Hello! In this article I will tell you how in "Live Typing" one clever QA with creative thinking and skillful hands helped his team and optimized the process of working with devices.

The mobile development market is vast and in order to stay competitive it is necessary to ensure the quality of the product at the highest level. The team must be confident in their product, in its reliability, convenience, in that it looks the way it was originally intended. In order to check all this, QA exists.

QA is a department of brave guys who evaluate the UI / UX of an application or a website, and also test the application for fault tolerance and bugs, thereby ensuring the quality of the product.

Devices (tablets and phones of different models) are a key tool of every QA: it is on them that we test applications and prepare them for release.

In the testing process, it is necessary to rely on the postulates of the tester - a set of rules accumulated by many years of experience. They help to conduct quality testing. I would like to dwell on two of them in more detail:

- The pesticide paradox suggests that testing on monotonous cases is ineffective, since it will not reveal all possible bugs.

The paradox works like this: when we test an application on only one device, we cannot guarantee that it will work stably on models newer or older. Therefore, we need different versions of iOS and Android and, accordingly, a fleet of phones.

- Exhaustive testing is unattainable - the rule says that a program, site or application cannot be thoroughly tested. If you didn't find bugs, it means ... that you didn't find them, and not that there are no bugs at all.

So we don't even try to check everything. But testing a large number of cases on diverse devices gives us confidence in the quality of the product: this way we eliminate more possible errors. This allows us to make sure that we cover enough tests to provide the client with a quality product.

From these two postulates, we can conclude: the need for a quality product justifies the need for a large number of devices.

But testing, QA, postulates - all this happened later. Let's go back a little - I'll tell you how my journey as a tester began ...

1. Becoming. Mastering. Pain

How I got to Live Typing

I learned about Live Typing back in 2014 at happyDev-lite. I always admired with what positive and interest the speakers of this studio plunge into their topics, with what glowing eyes they tell and how it strongly distinguishes them from the background of other companies.

I remember how I admired the performance of Roman Belyaev: he said that he became a designer at LT thanks to his soft skills. He was hired with an empty portfolio right after a test assignment that he plowed over all night. It was not even that he was taken to a key position without experience that struck me, but that the company saw the potential and gave him the opportunity to reveal himself. Positions in other teams require young professionals with long-term experience in promising IT companies and a set of cases in their portfolio. I was delighted that there are people who are ready to develop talented guys from scratch.

Having studied the basics of design and layout, I decided to try myself in testing. I was confident that this knowledge would help me better understand workflows, user scenarios, and usability. And I was not mistaken.

I graduated from the Tamtek school, where I got a solid base in design, and realized that none of the Omsk companies gives such knowledge. And after that I tried my luck at an interview in "LT". I got into the company after passing a test assignment and two interviews as a QA with experience in design.

How accustomed

When I started working at Live Typing, I continued to be amazed at the cozy atmosphere in the studio and how everyone lives together in one big “home” office. How everything is optimized and tuned for a comfortable working mode. How close and warm the interpersonal relationships of colleagues are. And I was pleased with such an environment.

Work in such an atmosphere went on by itself - it seemed that everything was perfect, but at that moment I still did not suspect anything ...

Why did it hurt

At one of the stages of testing the project, I needed a variety of devices. It was then that my acquaintance with the main character of the story happened.

