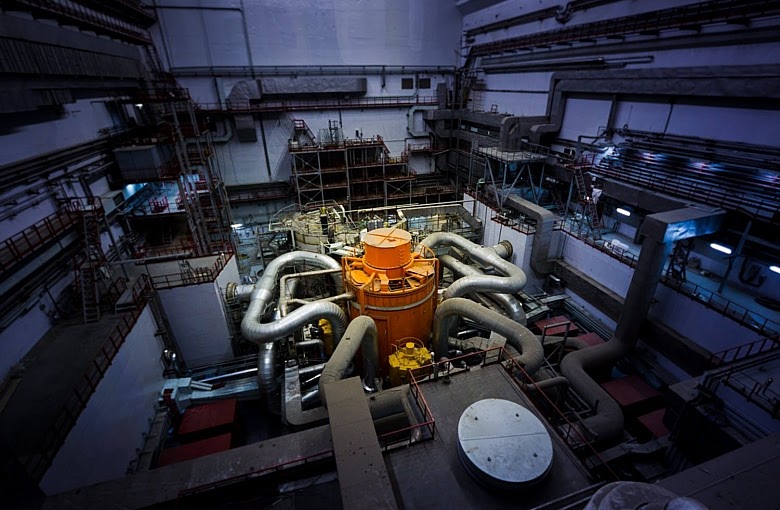

BN-800 at the Beloyarsk NPP is one of two operating fast reactors in the world. Brought to rated power in 2015

Under the cut - a story about the design of classical nuclear reactors on thermal neutrons, the principle of operation of nuclear reactors on fast neutrons (there are only two in the world, and both in Russia) and the closure of the nuclear fuel cycle.

I am sure it will be interesting to those who liked the story about the international construction of the 500 MW ITER thermonuclear reactor .

Our narrator is Aleksey Germanovich Goryunov, Head of the Department and Head of the Nuclear Fuel Cycle Department of the School of Nuclear Technology Engineering from the Tomsk Polytechnic University, who gave a lecture on two-component energy at the Tomsk Boiling Point .

Today's story is about new technologies for the peaceful atom: closing the nuclear fuel cycle and two-component nuclear power.

But let's start with how the nuclear fuel cycle functions now.

Classic fuel cycle

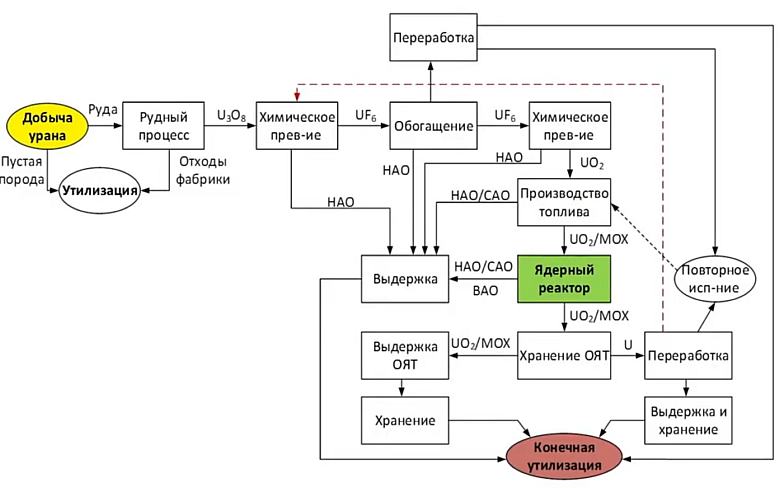

MOX (Mixed-Oxide fuel) - nuclear fuel, contains several types of oxides of fissile materials (usually plutonium and uranium). NAO, SAO, HLW - different types of radioactive waste. SNF - spent nuclear fuel

center of the modern cycle - nuclear reactor on thermal neutrons . It is highlighted in green. The reactor uses uranium enriched in the isotope-235 as fuel. To obtain it, uranium ore is extracted, processed, and then a long and expensive enrichment is carried out.

In large reactors prevailing in nuclear power, such as the pressurized water-cooled VVR-1000 or the channel RBMK-1000, the spent fuel is not reprocessed. It is stored in the reactor cooling pools and then transported to the long-term storage site at the mining and chemical plant.

The basic process of obtaining fuel is expensive, and raw materials are an exhaustible resource, therefore, humanity is tensely solving the problem of closing the fuel cycle - this is when fuel is again produced from nuclear waste. Now this scheme exists only in a small segment of nuclear power - in transport and research reactors.

Let's now look at the design of modern reactors.

