We have already covered the main dispensing system in full .

Today we will consider the design features of the diffuser and throttle valve.

Most motorcycle carburettors are based on a variable diffuser and metering needle. The diffuser section is controlled using a cylindrical or flat throttle valve. The throttle valve is arranged with a metering needle. It turns out that the regulation of the fuel supply is carried out simultaneously with the change in the diffuser section. For more information on section control, see this publication.

Diffuser capacity

The diffuser is one of the main elements of the carburetor. The defining parameters of a diffuser include its diameter. The choice of diameter is strictly dependent on the requirements for the engine. The numerical values of the diffuser diameter and other important parameters are initially determined based on engineering practice and experience in designing various motorcycles and engines for them. The final selection of the diameter is carried out during tests on the engine.

For example, small-volume two-stroke engines used on mopeds and scooters are equipped with carburetors with a diffuser diameter of 12 to 14 mm. The 125cc sports engines use diffusers with a diameter of 36 to 40 mm. On racing engines with spool valve timing, you can find carburetors with an even larger diffuser. This tendency is due to the fact that the diameter of the diffuser determines the maximum throughput of the main air channel, i.e. - maximum filling of the cylinder. The more power is supposed to be developed, the larger the diffuser should be, since it will offer less resistance to the mixture flow.

However, the large diameter of the diffuser makes the engine less responsive, as it worsens fuel atomization at low and medium loads. For engines operating over a wide rpm range, throttle response is more important than maximum power. In this case, carburetors with a small diffuser are used, which improves the fuel flow due to a higher vacuum.

To increase the throughput without changing the diameter of the diffuser, special inserts are used to exclude a step change in the cross section along the path of the air flow, thereby reducing parasitic eddies.

Diffuser shape

After determining the cross-sectional area, it is necessary to determine the shape that this area will be limited to.

For sports and other high-performance engines in which maximum power is paramount, a round shape is preferred. A circle is a figure with the smallest perimeter among other figures of the same area, therefore the walls of a circular diffuser provide the least resistance to air flow.

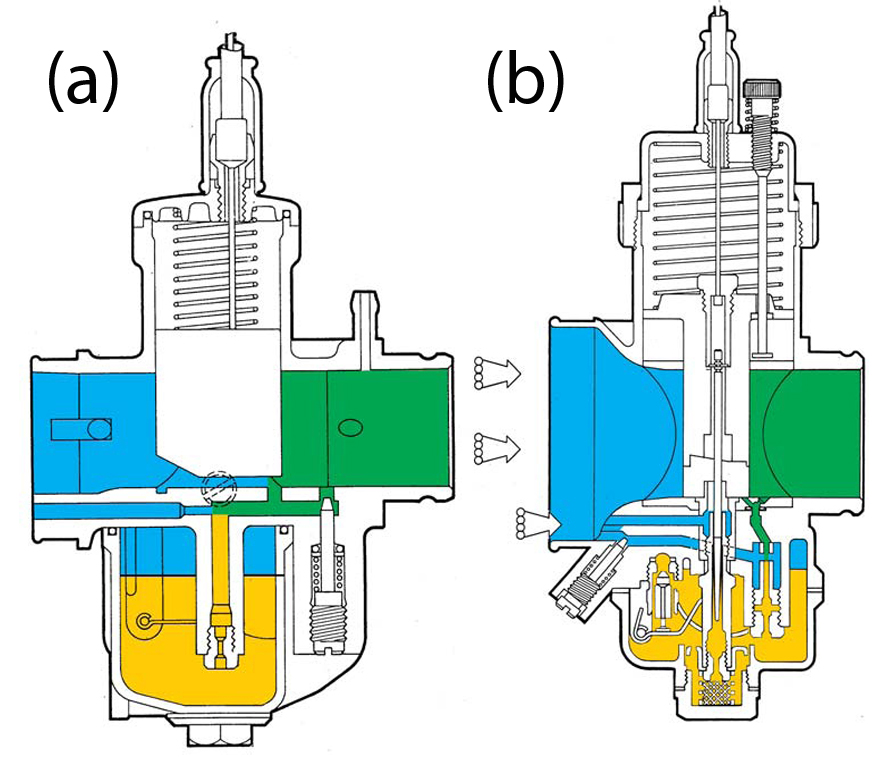

On engines where smooth power control is important, carburetors with an oval diffuser section are used. There are also more complex shapes, for example, the shape of the "shield", as the engineers called it Dellorto - a further evolution of the oval shape.

