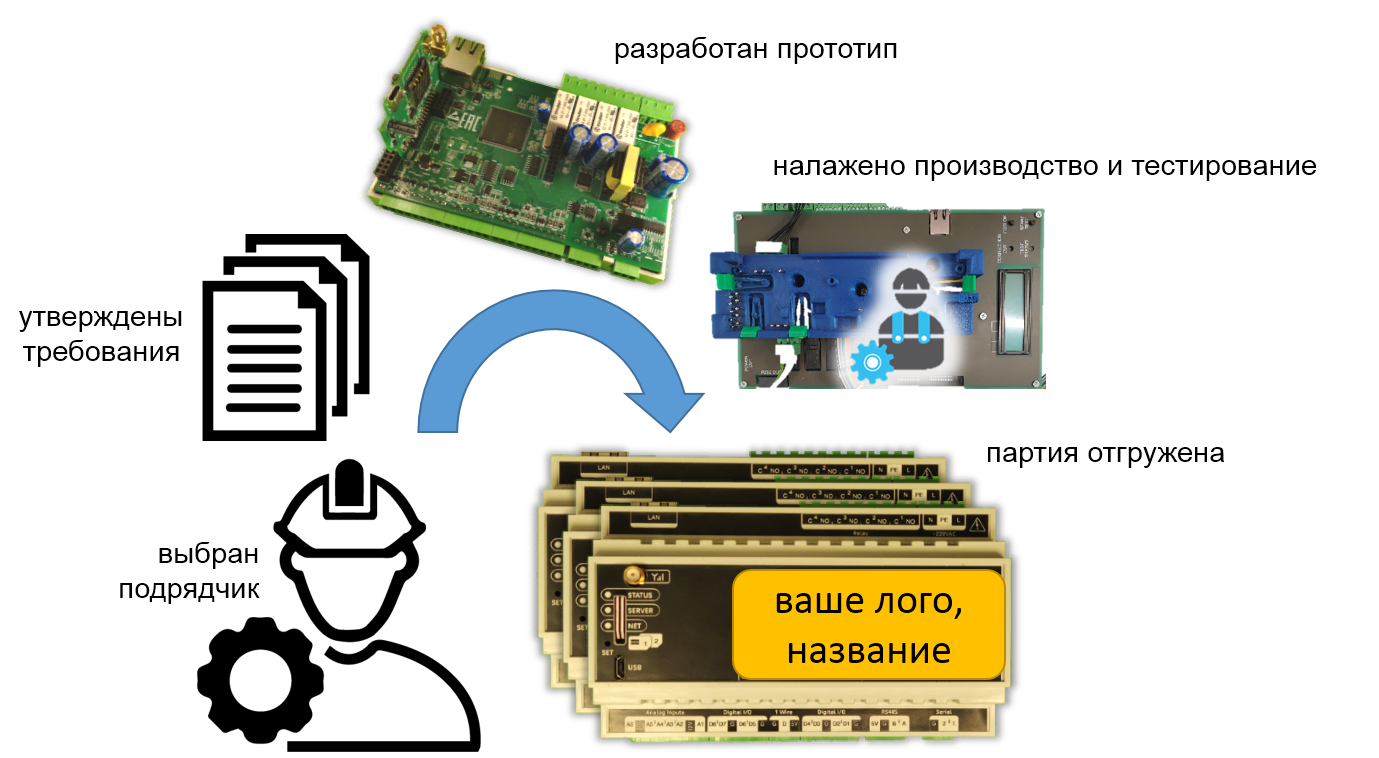

Not everyone is familiar with the custom design option. Most industrial controllers do not need deep space in the form of a unique functionality or design case . With a successful choice of a contractor who has the necessary developments, prototypes can be made in 2-3 months, and after a couple of months, serial production can be started. Development can pay off due to the use of inexpensive hardware components and the implementation of the required number of functions for a specific project. The complex of equipment at the facility will consist of a minimum number of devices (often one), which means that there will be less assembly, installation and commissioning work.

Custom hardware development has long ceased to be the domain of select customers with huge budgets. However, there are a number of features that it is better to familiarize yourself with on

Step 1. Is there a finished product?