Thermal nuclear reactors

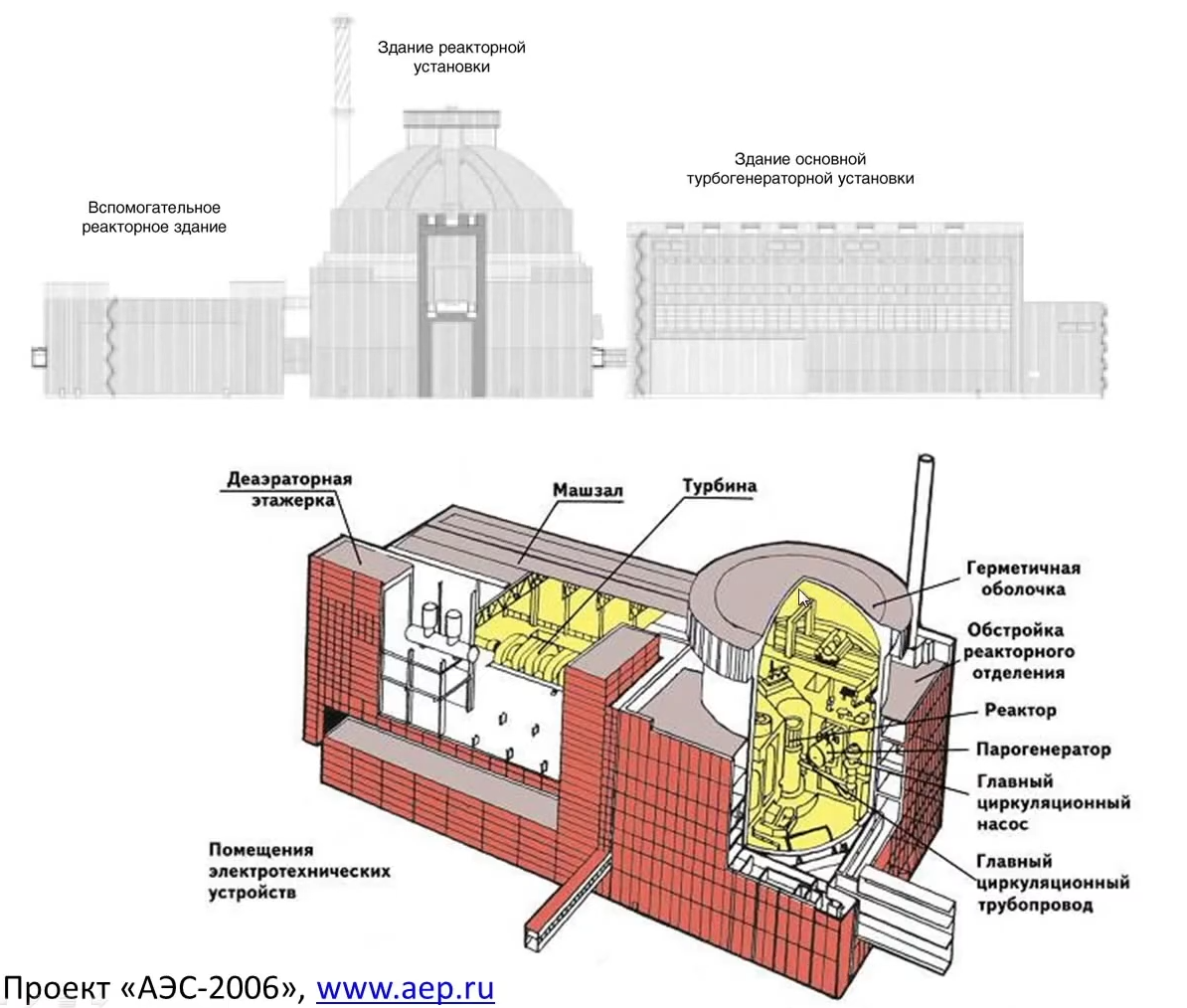

A nuclear power plant with a thermal neutron reactor can be schematically represented as follows:

Further we will talk about the so-called nuclear island, which includes the reactor part. Consider which reactors are currently in use and which may be launched in the near future.

Conventional diagram of a nuclear power plant A

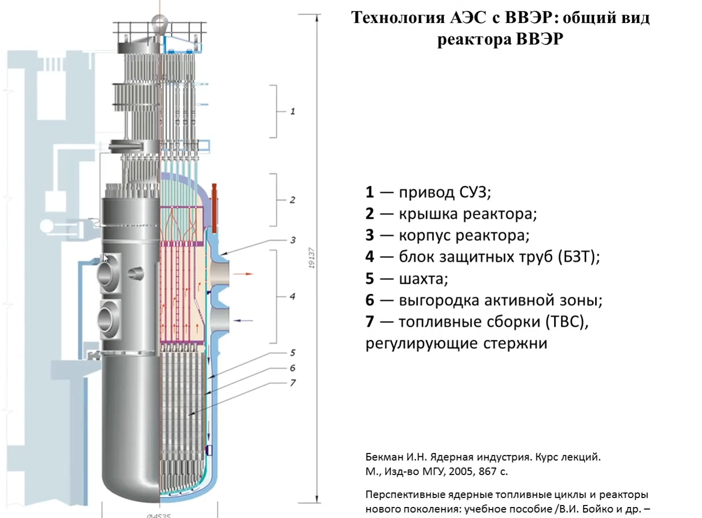

reactor is a device in the core of which a controlled self-sustaining chain reaction of fission of heavy elements, in particular uranium-235, is carried out. Today, the most common water-to-water power units. The picture shows a diagram of just such a reactor.

Conventional diagram of a power plant with a pressurized water reactor

The reactor is located in a protected building and adjoins a separate building where traditional power units are located - the turbine hall and others that are in conventional heat power plants.