Diffuser shapes: a - oval shape, b - shield shape

As already mentioned, with a small diffuser diameter, the engine has better throttle response by maintaining a high air velocity in the carburetor. At low throttle lifts, the oval profile forms a smaller cross-section. In this case, the carburetor works as if it has a smaller diffuser than it actually is. Shield-shaped carburetors at low inclines have an even smaller cross-sectional area compared to a simple oval. This makes the engine even more responsive to throttle position changes, which is very important for some engines with automatic transmission.

The complex shape of the diffuser makes it possible to improve the quality of the mixture in unsteady modes, without deteriorating the filling of the cylinder with a fully open throttle, since at full lift the area increases to the maximum power calculated for the mode. In addition, the sophisticated diffuser shape allows for a wider operating range and makes power management more predictable for the driver.

Thus, it can be argued that the filling capacity of the cylinder is mainly determined by the diameter of the diffuser and the shape of its section (both in the transverse and in the longitudinal plane). Also, the filling capacity is influenced by the shape of the carburetor inlet and the geometric parameters of the mixing chamber.

Throttle valve

The throttle valve is a regulating element of the carburetor, connected to the gas control by means of a flexible connection. It regulates the flow area of the diffuser moving perpendicular to the axis of the main air duct. In many carburetor models, the throttle valve is a cylinder that slides into the body of the carburetor.

Even in carburetors with a constant vacuum (in the literature there is a term - with a constant flow rate), in which the throttle valve makes rotational movements, there is a valve that regulates the cross section by moving perpendicular to the diffuser axis. The design and principle of operation of such carburetors will be discussed later, since their features deserve a separate section.

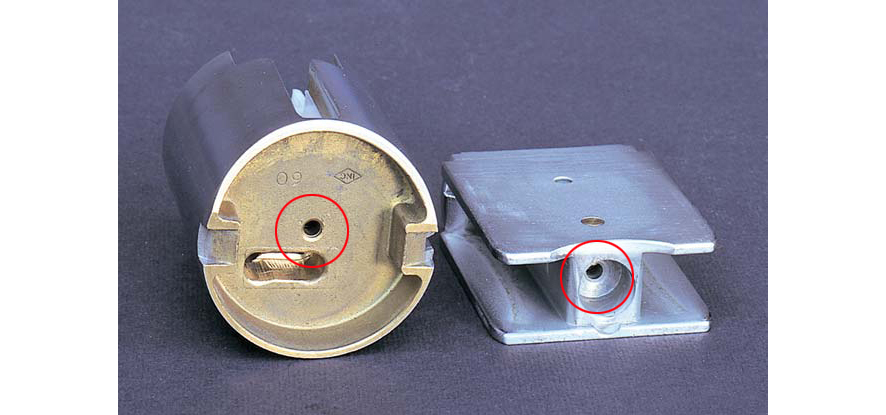

Throttle valves are classified according to their shape into cylindrical and flat (they are also called gate valves - the term is appropriate, since in accordance with GOST 24856-2014 "Pipeline valves. Terms and definitions" a gate valve is defined as a "parallel the form of a plate "). The figure below shows a comparison of the sizes of round and flat damper. A flat throttle valve creates less parasitic turbulence underneath by reducing the length of the diffuser.

General view of round and flat throttle valves. The color highlighted guide holes for the metering needles in the center of the flaps.

The following figure shows the difference in the lengths of the main air passages when using a round and flat damper. It can be seen that in a carburetor with a flat throttle valve, the channel is shorter, which means that the resistance to air flow is less.

