Many modern NAND flash memory devices today use a new type of architecture in which the interface, controller and memory chips are integrated into one common layer of compound. We call this structure monolithic.

Until recently, all memory cards such as SD, Sony MemoryStick, MMC and others used a simple "classic" structure with separate parts - controller, board and NAND memory chip in a TSOP-48 or LGA-52 package. In such cases, the recovery process was very simple - we soldered the memory chip, read it in PC-3000 Flash, and carried out the same preparation as in the case of ordinary USB flash drives.

However, what if our memory stick or UFD device has a monolithic structure? How to access and read data from a NAND memory chip?

In this case, to put it simply, we need to find a special process output contact on the bottom of our monolithic device, removing its cover for this.

But before you start recovering data from a monolithic device, we must warn you that the process of soldering a monolithic device is complicated and requires good skills in working with a soldering iron and special equipment. If you have never tried soldering a monolithic device before, we recommend that you practice on donor devices with unnecessary data. For example, you can buy a pair of devices just to practice preparing and soldering.

Below is a list of the required equipment:

- High quality optical microscope with 2, 4 and 8 times magnification.

- USB soldering iron with a very thin tip.

- Double sided tape.

- .

- .

- (, Lukey 702).

- .

- .

- (75% ).

- 0,1 .

- (1000, 2000 2500 – , ).

- 0,3 .

- .

- .

- .

- - PC-3000 Flash.

When all the equipment is ready, the process can begin.

Let's take our monolithic device first. In this case, it's a small microSD card. We need to fix it on the table with double-sided tape.

After that, start removing the compound layer from the bottom. This will take some time - you need to be patient and careful. If you damage the layer with contacts, the data cannot be restored!

Let's start with the coarse sandpaper, with the largest grain size - 1000 or 1200.

Having removed most of the coating, you need to switch to a smaller sandpaper - 2000.

Finally, when the copper layer of contacts appears, you need to switch to the finest sandpaper - 2500.

