Electric batteries of various types and formats have long become an integral part of the life of modern people. It is believed that the first battery was created about 2000 years ago. It consisted of an earthenware jar filled with vinegar, an iron rod, and a copper cylinder. Much has changed since then in the technology of manufacturing these energy sources. Modern batteries have been developing and perfecting for over two centuries. The battery, the similarity of which is used in our time, was created in 1798 by Alessandro Volta. In addition to his own knowledge, Volta used the results of the experiments of Luigi Galvani.

This technology continues to improve, develop, and reduce the cost of its implementation. Today we are surrounded by electrified appliances. Moreover, many devices and systems are simply impossible without an autonomous power source - an electric battery. From smartphones and portable headphones to electric cars, drones, medical devices, and autonomous life-support systems for living quarters and hospitals. At the same time, the number of electrified devices, systems with an autonomous electric power source in the modern world is growing rapidly. Batteries are used in a wide variety of devices: household, transport, infrastructure, medical.

All digital devices, such as players, smartphones and other wearable gadgets, as well as electric cars, are increasingly improving in their capabilities, and these capabilities are determined mainly by the energy stored in batteries.

The technology of electric batteries has been known for a long time, but their full-fledged use began in the 20th century, there was a continuous process of improving the technology: increasing efficiency, reducing the cost of producing batteries, reducing weight and much more.

In recent years, the growing demand for batteries and accumulators in the global market has launched many innovative developments. Some of them are currently being actively tested. Ultra-light lithium metal batteries, lithium titanate batteries, flexible batteries for wearable devices, aluminum-air batteries, carbon batteries with a very high charging rate, inexpensive organic ones, and many others are being investigated. Improved batteries must charge faster, store many times more energy, and withstand more charge / discharge cycles.

Engineer Tool

What tools can engineers use to design highly efficient, complex electrical systems? In the context of the methodology of Dassault Systemes system engineering has created a special tool for the development of electric batteries - BATTERY LIBRARY library system simulation of mathematical modeling of the behavior of systems DYMOLA . It is a library for mathematical modeling of the behavior, operation of the electric battery and its auxiliary systems.

It is based on the Modelica language and is used to integrate electric storage batteries into complex electrical systems with an independent, autonomous power supply. There is a mathematical model of the cell: chemical, thermodynamic, electrical, aging model of chemical elements, as well as a ready-made template for implementing the requirements of ISO standards.

A feature of this tool is a reduced threshold for entering technology. A specialist developing an electrified system does not need specialized education and some kind of vast experience in this area. The entire world engineering experience in this area is contained in the mathematical equations of this library. The developer can be sure that with its help he will create an efficient, modern electric battery that meets all international standards and its auxiliary systems. Essentially, it's a treasure trove of engineering expertise. Such a tool greatly simplifies the creation of a competitive product.

Electrification of the whole country

The electrification trend can be seen in many industries today. For example, in the aerospace industry, two main areas can be distinguished: replacement of mechanical and part of hydraulic control systems of an aircraft with electrical ones and, thereby, increasing autonomy, compactness, and simplifying operation. This became possible due to the increased reliability and manufacturability of electrical systems and, in particular, batteries.

Batteries are indispensable where autonomy criteria are important. For example, an exoskeleton was developed at Skolkovo, which is used in the rehabilitation of the musculoskeletal system of patients. Its other application is to reduce physical activity in enterprises. The exoskeleton system would not have been possible without an autonomous power source, without a battery. Only if it meets all modern requirements, the product can be in demand and competitive.

One of the latest trends in aviation is the drive to reduce environmental impact. Electric power plants, which, as you know, do not emit anything into the atmosphere, require the development and use of literally all types of electric batteries - lithium-ion, hydrogen, hybrid.

If we talk about space, then everything is obvious even without external factors: all used sources of electricity, in fact - batteries: solar, chemical (lithium-ion, lithium-cadmium, hydrogen, etc.), as well as radioisotope (RTG ). The only alternative to them is a nuclear reactor.

