Modern hard disk drives (HDDs) in an interesting way combine the culmination of precision engineering in mass production and the most despised storage technology. Despite such unflattering nicknames as "spinning rust", most disks manage to rotate extremely smooth magnetic plates a few nanometers from the recording and reading heads throughout their lives. The brackets of the latter, in turn, pull the solenoids, capable of positioning the head exactly over the microscopic magnetic track in a few milliseconds.

Despite the fact that for many decades more and more of these magnetic tracks have been crammed into one square millimeter of platters, and the read and write heads are constantly being replaced with more and more complex ones, the reliability of hard disk drives is constantly growing. In a second quarter 2020 report from storage company Backblaze, it is clear that the annual failure rate of their hard drives has decreased significantly compared to last year.

The question is, does this mean that hard drives will become even more reliable over time, and how new technologies like MAMR and HAMR can influence this process in the coming decades.

From mega to tera

Internal mechanism and its fifty 610 mm platters. IBM 350

HDDs The first HDDs were sold in the 1950s. The IBM 350 had a storage capacity of 3.75 MB and had fifty 24 "(610 mm) discs in a 152 x 172 x 74 cm cabinet. Today, the most advanced hard drives in the 3.5" (14.7 X 10.2 x 2.6 cm) can hold up to 18 TB using conventional (non- tiled ) recording technology.

The cymbals in the IBM 350 were spinning at 1200 rpm. New HDDs focus on reducing insert size and increasing spindle speed (5400 - 15,000 rpm). Other improvements include placing the read and write heads closer to the platter surface.

The 1961 IBM 1301 DSU (Disk Storage Unit) was a significant innovation - it used separate brackets with read and write heads for each of the platters. Another innovation used aerodynamics - the heads were in free flight above the surface of the plates, supported by an air cushion, which made it possible to greatly reduce the distance from them to the surface.

After 46 years of development, in 2003 IBM sold its HDD business to Hitachi. By that time, the capacity of the disks had increased 48,000 times, and the volume had greatly decreased. 29 161 times. Power consumption fell from 2.3 kW to 10 W (desktop models), and the cost per megabyte fell from $ 68,000 to $ 0.002. At the same time, the number of plates decreased from tens to a maximum of a couple.

We store more data in less space

Internals 1 ″ Seagate MicroDrive

Miniaturization has always been the primary goal of all fields - be it mechanics, electronics or computing. The giant tube or relay computer monsters of the 1940s and 1950s evolved into smaller transistor systems, and then into modern, slim ASIC wonders. Storage technology has undergone the same changes.

The drive electronics of HDDs have experienced all the benefits of the increasing popularity of VLSI circuits, as well as the ever increasing accuracy and power consumption of servos. The density of recording per unit area increased with the development of materials science, thanks to which less and less heavy and smoother plates (glass or aluminum) appeared, and the quality of the magnetic coating improved. As we got better at understanding the properties of individual components (ASIC cases, solder alloys, solenoids, bracket aerodynamics, etc.), revolutions were gradually replaced by incremental improvements.

Six open hard drives ranging in size from 8 "to 1"

Although they tried to approach extreme miniaturization of hard drives already twice (1.3 "HP Kittyhawk microdrive in 1992 and 1" Microdrive1999), eventually the market settled on 3.5 "and 2.5" form factors. The Microdrive form factor was touted as an alternative to CompactFlash cards that used NAND Flash technology - an alternative with higher capacity and virtually infinite rewrites that was well suited for embedded systems.

As in other areas, physical limitations on write speed and random access time make hard drives most useful where large amounts of storage are important for little money, as well as high reliability. As a result, the HDD market was optimized for desktop and server computers, as well as for video surveillance and backup purposes (competing with film).

Understanding the reasons for hard drive failure

Although it is generally believed that the weak point of hard drives is their mechanical parts, various reasons can be to blame for failures, namely:

- Human error;

- Equipment failure, both mechanical and electronic;

- Damage to the firmware;

- External factors (heat, humidity);

- Nutrition.