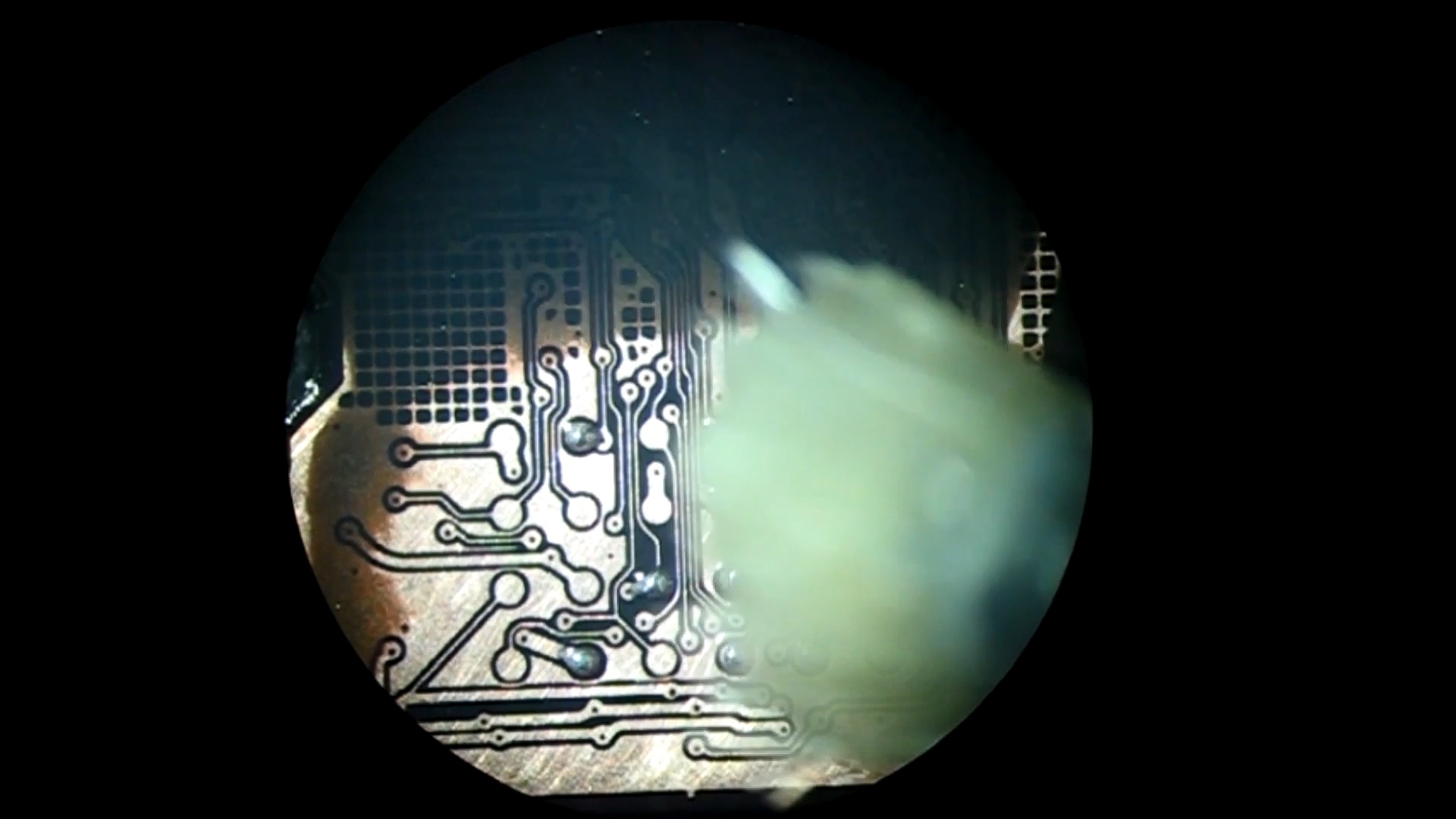

If everything is okay done right, you get something like this:

Instead of sandpaper, you can use this fiberglass brush, which ideally scrapes the layers of compound and plastic, and does not harm copper:

The next step is to look for the pinout on the Global Solution Center website .

To continue working, we need to solder 3 groups of contacts:

- I / O data: D0, D1, D2, D3, D4, D5, D6, D7;

- Control contacts: ALE, RE, R / B, CE, CLE, WE;

- Power pins: VCC, GND.

First, you need to select the category of the monolithic device (in our case, it is microSD), and then select the compatible pinout (we have this type 2).

After that, you need to fix the microSD card on the adapter board for easy soldering.

It is a good idea to print out the pinout of your monolithic device before soldering. It can be placed next to it to make it easier to check with it if necessary.

We are ready to start soldering! Make sure your desktop is well lit.

Apply liquid flux to the microSD contacts using a small brush.

Using a wet toothpick, place all balls on the copper pins marked on the diagram. It is best to use balls with a diameter of 75% of the contact size. The liquid flux will help us fix the balls to the microSD surface.

After placing all the balls on the contacts, you will need to use a soldering iron to melt the solder. Careful! Perform all procedures gently! To melt, touch the balls with the tip of a soldering iron for a very short time.

When all the balls have melted, apply a BGA gel flux to the contacts.

Using a soldering dryer, you need to warm up the contacts to a temperature of +200 C °. The flux will help distribute the temperature to all contacts and melt them evenly. After heating, all contacts and balls will take a hemispherical shape.

Now you need to remove all traces of the flux with alcohol. You need to sprinkle it on the microSD and clean it with a brush.