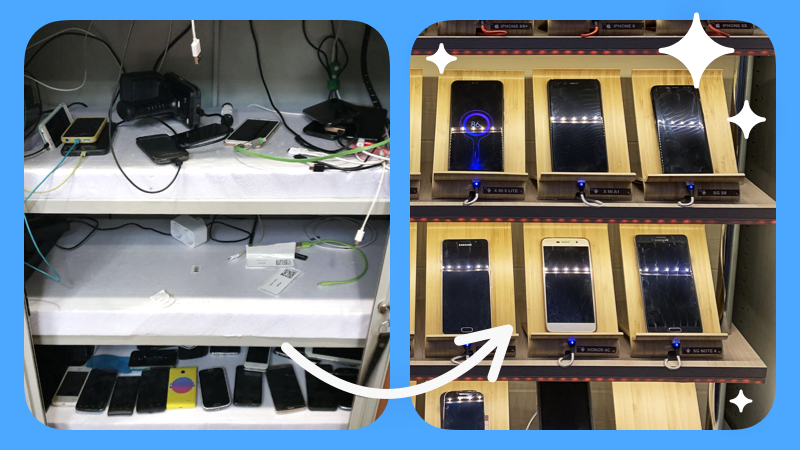

It was a modest, nondescript, very offended and neglected closet - all our test devices were stored in it. Opening it, I prowled for a long time among a heap of dead souls in search of the right smartphone, until Rose (my colleague-QA) came to my aid and found it for me.

2. Selflessness

The story of a long search for devices and / or wires began to touch me every day. Such a trivial task, how to find Xiaomi Mi A1, took a lot of time and brought mental anguish. After a while, I came to the conclusion that it pisses me off and it shouldn't take so long to find a device. I found a bottleneck in workflows and decided to eliminate it.

Later, I discovered that I was not the only one with such problems: I often observed how much time people spend on finding a phone, finding a wire, putting it on charge. And the cabinet constantly clamped the wires and it was not always possible to close it the first time.

And what scared me the most was how people were calm about it - the chaos did not surprise anyone. The guys just got used to it.

Gradually, a plan was formed on how to improve the corner of devices, and I decided to try to create a small Eden inside "LT" - to make not just a storage cabinet, but a convenient space in which each phone will have its own place. So that even a new person who comes to "LT", in a few seconds, finds a device or a wire, while receiving aesthetic pleasure from the process. These are the goals I set for the future "project".

“Well, cut holes in the foam, lay out the devices - why are you so worn out,” they said ...

When I read smart articles and books about management, I was faced with conclusions about how the correct organization of the workplace affects performance and concentration - these things are the foundation of work processes.

"If a cluttered table testifies to an orderly mind, then what does an empty table testify to?" Albert EinsteinWhen there are a lot of objects in the work area, attention is scattered. What to look at? What to focus on? Chaos is going on in my head, I feel tired, irritated, inability to concentrate on work tasks. According to research by scientists from the University of Priston, about 38% of the total level of concentration depends on the organization of the workplace, and this, you see, is a lot.

To concentrate on one thing, you have to ignore everything else. Concentration appears only when we say "yes" to one option and "no" to all others. In other words, exclusion is a prerequisite for concentration.

"What you don't do depends on what you can do." Tim Ferris, writer, speakerYes, of course, the correct organization of the workplace increases productivity, and for LT it is critically important, in my opinion. I never knew how to put this into practice and did not understand the value of these conclusions, perhaps I would not have understood if I had not seen the closet.

3. Seed

The first and priority task was to establish orientation in the closet so as not to get confused with a bunch of devices. I got fired up with the idea of "rotational" distribution of devices, where each device has its own cell with a tag and name.

Yes, that would be more convenient, but when the first ardor subsided, I began to soberly assess the situation. For "LT" this output was not suitable: it had a lot of shortcomings from unreliable fastening of devices and cable management to lack of solidity.

Fulcrum

Having rummaged on the Internet, I did not find an ideal option that would suit me in all respects, and decided to implement it myself.

It was necessary to decide how it should look, a fulcrum was needed. On one of the days of wandering around the shops in search of ideas, I came across two samples in IKEA with the beautiful names "Sigfin" and "Bergenes" - from them the path of a large project began.

The first option seemed to me close to ideal: it was simple, aesthetic and quite convenient. He had an outlet for the wire, which partly solved the problem of cable management. I decided to use the second option for other, more voluminous devices. he was in the same style and perfectly held tablets. The other stands were too bulky for them.

4. Initial calculation

And finally, the general picture gathered in my head - I took all the measurements and started to fulfill my idea. The first foray into the "Baucenter" behind the planks, drawings, the screeching of a drill, the creak of a drill tearing wood shavings - and now something began to appear.