HDD is assigned the value of permissible physical impact when the power is turned off or during operation (when the plates are spinning, and the heads are not parked). Exceeding this value may damage the solenoids that move the arms, or the head may hit the plate surface. If these values are not exceeded, then the main reason for failure will be natural wear and tear, the degree of which is determined by the number of MTBF (Mean time between failures, " mean time between failures ").

MTBF is derived by extrapolating from observed wear over time. The MTBF for a hard disk drive is typically 100,000 to 1 million hours, and to test the drive's performance over this entire period, it would have to stay on for 10 to 100 years [not quite -here is a more correct explanation / approx. transl.]. This number assumes that the hard drive is operating under the recommended conditions.

Obviously, subjecting the hard drive to sharp shocks (dropping it on a concrete floor) or power surges (power surges, electrostatic discharges) will shorten its life. Less obvious are manufacturing defects that can be found on any product, so most products have an “acceptable failure rate”.

It's not about you, it's about the production line

Despite the strong MTBF and the apparent effort by Backblaze to make sure its 130,000 hard drives are spinning happily for life and then into hard drive heaven (usually through a metal shredder), Backblaze reported that in Q1 2020, the annual probability of failure (AFR ) was 1.07%. Fortunately, this is the lowest number for the company since it began publishing reports in 2013. For example, in the first quarter of 2019, the AFR was 1.56%.

