In version 2.0 of the nanoCAD Design BIM program, a new functionality has appeared - a constructive assembly tool, which allows you to optimize and simplify the work of the designer, especially in the case of large models.

Without delaying acquaintance with the new product on the back burner, let's take a closer look at the operation of the tool, study its settings, and towards the end of the article I will share with you one very useful life hack ...

What is constructive assembly?

The Structural Assembly tool allows you to assemble individual structural elements into a new object that has information parameters and an insertion point into the project. Having created an assembly and replicated it according to the drawing, in the future we can, by making changes to one of the assemblies, automatically apply them to the rest of the assembly occurrences.

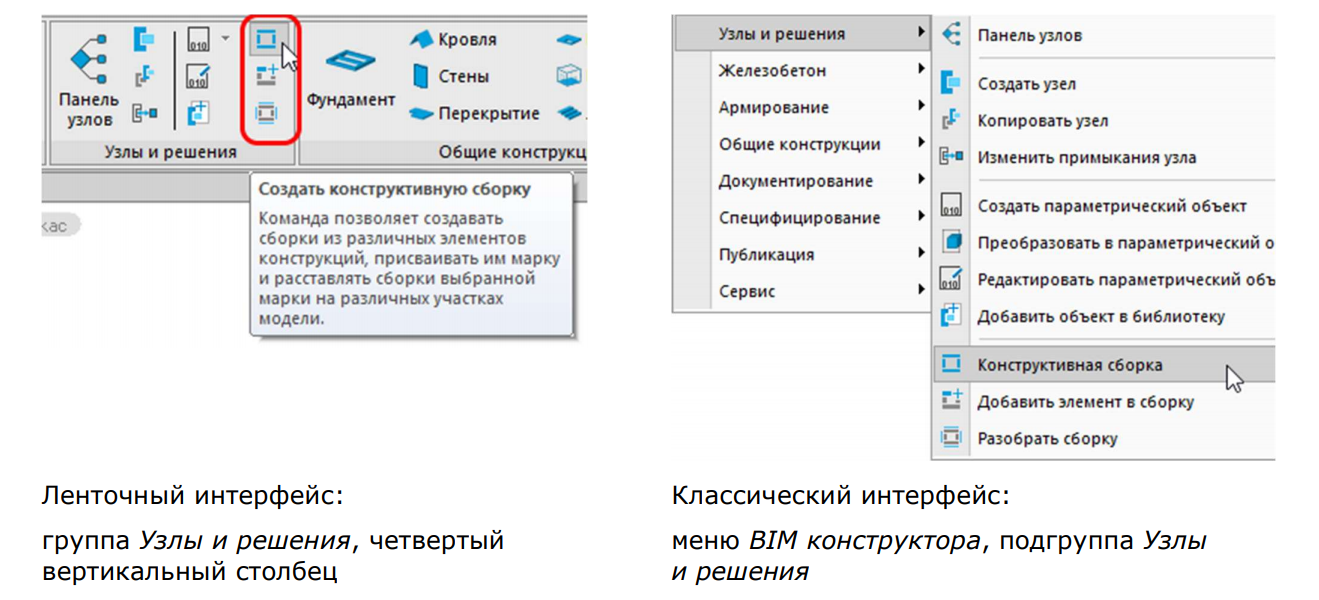

The primary command for working with structural assemblies is the Create structural assembly (AEC_ASSEMBLY) command. Its location in the interface is shown in Fig. 1.

