Not so long ago we published the news that a domestic company has developed a data storage system at Elbrus with a localization level of> 90%. We are talking about the Omsk company "Promobit", which managed to achieve the inclusion of its storage system Bitblaze Sirius series 8000 in the Unified Register of Russian radio-electronic products under the Ministry of Industry and Trade.

The material caused a discussion in the comments. Readers were interested in the details of the development of the system, the nuances of calculating the level of localization, the history of the creation of storage systems. To answer these questions, we interviewed the head of Promobit, Maxim Koposov.

Maxim, please tell us when and how did you get the idea of creating a domestic storage system based on Russian Elbrus processors?

You know, we began to develop our own data storage system even before the appearance of Elbrus. It was a conventional storage system that ran on Intel processors. You can read more about this project at RBC.

Around 2013, I saw a video presentation of the Elbrus processor, which was conducted by Konstantin Trushkin, Marketing Director of MCST JSC. I heard that this company was developing a domestic processor back in the late 90s or early 2000s. But then it was just news, I did not think that the project would be implemented.

After I was convinced that the processor is real and can be bought, I wrote to the administration of MCST JSC with a request to send a commercial offer. After discussing the details, the manufacturer Elbrusov agreed to cooperate.

Why am I interested in the Russian processor? The fact is that domestic systems based on imported components, including Intel processors, are quite difficult to sell. On the one hand, there is the corporate market, which has long been accustomed to the products of HP, IBM and other foreign companies. On the other hand, there are inexpensive Chinese solutions that are in demand among small and medium-sized businesses.

Having learned about Elbrus, I thought that storage systems based on this chip would be able to occupy their own niche and get buyers from the state and the defense sector. That is, those for whom it is extremely important to use a trusted platform, without hardware or software "bugs" and undeclared capabilities. Once I looked at the dynamics of the budget of the Ministry of Defense of the country and saw that the volume of budgeting is gradually growing. They began to invest money in digitalization, information security, etc., completely or partially abandoning imported storage systems and other electronic systems.

And so it happened , though not immediately. According to the decree of the Government of the Russian Federation of December 21, 2019 No. 1746 "On the establishment of a ban on the admission of certain types of goods originating from foreign states, and amendments to some acts of the Government of the Russian Federation", in order to ensure the security of the critical information infrastructure (CII) of the Russian Federation, in including the one used in the implementation of national projects, a two-year ban on admittance to purchases of foreign software and hardware systems is introduced. Namely - data storage systems ("Storage Devices and Other Data Storage Devices").

Let me note that we started work long before everyone started talking about import substitution. Moreover, in 2011-2012, it was stated from the highest stands that import substitution in a number of industries, including electronics, should not be dealt with. Innovation is needed, not a repetition of what others have already gone through. At that time, the term "import substitution" had a negative connotation, we tried not to use it.

We continued to develop domestic systems, considering it correct. Therefore, if someone says that we started working only after import substitution became an upward trend, it is not so.

Tell us more about the development process

Work on the creation of the Bitblaze Sirius 8000 series storage system began in 2016. Then we applied for the competition of the Ministry of Industry and Trade. The resolution of February 17, 2016 describing this competition has a long title: “On the organization of work in the Ministry of Industry and Trade of the Russian Federation to conduct a competitive selection for the right to receive subsidies from the federal budget by Russian organizations to reimburse part of the costs of creating a scientific and technical reserve for the development basic technologies for the production of priority electronic components and electronic equipment within the framework of the state program of the Russian Federation “Development of the electronic and radio-electronic industry for 2013–2025”.

We offered the Ministry of Industry and Trade a detailed detailed business plan with technical and economic justification. They told us what exactly we want to develop, what market we are counting on and who we see as a target audience. As a result, the Ministry of Industry and Trade signed an agreement with us, and we started development.

