Self-driving systems, the introduction of electronic components into power plants and the networking of vehicles - all of these innovations are based on semiconductor technology. “More than 80 percent of all innovations in modern automobiles are made possible by microelectronics,” said Stefan Simon, semiconductor expert with quality control. “In total, a modern car uses about 8,000 semiconductors in 100 interconnected control units. The computing power of each of these devices is higher than that of the first rocket to reach the moon. "

The Audi Semiconductor Lab follows the principles and methods of preventive quality management. The laboratory performs an important function of communication between different departments - it is the center of quality control and analysis of conductors, as well as it deals with assembly and connection technologies. All this works both internally and in collaboration with partners from the industrial and research industries.

Also, the laboratory is an expert body, as it carries out cross-industry and interdisciplinary assessment of components and assemblies, as well as examines assembly and manufacturing processes. Another of its tasks is the qualification of employees of various specialties. This wide range of powers and capabilities makes Audi Semiconductor Lab absolutely unique in the entire European automotive industry.

Laboratory experts evaluate the various components (own assemblies of control modules) for suitability, reliability and build quality. In the early stages of development, employees create and validate the requirements for a chip that will later be used in cars (and these requirements differ markedly from those used in other industries). The average lifespan of a smartphone is two years, while that of a car is about 15 years. What's more, the use cases and loads that cars are subjected to are incomparable to those faced by smartphones. “Semiconductors must be designed and manufactured to take into account temperature fluctuations, humidity and vibration in the vehicle,” explained semiconductor expert Oliver Zentfleben.

Also, the components are checked for resistance to temporary wear, since accelerated aging processes can occur in the car. Among the various studies in this area, accelerated aging in a thermal chamber can be distinguished. Physical analysis is also used to study the performance of devices and their aging behavior.

