Photo: Kihopczmaluoch / Wikimedia Commons

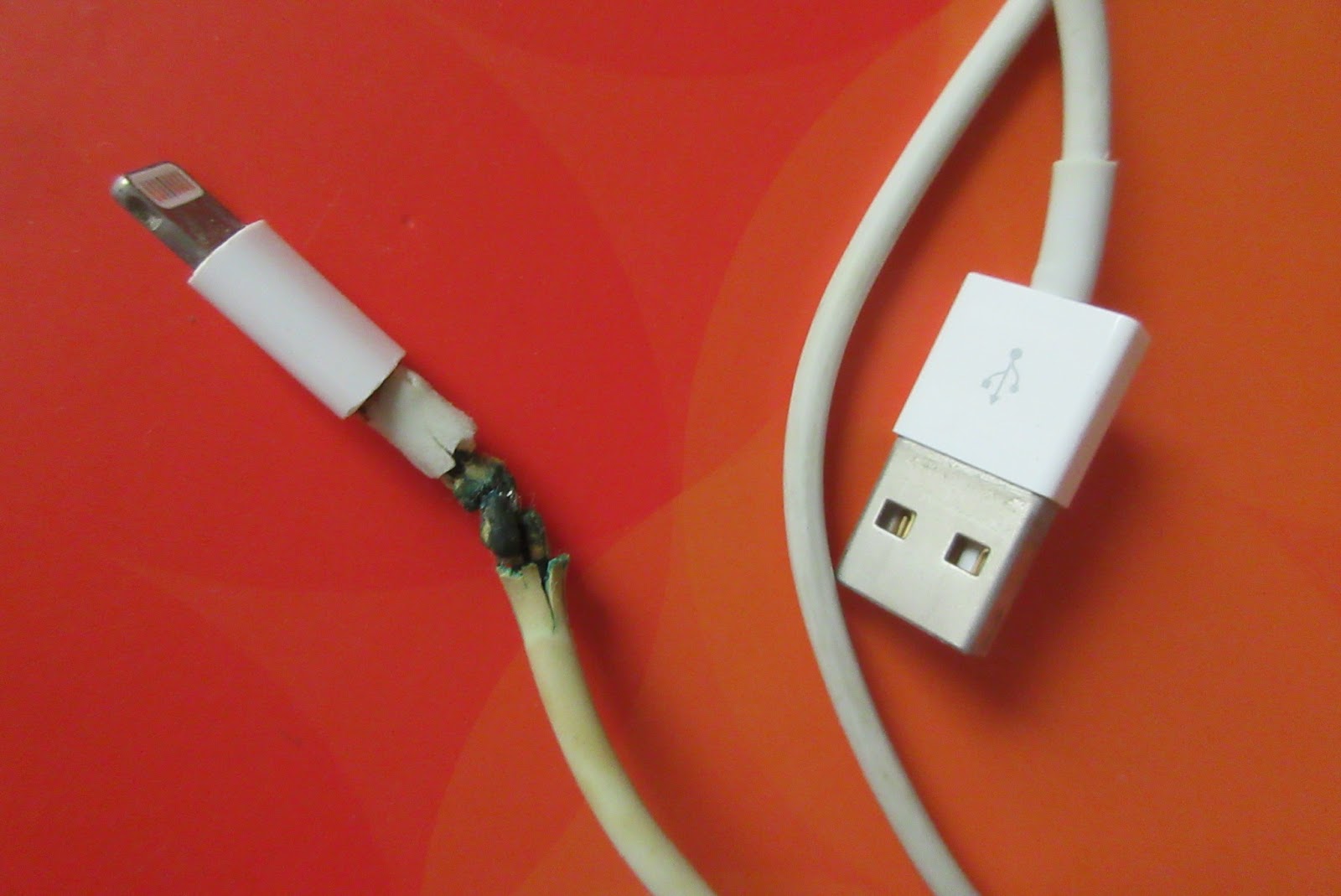

Problems with native cables

Apple users hardly need to be told what the braids of the original charging cables look like. No one is surprised by the proximity of an expensive MacBook Pro or a brand new iPhone for more than a thousand dollars and a cable rewound here and there with electrical tape. The picture is so familiar and ubiquitous that the jokes have already been joked, and 33 different methods have been tried, the people simply resigned themselves.

Photo: Twitter

There is only one official reason for such a wonderful state of insulation - concern for the environment. Apple claims that the polymer is biodegradable, you touched it with not very clean hands, then ultraviolet light and bacteria did their job. There are two solutions - either constantly wipe the cable with an alcohol wipe, or store it like tablets in a cool dry place. Great solution, very convenient. Well at least the new Thunderbolt 3 cable for $ 130 was made with a fabric braid - it won't fall apart in a year.

There are also a few other options - for example, buying once a year wires from Apple (or any other brand that is also “eco-conscious,” creating tons of e-waste). Well, or sponsor Chinese basement production - and take some consumer goods on AliExpress.

