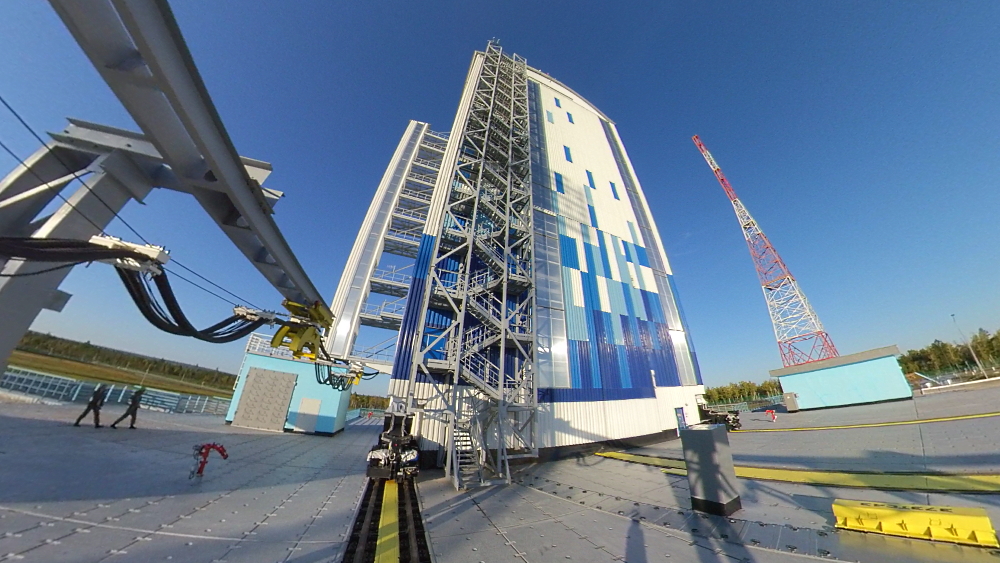

Mobile service tower at the Soyuz launch site

You will get the most complete feeling of being at the cosmodrome if you watch the video I shot in 360 ° format.

By rocket

The cosmodrome is work sites located at a considerable distance from each other, it is difficult to find an everyday analogy for such an arrangement. "Vostochny" is much more compact than Baikonur, and moving between objects takes noticeable, but not significant time. The cosmodrome is under active construction, so it makes sense to give a diagram of how it will look in the future.

Image of Roscosmos

It hardly makes sense to reproduce the order of our trip in the story, it seems to me that it will be clearer if you choose a sequence that resembles the movement of the rocket to the start - a universal technical complex, a launch complex, a command post, a command and measurement point and, finally, warehouses with equipment and under construction objects of the second stage of the cosmodrome.

Unified technical complex

In order to understand how the unified technical complex (UTK) works, it is best to take a satellite photograph and supplement it with explanations of what is going and where.

Launch vehicles, booster blocks and satellites arrive at the UTK at the block warehouse, then they are transported to their assembly and test complexes (MICs) using the so-called transborder gallery. It is a feature of Vostochny, there is no such thing at Baikonur or Plesetsk. Imagine a pallet the size of a railway carriage, which moves across the gallery not along, but across. And this is how it looks from the inside. Pallet is a yellow farm in the distance.

The pallet movement is automated, and it is positioned using lasers. The main plus of the transborder gallery is the reduction in the transportation of blocks on overhead cranes. Close-up view of the pallet.

The UTK was built with the expectation of further development and will be built up on the principle of a designer. For example, we were shown an inconspicuous door, in the place of which the MIC gates of manned ships will be located.

During our visit, freshly brought parts of a huge pressure chamber for the manned spacecraft "Eagle" were located in the block warehouse during our visit. Due to its diameter of 9 meters, it had to be delivered by the Northern Sea Route. In general, this is a rather rare case of delivery of something to the Russian cosmodrome by sea. Imagination, of course, begins to paint pictures of large-diameter missiles traveling along the Northern Sea Route, no longer constrained by the restrictions of the railway, but this is still a fantasy, even in the project of a super-heavy rocket, it is assumed that blocks of "railway" diameter will be used.