X-ray analysis

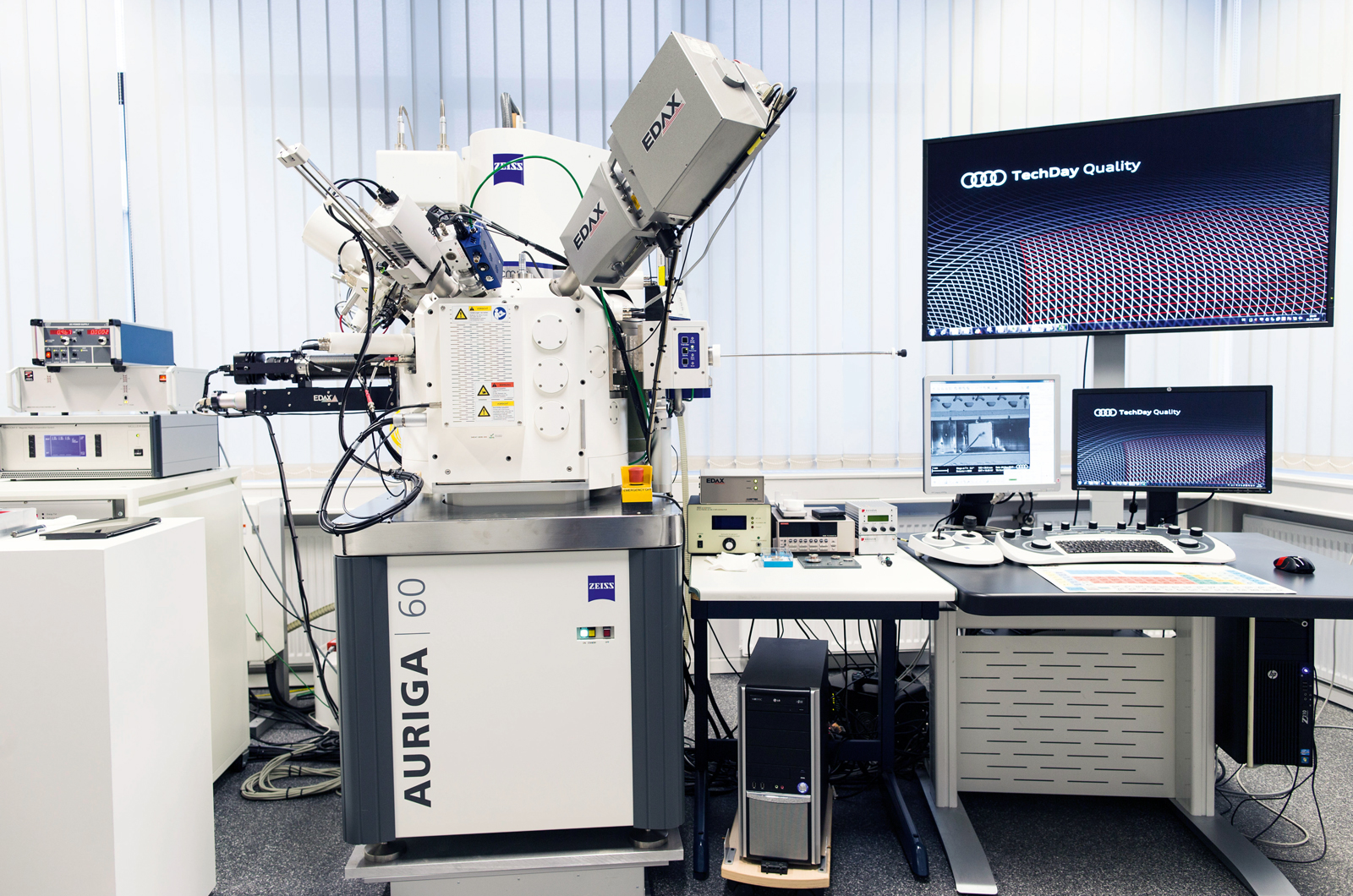

The laboratory has a modern X-ray apparatus and a scanning electron microscope. For specific analysis procedures on semiconductor chips, laboratory specialists work together with colleagues from the materials science laboratory.

For example, they jointly carry out sample preparation using focused ion beams (FIB) (using a scanning electron microscope that emits beams of focused ions). All of these methods can be used to check control units for serial and process errors.

Digitalization

In recent years, priorities have changed markedly. Despite the fact that drivers compare the characteristics of different vehicles and pay attention to their design, they also expect the introduction of modern technologies. Examples of such technologies include Audi Connect traffic data, smartphone connectivity and integration, and modern driver assistance systems.

To meet customer requirements, the automotive industry must increasingly use and implement advanced technology. It used to be that components were considered suitable for use in automobiles after years of use in consumer electronics. Now, new components appear in cars much faster, and to ensure high performance, they are pre-tested. To ensure high quality standards, the Audi Semiconductor Lab engages in requirements formulation and technology evaluation. Various consumer standards (for example, temperatures from 0 ° C to 40 ° C) are compared with automotive standards (from -40 ° C to 125 ° C), and life requirements are verified. For example, the Audi MMI app can be used to view the vehicle status,climate control or checking the charge level. In this way, the vehicle is constantly connected to and interacts with infrastructure elements, which significantly increases the uptime of the components for networking. It is also worth noting that some automotive applications will be operated as "always running".

autoSWIFT —

To keep pace with the industry's high pace of innovation and be able to respond quickly to new developments, AUDI AG partners with leading companies in the semiconductor and electronics industries. For example, the foundations for a standardized technology assessment will be laid with FZI Forschungszentrum Informatik, Globalfoundries, HOOD GmbH, Infineon Technologies AG and Robert Bosch GmbH. The autoSWIFT research project aims to "accelerate the development cycles of electronic systems throughout the entire value-added vehicle value chain." The program aims to introduce innovative and high quality electronic components into vehicles based on the latest manufacturing technologies, with development and integration going faster than ever before. As for the requirements,which will be presented to development processes in the future, employees are currently investigating how they can turn the value chain into a full-fledged network.

Bond Tester

“Company collaborations and interdisciplinary collaborations are designed to assess the suitability of technologies during the development phase and integrate them into product design processes early on,” explains Helmut Lochner, Audi Semiconductor Lab expert and project leader for autoSWIFT. This approach will bring semiconductor technology in line with the high quality standards of the automotive industry.

Lighting technology

In the new Audi A8 and Audi TT RS (total fuel consumption in liters per 100 km: 8.2 - 8.5, CO2 emissions in grams per km - 187 - 194), the company uses new rear lighting systems using OLED technology. Unlike single point light sources (such as LEDs), OLED devices are surface sources. Their glow takes backlight uniformity to the next level. They do not cast harsh shadows and do not require reflectors, LEDs or other optical components. All this makes OLED units efficient and lightweight, and their space requirements are minimal. Dividing OLED lighting into small, individually controllable segments with a three-dimensional arrangement allows the development of new lighting scenarios that give designers more creative freedom in design and animation.

