What will it be

I have been dealing with this topic for more than one year. Behind him - a bunch of broken walls in matters of abnormal use of robots - control on the fly, auto-generation of programs, control of technological processes. Our products are dedicated to welding and painting, troubleshooting and calibration. We work with wood for furniture makers and with iron in car manufacturing. We have never undertaken projects of classical application of robots in serial production. Each time we solve tasks that usually require an operator who corrects the program for a long time and painfully before each launch.

In theory, if the material will be of interest to the Habr audience, it will be a series of articles in which we will consider the questions:

- about robert programming. I do not pretend to take a course, but rather about the features of these guest workers

- development of automatic programming systems

- about the difficulties on the way to enter the profession

- technical nuances of limb swinging

- remote management of the development and debugging team

- programming cortex and optimizing algorithms - you give the implementation of what worked on the i7 inside the STM32

- about fuckups, startups

and much more. A lot has accumulated, to tell you what to eat.

Today - a summary of the situation in the Russian Federation with our, in many ways insane, bell tower.

Introduction

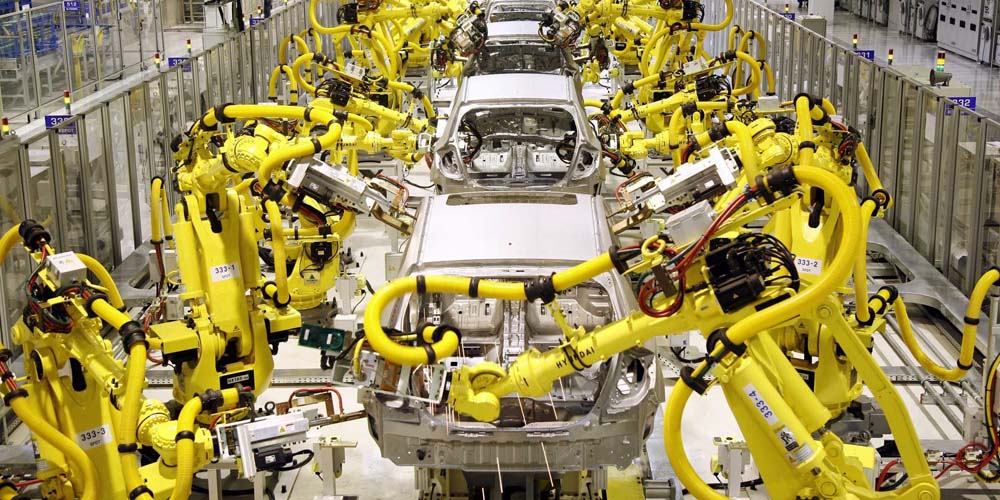

Today on the market there are 4 and a half iron-handed representatives, which are very common. These are Fanuc, Yaskawa, ABB, Kuka (I will not mention rare earth samples). Next to them are Universal Robots - cool guys whose robots look like a pretty jumble of aluminum pipes and plugs that are very actively promoted on the market. I will tell you on the example of the first two, which I had to deal with directly in the work. About ABB, I only know that they are white, and about Cook - twice as much: they are orange and if you change the first letters in the phrase "Remote Cook", it turns out fun.

The most common in relatively small enterprises are just a yellow Robert named Fanuc and a blue one called Yaskawa. In particular, this is due to their greater affordability and liberality in relations with partners. Well, Universal, which are often used in packaging / sorting, although with the recent release of a robot with a load capacity of 40 kg, something may change.

The situation in the RF

My country can hardly be called a leader in robotization. It's hard to call it even a serious player)). And this is not because we do not know how to cook them. Three factors hinder mass distribution - the cost of the equipment itself, versatility and integration.

The cost

It is not great on its own - there are a lot of things in industry that make buying a robot roughly the same as buying a pie in a cafeteria. It's about financial efficiency.