Huge hangars and wide-angle lenses obscure the scale. Here is a general view.

But with a field of view close to our eye, the perception of size changes dramatically.

The posters next to it indicate that the installation of the pressure chamber will be carried out from 2020 to 2022, then it will be tested, and the date of readiness is called May 1, 2023.

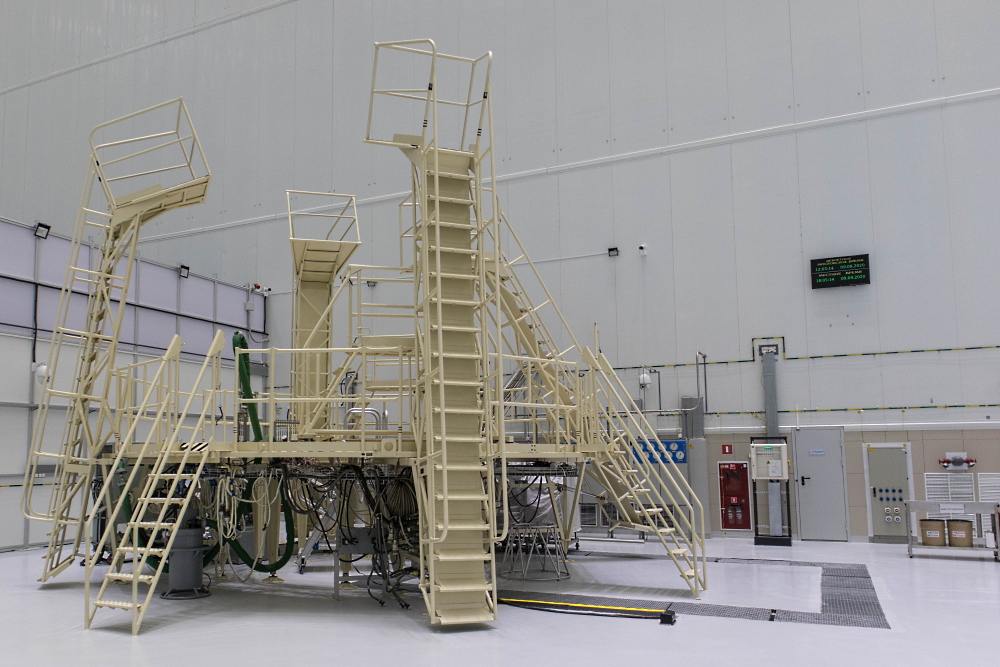

We are moving to the MIC of upper stages and spacecraft (RB and SC). A curious scheme is implemented here, in which a large hangar is divided into many fenced workplaces - each satellite or booster unit has its own room. In the photo below, on the left, these "rooms", and on the right, the tilter is a device on which the upper stage, dispenser, satellite (s) and halves of the head fairing are assembled into one whole.

We look inside. For example, here is a rig for working with the Fregat upper stage. So that we do not bring dirt and dust from the street, we walk around the MIC in dressing gowns and shoe covers. And the operation of the air conditioning system can be seen by the significantly more humid air than outside.

The order is emphasized by the fact that the equipment has labels. The big black in the background is a cargo model, and in the foreground there are 373CM83 load handling devices.