Each OLED device contains two electrodes (at least one of them is transparent) and many thin layers of organic semiconductor materials. Low voltage makes these layers (200 times thinner than a human hair) glow. All this allowed Audi to transfer its DNA to modern technology.

The laboratory staff took part in a multi-stage testing process that this technology was subjected to before being introduced into mass production. Testing ranged from developing specific implementation modules and validating basic technology and OLEDs to testing tail light assemblies. Special attention was paid to the unique aspects of use that are characteristic of the automotive industry (for example, accelerated aging caused by the environment or conventional passive aging).

The first ever use of OLED blocks in the automotive industry required the development and analysis of specific parameters of this technology. Audi Semiconductor Lab worked with Engineering Development to fully evaluate the technology for various applications during the development phase. Weaknesses have been identified and eliminated in the technology itself and in the manufacturing processes of the products that use it. OLED technology requirements have been identified for future projects and enshrined as standards.

Electrification

Audi is actively working on electrifying its systems and developing green mobility concepts. Part of these projects is power electronics - the heart of any electrified vehicle. At the core of these systems are PWM inverters (in terms of technology, this is one of the most demanding components).

This device converts the DC voltage from the high-voltage battery into three-phase AC to power the electric motor. High performance semiconductors in inverters take up approximately 1 square centimeter. Each of them must carry a current of 100 amperes at a frequency of 10 kHz. Despite effective cooling, the resulting loss of power in the die leads to rapid aging of the electrical contact connections.

From Audi Q5 hybrid quattro (2011), then Audi Q7 e-tron quattro (2016; fuel consumption in l / 100 km: 1.8 - 1.9; energy consumption in kWh / 100 km: 18 , 1-19.0; CO2 emissions in g / km: 48-50) and for the upcoming Audi e-tron (2018), Semiconductor Lab has done a lot for the technological development of power electronics. For example, they evaluated the process connections between microcircuits and heat sinks, due to which they checked the thermal characteristics. The aging mechanisms, in this case, were evaluated on a par with the technical processes applied to individual technologies. The technical processes include soldering, welding and firing - the so-called assembly and connection technologies. The results of the experts' work were fundamental to the creation of a general corporate norm,which was partially revised to the German Industrial Standard in 2017.

RoBE - secure mountings in electric vehicles

To provide reliable predictions of the life of each fastener during the use phase, Audi has partnered with industry partners and third-party researchers in the RoBE (Reliability of Mounts in Electric Vehicles) project. The goal of this project is to at least extend the lifespan of consumer electronics. The project, which also involves research institutes Fraunhofer IZM and Fraunhofer ILT, aims to build a deeper understanding of the diversity and interdependencies in joining technologies. New technologies are being developed (such as laser welding) and new materials are being investigated to overcome current limitations.

The most important incentive for research institutions to conduct joint research on innovative solutions is the pooling of competencies throughout the entire product development chain. Evaluation criteria and testing standards for new technologies often simply do not exist. Thus, Semiconductor Lab participates in the development of quality specifications at the earliest stages of various projects and promotes their promotion in various industries.

Driving automation

The new Audi A8 is the world's first production vehicle designed for partial use of Level 3 self-driving systems in accordance with international standards. The Audi AI system can take over in slow traffic at speeds up to 60 km / h, on highways and on multi-lane roads with a physical barrier separating the lanes. As you ride the AI, the central controller (zFAS) continuously analyzes environmental information by combining data from different sensors. Audi was also the first company to use laser scanners in cars.

The scanner increases the viewing angle of the long-range radar from 35 to 145 degrees. Thanks to the wide field of view, the vehicle can recognize other road users earlier and interpret their behavior (for example, leaving the lane). “Imagine a laser scanner emits beams of light that scan the vehicle's surroundings in a fraction of a second,” said Robert Kraus, a manufacturing technology expert at Semiconductor Lab. A rotating mirror in a compact body directs the beams of a powerful diode over the scanning area. The new scanner not only detects obstacles, it can also determine the exact distance to them. This is done by measuring the time between the emission of a beam and its detection on the photodiode.

Semiconductor Lab employees have been preparing to implement laser scanners in the new A8 since 2014. In collaboration with Technical Development, they have developed comprehensive specifications for the part itself and its components. Before being used for the first time in the automotive industry, laser diodes were used in consumer electronics, and even before they were subjected to numerous tests and analyzes in various laboratories. Based on the results of these tests, the manufacturing processes for the diodes were optimized to meet the quality requirements.