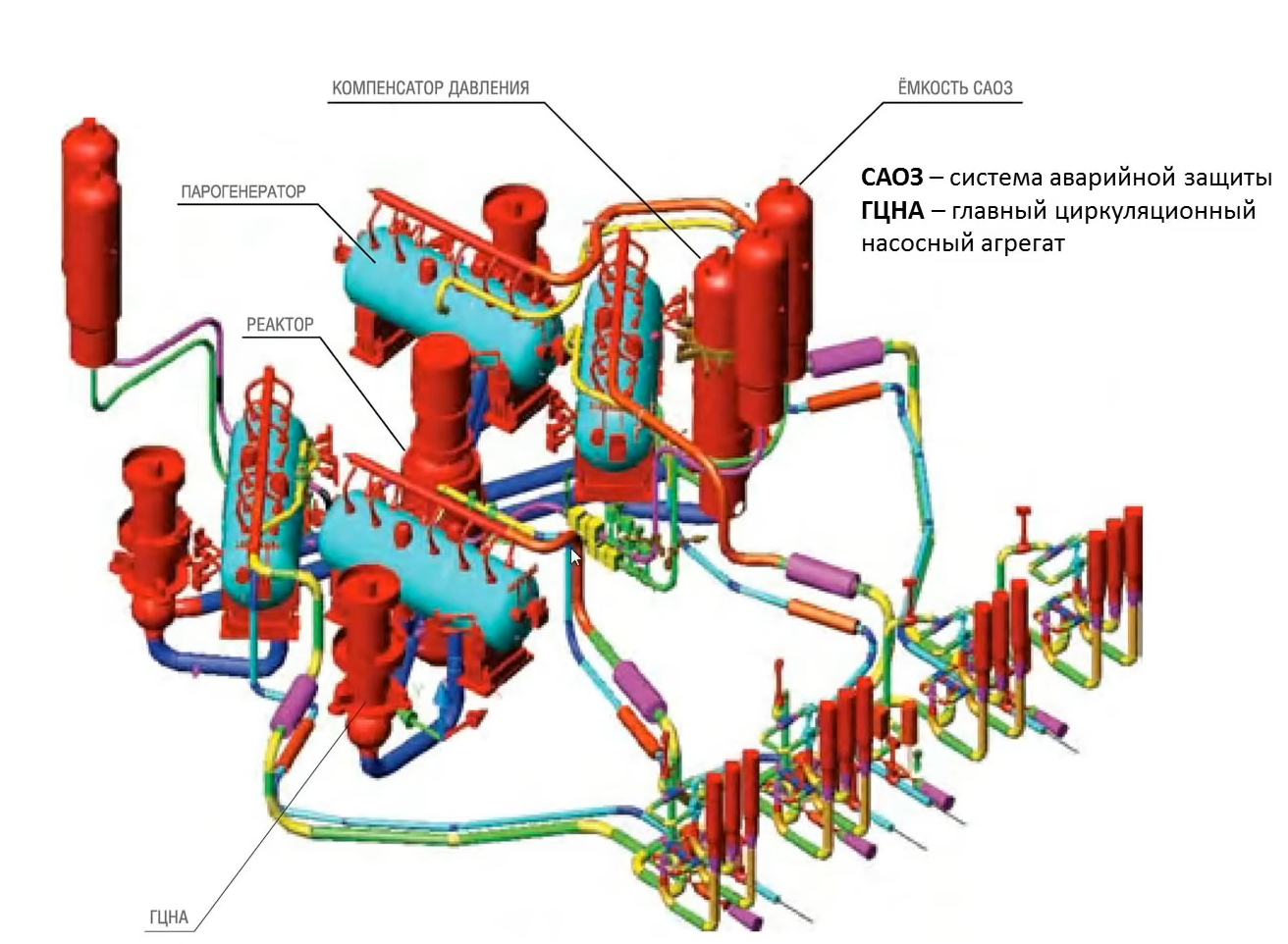

Typically, reactors use four cooling strands to improve reliability. The first reactor cooling loop includes the reactor itself, as well as the main circulation pumps. Their number corresponds to the number of cooling threads - four. A steam generator is installed on each of the cooling strands, which separates the first loop of the reactor from the second one, which contains the coolant entering the traditional island.

Power plant with a VVR reactor

General view of the reactor itself:

It should be noted that this is a pressure vessel reactor, this design allows achieving high safety indicators.

Fast Nuclear Reactors

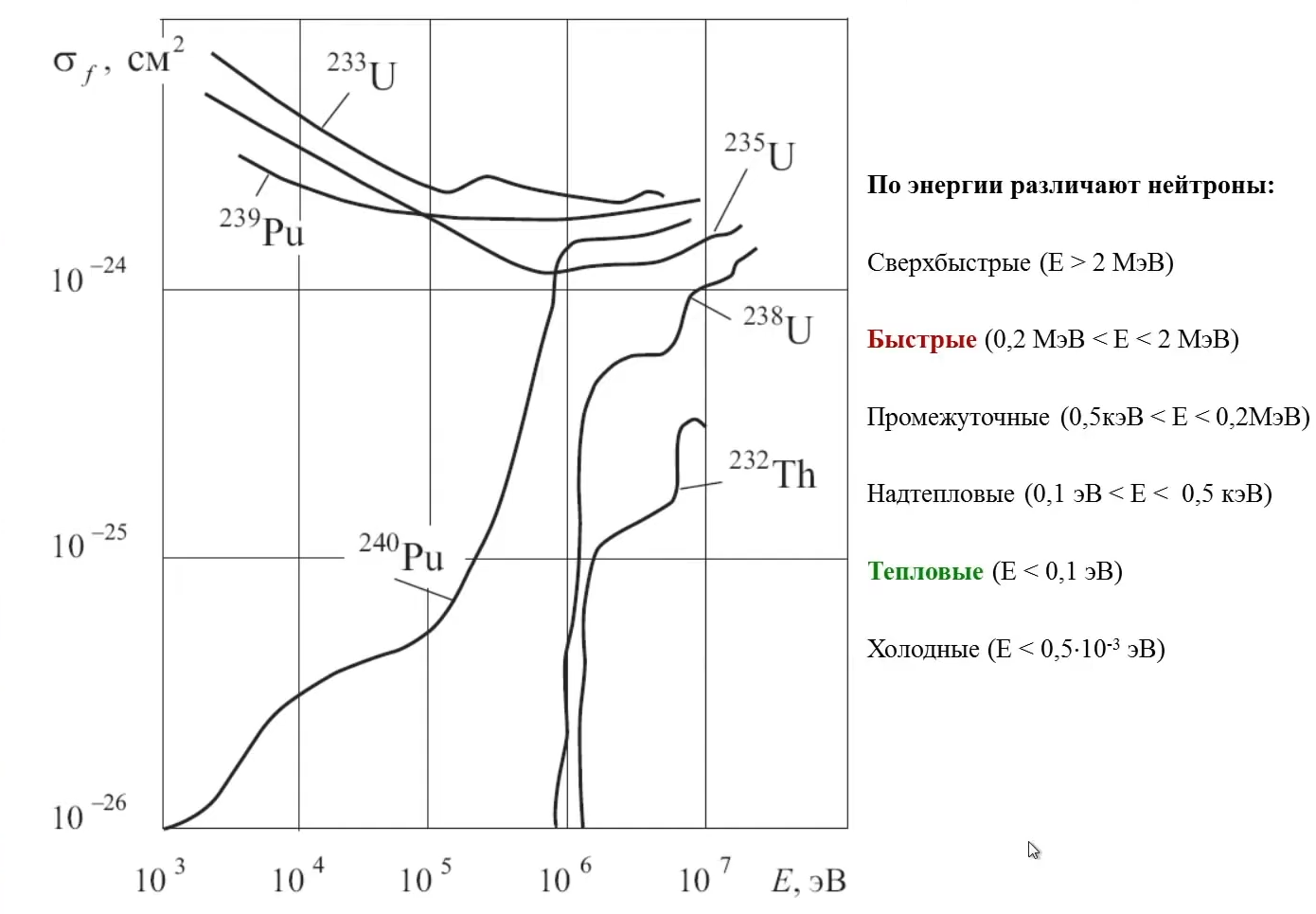

A little physics first. Let me remind you that isotopes are elements that have the same atomic numbers, but different atomic weights. The most interesting thing is that they have different properties. For example, uranium-238 is practically not fissionable in thermal reactors, while uranium-235 is fissionable. To describe the probability of an isotope fission, nuclear physics uses the concept of "fission cross section".

Cross-section of the fission reaction of uranium, plutonium and thorium isotopes depending on the neutron energy The

figure clearly shows that for uranium-235 and plutonium-239, we can create a chain reaction using both thermal and fast neutrons. And uranium-238 on the left side of the graph (where the thermal neutrons are located) will not fission. In nature, the isotope of uranium-238 is prevalent, which cannot be directly used in a thermal reactor. There is very little uranium-235 in nature, and expensive enrichment is required to obtain fuel.

The fast neutron reactor allows avoiding the uranium-235 enrichment procedure. But technically it's not that simple.

In a thermal neutron reactor, as in all modern power plants in general, water is used as a coolant. It is she who transfers thermal energy to the turbines. It is clear with her how to work, what construction materials to use. However, we know from nuclear physics that water slows down the fast neutrons produced by nuclear fission.

Therefore, in a fast neutron reactor, liquid metals, as a rule, are used as a coolant, which significantly complicates the design.

Here it is necessary to solve a whole layer of scientific and experimental-design problems, including the development of new materials.