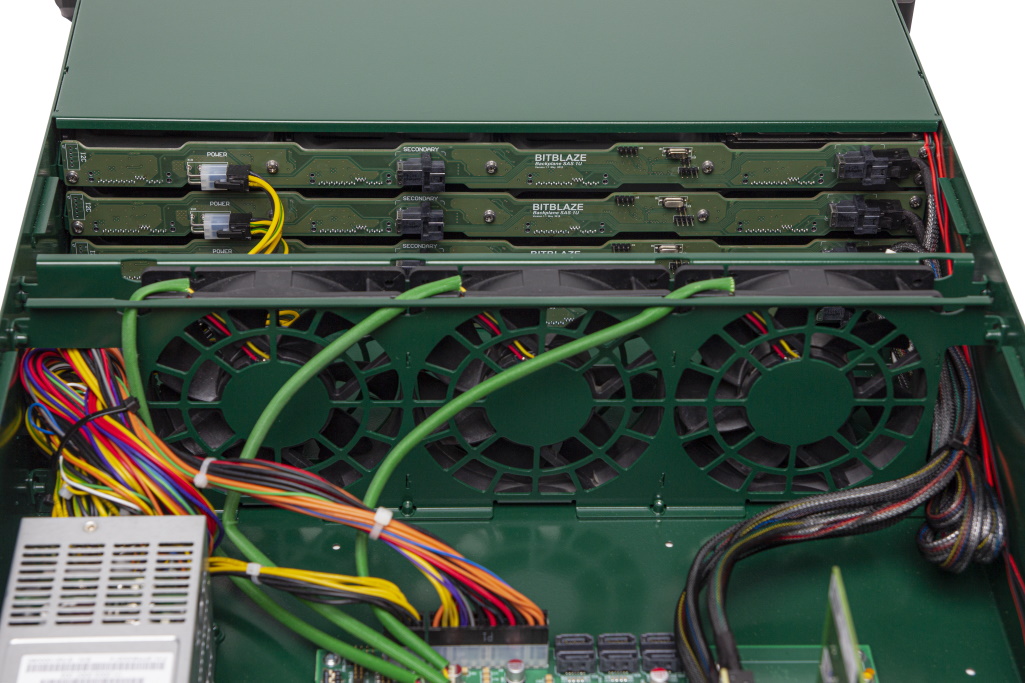

The project practically did not differ from other projects for the development of software and hardware platforms. First, we assembled several teams of engineers, programmers and other specialists. At the first stage, we created a mock solution, on which several teams worked in parallel. We tested different versions of the software, after which we developed three models with different characteristics.

As a result, we chose the option that allowed us to follow the path of horizontal scaling of the storage system. The market was developing in this direction just then. Horizontal scaling was the answer to the ever-growing volume of data for storage users. It makes it possible to increase the capacity of a data center with storage.

The developments for the other two models were also not in vain - we use them in other projects.

What difficulties arose during the implementation of the project to create a domestic storage system?

In general, problems can be divided into two categories: software development and hardware. As for software, a huge number of different books and articles have been written about this, in our case there is nothing unique in this regard.

From the point of view of hardware, everything is much more interesting. Difficulties arose already at the design stage of the hull. We needed to build everything from scratch. Well, since we are participants in the project of the Ministry of Industry and Trade, we must work with domestic specialists. The professionals who could help us are mainly employed at the enterprises of the military-industrial complex. It is quite difficult to build relationships with them from a business point of view, since we speak different languages. They are accustomed to working with such customers as the state, the military, with us it was very unusual for them at first. We got used to each other for a long time.

Over time, state corporations and enterprises began to allocate departments for the production of civilian products - a kind of mediators between business and production, which is "sharpened" for the production of military products. The leaders of these departments understand the language of the business and are much easier to deal with than the management of the entire enterprise. So far, there are a lot of problems, but much less than there were at the beginning. In addition, current difficulties are being gradually resolved.

Please tell us about the import substitution of the main storage system components and element strapping. What is domestic here, and what came from abroad?

Our main goal during the implementation of this project is the import substitution of large integrated circuits, which may have some undeclared capabilities.

Besides integrated circuits, we also use other domestic components. Here's a list:

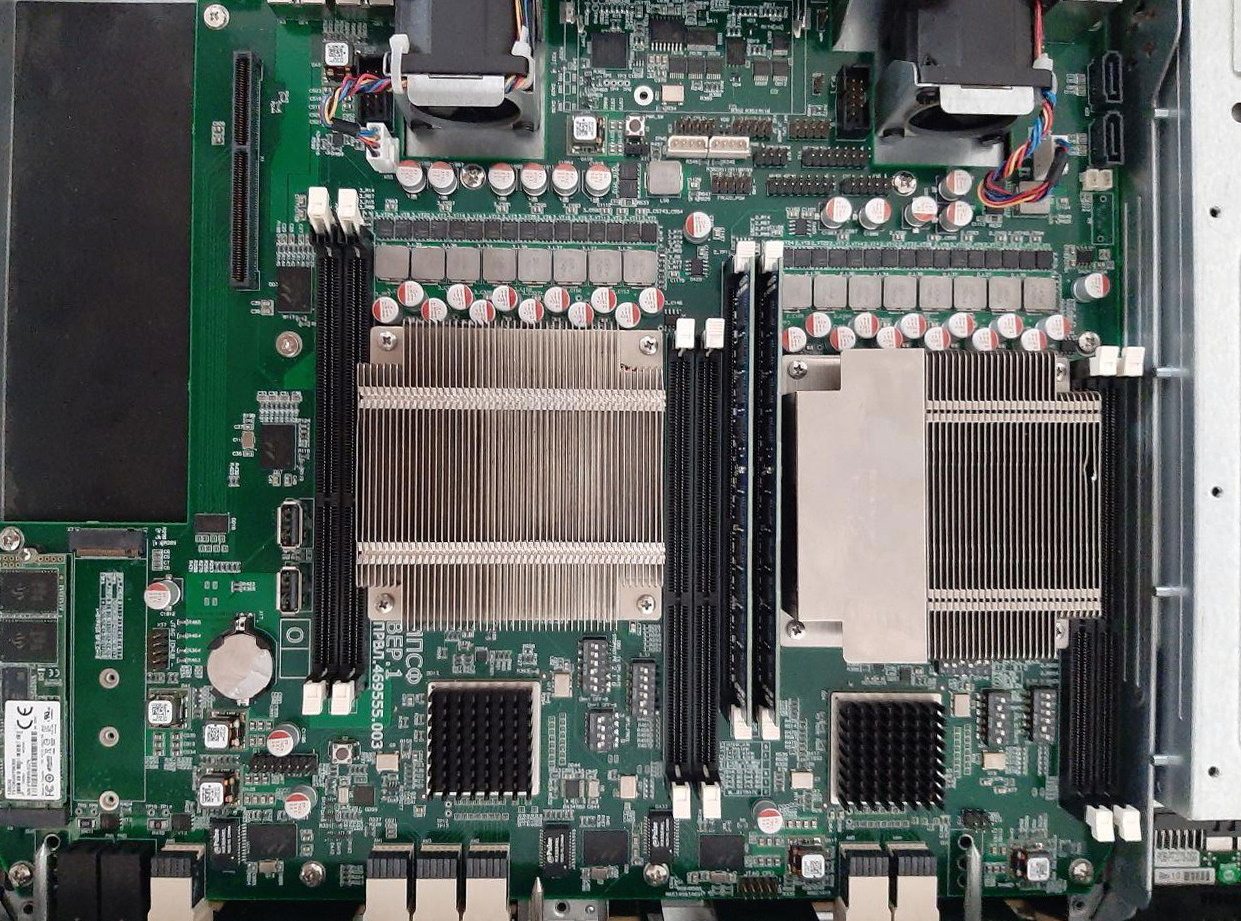

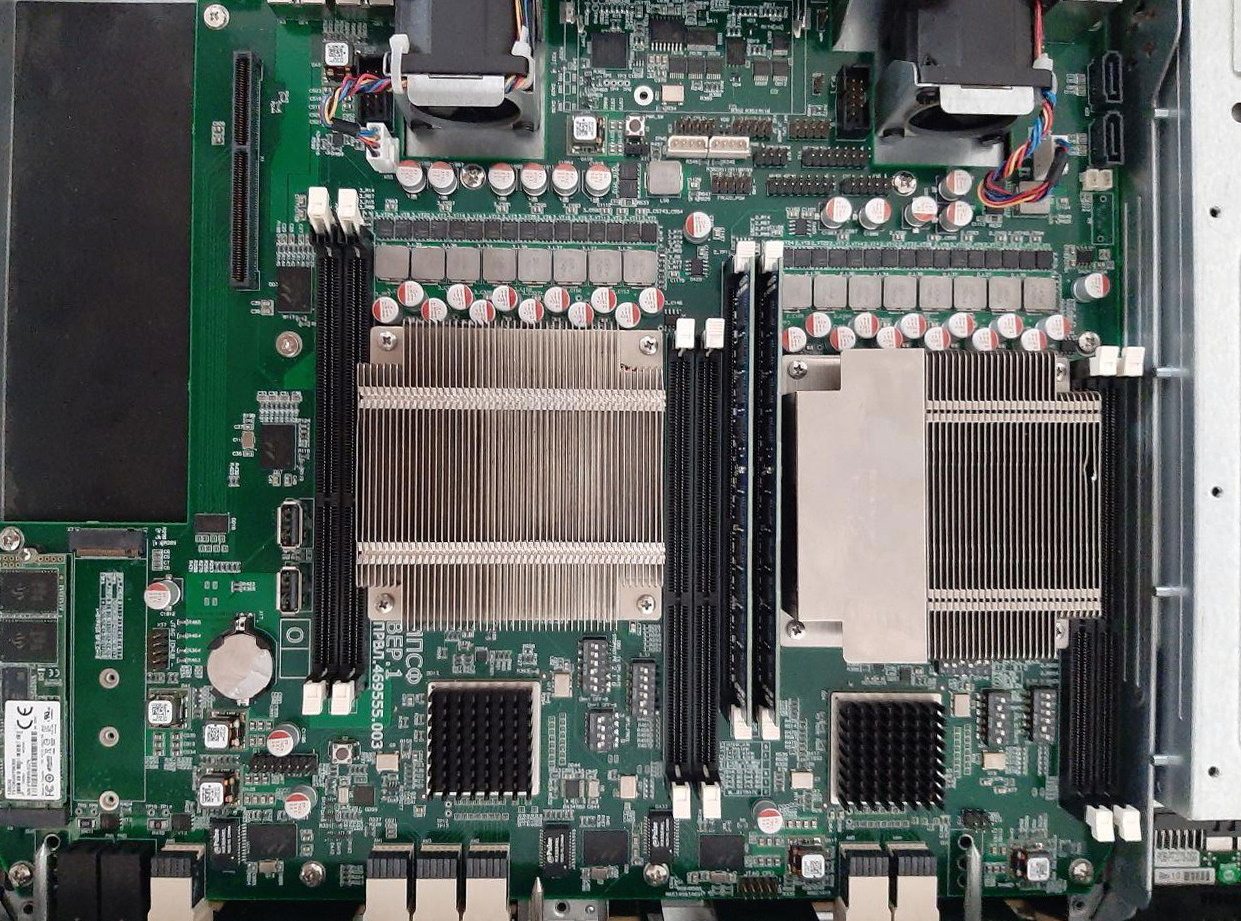

- Elbrus processor.

- South bridge.

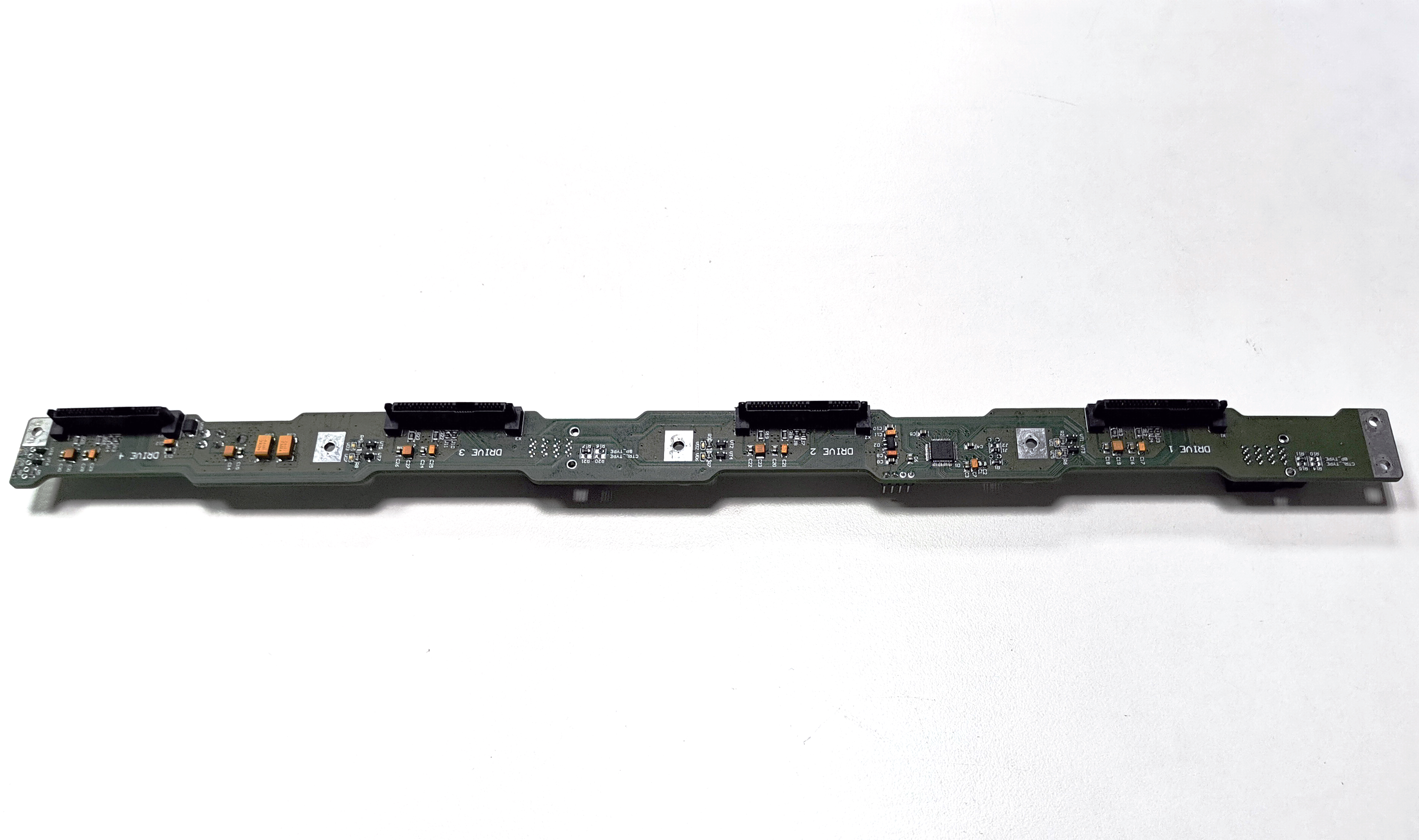

- Printed circuit boards.

- Motherboard.

- Light guides.

- Body and body metal parts.

- Plastic parts and a number of structural elements.

"Promobit" has developed most of the components used, there is design documentation for everything.

But we purchase the element strapping, capacitors, resistors from abroad. When domestic capacitors, resistors, etc. will enter mass production, and their quality and reliability will not be inferior to foreign samples, we will definitely switch to them.

How was the localization level calculated?

The answer is simple. In the decree of July 17, 2015 N 719 "On confirmation of the production of industrial products on the territory of the Russian Federation", formulas are given according to which all this is calculated. Our certification specialist was guided by these formulas, requesting additional information if necessary.

It should be noted that our calculations were not accepted by the Chamber from the first time, we were mistaken several times. But after all the shortcomings were corrected, the Chamber of Commerce and Industry confirmed everything. The cost of the components plays a major role here. It should be remembered that in Resolution No. 719, the requirement to comply with the percentage of the cost of foreign components used in the production of a basic product does not take into account the cost of data storage devices - magnetic hard disks, solid-state disks, magnetic tapes.

As a result, screws, capacitors, LEDs, resistors, fans, a power supply - components of foreign origin - make up 6.5% of the cost of the BITBLAZE Sirius 8000 storage system. 94.5% of the cost includes the case, printed circuit boards, motherboard, processor, optical fibers, produced in Russia.

What happens if access to foreign components is closed?

Access to the element base, the manufacturers of which are controlled by the United States, can be closed. If this question suddenly arises, then we will use components produced by Chinese companies. There will always be companies that do not pay attention to sanctions.

Perhaps we ourselves will organize the production of the necessary components - at home or in another country. All is well in this respect.

A more real threat is if the Taiwanese contract manufacturer is banned from producing Elbrus. Then problems of a different order may arise, as was the case, for example, with Huawei. But they can also be solved. Our software is cross-platform, so it will work even if the processors are replaced with others. We use the simplest and most efficient algorithms that can be transferred to another architecture without any problems.