Fig. 1. Command location in the interface

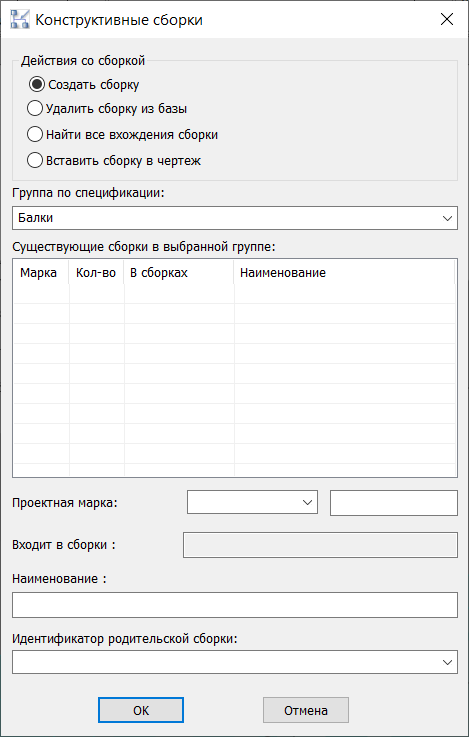

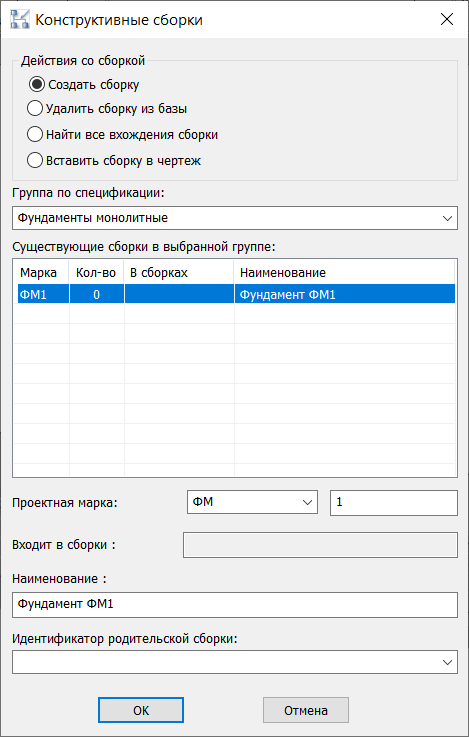

The AEC_ASSEMBLY command calls the Constructive Assemblies dialog, which allows you to create new assemblies, maintain a list of assemblies represented in the model, quickly find all occurrences of the assembly in the model, as well as place new assemblies, delete them, and perform other operations (Figure 2).

Figure: 2. Dialog box Structural assemblies

The dialog box also contains the BOM group field , where you can select one of the existing options from the drop-down list or specify your own.

List assemblies, previously created in a particular group of specifications, will be displayed under an existing assembly in the selected group: .

Design mark - alphanumeric designation of the assembly;

Included in assemblies- the field where the design mark of assemblies is displayed, which will include the assembly selected from the list;

Name - indicates the name that we want to set for the assembly;

Parent assembly identifier - specifies the identifier of the assembly in which you plan to include the newly created assembly.

What parameters does the assembly have and what parameters are important for the elements included in it?

Build an assembly

To make the most of the program's capabilities, it is important that all the elements in the drawing not only have a "physical" representation, but also have certain informational parameters. The more carefully the information component is worked out, the more efficiently we can generate the necessary documentation (2D views, drawings and specifications).

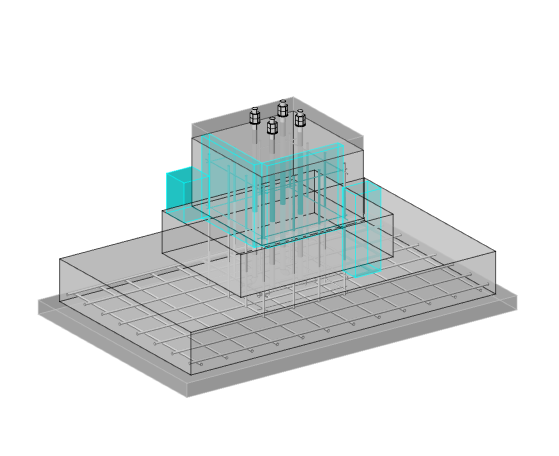

Let's take a concrete example to see what information parameters are important for structural assemblies. As an example, let's take a columnar foundation with reinforcing bars and anchor bolts (Fig. 3).

Figure: 3. Column Foundations

Calling the Create structural assembly (AEC_ASSEMBLY) command, the Structural assemblies dialog box opens . We select the item Create assembly and specify the following parameters:

- Specification group - Monolithic foundations;

- Design brand - FM1;

- Name - Foundation FM1.