Comparison of the lengths of the main air passages with cylindrical and flat valves The

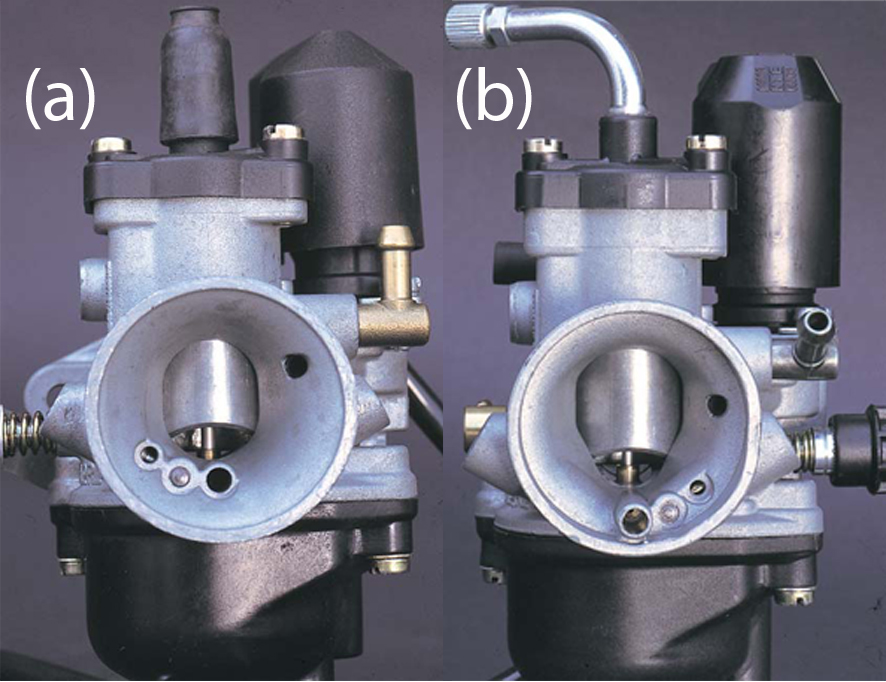

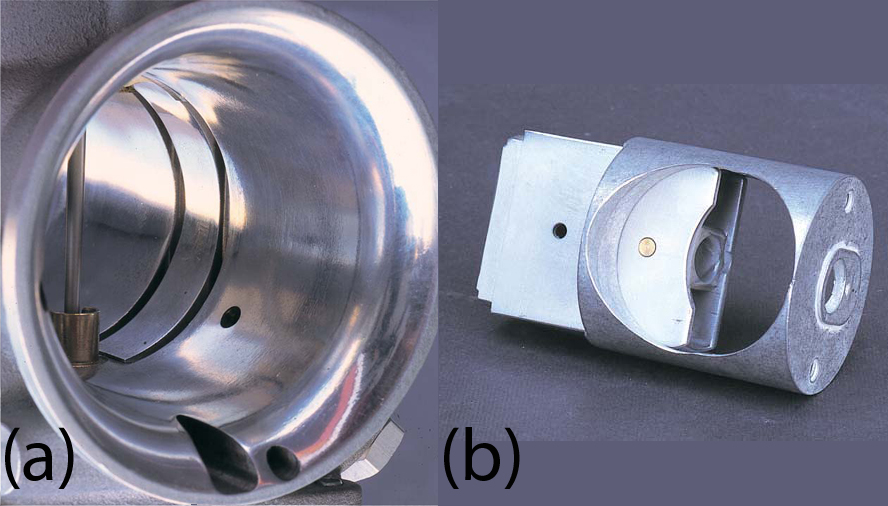

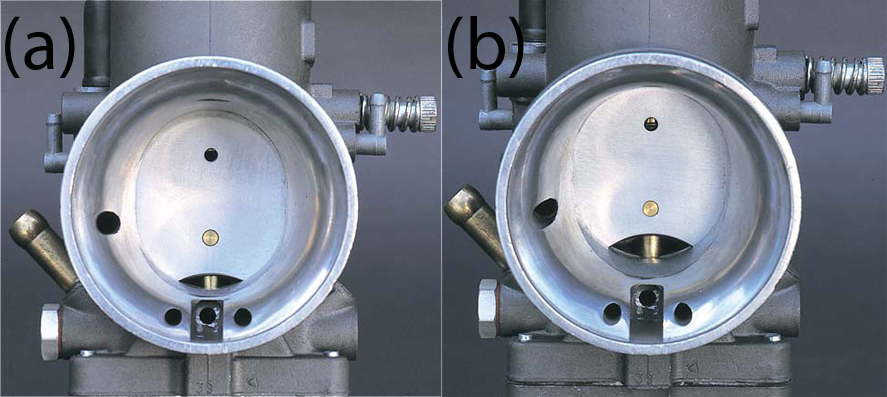

diffusers of modern carburetors are carefully designed to reduce parasitic turbulence at the interface of the throttle valve with the carburetor body. For example, in the picture below, under the letter adepicts a Dellorto carburetor of the VHSD series (For example, the designation PH in the Dellorto series of carburetors stands for P (Piston) - a cylindrical throttle valve, H (Horisontal) - the horizontal orientation of the longitudinal axis of the main air channel. The letter V (Valve) in the name of other lines (for example VHSD ) indicates the presence of a flat throttle valve), in the diffuser of which two thin guide grooves are visible along which the throttle valve moves like a guillotine.

And the figure under the letter b shows the throttle valve of the VHSB series carburetor, installed in a special "cup" that serves as a guide for its movement. The damper assembly with the cup is installed in the cylindrical seat of the carburetor body.

a - throttle body guides, b - throttle body guide cup.

The throttle valve of carburetors with a metering needle, both flat and cylindrical, has a bevel, which affects mixture formation at low throttle rises. A slightly chamfered damper enriches the mixture up to 1/4 throttle lift, but if the mixture is too rich, you can use a damper with a large chamfer. It should be borne in mind that even a small change in this control parameter can significantly affect the mixture formation.

Throttle valves with different bevel

Parasitic Effects

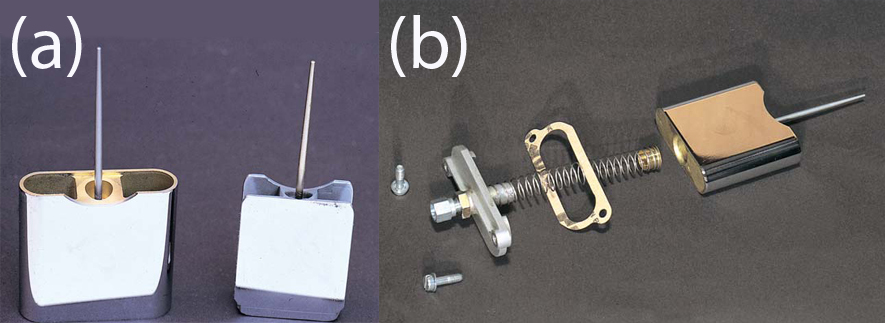