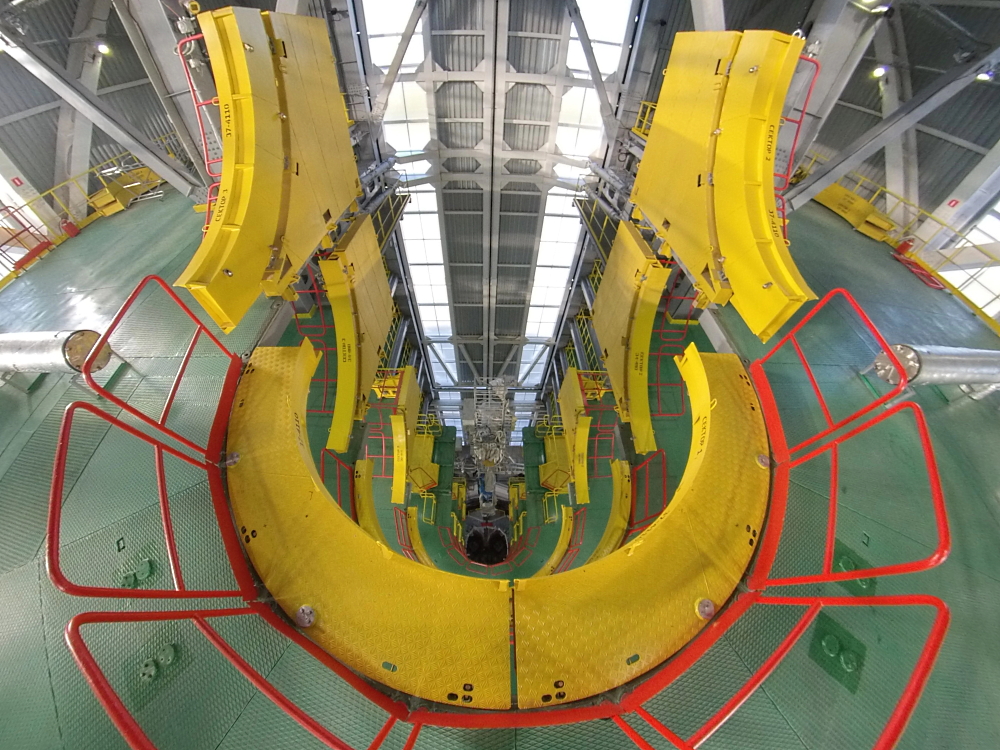

We pass to the MIC of launch vehicles. On both sides there are two almost assembled "Soyuz-2" - the first and second stages are assembled, the third - separately. Pay attention to the stairs in the background, from which you can roughly estimate the size of the hall.

The warhead is delivered to this hall from the MIC RB and the spacecraft, the rocket is assembled into one whole, put on the transporter-installer (white-blue structure in the photo below) and sent to the launch site. On the sides of the hangar there are halves of the head fairing wrapped in a shipping cloth and another "Soyuz-2" in a disassembled state.

Launch complex

We leave for the launch site. A feature of Vostochny is a mobile service tower (MBO). It is based on the project for the Kourou cosmodrome in French Guiana, it is larger and heavier than the first version - 1600 tons versus 800. The main advantage of the tower is that it shelters not only equipment, but also, most importantly, people from wind, cold, rain and snow ( read about the starting structures ). Preparations for launching a rocket in the open areas of Baikonur or Plesetsk are much less comfortable.

After installing the launch vehicle in the launch facility, the MBO runs into it to perform pre-launch preparatory work. Shortly before the start, the tower departs about a hundred meters. The speed of the tower is 12 meters per minute.

We go inside. A very wide angle lens is needed to capture the launch facility. Below is a maintenance basket, it is needed to, among other things, install 32 birch "matches" , which start the engines of the first and second stages. Before the start, the basket is removed under the starting table.

We rise to the upper platform of the tower. A rocket stands in place of the camera in preparation for launch.

On the side of the tower there is a small balcony of the emergency evacuation system. From a height of about 50 meters, beautiful views open up.

Switch to the telephoto lens. Here is a view of the UTK from a distance of 4 km.

The launch complex under construction for the "Angara" launch vehicle is almost twice as close. On the left is the future launch facility, in the center you can see huge green-covered tanks for storage of propellant components (the launch will store two full Angara refueling stations), white buildings in the distance are workers' dwellings. Our guides (as in the joke "I don't know what kind of bloggers they are, but their guides are Dmitry Rogozin and the general director of TsENKI Andrei Vasilyevich Okhlopkov" ) emphasized their comfort in every possible way. This is really important for normal operation.