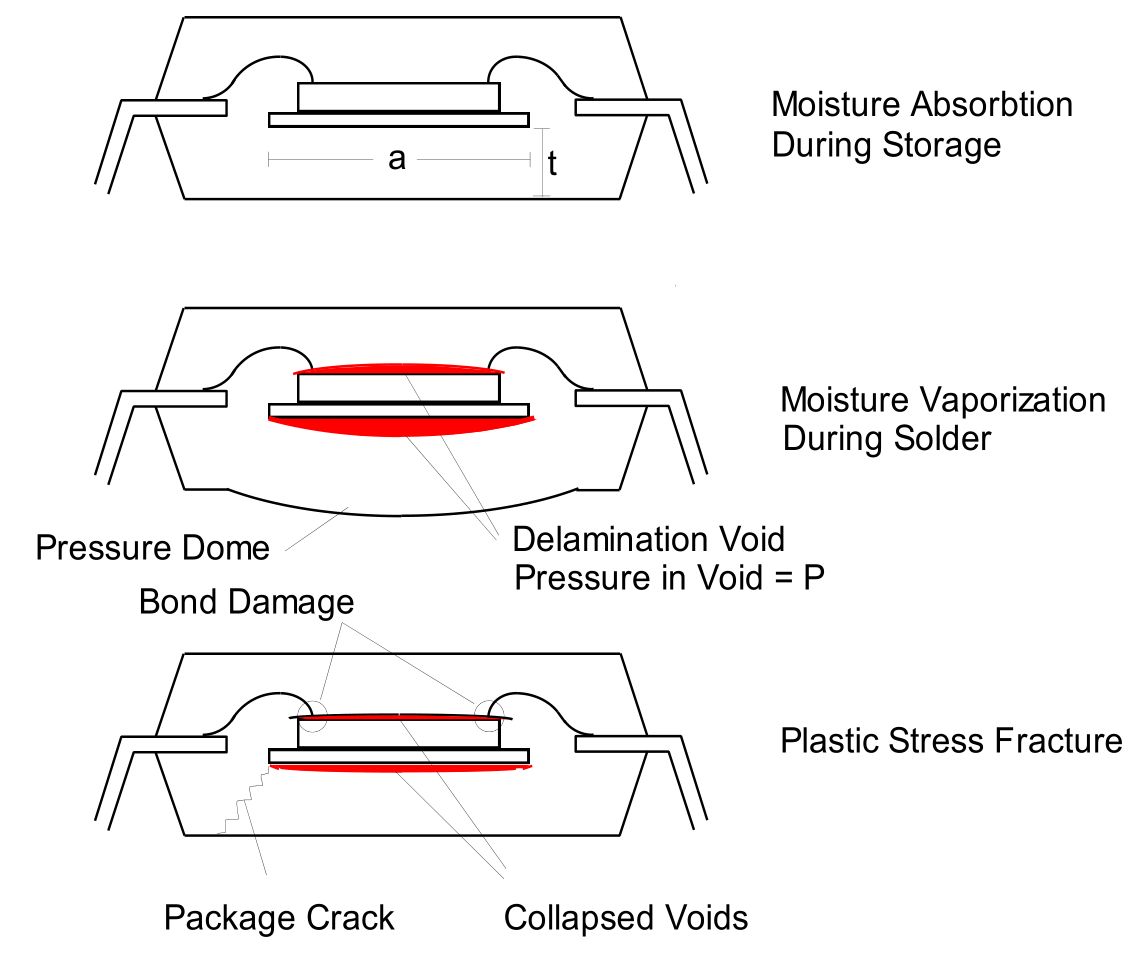

As we have already mentioned, during the production and installation of integrated circuits , flaws may appear , which will manifest themselves already during the operation of the HDD. Over time, things like electromigration, heat and mechanical stresscan cause circuit failures, from bursting wires inside the IC package, to wear on solder points or circuits inside the IC due to electromigration (especially due to electrostatic discharge).

The mechanical components of HDDs are subject to precision engineering tolerances as well as proper lubrication. In the past, there may have been a problem of head sticking where the properties of the lubricant changed over time until the brackets lost the ability to move out of the parked position. Today, improving lubrication has more or less solved this problem.

Yet at every step of the manufacturing process, there is a possibility of flaws that eventually accumulate and can spoil the beautiful shiny MTBF, putting the product on the bad side of the bounce rate graph (shaped like a " bath "). This curve represents an early peak in the failure rate due to severe manufacturing defects, after which the failure rate drops until the graph approaches the end of the device's lifetime.

Looking ahead

Today's hard drives clearly reflect how mature the production process has become - many of the old problems that have plagued them over the past decade have been resolved or circumvented. Some major innovations, such as the move to helium-filled drives , have not yet yielded significant gains in efficiency or reliability. Other changes, such as the transition from PMZ, perpendicular magnetic recording , to HAMR, thermomagnetic recording, should not greatly affect the life of the hard disk drive, except for any problems associated with the technology itself.

In fact, the future of hard disk drive technology seems dull for anyone who loves high-volume storage for little money, which should last at least ten years. The basic principles of hard disk drives, that is, storing magnetic orientations on a wafer, can be transferred even to individual molecules. Innovations such as HAMR should increase the long-term stability of these magnetic orientations.

This is a huge advantage of HDDs over NAND Flash, which uses small capacitors to store charges, and a write method that physically damages them. There, the physical constraints are much more severe, and they have led to more complex designs, such as four-level cell (QLC) flash memory, which has to distinguish between 16 different voltage values in each of the cells. This complexity has meant that QLC-based drives are barely faster than 5400 RPM hard drives in many cases, especially when it comes to latency.

Slow down rotation

The first hard drive I used in my own computer was a 20 or 30 MB Seagate in the IBM PS / 2 (386SX), which my father gave me after they switched to new PCs at work - apparently, they needed to free place in the warehouse. In the days of MS-DOS, this was enough for the OS, a bunch of games, WordPerfect 5.1, and much more. By the end of the 90s, it was already a ridiculous volume, and when it came to hard disk drives, we were already talking about gigabytes.

Despite the fact that since then I have changed many PCs and laptops, so far only solid state drives are dying. This, as well as the industry indicators - like those reports from Backblaze - give me confidence that the new hard drives will spin for a long time. Perhaps, when 3D XPoint memory becomes cheap and large enough, the situation will change.

Until then, spin yourself.