The article will focus on the use of machine learning and computer vision technologies in the mining industry of our country.

In my humble opinion (an employee of one of the enterprises of the mining and metallurgical industry), IT solutions in the field of mining transport and processing plants froze at the level of automation of the main, key technological processes. Now, in the third decade of the 21st century, the time for optimizations and improvements has come for large enterprises, the time for the introduction of new technologies of machine learning and technical vision. And this work has already begun.

Introduction

According to Wikipedia, there are 26 mining enterprises in Russia (there are actually more of them). The largest and most famous of them are: Alrosa, Norilsk Nickel, RusAl, Polyus and others. All of them are united by a similar device and organization of key technological processes: there is a place for the extraction of minerals (quarry), as well as a processing plant (plant).

Redistribution of the GTK (mining and transport complex) is more or less the same for everyone: ore from the quarry is transported either directly to the factory, or to the ore warehouses, and from there to the factory. Empty overburden is stored in dumps. Transportation can be carried out both by heavy-duty dump trucks and conveyors, or by combined methods. Delivery by rail, it seems to me, is not widespread in our country, in contrast to Australian companies.

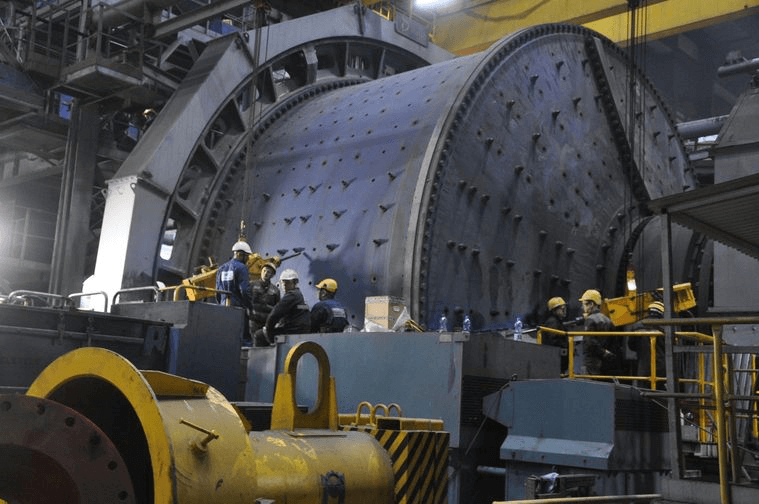

Factories vary widely from company to company. However, some branches are similar. For example, the task of the ore preparation department at all factories is to grind the ore to acceptable fractions. This is done with the help of crushers and mills (by the way, this is most often the most expensive operation in factories).

Further, depending on the type of ore and the mineral, different beneficiation approaches are applied. For example, diamond mining uses its unique property - luminescence (glow) in X-rays, which allows simple pneumatics to "shoot" diamonds from the crushed ore stream. For gold mining, chemical processes are used (flotation, sorption and desorption, electrolysis) and even biotechnology (specially removed bacteria that help the gold to be released from the shell). And for the production of aluminum from alumina, the basis of everything is electrolysis.

Current trends in the State Customs Committee

So, as we understood, at the redistribution of the mining and transport complex, the main task is to overwhelm, blow up and transport the rock mass from the quarry. A fleet of drilling rigs, heavy-duty dump trucks and excavators is engaged in this.