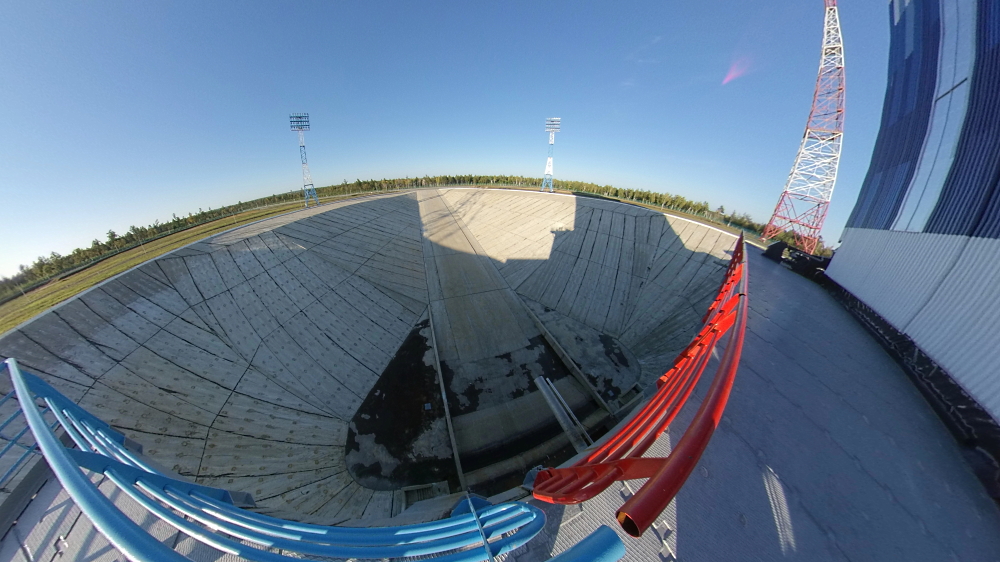

View of the flue and surrounding landscapes. Frankly, we were lucky with the weather.

But this unseemly looking hole is a system of emergency evacuation of personnel from the tower. The principle is simple - we jump into the sleeve, spread our knees and elbows and brake them to the surface. If you jump with straight legs and arms pressed to the body, then you can accelerate very unsafe for health. So, in order to use the system, personnel undergo training and pass tests.

The depth of the flue bowl is 22 meters, and in order for it to fit into the frame close up, you have to use the capabilities of the 360 ° camera.