For example, a normal welder in an immense region receives an average of 40-80 per hand. Let's take 50 generously, throw in taxes and round up to 75. In theory, Robert replaces 3 to 6 welders (if he works with a respectable load of 60-80% of the theoretically available one), or saves about 300K per month. With a complex cost of 15-20M, its payback will be 50-70 months, which is 4-6 years. In general, it is tolerable. In addition, the robot is capable of stable quality, does not get tired, does not go on vacation. Makes a person faster, it's not about multiple acceleration, but faster.Oh, the tomatoes will fly at me, let's make a reservation: faster in constant daily work. A person will be able to make a piece of iron within the framework of socialist competition due to a number of nuances. But for wear and tear, from day to day, he will not be able to work in such a rhythm.

While 4-6 years old look with such introductory norms? We will throw in the service, we will throw in a person who will bend the robot and courting in every possible way, and so on. It will turn out to be something in the region of 6-9 years.

And now let's compare with the salary of a welder in Europe, which is generally twice as high, but we will throw in deductions for very harmful production, and we will remove customs clearance. And it turns out that in the EU the payback will be 2-3 times faster. This is the first reason why you do not take the subway in the morning with Robert, who reads the manuals, to work - its basic payback, if we omit quality issues, is very prolonged.

Second trouble:

Versatility

Not all is well here. More precisely, not all is well. Let's start with a classic: the auto industry.

Once upon a time, when it was customary to write "empire" in the names of countries at the end, cars were made by hand in carriage workshops. This is how most brands were born. And with manual production, a person can always twist something, hold out, stroke it with a sledgehammer, at worst. There are legends that AvtoVAZ still assembles cars like that (no).

And today a machine is a shitty cloud of parts that begins its life in the form of sheets and blanks that pass through presses, molds, CNC machines and other joy, giving the desired and predictable accuracy at the output. The ideal state for a robot is holes where they should be, everything is inserted and docked, control at every stage. And specifically in mass production, auto robotization at domestic enterprises does not differ much from the EU.

The production of small-scale products is another matter. Robert is such a creature who knows how to come to the required point with some accuracy (in fact, not either)))). The operator should point out the points by running the program for the robot on the remote control. This is a very dreary action, since the remote control is such a fool (from different manufacturers - different degrees of elegance):

No matter how it looks, this does not change the essence of the process: each record is associated with the translation of the robot to some point in space by poking buttons, recording a point and adjusting its parameters (speed, movement rounding, etc.). Plus all sorts of instructions for working with peripherals, registers, and so on. Well, for dessert - all this is through the menu. This is the same as in Dotnet's public static void, each word would have to be inserted through F1-> Menu-> Commands-> Standart-> Base and some other action. With menu navigation arrows. This is a long, dreary and not very romantic affair.

Writing a program for a product is not a task for one day. And after that we can only work out this particular type of product as many times as we need to produce. There is, of course, time saving, but in general it looks less attractive. And then - once, and we have a second problem at full height, the name of which is accuracy.

To use a pre-recorded program, we must fulfill two conditions: to position the product with the same precision in space (along the 6 coordinates XYZWRP). And also to ensure that all parts of the product are made with an accuracy sufficient for the technical process. If we are talking about welding, then the error is measured in tenths of a millimeter, if about painting, then everything is simpler, but "shadows" and unpainted are possible with a shift of several mm.

Despondency has already knocked on the factory door? Do not close - there followed depression runs. Which was born from the thermal deformation of the metal during the welding process. And the program, written on a product assembled on tacks, suddenly starts to mow when working.

As a result, the programs for the operation become much more complex. Verification and adaptation is required before each product. Somewhere in the “come on” zone, there should be an operator who, if poor Robert was shocked and the process got up, will correctly make changes to the program to continue.

You can live with all of this, but it increases cycle times and decreases productivity, which leads to an increase in the payback period. You just need to be ready for this, or look for technological solutions, which, besides our products, are actually enough. And here we have problem number three:

Integrators

This is where things get interesting. A conditional integrator comes to the plant and says: let’s put Robert on you, but we’ll start everything in the machine, but how will it start rolling! The plant, after thinking for a year or two (the transaction cycles in industrial automation are simply monstrous), says, throwing the iPhone down to the ground: “Come on, devil!”.