Click OK and, following the program prompts, create an assembly: select the objects that we want to place in it, indicate the base point of the assembly (later on it will be the insertion point for new assemblies and "handles" for moving and rotating the object), and then set the direction of the axes coordinates.

The command line displays the message: "Assembly FM1 has been successfully created in the Monolithic foundations group."

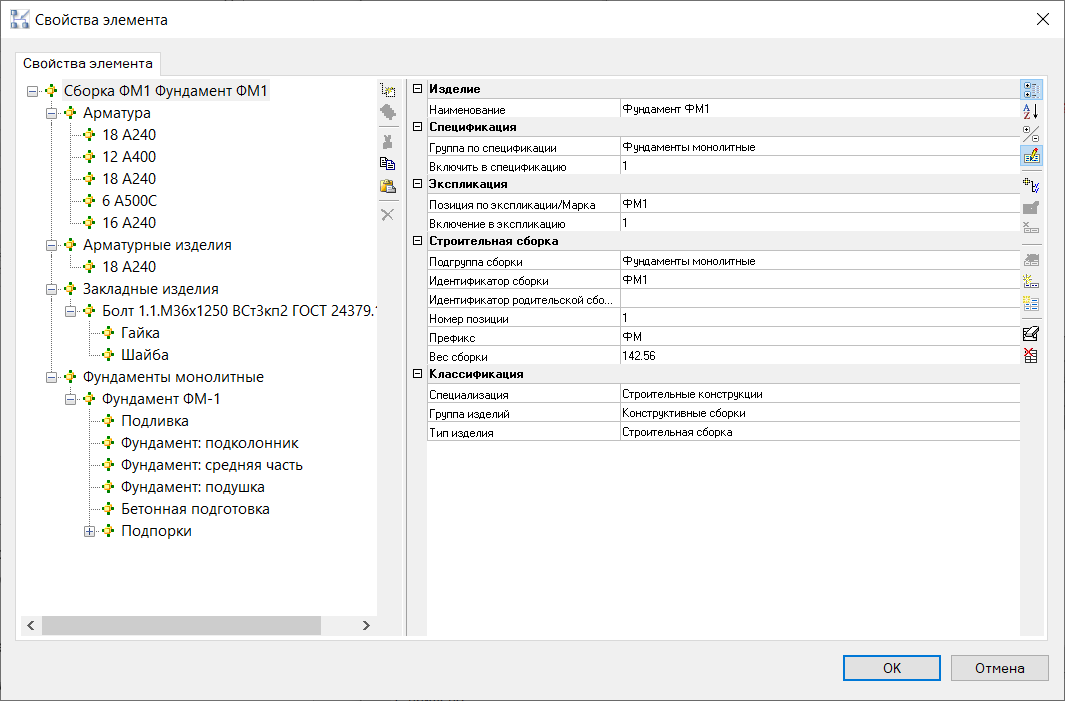

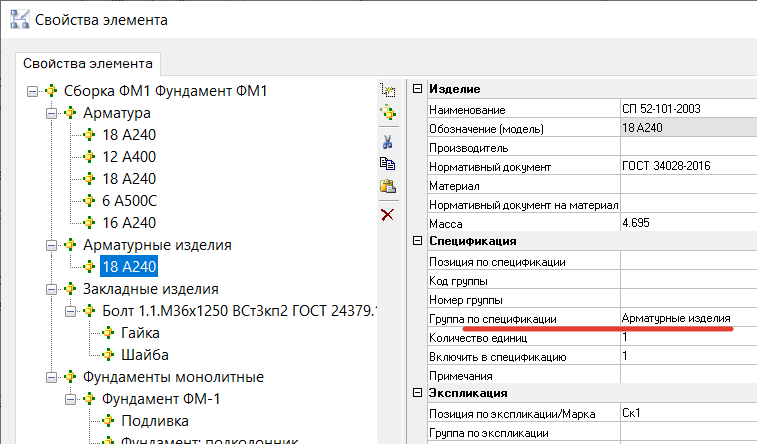

Let's open the properties of the newly created assembly (Fig. 4).