Command post

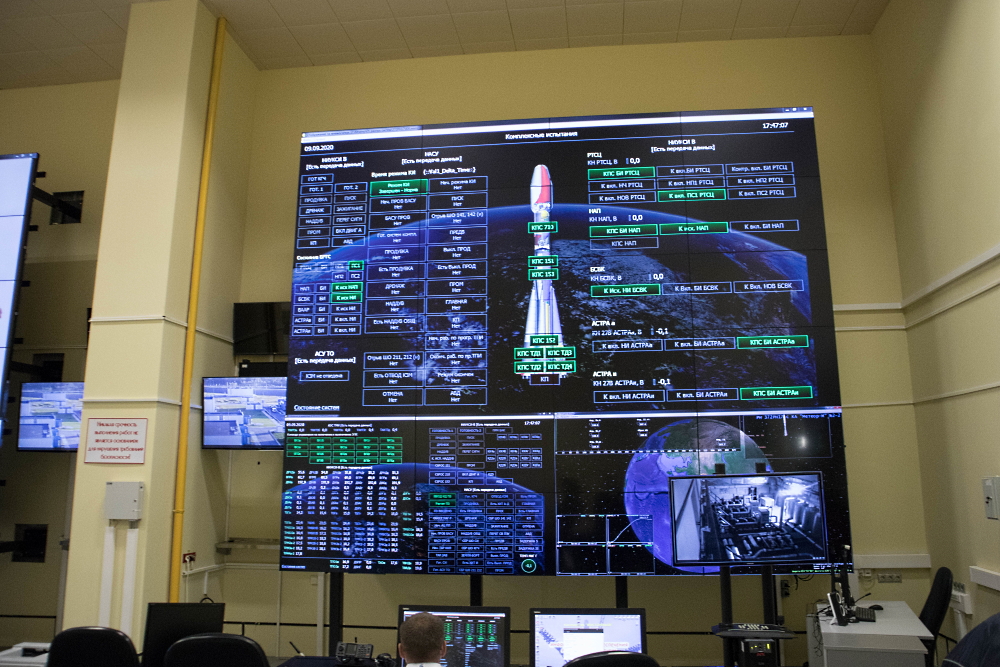

Our next stop is the command post, from which they control the preparation of the rocket for launch and directly give the command to launch. The building was designed taking into account possible accidents, we pass through armored doors, and we are told more than once about the overpressure inside the building, made specifically for the safety of personnel. And at Baikonur there is a bunker with periscopes.

In the first room, there are workplaces for operators of ground systems - thermostating, provision with liquefied gases, etc. The terminals are full of young people, I personally was pleased.

And in the second room, the operators work with the rocket and control the launch.

The legendary start key on Vostochny turned from a physical key into a rotary toggle switch.

Command and measurement point

When the rocket lifted off the launch pad, it transmits telemetry and footage from the onboard camera . When a satellite enters orbit, two-way communication is established with it. The data is received and transmitted by antenna systems at the command and measurement point (KIP), located 11 km from the start. The Vostochny KIP is a small building (it is the most compact of the four Russian ones), surrounded on all sides by antennas.

The largest antenna in the photo works with one of the Luch-5 repeater satellites. Repeaters in geostationary orbit extend visibility. Otherwise, communication with the satellite would be lost when it goes over the horizon.

Employees are offended when they hear how antenna systems are called dishes, especially since under some spherical domes there are not dish-like phased array antennas at all.

Part of the cosmodrome under construction

Now at Vostochny, objects of the second stage for the Angara launch vehicle are being actively built - the launch facility (GP-1), the command post (GP-3), premises for storing propellant components (GP-6 and -7), a building to ensure the temperature regime and supply consumers with compressed gases (GP-4). The launch complex is being built with a reserve for the future, facilities for working with liquid hydrogen (GP-5) are envisaged, which will be used by the developed upper stage KVRB. It will significantly increase the carrying capacity of the Angara.

Equipment warehouses

The launch complex is a huge amount of equipment that is produced throughout Russia and brought to the cosmodrome in large blocks. Our tour began with a warehouse that stores equipment that requires constant temperature and humidity. For example, a liquid oxygen filling system is waiting for its turn. The guide says that the equipment is delivered on time or even ahead of time.

The blocks of the cable-filling tower lie near the open air. A huge structure 66 meters high and weighing 3000 tons was produced, dismantled into blocks weighing from 17 to 50 tons and delivered to Vostochny.

Launch complex

Command post building under construction. Functionally, it is similar to the command post we have already seen for the Soyuz, there will also be two main rooms for ground equipment and a missile, only here they will be located on different floors. No less attention is paid to safety, the structure is designed for a direct hit from an emergency missile, there will also be a system that creates overpressure.

And this is part of the launch pad for the Angara, delivered just before our visit.

In the distance you can see the mobile service tower of the Soyuz launch complex.

The scale of the construction perfectly conveys the view from the side of the gas duct. The launch of the "Angara" will be similar to the Soyuz one, only more, and with a stationary service tower. The flue will be a similar bowl, but of course larger and deeper.

View strictly from the end.

And now we are going down under the surface of the future launch facility. Soon the reinforcement will be filled with concrete.

Pay attention to the number of ties and the fact that the reinforcement rods are connected with couplings. Together with the special concrete we are told about, the structure must be able to withstand enormous loads.

I express my gratitude to Roscosmos for the invitation to the press tour.