Electric batteries are used in standby autonomous power systems (data centers, hospitals and other critical facilities), electric trains, electric vehicles, drones, heavy engineering (excavators, loaders), shipbuilding (jet skis).

At the end of September, BASF will start mass production of new lithium-free batteries. So far, such technologies are expensive, but the ban on classic diesel engines and even on internal combustion engines will spur the development of electric transport. For example, in Sweden, new cars with diesel or gasoline engines will not be sold after 2030, Norway plans to ban the sale of cars with internal combustion engines from 2025, and Denmark, like Sweden, from 2030. Among the states that have adopted similar norms, there are also such large economies as Great Britain and France. The latter are inclined to ban internal combustion engines by 2040.

In modern realities, the developer of this or that system with an autonomous power source pays great attention to it, because this subsystem largely determines how successful the product it develops will be.

One of the most promising areas is hydrogen fuel cells.

Hydrogen fuel cells

Hydrogen fuel cells are one of the engineering trends in the field of new power supplies for power plants of various autonomous systems. The first hydrogen fuel cell was designed by English scientist William Grove in the 1830s. The feasibility of producing energy in a hydrogen-oxygen fuel cell using an acidic electrolyte has been demonstrated. NASA used the updated fuel cells on the Apollo spacecraft as the main source of energy.

A hydrogen fuel cell is a technology that, if properly developed in the future, could displace hydrocarbon fuels. The main advantage of hydrogen cells is environmental friendliness. Fuel cell systems have already been designed to power computer systems, lighting in small courtyards and even cars and buses. There are even plans to launch hydrogen fuel cell aircraft.

Today, there are already many completed projects: cars, military autonomous uninterruptible power supplies, unmanned aerial vehicles, and in the middle of last year, Bill Gates ordered a yacht on hydrogen fuel cells.

This technology is well known in the Russian Federation, there are advanced developments. They are used in flying drones, a hydrogen train has been created: the Transmashholding group, together with Rosatom, plan to produce hydrogen-fueled trains in Russia, and Russian Railways is considering Sakhalin Island as a pilot testing ground for their launch.

Overseas, BMW and Toyota have developed a hydrogen transmission for green cars. A hydrogen fuel cell powertrain will form the basis of BMW's Hydrogen Next. Mercedes-Benz has unveiled its first production car with hydrogen fuel cells, the GLC F-Cell.

Hydrogen fuel cells have a high efficiency of 60%. And according to this parameter, hydrogen energy is the most attractive source of energy. This technology, in comparison with electric batteries, also provides a number of other advantages, such as increased battery life of the product, higher energy efficiency.

It does not take time to charge hydrogen fuel cells, it just needs to be charged with hydrogen. In particular, the advantages and features of hydrogen fuel cells are in demand in aviation. For example, drones for monitoring remote oil and gas or other objects must have a significant power reserve - 4-5 hours. It is not easy to provide such indicators, and VTE is one of the most successful ways. There are several promising electric passenger aircraft projects in the world today. Hydrogen batteries may well become a key element of these systems.

The main application at the moment is high-tech projects. This is a global trend, and in the future, with a decrease in the cost of project implementation, the cost of this technology, it will find wide application. And Dassault Systemes has a number of successful projects in this area.

Meanwhile, at present, the complexity and cost of hydrogen technology in the design and production process is stopping many engineering communities, making it difficult to apply. Therefore, compiling engineering data is important - when buying such data, you will not have to start with basic things.

To help developers

Dassault Systemes has a dedicated tool for developing hydrogen fuel cell systems - the Hydrogen Library in the DYMOLA simulation suite . The library, written in Modelica, contains the key components of PEM hydrogen fuel cell systems for integration into various energy systems and power plants.

A detailed model of fuel cell stacks, a model of temperature and pressure dependence of various gases: oxygen, hydrogen and water vapor, and much more have been created. The designer can design an efficient, modern, world-class hydrogen fuel cell system and its auxiliary subsystems.

