, the higher the temperature rise. The resistor value changes depending on the incident radiation (the influence of infrared radiation, which heats the surface, is especially strong). Each pixel is represented by an input CMOS cell (readout integrated circuit -ROIC) and processed by the microcircuit to create an image on a computer or monitor using an FPGA (Figures 6 and 7). Typically, the structure of microbolometers is optimized for higher sensitivity in the spectral range of 8-14 µm. Hikvision DS-2TD2166-15 / V1 uses IRAY RTD6171MR sensor with 640 × 512 pixels resolution (17 μm step),60 Hz (analog output) and SMD.

Figure 6: Microbolometer - IRAY RTD6171MR.

Figure: 7. Microbolometer RTD6171MR 17 microns - disassembly.

The getter significantly reduces gas evolution and maintains a low pressure in the body cavity.

System Plus has highlighted the physical characteristics of the microbolometer, summarized below:

- Die area: 175.2 mm² (13.6 x 12.8 mm)

- Pixel area: 96.4 mm² (10.9 x 8.85 mm)

- Pixel matrix: 641 x 520

- Active Pixel Matrix: 640 x 512

- Number of substrates: 107

- Wire connection: 32

By analyzing it from the inside, we can see that the reflector is located under the absorbing material and is in contact with the substrate, which redirects the light to optimize the signal. The absorbent material is “suspended” from the substrate to provide thermal insulation, while the pixel grid is vacuum sealed to enhance durability and reliability. Most microbolometers used in thermal cameras use vanadium oxide as an absorbent material because of the better thermal contrast, which provides more accurate and clear images.

Vanadium oxide detectors have an impedance of about 100 kΩ for the middle resistor, as opposed to α-Si detectors, which usually have an impedance of about 30 MΩ. Under these conditions, vanadium oxide has a lower Johnson noise voltage, and therefore measurements will be less noisy. Johnson noise voltage is dependent on three conditions: resistor rating, circuit bandwidth, and temperature.

The chamber is equipped with a reference temperature and Peltier temperature stabilization system, equipped with a four-channel 14-bit AD5645RBRUZ DAC with integrated reference and MAX1978ETM + T temperature controller for the Peltier component.

Peltier elements are inexpensive thermoelectric devices used for power generators, cooling and precise temperature control and, as with this chamber, to maintain a constant temperature of an object at a given level. Peltier elements are based on thermoelectric phenomena. These phenomena are based on the formation of a voltage level difference in PN junctions of two different metallic materials.

The MAX1978 has built-in power field effect transistors and thermal management circuitry that minimizes external components while maintaining high efficiency. An ultra-low drift chopper amplifier provides temperature stability of ± 0.001 ° C. The temperature sensor is located on the lens module and is based on an NTC / PTC thermistor. An optional digital temperature sensor, TMP75AIDRG4, monitors the system (ambient) temperature directly controlled by the FPGA.

Unlike other types of infrared detection equipment, vanadium oxide microbolometers do not require refrigeration. Vanadium oxide behaves differently depending on temperature. Coated glass blocks infrared radiation (but not visible light) at certain temperatures, allowing the camera electronics to process an image from the electromagnetic spectrum and reproduce it in pseudo colors.

Other modules

The thermal camera supports RS232 transmission (via SP3232EEN-L) for industrial interfaces and Ethernet transmission with RTL8201FI-VC-CG support. Board 6, as shown in Figure 2, includes an AC / DC power system with transient voltage suppression diodes to protect the electronics from transients and ESD.

Figure 2: Some of the boards from Hikvision.

The thermal camera also has a built-in PoE interface, which is supported by the TPS2378DDDAR PoE High-Power PD Interface and the Texas Instruments TL2845BDR-8 controller. The latter provides all the functions needed to implement fixed-frequency DC control circuits in stand-alone or DC mode with a minimum of external components.

The low switch resistance (0.5 ohm) of the TPS2378DDAR, combined with the improved heat dissipation of the PowerPAD chassis, enables the PoE system to continuously handle up to 0.85 A. Power over Ethernet (PoE) is a technology that transfers power over an Ethernet cable: a device that provides a powered device is called a power supply unit (PSE), and a powered device is called a powered device (PD). When a powered device is connected to a power source, the PoE standard determines inrush current to prevent large surges. In addition, the PoE standard provides an analog handshake (classification) between the power supply and the powered device for power matching.

Working with video at the camera is provided by a system based on the HI3519 V111 SoC. It uses the H.265 video compression codec, and features low power consumption and architectural design. Hi3519 V101 supports 90 ° or 270 ° rotation, hardware-assisted lens distortion correction, algorithms for various IP camera models, and audio codecs. This SoC is equipped with two pairs of DDR4 4GB each and GD5F2GQ4UB9IGR Flash NAND 2MB SPI.

Intel Movidius MA2450 VPU 2x32Bit RISC Proc. LPDDR3 4Gb at 933 MHz is located on board 4 (Fig. 2) and allows the system to quickly recognize objects and people, analyze the number of people, check manufactured products and much more. A computer vision system uses deep learning to form neural networks that guide systems in image processing and analysis.

A variety of thermal chambers with cooled and uncooled sensors stand out in the market. Thermal imagers with cooled sensors are more expensive. Many modern thermal cameras have built-in sensors with cryocoolers.

Thanks to the microbolometer, the thermal imaging camera provides good accuracy at a low cost. The camera measures the surface temperature of the heat emitted by the object and projects it as an image.

- Russia's first serial control system for a dual-fuel engine with functional separation of controllers

- In a modern car, there are more lines of code than ...

- Free Online Courses in Automotive, Aerospace, Robotics and Engineering (50+)

- McKinsey: rethinking electronics software and architecture in automotive

About ITELMA

List of useful publications on Habré