Cheap things for the rich

What's wrong with an inexpensive wire? Does it work? If it breaks - a hundred rubles, it's not a thousand - you can buy ten of these and not bathe. From some side, it sounds plausible: well, one inexpensive cable died, threw it into the trash bin, took out a new one from the shelf - anyway, for the sake of free delivery, I ordered a whole box, why suffer. But with cheap wires, there are always some adventures.

First, it's good if it works fine at all. Bought for a penny "basement" Type-C can flaunt textile braiding, metal cases of connectors and even backlighting at the end of the cable ... But they will only work in one of two positions. And it’s good if the “wrong” position of the connector simply will not charge the smartphone, and will not close something in the counterpart of the smartphone. In such a situation, the best thing awaits you - halving the Type-C capabilities of your device, it will also become one-way. The worst option is cosplaying a fun burning Galaxy Note 7 performed by your device.

Secondly, an inexpensive cable made by no one understands and it is not known in what conditions it can be simply unreliable. Modern smartphones charge no longer a measly 5 volts at 0.5 amperes (2.5 W), but up to 30-40 watts in fast charging mode. The manufacturer saved on copper (or even installed copper-plated aluminum conductors) - the conductor got hot - the resistance increased - the temperature rose even higher. It's good if the charger is smart, sees inadequate currents and loses speed out of harm's way. The same applies to fast data transfer, connection of any peripherals and other aspects of non-standard accessory. Double-sided Type-C with USB 2.0 inside is the same classic from AliExpress, like fake product photos.

Another common problem is insulation problems. The cheapest cables often have a polymer braid that hardens and breaks over time - not because of environmental concerns, but because of banal savings and the rapid weathering of plasticizers. And if the "native" cables at least remain flexible and soft, and they are convenient to use, then these ones turn into a fossil twisted in loops forever. And you breathe phenolic compounds. And there are many more such aspects to remember. Among them are unnecessarily long connector housings, which, when dropped, have a large lever and break the connector out of the device's board, or a smart "put aluminum, but thicker" trick - you get a thick cable that is ready to compete with the power cable of a monitor or a system unit in flexibility.

( -) (Apple, Oppo, Vivo, Oneplus). : Anker

The situation is bleak, so it's time to dispel the grief. The fact that the market is a mess and chaos on both sides is understandable. There must be an adequate solution? As is the case with fast chargers, there are manufacturers (we will not name who, although it was Anker

Photo: Anker

The wires have several problems, and each had to be solved separately. It all started, of course, with a braid: something had to be done with the ever-dying isolation. Our first everlasting cable, Powerline +, received a braided aramid fiber shield. It is called by different names, but this material is best known under the patented Kevlar brand. Used to make body armor. By themselves, aramid threads are not capable of stopping a bullet, but they can withstand an enormous breaking load. You can make fabric, stack many layers, and voila - all the kinetic energy will go to overcome many heavy-duty threads, and not to hit the target. The cable was so strong that one blogger was even able to tow a car with it. And then charge your smartphone.

However, aramid fibers also have disadvantages: they lose strength due to water and gradually degrade at high temperatures. For body armor, this is not a problem: it is not difficult to protect the fabric from liquids, and after contact with a bullet, the vest is still scrapped. But for a power cable experiencing constant and regular heating ... In general, the braid required a material that was more flexible in characteristics and resistant to impacts. I had to spend time and money on researching high-density polyethylene: to modify it in such a way that it would not be afraid of high temperatures, withstand bending and tearing loads well, while not being "oak" and not absorbing dirt.

The result was Powerline + II and Powerline + III cables, and while the Powerline + was strong but relatively thick, the improved version provided comparable performance with a noticeably slender figure: the diameter was reduced by almost a third. In addition, the increased density of the material protects the cable from contamination and simplifies its cleaning - the absence of microcracks and resistance to ultraviolet radiation allows the braid to maintain its structural integrity for a longer time and does not "store" dirt inside. In addition, such a cable holds bending loads much better - ultra-dense polyethylene does not tear even after 30,000 bends in one place.

Photo: Anker

After solving the problems of "packing" the conductor, the rest was a matter of technology: introduce a quality management system, set up input and output control of products, organize a system for testing and testing finished cables.

The final step is obtaining certificates of conformity from vendors. The most famous program is Apple's MFI (formerly called Made For iPod, then the name was shortened): MFI-certified Lightning chip cables are in no way limited by the iOS operating system either in charging currents or in data transfer rate, and work exactly like the original ones, only much longer if designed and manufactured to last.

Anker is the first third-party accessory company to receive such certification for the new Type-C ← → Lightning cable.

Original does not mean quality, and unoriginal does not necessarily mean bad

Obviously, the two extremes (the expensive original and the cheapest copy) have opposite qualities. The factory solution works well (albeit not very long, in the case of Lightning and other cables from Apple), inexpensive - it is sold on every corner, but it performs its functions nominally (or does not). For some reason, many people forget about the third option - top solutions from companies whose business is built around power supplies and chargers. What is strange: who, if not the creator of a more powerful and compact charger than the one that is put in the box with the device, provides the same high-quality delivery of electricity to the gadget?

A non-original power cable can be in no way inferior to the factory one and even surpass it in a number of qualities - you just need to choose high-quality models that have received all the necessary certificates and have passed strict control by the manufacturer.