In total, "LT" has 19 operating devices + 6 tablets, and only four stands with phones could fit on the shelf - and this was the first problem that was solved by the variability of fastening: if earlier the shelves were attached from two sides, now they are attached only from the bottom, so most accommodating five coasters on one shelf.

In order to cover the entire set of devices, it was decided to make five shelves:

- Upper shelf for tablets

- Top iPhone shelf

- Top shelf for Android

- Descending novelty Android

- By the residual principle

5. Difficulties in the studio!

Well that's all. At this stage, I was stuck for the next four months due to quarantine, since I did not tinker at home, but at my parents. But self-isolation was not so terrible - you could wait and finish. Worse, all the layouts that I used to make the shelves mysteriously disappeared from my parents' apartment. So I had to start over.

In order to fit the shelf on the pipe from both sides, and to make it look dignified and neat, it was necessary to make mockups again, which were subsequently checked and tried on on previously made shelves.

A mock-up is a piece of cardboard that is laid on a wooden board, and on the cardboard there is an equidistant point. Through this point, the center of the future circle is drilled and a circle is subsequently made with a pen, which is put on the pipe. It sounds complicated, so here's a picture to understand.

Naturally, the layout did not work out the first time, and even the tree began to splinter at the entrances. But I didn't despair. Hence the second trip to the "Baucenter" for additional boards to replace the damaged shelves. There I came up with the idea to upgrade the future cabinet, but more on that later.

The next difficulty was that it was necessary to figure out how to attach the mobile stands, otherwise they would dangle and fall constantly.

The coasters looked aesthetically pleasing, so I didn't want to spoil them with a self-tapping screw, the hot melt looked ridiculous and left big marks, but high-quality and strong double-sided professional adhesive tape "3M" from our favorite CHIP and DIP was just the right thing.

The scotch tape firmly fixes the stands and is hidden from view. Super.

The convenient arrangement of devices on the shelves was not enough for my purpose (it is too simple), so the idea of lighting devices found itself.

6. Upgrades

At this stage, it was necessary to choose lighting, choose the optimal height for the location of the cabinet, figure out how to position it correctly, calculate the power of the power supply, put the back wall for greater rigidity of the structure, make holes in the back wall for wires and distribute the power, and also do so, so that the lighting does not dazzle people opening the cabinet.

A small LED strip was chosen as the lighting, a 40-watt block covered it with a margin, a light visor, a button under the second shelf from the top simplified the control of the light, which would not give the effect of heating with constant light.

Next, it was necessary to drill three holes in the back wall of each shelf, so that they were not visible and an armful of wires passed through them.

Two at the edges and one in the middle, for routing wires from the hub. I drilled on each shelf, taking into account the possible change in the position of the hub.

But besides this, there were also problems - the condition of the wires. Oh yes, wires ...

The new plane does not fly long on old wings

How could you leave that in the closet?

"Every problem always has a solution - simple, convenient and, of course, wrong." Henry Louis MenckenThere is such a thin line between solution and problem that they can be equated. What is the solution for one problem, then the basis for another - and so on ad infinitum. The only hope is that the next one will be less than the previous one.

The above problem came to me with an old, cool idea for magnetic wires, which I still use at home. The advantage of magnetic wires is their versatility and unification. They consist of two parts: wire + tip.

There are three types of tip for each connector: micro, type-c and ligthning. It is inserted into the device and is there constantly, and the wire, when brought to the tip, is magnetized and held - thus extending the life of the connectors. In addition, it is quite convenient to put the devices on charge. It looks something like this.

The choice was determined, it remained to calculate, approve, agree and, in fact, order.

After approval, I ordered 26 wires with lugs (I took with a margin) and proceeded to the next step.

Subject visualization is the key to minimizing errors

The actual change of the cabinet is a prerequisite for the redistribution of wires between devices and a change in cable management.

"A good drawing is half the solution" (c)I needed to minimize risks with a shortage of wire length, because all charging wires were one meter long and calculate the location of the hubs so that the wires from them reach all devices.