Figure: 4. Assembly properties

On the left, in the properties window, the composition of the assembly is displayed - it is presented as a tree of subordinate elements. The properties of the assembly as an object are shown on the right. In addition to the parameters we are familiar with, a section of parameters "Building assembly" has appeared, where information only about the assembly is collected.

Let's look at the principle by which elements are grouped in a tree.

We see four sections of the first level: "Rebar", "Reinforcement products", "Embedded products" and "Monolithic foundations".

The name of the section corresponds (in order of importance of the parameter) to the subgroup of the assembly from the section "Building assembly", and if the parameter is not specified, then the group according to the specification and / or the group according to the explication of the elements included in it.

As you can see in the structure of the assembly, almost all reinforcing bars are combined in the "Reinforcement" section and only for item 18 A240 the section "Reinforcement products" is indicated. Let's see why this happened.

If we look closely at the properties of this bar, we will see that the value of Reinforcement products is specified in its BOM Group parameter( In this case, the Assembly subgroup parameter has an empty value) - that is why it was placed in a separate section (Fig. 5).

Figure: 5. Properties of the reinforcing bar

To avoid any inaccuracies in the assembly specification in the future, we will change the Specification Group of this bar to the value Reinforcement . This can be done directly in the assembly properties window.

We will return to the discussion about the importance of uniformity of information parameters at the stage of specification ...

Each element of the assembly is also added a section of parameters Building assembly with a set of fields Parent assembly ID and Position number... Subsequently, these parameters will allow filtering the selection of objects for specification.

I would like to draw your attention to another parameter that will be important for us at the stage of specification: Assembly subgroup . For objects included in the assembly, I recommend setting this parameter before the assembly is assembled. And for this, you need to at least roughly think over which section of the specification you will need to place this or that element. However, let's come back to this topic a little later when we begin to take a closer look at the structural assembly specification.

Editing an assembly

To make any more significant changes to the structure of the assembly or to the properties of its constituent elements, you must edit the assembly. This operation is performed according to the following algorithm: parse one of the occurrences of the assembly - make changes - rebuild the assembly under the same name.

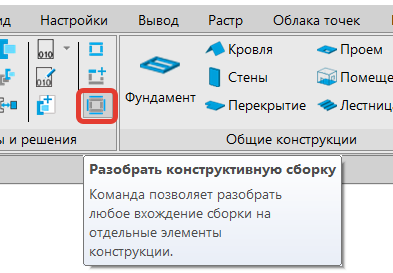

For example, you need to remove one of the anchor bolts. To do this, select the assembly of interest to us in the drawing field (if there are several identical assemblies, select one of the assembly's inclusions) and call the Disassemble structural assembly (AEC_ASSEMBLY_DISASSM) command - Fig. 6.

Fig. 6. Location of the Disassemble structural assembly command

Then we make the necessary changes to the disassembled assembly (both in "physical" and in informational parameters). After that, we call the command againCreate structural assembly (AEC_ASSEMBLY). In the Constructive Assemblies dialog box that opens, select the Create assembly item , select the one you made changes to in the list of existing assemblies, and click OK. Leave the design brand and assembly name unchanged (Fig. 7). Click OK.

Figure: 7. Dialog box Constructive assemblies during editing

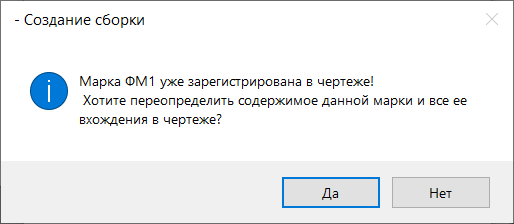

The program displays a warning that this assembly is already in the drawing, and asks if we are sure that we want to rebuild it (Fig. 8). Click OK , and then we perform the actions already familiar to us to create an assembly, namely, we indicate the objects that should be included in the assembly, the base point and the direction of the axes.