You can seriously save money by choosing equipment for the project, for example, on this service .

The selected controller must be compatible with the top-level system and support all object devices. Except for the closed solutions of a single manufacturer, the compatibility issue is solved either by the support of the necessary protocols in the controller (by its developer), or by the support in the upper-level system of the protocols "wired" into the controller.

The search may fail at this stage. Then it will turn into a "market overview", which certainly does not hurt. Especially if in the end a decision is made to start developing your own device. And successful technical solutions used in finished products are

Step 2. Choosing a contractor: "WhenHow muchHow" and protection from the "Italian strike"

If you decide to develop your own equipment and there are no contractors nearby, it's time to look for a contractor. The best place to start is with companies that are already producing what you need. It is important to understand whether you need development rights, source codes for design documentation (CD) and embedded software (VPO), or it is enough to have an exclusive (for the territory of implementation, design, ...). Development companies can refuse to work on the terms of interest to the customer, or offer protective prices. The cheapest option may not be a full-fledged development, but revision or OEM supply of equipment under your brand. However, this option also carries a risk - you can grow yourself a competitor.

If the agreement did not work out, you need to look for a contractor on the recommendations, or on the Web for the request "contract electronics development". To help with working with candidates, questions from the checklist below.

For the pre-selected contractor (s), the primary equipment requirements must be formulated. The more detailed the requirements are, the easier it will be to determine the cost of work and the development time of samples. You can also show the contractor (s) examples of finished equipment of interest.

It is necessary to leave the meeting with a potential partner with an answer to the question "when how much?" This is often forgotten. The customer's expectations (prices, terms) may turn out to be much less than the contractor's requests. If in the end we managed to synchronize them, you can proceed to coordination:

- thesis concept: TK in large strokes, terms, development cost,

- prices for products in lots, delivery times,

- terms of the contract (rights, sources, exclusive).

Not everything can be fixed in a contract. The contractor can call an "Italian strike" for which he cannot be punished. Also, there may be unforeseen difficulties or new requirements, which will have to work more than agreed. In order to protect against these problems, you can use simple principles:

- When choosing a contractor, human contact is required. There are no ideal customers and contractors, but it is absolutely possible to find a partner with whom you will be comfortable working.

- It is great if the contractor takes the initiative and sincerely "cheers" for the case (you can understand by the answer to the question "how did you solve serious problems in the past?").

- . , , .

-

| – « » | |

| (, ), , ( ) | |

| / ( ) | |

| (, , , …) | |

| : , , | |

| , |

3. IIoT

Only the full compliance of the result of the development of the TK is the basis for the acceptance of work and the final payment. Changes to the requirements after the conclusion of the contract can be painful, therefore it is very important to responsibly work on the text of the TOR on both sides. The cost of an error at subsequent stages will be significantly higher.

Constructive type approval

As you know, "the device should not work in principle, but in the case." The start of the discussion of the TK from the case will allow both parties to imagine from the first minutes what kind of device will turn out in the end.

For each application and project, its own form factor is optimal:

- For power engineering, industrial automation and resource accounting, housings on a 35mm DIN rail are used. Perhaps the most popular format for the industrial IoT, however, it is not a silver bullet for all cases;

- 19’ . , U (44,45 ).

- 19’ ( ). , «».

- / ,

- , : , ( IP), ..

- , , , , ( , ).

Often the construct is chosen by analogy with ready-made devices (from the market). In some cases, this is a mistake, since an expensive branded case (with processing, marking, connector system, etc.) can cost up to 50% of the cost of the product. For reference: a similar share for a budget case may be less than 5%.

Choosing a processor core

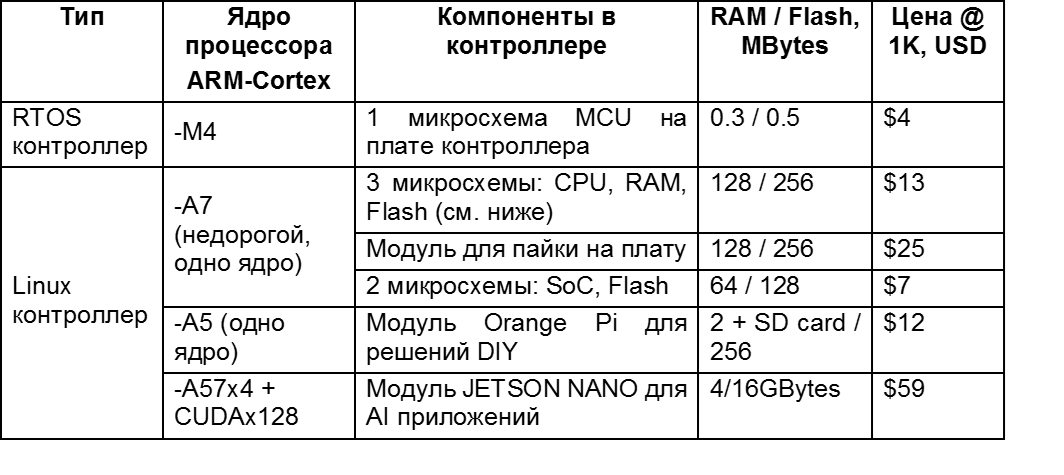

Low-end devices usually use single-chip microcontrollers (MCU), with random access memory (RAM) and ROM (Flash) in one package. Most devices run on a compact operating system (OS) like FreeRTOS or TNKernel, and can work without an OS. We will call them RTOS controllers.

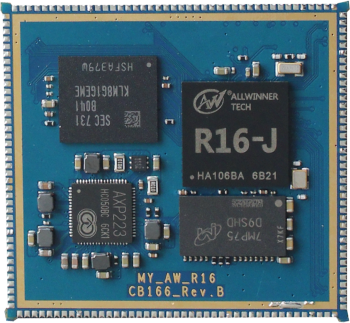

More powerful controllers use a processor (CPU) with external RAM and Flash chips. Most of these devices use different versions of Linux OS (Linux controllers) or less common OS such as VxWorks or Windows CE (not considered here). It is not so easy to make a board on a modern processor: on a board from 4 to 10 layers, you need to place several BGA packages with fairly strict requirements for power supply, geometry and track lengths. To simplify the life of developers, hundreds of processor modules are offered, which can be made in the form of a daughterboard with connectors or soldered edge contacts (see below).

System on chips (SoCs) also appear on the market, containing a processor and large memory, sufficient to run Linux. The SoC layout is significantly simpler than the CPU + RAM + FLASH set. In addition, SoCs can be very budgetary.

Below are typical specifications and prices for several examples of ARM processor cores that can be used in IIoT controllers.

It is often justified to use two processors in one controller : a powerful one for resource-intensive applications and a small single-chip processor for simple real-time applications.

Harmonization of power requirements

Depending on the type of objects, the requirements for the power supply are determined, which can be either external or built into the device:

- home / office use, energy - ~ 220 / 380V,

- telecom - 36 ... 72V (station power) and PoE,

- industrial automation - 18 ... 36V,

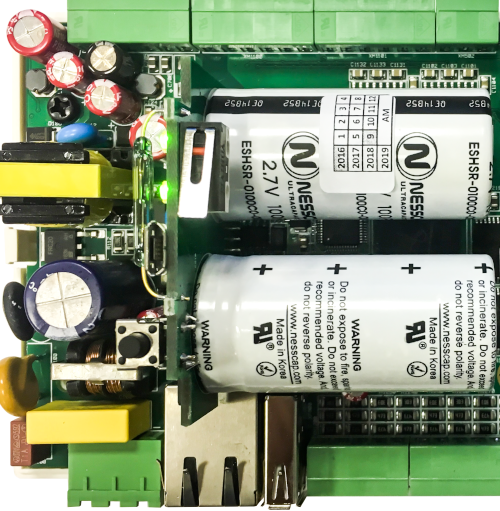

An isolated power supply is often damaged by drying out electrolytic capacitors. There was a case when a massive breakdown of equipment occurred literally six months after the start of operation. For this reason, the contractor must have experience in the development of power systems and know their "pain points", ... or use expensive converters, the quality of which is guaranteed by the name of the manufacturer.

Many applications require backup power from one minute (short-term reserve to signal a power failure) to several hours / days (security and industrial safety). To implement a short-term reservation today popular supercapacitorswith a lifespan of up to 15 years and resistance to negative temperatures. Long-term backup requires batteries, usually lithium-based.

All Russian devices require EAC certificates for electrical safety and electromagnetic compatibility. To pass the test, you need to know how to design filters and board layouts, and select the right components.

Communication ports

Common interfaces used in IIoT controllers are shown in the table below. The choice of types and quantities - for the task and budget.

| For communication over an IP network | For communication through an intermediate HUB | For local communication on site |

| * Wired Ethernet | * RS485 / 422 | RS232 |

| Cell 2G / GPRS ... 4G / LTE | * CAN | USB |

| Optical Ethernet | PLC (G3, Prime) | 1-wire, s-wire (for digital sensors) |

| Optical GPON | Radio: LoRA, NB-Fi (Rus), UNB | Radio: Zigbee, 6loWPAN, ISM 433/868/2400 Mhz |

* can also be used for local communication with equipment at the facility

Inputs and outputs

To connect sensors, the controllers are equipped with discrete, counting and analog inputs. Analog inputs can be potential (for example, at 0..10VDC or isolated at 220VAC), or current (4..20mA, NAMUR, "fire"). To implement the outputs, relays are used (conventional and semiconductor, for example, opto-simistors ), as well as transistors connected according to the "open collector" (OK) scheme.

In the case of using long lines, or if there are special requirements, the inputs and outputs can be performed with individual or group galvanic isolation.

To reduce the size and save connectors, they use universal ports that perform different functions depending on the settings and use the same pins. For example, a discrete input with an OK output function.

Indication

For a long time in IIoT devices, it was enough to use several LEDs. More advanced controllers used "TVs" - a line of seven-segment LED indicators, electroluminescent, text or graphic LCD indicators. But from the "TVs" more often still refused because of their high cost and little use in operation.

Today "TVs" have become fashionable literally everywhere: from cars to "smart homes". There are more and more contests in which the presence of a screen is mandatory for IIoT devices.

The good news is that the cost of LCDs or OLEDs is decreasing and the processor power required for graphics output is increasing. For this reason, "TV" is no longer an expensive option.

The lineup

It is good practice to develop not just one device, but an entire line. At a minimum, this requires the development of only one board, designed for the maximum configuration. Other, more budgetary, versions will be soldered on the same board, but from fewer parts. Part of the board will be empty, but this is not a problem (PCB is inexpensive).

I advise you to add this item to the TK.

Firmware requirements

The development of malware can take up to 80% of the implementation time of the entire project. Since this post is about hardware, I will limit myself to listing the main functions that should be implemented in almost any IIoT controller:

- Data exchange with the upper level system, including the transmission of emergency notifications;

- Data exchange with downstream devices and sensors;

- Control of executive mechanisms;

- ;

- ;

- ;

- ;

- (Edge );

- ;

If the TK is agreed, it is time to sign an agreement with annexes (TK, schedule with prices, test methodology, ...) and start implementation.

The development of a new IIoT controller is a relatively small project, for the success of which, nevertheless, well-coordinated work of the customer's and contractor's employees is needed. On the part of the customer, a project manager is immediately needed, and later - a testing engineer (s) (you cannot do a product without independent testing). Moreover, development is usually transferred on an "As is" basis. After the signing of the acts and payment for the work, it is difficult to prove the need for correction under the guarantee.

Hundreds of books have been written about project management. In terms of controller development, I highlight the following mandatory points:

- (, , , , …), ;

- ;

- , , . ( 10% ).

- , , .

- . , – «» ,

Good project management document forms are here .

Conclusion

You can't do great work with your hands in your pockets. You have to work hard, take risks and sometimes go beyond.

One such opportunity for an IIoT project is the use of custom controllers. To implement it, the customer needs to go through three quick steps:

- market analysis,

- selection of a contractor (for example, us ),

- coordination of technical specifications.

The next step is to work with the selected contractor: development of prototypes, production and support. Prices for custom controllers, their installation and commissioning can be significantly lower compared to using off-the-shelf equipment. Additional values for the customer will be:

- development of your own brand,

- implementing a specific set of hardware functions, and

- ( ).