I decided to visualize the hubs to understand their location, so that two hubs cover all cases and reach all shelves. I measured the dimensions of all hubs and recreated an accurate cardboard model of both of them, and also measured a rope meter to simulate a wire for convenient testing of all cases. ...

It turned out that each hub with a length of wires covers three shelves, respectively, one above, the other below. Considering that access to the hub may be required, I did not hide it behind the cabinet, but left it behind the stands on the third and fifth shelves.

Package with wires or suitcase without handle

After some time, the cherished package arrived. I ordered on Aliexpress from an official representative of Floveme, but even here there were risks. Despite the positive reviews and my trust in the brand, the seller sent in everything except 15 lighting tips. Hunger for money, cheating or an accidental mistake? It is not clear, but the panic appeared definitely.

The deadlines for the closet are already burning, and you can't put it unfinished. The Chinese are very cunning and proud of their brands so much that they make incompatible wires from one manufacturer and lugs from another.

I understood that I was responsible, and there was no point in ordering another set of tips, so I came up with the following.

I disputed part of the money from the seller for the lack of tips and re-ordered the missing ones from him under another account under another name. And after a week and a half, they were already waiting for me at the Post Office. Problem solved, hurray!

7. Tags

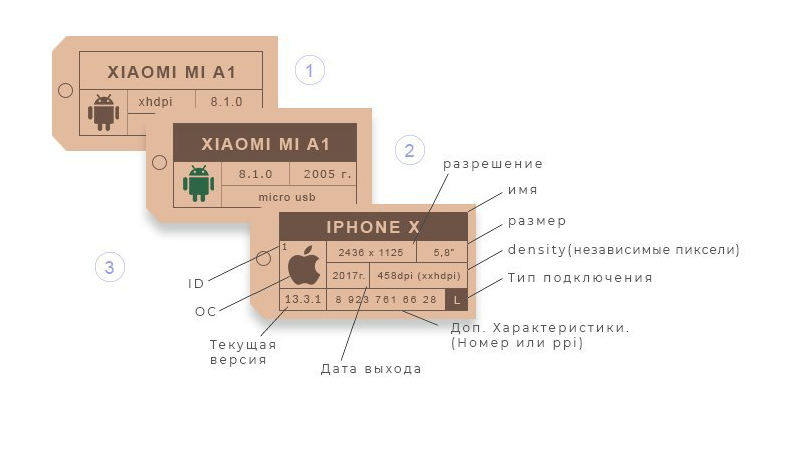

One of the most important steps that influences quick orientation in the closet is the designation of devices. How? With tags.

They should be capacious, contain all the necessary information, and also name what is in front of us. Throughout most of the time I was working on the cabinet, I simultaneously designed and tried on various options.

I stopped at the third option, because it was more suited to my requirements. I placed the tag on the back of the stands, and on the bottom of them I duplicated the names so that if the phone is on the stand, you could identify its model.

8. Excellence, conclusions and development strategy

At this stage, I have done what I intended: the cabinet fits perfectly into the LT corner.

Father and child

“Do not be afraid of perfection - you will not achieve it. Moreover, there is nothing good in perfection. " Salvador DaliNo, the closet is still imperfect, there are still flaws. It's too easy for us as a mobile development studio to have a nice and comfortable closet. There are problems with registering devices, what is assigned to whom, when and what time the devices were picked up, when they returned. It is for this reason that I am making further plans to improve our beloved wardrobe.

I will reveal the secret of the second stage of development, which I am thinking about: what if each employee has his own unique id on his badge, and on the closet a tablet with a simple application connected to the database? And every time an employee wants to take the device, he will need to bring the badge to the rfid scanner.

The tablet will display the devices that are registered on the employee, and in order to register or deregister the device, you will need to scan the device's QR code. By the way, Yandex has now implemented just such a system for accounting for devices, but they do not have such a beautiful cabinet as we have. If this idea deserves multiple sympathy, I will take on this stage in the near future.

Any problem is solvable if you believe in it and give yourself completely. It's always nice to contribute to a common cause and improve a process. I think that there is another reason for pride in LT.