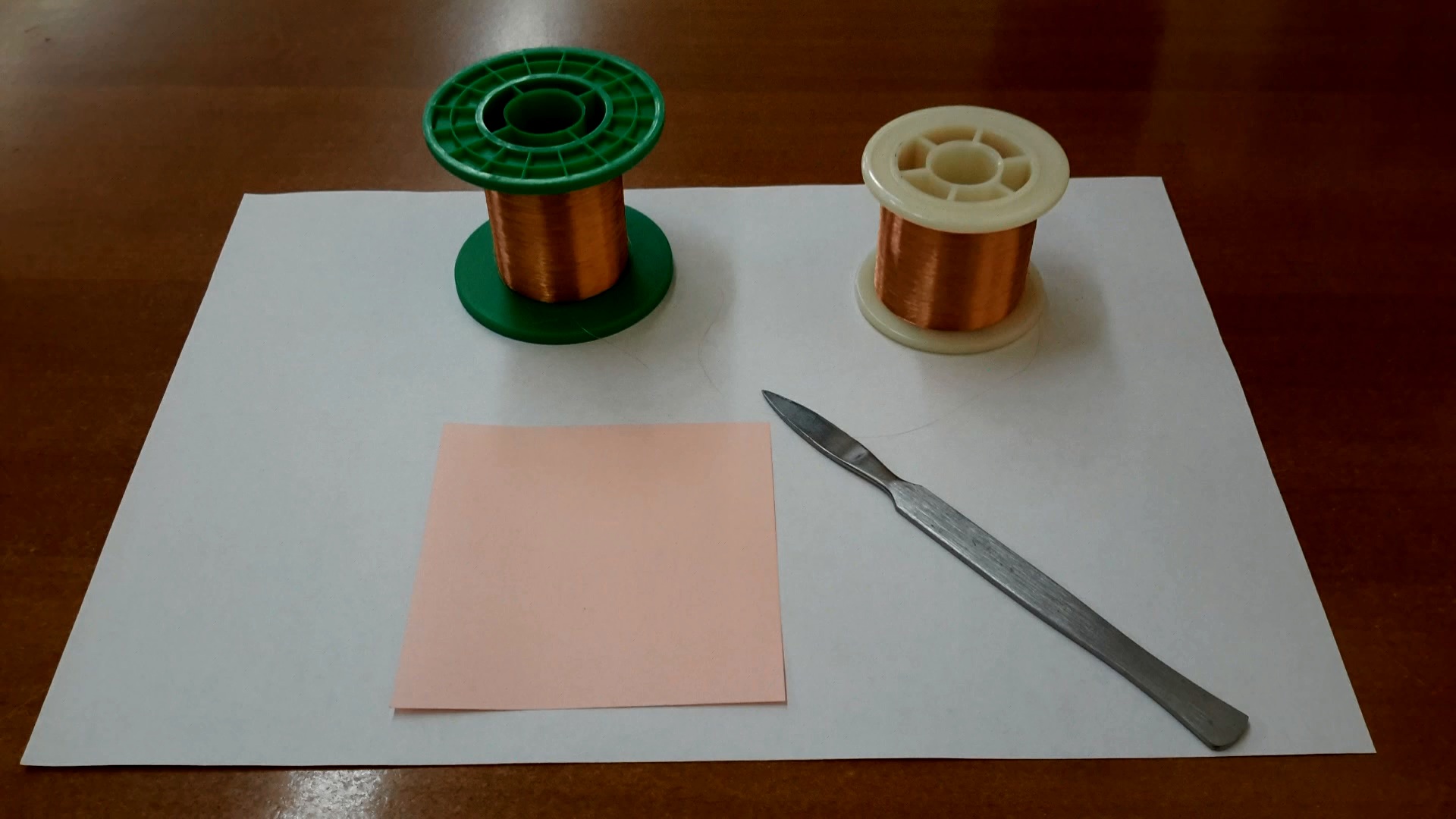

Next, we prepare the wires. They should be the same length, about 5-7 cm. You can measure the length of the wires with a piece of paper.

After that, you need to remove the insulating varnish from the wires with a scalpel. To do this, simply scrape them gently on both sides.

The last stage of preparing the wires is tinning them in rosin so that they are better soldered.

And now we are ready to solder the wires to the adapter board. We recommend starting the soldering on the board side and then soldering the wires on the other side to the monolithic device under the microscope.

Finally, all the wires are soldered and we are ready to use the microscope to solder the wires to the microSD. This is the most difficult operation and requires a lot of patience. If you feel tired, take a rest, eat something sweet and drink coffee (blood sugar will eliminate hand tremors). Then continue soldering.

For right-handers, we recommend that you hold the soldering iron in your right hand, and with your left - hold tweezers with a wire.

The soldering iron must be clean! Remember to clean it while soldering.

After soldering all pins, make sure none of them touch the ground! All contacts must be very tight!

Now you can connect our adapter board to PC-3000 Flash and start reading data.

Video of the whole process:

Approx. transl .: Just before the translation of this article, I came across the following video, relevant to the topic: