In the age of nanotechnology and all kinds of miniaturization, despite the transition of assembly of electronic products to surface mount technology using chip components, some components are available only in pin design. Even the most modern electronic products cannot be manufactured without them, since these components give a higher mechanical reliability compared to SMD components. Almost all modern phones or tablets use holes-mounted connectors. There are also limitations associated with the inability to use chip components in high-voltage circuits. In this case, the designer has no choice but to use the through-hole components.

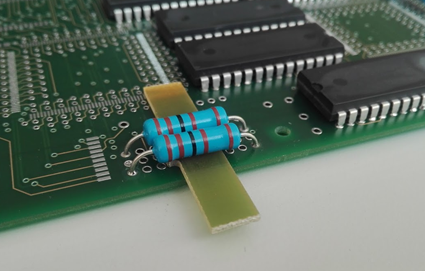

The use of such components leads to some difficulties in their installation into products. The first problem may be due to the need for tinning the leads in order to exclude poor-quality soldering of the leads due to non-compliance with the storage conditions of the components. You never know where and how they were stored before they got into your hands. For these purposes, there are solder pots (Fig. 1). In such baths, you can tin the leads before soldering to the board. And to prevent overheating of the element body during tinning or soldering to the board, heat sinks are used (Fig. 2). To obtain a good soldering result, it is better not to neglect this operation. After tinning, it is recommended to remove the remaining flux from the surface of the terminals.

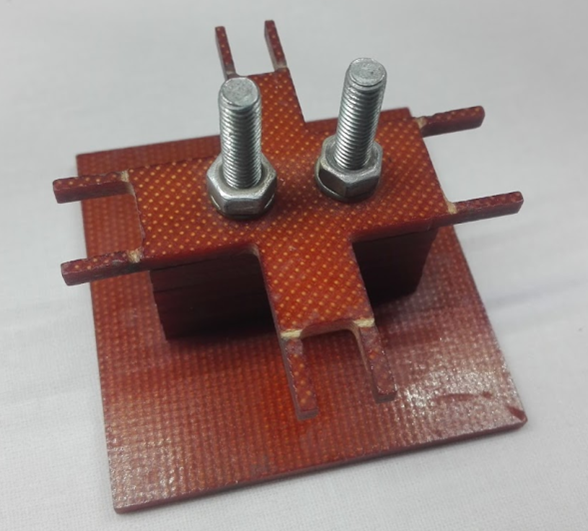

. , . , , (.3).

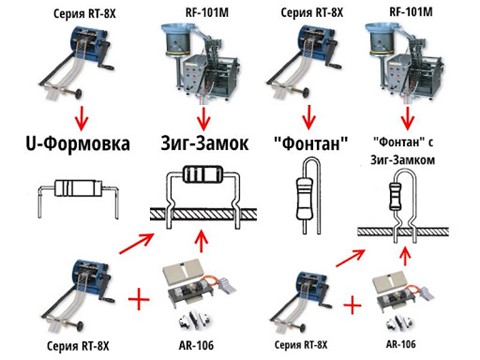

(, 29137-91, 92-9388-98). , , . , (.4). .

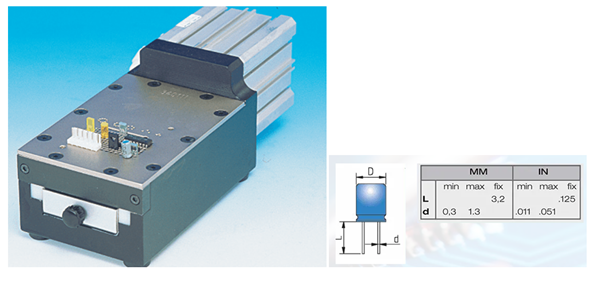

. . , (.5).

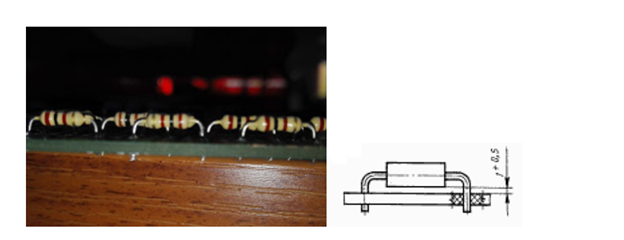

, , (.6).

, , . . , -, (.7)?

, . . , (.8).

. , - . , .

. . . , , . , , . (.9).

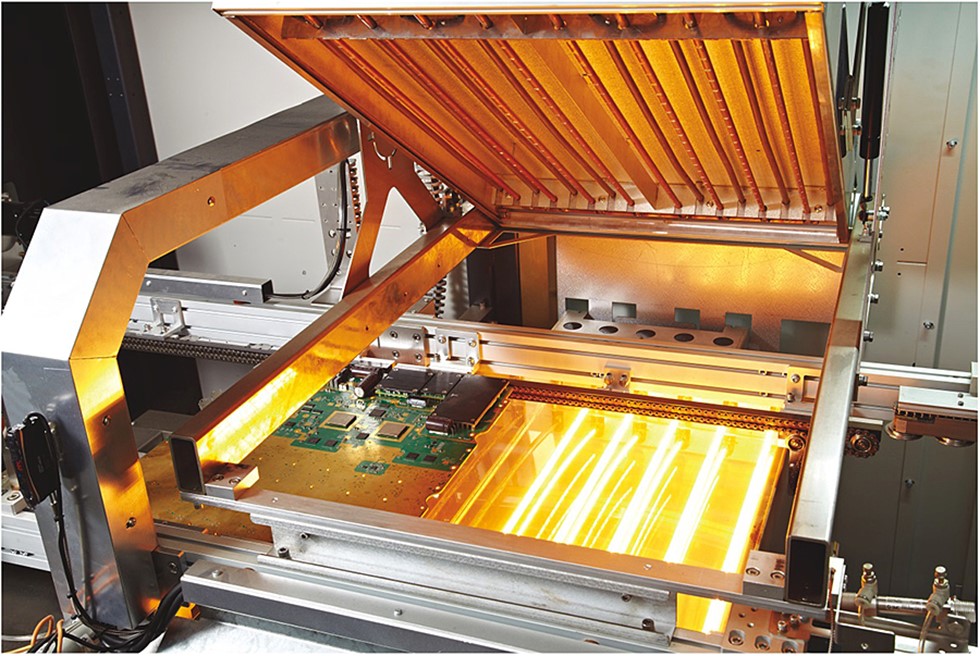

And in installations of selective soldering or solder waves, there must be modules for preheating the board before soldering or during soldering. Some selective soldering machines even have two preheat modules at the top and bottom (Figure 10).

All these accessories, installations and machines facilitate work, reduce labor intensity and allow you to obtain quality soldering. If you do not neglect these recommendations, then the quality of soldering in your product will meet all standards.