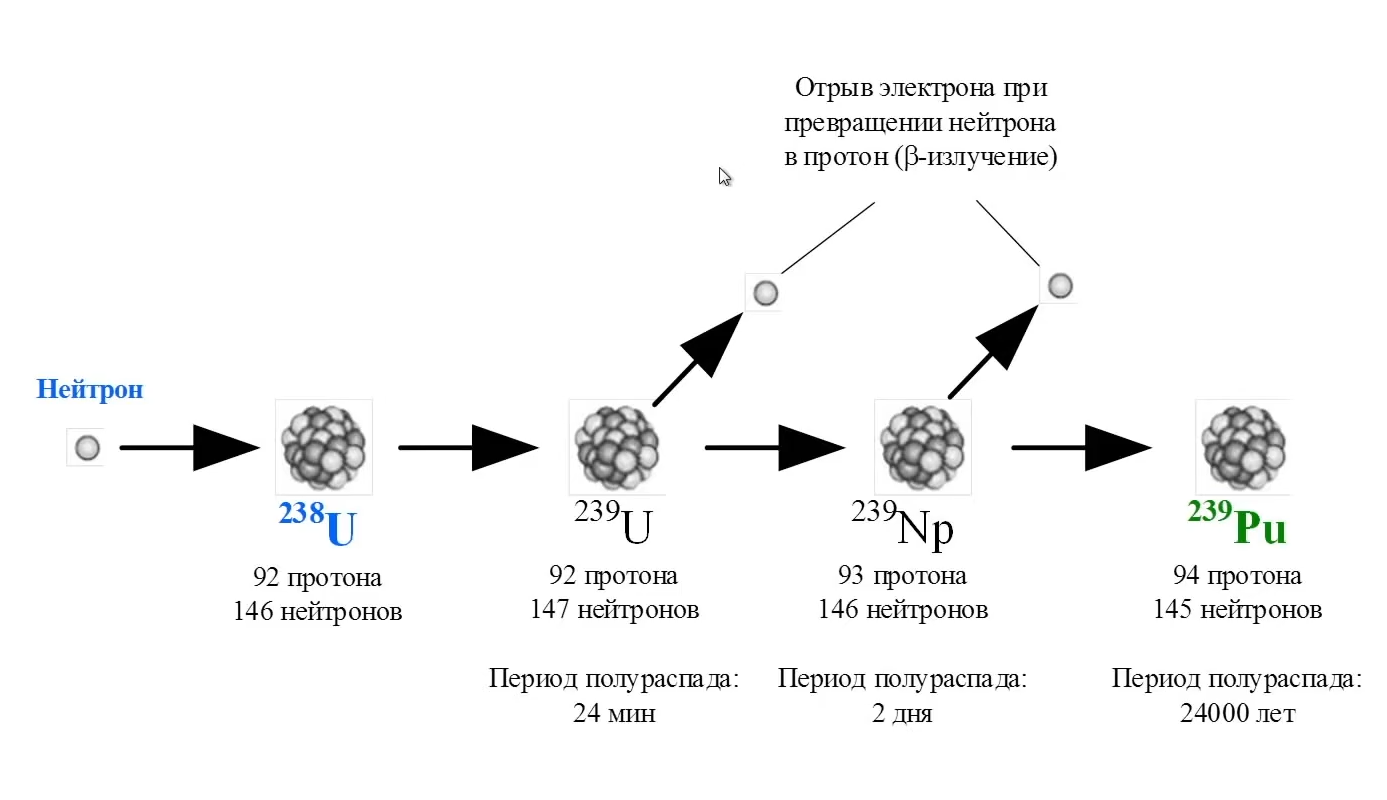

The most likely reaction in a fast neutron reactor - absorption of a neutron by the isotope uranium-238 - is shown in the diagram below.

As a result, natural uranium-238 is converted into the isotope plutonium-239, which has fission properties similar to uranium-235. And here it becomes possible to transform uranium-238, which is almost not fissile in thermal reactors, into new nuclear fuel.