Figure: 8. Assembly Override Warning

The assembly was successfully edited and the changes we made were applied to all of its occurrences in the drawing.

Assembly specification

Setting specification parameters and displaying them is certainly a topic for a large and separate article (or a webinar that was held on the first version of the product: www.youtube.com/watch?v=JgyCJDJYZ1o&list=PLaWJ5dzYEDotv6ufwDmBpkDXwpPcb7htW&index=20 , as well as online -schools are already based on the second version: www.youtube.com/watch?v=aSNjY89YtGw&t=2924s ).

You can view one of the examples and possible options for specifying assemblies in the file from the Sample nBIM folder . KM model , specification profile Specification for a structural element (QOL, assembly) .

Let's get back to talking about the importance of the Build Subgroup parameter... Roughly speaking, we will use this parameter in order to create a section in the specification where an assembly item will belong. Of course, you could use the BOM Group parameter for this , but there are situations in which it is necessary for these parameters to be different (for example, when the same assembly must be taken into account in different types of BOMs).

Here is an example from one of our pilot projects. There is an assembly of a frame column, consisting of an I-beam, several metal plates and a column base, which in turn also consists of plates. The information from this column needs to be compiled into two specifications:

- product specification, where the components of our column assembly will be presented;

- steel consumption sheet, where the elements that make up the assembly should be distributed by type, and not by belonging to any assembly.

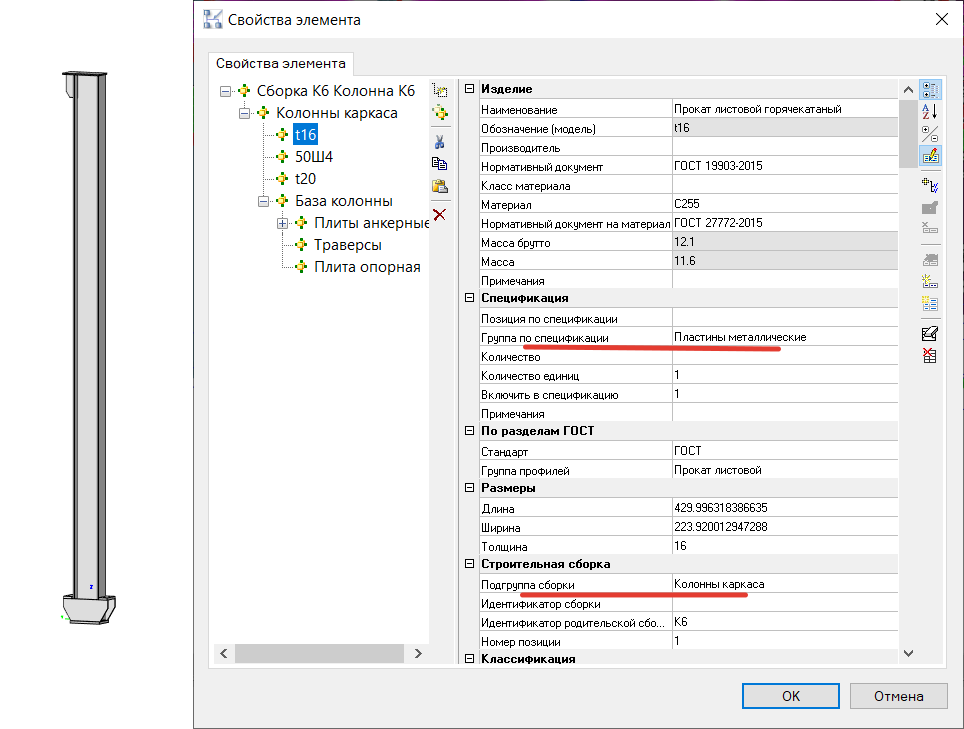

And in this case, the Build Subgroup parameter will help us a lot . For the elements included in the Column assembly, we will indicate the subgroup of the Frame Column assembly , and we will indicate the BOM group for each element in accordance with the section where it should be included in the steel consumption sheet. For example, for one of the plates we get the following values: Specification group - Metal plates; Assembly subgroup - Frame column (Fig. 9).