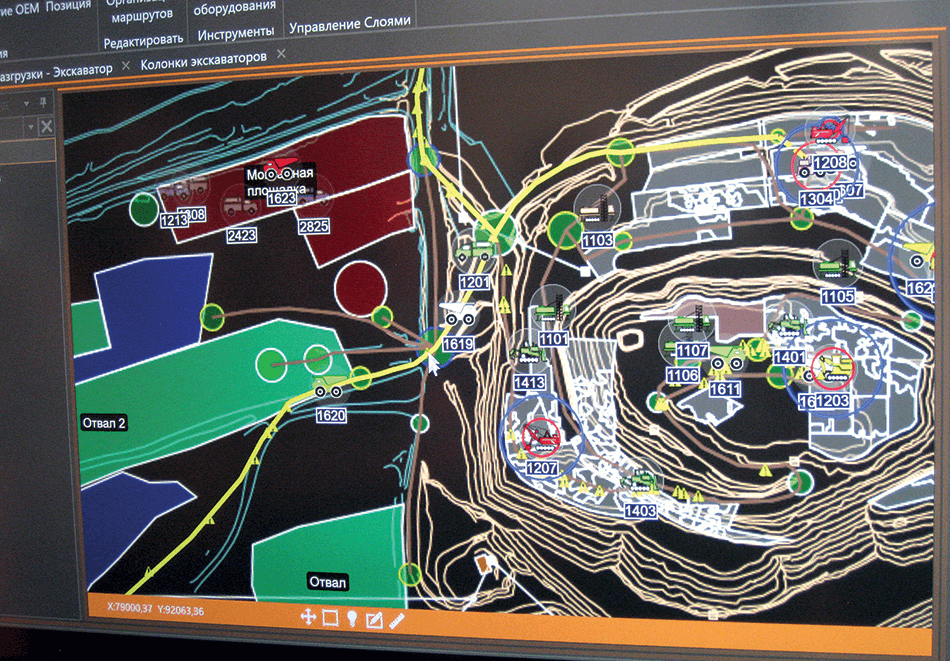

Control over a large number of equipment (sometimes parks can number 400 or more units) are carried out by dispatchers and operators using the automated control systems of the mining and transport complex. The tasks of the ASUGTK systems are to control the operating parameters and the state of mining machines, control and manage the loading of dump trucks, predict and monitor the implementation of the plan, provide reporting, and sometimes - in the optimization and dynamic distribution of dump trucks along routes.

But all this is already yesterday. Today point applications of machine learning and technical vision systems are becoming relevant.

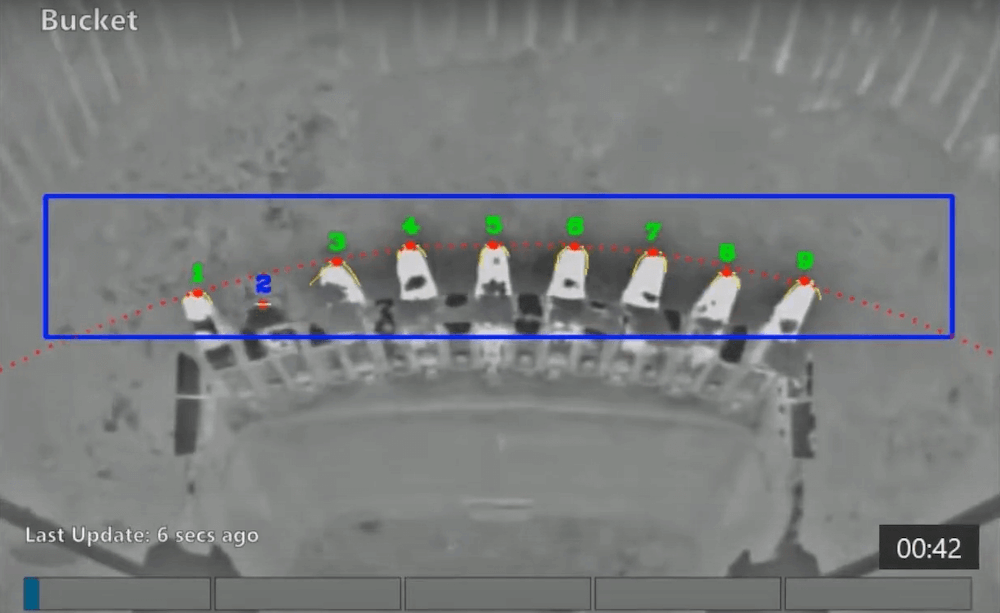

Analysis of the condition of the bucket teeth of a mining excavator

Parts of mining equipment, in particular the bucket teeth of a mining excavator, operating in the harsh conditions of rock excavation, are constantly exposed to so-called. shock and abrasive wear. At the same time, the loss of a tooth is fraught with troubles: starting from a decrease in the performance of the excavator during scooping, damage to the bucket itself, and ending with such a tooth getting into the crusher after transportation. As a result, the risk of significant material losses increases: prolonged downtime of equipment, restoration and repair, the need to extract a tooth from a grinder by a person (a rather dangerous event).

To solve these problems, solutions based on technical vision are applied. Here's an example of such a system. The system analyzes the frames and constantly determines the condition of the bucket teeth and the degree of their wear.

At night, a spotlight is used. Surveillance cameras provide the operator with a view on all sides of the excavator: all information collected by the system is displayed on a monitor in the operator's cab and allows you to detect missing teeth in time, assess the bucket payload and the degree of tooth wear.