The devil brings Robert of a certain price category and colors, creates a movement system, a curbstone, a conveyor for him (in fact, the process of creating a robotic complex is a separate task, not inferior in complexity to software development) and launches it on a certain type of product. Acts have been signed, cognacs are drunk, the girls are kissed, everyone is happy.

And then the nuances begin to creep out like worms. And then unambiguously poke your finger at someone with a shout "It's you !!!!" - will not work. Because each project is a collection of many inputs, on which the final result depends (oh, I wrote a trivial thing, but oh well ...). There is a customer who has built an atmosphere of shifting responsibility in the team. To cook porridge with such is a separate quest: no one is responsible for anything, while time passes, and the work does not move. There is an integrator who sold a project just to sell Robert. Sometimes inattention to the little things, which then leads to problems. Moreover, inattention both on the part of the customer, who has already fired everyone in his head and bought a dozen of iron ones, and now does not nag from the immigration service, and on the part of the integrator, who reached for the handle and missed “we are cooking steel,including stainless steel. " And there is no need to hope that everything will be stopped by the agreement and the prescribed nuances. Yes, there in every nuance - for a good almanac. We have been doing this for more than one year, and we continue to snatch. And the contract is not a panacea, the market is narrow, and even if everything is written in the contract, it will not save you from “but these guys are doing

Therefore, the only thing that remains is to improve the software and explain its limitations.

Eerie horror

One might get the feeling that robotization is such a black hole with no special prospects, and you shouldn't even get into it. But in reality, everything is a little different. There are at least two reasons for this:

- A general decline in the quality of training and a decrease in the number of graduates with a working specialty. Yes, yes, I understand that the audience of Habr is people who pierce, yaks Zeus with lightning, a debugger, any tricky bugs who write code with their left hand, set up the grid with their right hand, and dance a jig with their feet. But if someone was looking for employees, then they cannot fail to note a decrease in both the number and level of the same developers. And in working specialties it is even worse.

- Technology development. Oddly enough, the boom of AI and others like it, which is a consequence of the increase in the speed of computations and their availability, also plays a role here - it becomes possible to create systems that can quickly and efficiently replace the work of the operator, leaving him only the control function.

Both of these prerequisites ultimately lead to the fact that the development of robotics in the Russian Federation will continue, and it is worth doing it (who would doubt it, you are writing articles about it for some reason))

And since we decided to go - a brief overview of the vendors.

Vendors and their features

Regardless of other qualities, undoubtedly important, such as delivery times and party policies, I will give a brief description in terms of development:

Fanuc

Very responsive general, very competent (however, based on personalities) technical support in complex issues. You can even, after a while, ask Robert to "go for a ride" for some projects.

Yaskawa

That's right close to Fanuki, but from the point of view of technical support everything is more complicated, some questions do not have an answer right away, you have to contact Deutschland with an appropriate response rate to requests.

ABB / Kuka

Very pretentious (deservedly) guys. Which gives rise to the other side of the coin: you can beg for a robot until you blue in the face, even access to the demo room for tests is a huge problem. In this connection, we did not have projects with them.

Universal Robots

A sort of hipster). Nothing is clear, but very interesting. At exhibitions, the robot is endowed with the makings of a hedonist and a glass of cognac is twisted in his paw. And they bravely jump under a working piece of iron, demonstrating its capabilities and their belief that these Roberts cannot kill anyone in principle. But we saw everything in the film ourselves!

Our relationship is still in its infancy, I cannot say something.

This concludes the introductory part. In the second, we will consider the features of two specific vehicles and try to figure out what can and cannot be done with them, and how to take off with it all. Or - a question in the vote - let's talk about the threshold of entry and what a potential robert driver should know / be able to do in order to tie the knot of suffering with this fun business.