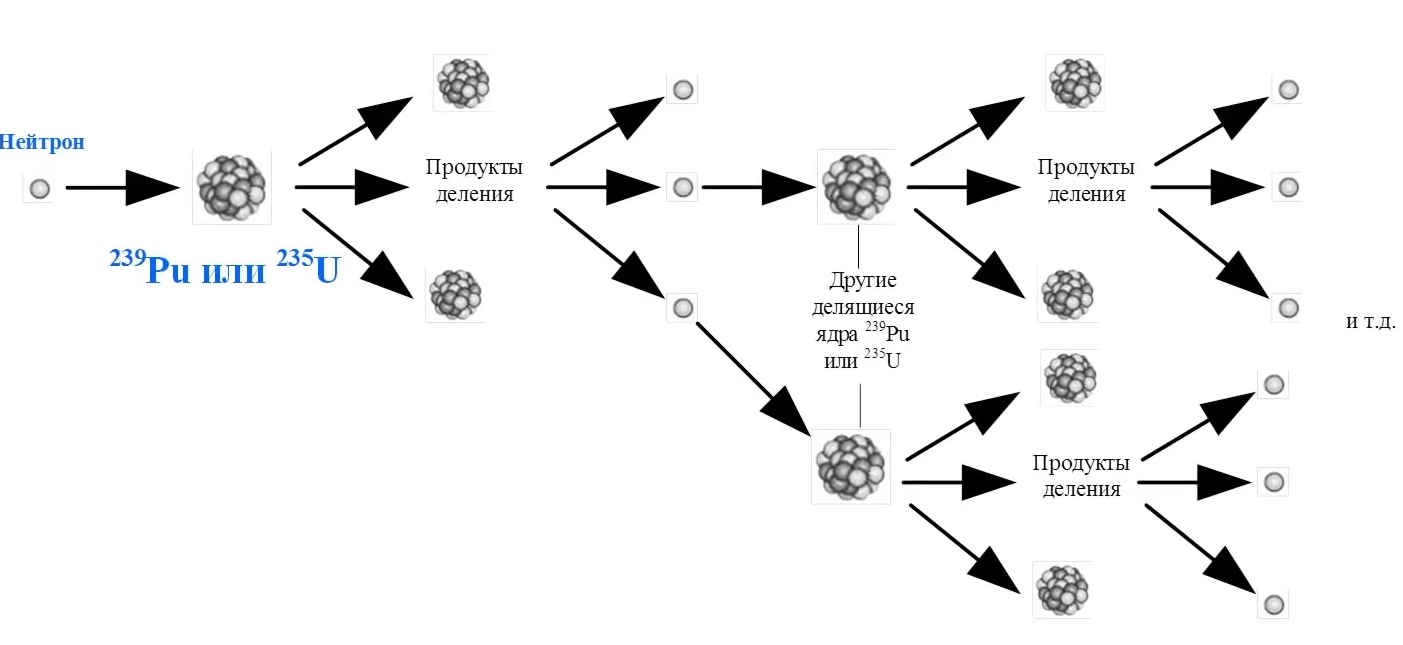

Uranium-235 and plutonium-239 are similar in their properties. On the basis of these nuclei, we may well get a chain reaction: by absorbing both fast and slow neutrons, the nuclei will fission, emitting secondary, tertiary neutrons, etc.

Historically, the most developed fast reactors are BN-600 and BN-800 .

And Russia is the only country in the world that has operating industrial fast neutron reactors.

Their design is much more complicated than that of a double-circuit pressurized water reactor using thermal neutrons, since liquid sodium with a melting point of ~ 98 ℃ is used as a coolant.

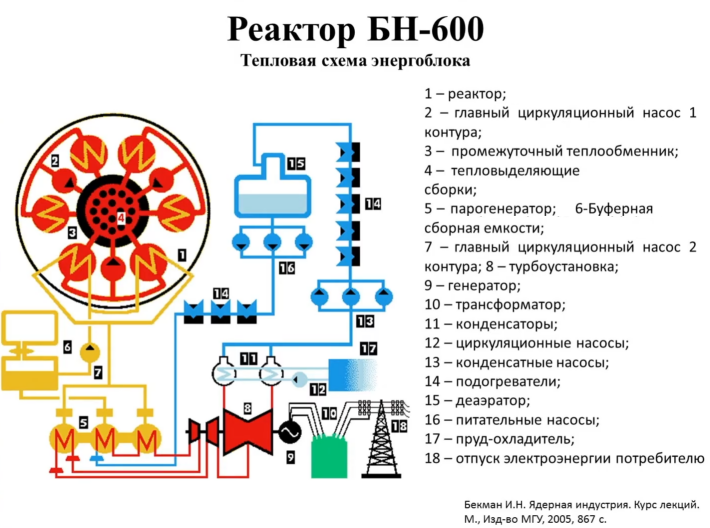

Scheme of a power unit with a fast neutron reactor

In reactors with a sodium coolant, we cannot use a two-circuit scheme, where the first circuit is filled with sodium, and the second with water, since the accidental interaction of irradiated sodium with water will lead to especially grave consequences. In the course of the reaction of these two substances, explosive hydrogen is released, and in the event of an explosion, it will be extremely problematic to neutralize the phonating sodium. Therefore, a three-circuit scheme is used. The first circuit is sodium (in the figure it is shown in red in the center of the reactor), then a heat exchanger and another (intermediate) sodium circuit (yellow), which allows to reduce the degree of sodium irradiation, and only in the third circuit water is used, a turbine is installed, thermal parts and the rest of the equipment. Three loops complicate both the operation of the reactor and its control.

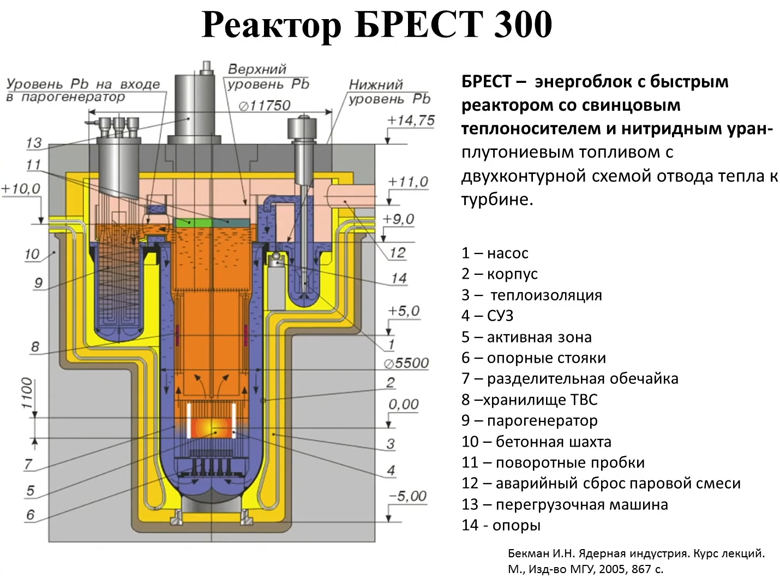

The next step is BREST

The BREST-300 energy complex is the next stage of development. It is being created within the framework of the Rosatom project "Breakthrough". Instead of sodium, lead is used as a heat carrier ( melting point 327 ℃). This allows, as in pressurized water reactors, to use only two circuits, simplifies control and increases energy efficiency.

The design of this reactor ensures the so-called natural safety: an accident is impossible at this reactor due to the uncontrolled appearance of neutrons, leading to chain reactions (acceleration of the reactor in power).

Great hopes are pinned on this reactor. It can "burn" fissile elements and produce plutonium, and then use it to close the nuclear fuel cycle.

The purpose of the closure is to gradually eliminate the part of the chain associated with the extraction of uranium by its enrichment, as well as to reuse nuclear waste.

Two-component nuclear power

Two-component power engineering is a solution to the problem of reducing the amount of enriched natural uranium required for the operation of all these reactors. It has not yet reached the peak of its development - this is what the generation of today's schoolchildren will be doing.

At present, we are starting to produce fissile elements in fast reactors, which will subsequently make it possible to load fuel here that is not enriched in uranium-235.

BN-600 and BN-800 are already operating on the so-called MOX fuel (MOX - Mixed-Oxide fuel), a mixture of plutonium-239 and uranium oxides. Moreover, the reactors can operate both on fuel enriched in uranium-235 - and in this case to produce plutonium-239 - and on plutonium.

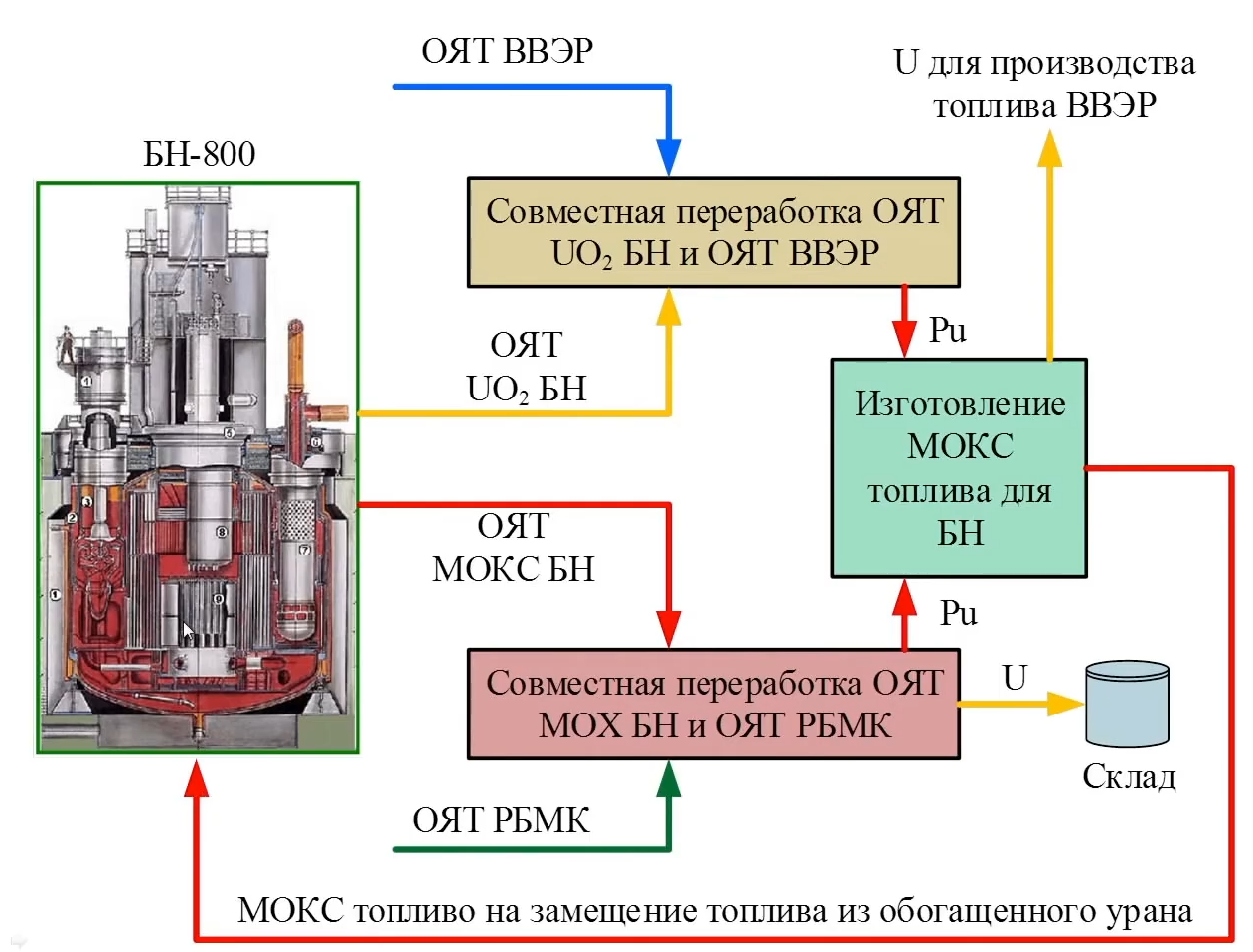

Partially closed nuclear fuel cycle

On the basis of the Experimental Demonstration Center in Seversk, and in the future the FT-2 plant in Zheleznogorsk, there is a storage facility for spent nuclear fuel. Now at the final stage of development is a technology that will allow reprocessing fuel after the VVR reactor and returning uranium and plutonium from it to the cycle. The reprocessing problem is solved in a very interesting way: uranium and plutonium are not separated, but transferred to production in a mixed form. As a result, we get fuel assemblies for reactors containing reprocessed uranium and plutonium, as well as added natural uranium enriched in the isotope-235.