Dassault Systemes is involved in many projects as a methodological consultant and software provider for modeling, analysis, comparison and data integration.

FMI standard

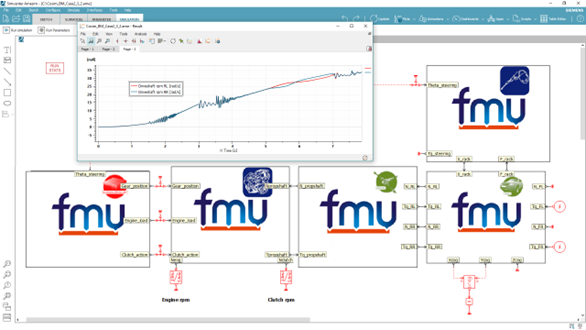

FMI (Functional Mock-up Interface) also comes to the aid of engineers and developers - a standardized interface used in computer simulation to create complex cyber-physical systems. FMI is an open standard developed for porting dynamic systems models between different multi-vendor modeling environments, as well as for conducting collaborative computational experiments. It solves one of the most painful problems in systems engineering - the ability to transfer models between tools. Today the FMI standard is supported on many modeling systems.

Today, the FMI standard - an interface for transferring and sharing models in various modeling environments - is a standard that is becoming more and more popular.

Exporting models in Functional Mock-up Unit (FMU) format has different applications. First of all, FMU can be used in different environments and programming languages. FMU also protects intellectual property by compiling the model code into a binary file, which can be useful when exchanging models with clients and colleagues.

FMI is supported by many development tools and is used in many engineering industries throughout Europe, Asia, and North America. It has become the de facto industry standard for the exchange of simulation mathematical models.

If at the end of the 20th century in the engineering community the standard for the development of a solid model of a product was the STEP, STL format, or any other format, then the FMI format becomes the next milestone in the development of engineering data exchange tools. It describes not only the geometric dependencies of the future product, the solid model, but also its behavior, that is, how the product functions in a particular mode of operation.

Back in 2008, according to the terms of reference of Daimler AG, Dassault Systemes created a European consortium called MODELISAR, which, after a series of technological studies, defined the specification of the future technology and FMI standard. His task was to define the characteristics of FMI, conduct technology studies that prove FMI concepts through developed use cases.

The main concept in the creation of FMI was to support a specific approach. It is based on the fact that a real product consists of a wide range of systems, subsystems and components that interact with each other in a complex way: they are controlled, governed by numerous laws of physics that describe the operation and behavior of a particular subsystem or component.

The following was proposed: to give an opportunity to create a virtual product where you can collect a set of models of systems and subsystems, each of which is a model of physical laws. And also include there a model of control systems (using elements of microelectronics and software). All this is collected into a single digital simulation mathematical model in the form of FMI.

This technology is most widely used in the automotive industry. For example, a parent vehicle designer creates a mathematical model at the top level, generates a file, and hands it over to their contractors. The contractor receives a file in the form of a technical specification and develops his own subsystem or some kind of component.

Then the head developer collects mathematical models of all components and subsystems, conducts comprehensive certification, validation, verification of certain engineering solutions, which, in turn, improves communication between different engineering enterprises and organizations with contractors. For the parent company, this also reduces risks: you can change a contractor at any time, relatively quickly switch to another. In addition, the time and development cycles for new systems are reduced.

This approach has been used for more than 10 years in other industries: aviation, instrumentation, shipbuilding, medical equipment development and many other areas.

Dassault is actively working on FMI implementation. Mathematical modeling as such, and the FMI format in particular, have become an integral part of the modern design process.

Continuing our article, we invite you to watch 3 video podcasts by Dassault Systemes covering the topics "Electric Batteries" , "Hydrogen Fuel Cells" and "Functional Mock-up Interface - FMI"

Subscribe to Dassault Systèmes news and stay up-to-date on innovation and technology.

Dassault Systèmes official

Facebook page

Vkontakte

3DS Blog WordPress

3DS Blog on Render

3DS Blog on Habr