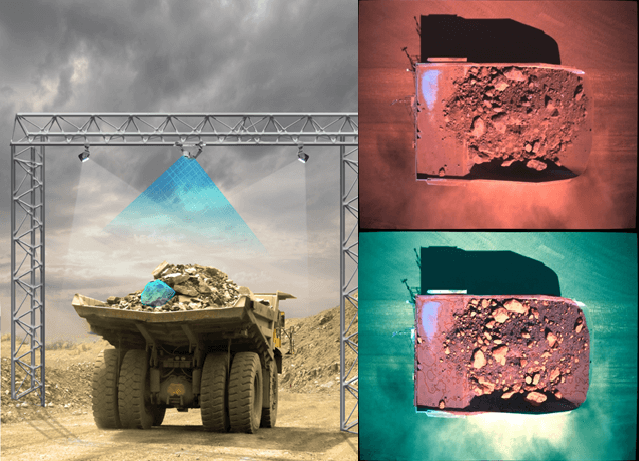

Control of gran-composition of transported ore

The particle size of the rock mass must be controlled at almost every stage of production: after explosion, during transportation, when ore is supplied to the factory, after crushing, after crushing. This is the most important indicator that is monitored, since the quality and continuity of technological processes depends on it: from the quality of the explosion to the possible backfilling (clogging) of the equipment.

At the GTK redistribution, technical vision systems are used to automatically measure the grain size of ore. They can track the particle size distribution of each truck on the way to the crusher and make recommendations for the removal of oversized material.

It looks like this:

Control of driver fatigue

Yes, in a career, drivers also work many hours. At the same time, they drive heavy 60 to 450 ton dump trucks. Shifts often last 12 hours with a single regulated break for lunch and personal needs. Accidents in the quarry are also dangerous by the fact that falls from ledges almost certainly end tragically, and as an additional nuisance - the likely blocking of exit for other cars.

Quote from the article :

According to the statistics for the company [author: Alrosa] for 2019, the main causes of accidents were the driver falling asleep while driving, distraction from driving and loss of control over its movement.

Naturally, driver fatigue monitoring systems have not bypassed mining companies either. Such systems are being actively implemented and used to prevent falling asleep while driving. In addition, they are able to collect and transmit data about the driver's condition and his actions to the operator. A device that looks like a video recorder is installed in the cab of the car. The software reacts to the driver's facial expressions, head turns and eye movements. When the metrics begin to indicate that the driver is falling asleep or distracted from control, a sound signal is emitted. After that, the driver must turn his gaze to the road and confirm his condition by pressing a button.

Autonomous technology

As far as I know, in Russia at the moment there is no practical industrial application of the technology of autonomous quarry transport, but I really wanted to mention it in the article. I may be wrong, but based on my own experience, as well as the experience of "colleagues in the shop", I can say that the modest attempts to implement such systems known to me have stumbled upon a harsh reality. Here's an interesting article from 2019.

BelAZ has been testing unmanned vehicles for a long time. However, behind the loud newspaper headlines "Career monsters will leave drivers without work: BelAZ showed completely autonomous special equipment", "They are not just with an autopilot, but with artificial intelligence", there is a sad reality: there are no large-scale implementations, although articles with such headlines are published consistently once every year last 5-6 years.

For example, here's the 2018 issue:

However, remote control is widespread. But these systems are not related to ML and CV.

Problems of introducing new technologies

In conclusion, I would like to touch on the topic of problems that stand in the way of introducing machine learning technologies at Russian enterprises of the mining and metallurgical industry. Unfortunately, these problems are often not technical in nature. Working in one of these companies, I can identify the following types of obstacles on our way to a brighter future: lack of competencies, lack of motivation, overestimation of ML and CV capabilities, organizational barriers.

A detailed analysis of these problems will draw on a separate article, so we will not delve into the details of the mentality of Russian managers and effective managers.

Of course, the ML and CV systems listed in the article are not all that are used today in mining enterprises. Improving efficiency and productivity is a long process, especially in the context of well-established work processes and under the guidance of “effective managers”. According to my subjective assessment, Western and Australian companies are 5-10 years ahead of us, and the high margins of Russian companies are due to completely different reasons, but this, again, is a topic for another story. It should be noted that with such a development and application of ML and CV technologies in industry, as in the West, specialists in these fields will very soon (if not already) be worth their weight in gold, especially those who have practical experience.

PS

Thanks for reading the article. If you like it, feel free to leave your vote and, if the response from the respected community is significant, an article will appear on the application of ML and CV in processing plants.

To make the industry great again and get a demanded profession from scratch or Level Up in skills and salaries, you can take online SkillFactory courses:

- Data Scientist profession with any starting level

- Data Analyst profession with any starting level

- Machine Learning Course

- Advanced Course "Machine Learning Pro + Deep Learning"

- Course "Mathematics and Machine Learning for Data Science"

More courses

- Data Science

- - Data Science

- - Data Analytics

- C++

- Java-

- JavaScript

- «Python -»

- -

- DevOps

- iOS-

- Android-

- UX-

- Web-