Of course, there is no complete closure of the nuclear fuel cycle, but this approach allows one to reduce enrichment costs.

In addition, the fissile elements that we will extract from the fuel spent in VVR reactors will go to the fuel cycles of fast reactors.

The scheme of loading MOX fuel containing plutonium-239 and uranium-238 into the BN-800 reactor has already been worked out, its path is shown in the figure below with a red line.

The scheme implies the use of spent nuclear fuel (SNF) from a VVER reactor together with oxide fuel with uranium-235 after BN reactors. During reprocessing, we separate a mixture of plutonium and uranium, which is used to make MOX fuel. And the spent MOX fuel is reprocessed together with the fuel after the RBMK reactor.

It turns out that we start with the usual loading of reactors with oxide fuel based on uranium-235 and gradually, by producing plutonium-239 in a fast reactor, we displace it with MOX fuel.

We will not be able to immediately switch from traditional reactors to fast ones, because for each fast neutron reactor we will have to build a reprocessing infrastructure, which will not be loaded at first, because the reactors must produce fuel that will subsequently be reprocessed. And the scheme above provides for a smooth transition from existing reactors to fast ones. This scheme involves the production of plutonium at the BN-800 reactor. In the future, more powerful and more cost-effective installations should appear - BN-1200, which will embody the two-component nature of our nuclear energy for the next decade and the strategy of the same Rosatom.

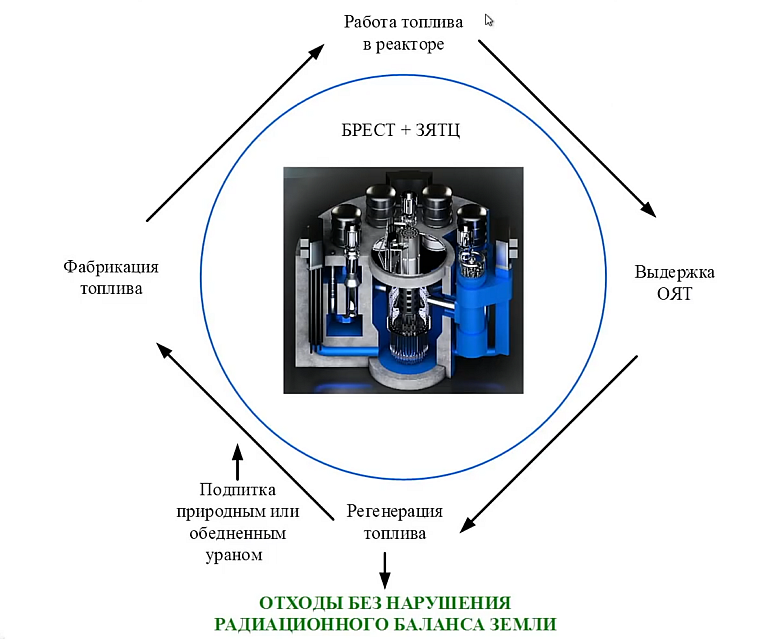

But what's more interesting is what is happening in the BREST project. A reactor of this type with an electrical power of 300 MW has already begun to be erected in Seversk. A complex will be built around it, which will allow solving the problems of fuel regeneration, i.e. all processes within the framework of closing the fuel cycle will be concentrated in one place.

At the initial stage, replenishment with natural or depleted uranium will be needed, as noted in the picture. Not having the required amount of plutonium, we can, as in the previous scheme, start using combined fuel and gradually produce plutonium, switching to a closed cycle.

Great hopes are pinned on this reactor: the above-mentioned natural protection circuit does not allow it to be accelerated to severe accidents. But here we have to face a number of problems. The problems associated with the production of plutonium have already been solved to some extent. But the reprocessing of nuclear fuel after fast reactors is an open question. Here it is necessary to ensure a short exposure of the fuel: it is hot and with a high background radiation. It is necessary to create new technological processes, test them at the stands and implement them.

, .

In parallel, it is necessary to complete the solution of the problem of removing waste from the cycle without disrupting the natural radiation balance of the Earth. The projected fuel cycle must return exactly the same amount of radiation that we have extracted. Theoretically, this problem has been calculated and can be solved. It's up to practice.

Unlike the last century, when it was necessary to obtain nuclear weapons and, at the same time, nuclear power at any cost, and no one calculated the economy, now the task is to make everything energy efficient, economically feasible and with natural security. And someone has to do all this. So specialists in this and related areas will not be left without work.