Figure: 9. Properties of the plate in the assembly Column K6

These informational parameters will allow us to easily create both required specifications.

In addition, I would like to once again focus your attention on how important it is to maintain uniformity of information parameters for the elements included in the assembly. Because if you define the same Assembly Subgroup parameter for one of the elements as Framing Columns , and for the other as Framing Column (that is, use the plural and singular), they will be collected in different sections of the BOM. Or one of the elements will not be included in the specification at all - if earlier, for example, we indicated in the selection condition that the object with the Frame column parameter is not taken into account.

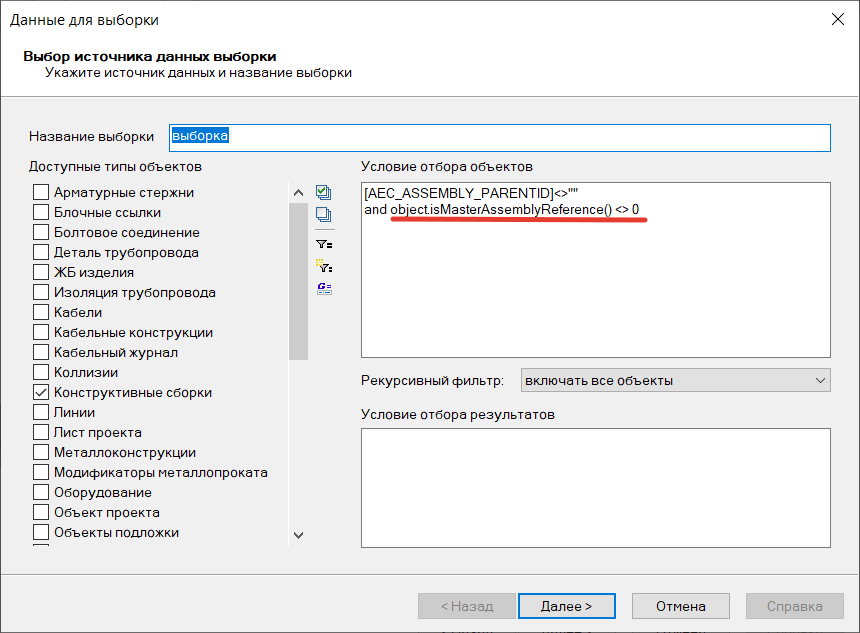

Another point that we may encounter when specifying assemblies is counting the number. For example, in our drawing there are several assemblies of the same type and we need to make two BOMs, one of which will take into account the total number of elements in all assemblies, and the second only one of the occurrences of the assembly. This is where the time has come to share with you the promised life hack, namely the command object.isMasterAssemblyReference () <> 0 .

More precisely, this is a filter that needs to be added to the object selection condition in the Specification Setup Wizard (Fig. 10). It takes into account only one of all occurrences of the assembly, and you can be sure that you are specifying one unique object, and not all of its occurrences in the drawing.

Figure: 10. Specification Wizard window

Generally speaking, the specification of structural assemblies does not cause any problems, provided that all information parameters of the elements that make up the assembly have been set uniformly and correctly, and the specification is adjusted in accordance with these parameters.

Summing up

Structural assemblies are new functionality that provides great opportunities for working with the model and specification, but at the same time requires serious attention to the information component (as, indeed, any tool in BIM design).

It is likely that you will spend more time initially setting the correct information parameters for the objects in an assembly than if you were using them individually. However, once you get the hang of it, understand the logic and how these parameters work, your productivity will increase. It will become more convenient to edit the model, because you no longer have to worry about an object being lost in model space when making changes. The speed and convenience of preparing specifications will also be greatly improved.

And I would like to conclude this review with the words of the American journalist, writer and psychologist Napoleon Hill: "Mastery comes only with practice and cannot appear only by reading instructions . "

Therefore, I urge you, without delay, to start using a new tool, improve your professional skills, as well as share your successes, ask questions and leave your wishes on our forum at forum.nanocad.ru .

Tatiana Tolstova,

technical specialist