In carburetors of four-stroke engines, the throttle valve sticking effect can be observed when closed due to the very strong down-pressure of the low pressure in the intake tract. To reduce this effect, as well as to prevent rapid wear, leading to parasitic air inflow, the surface is chrome-plated to increase hardness and smoothness (picture below under letter a ).

This same effect forces the use of very stiff return springs to ensure that the throttle valve is closed. However, since the spring rate determines the force on the throttle grip from the driver's side, efforts should be made to minimize friction between the damper and body. For example, in the picture below, under the letter bintroduced the chrome-plated VHSD sport carburetor spring-return throttle body. It can be seen that a spring of very modest size is used, but its effort is quite sufficient to close the throttle, since the chrome coating of the damper significantly reduces friction against the body.

a - chrome-plated throttle bodies, b - spring return throttle body

We have previously noted the advantages of a flat throttle body, but it is not without its drawbacks. A flat throttle valve introduces difficulty in the idle air via. This hole (holes) is necessary for supplying fuel at the moment when the low idle speed hole can no longer supply the required amount of fuel, and the main metering system has not yet been put into operation. In the technological cycle of manufacturing the carburetor, these holes are drilled after processing the main fuel well and, for proper functioning, are located slightly beyond the edge of the throttle valve. With a flat orifice, the holes are very close to the nozzle, which complicates the layout. Despite this, flat choke carburetors are the most advanced in their design.

To be continued...