Introduction

This article is a continuation of the publication “Looking into the past. Technology of the 18th century " .

In it, we built a really working steam engine, which should become the main part of the future.steam motorcycle, and even carried out trial experiments on its launch in air.

Now we need to solve the energy issue. And here the main differences from internal combustion engines (ICE) begin. In such engines, gasoline, mixing with air, enters the engine cylinder and when this air-fuel mixture ignites, energy is released. Expanded combustion products press against the piston, producing work. But in steam engines, energy is not born in the engine. She is born in a cauldron. The boiler produces steam, which in turn will press on the piston of our engine. It is this ancient energy that we need to curb!

Device

Steam boiler - a boiler designed to generate saturated or superheated steam. It can use the energy of the fuel burned in its furnace, electrical energy or recycle the heat released in other installations. (Wikipedia)

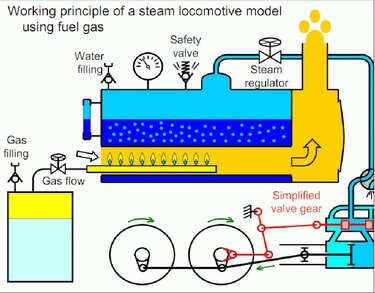

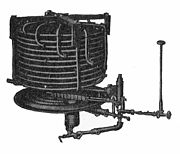

There are two main types of boilers: classic and direct-flow. The first type was most often used to operate steam engines. It can be described as an iron tank with a firebox embedded in it. The fuel burns in the firebox, heating the water in the tank. The water begins to boil in it and steam is created under pressure. This type was used on steam locomotives and all the first steam engines:

Classic boilers have both advantages and disadvantages. The advantages are that no pumps are required to create steam pressure, since the stored energy of the water can supply the engine with steam for a long time even in the absence of fire. Such boilers are not very demanding on water quality. The locomotives were filled with the most ordinary water from rivers, springs, wells and so on.

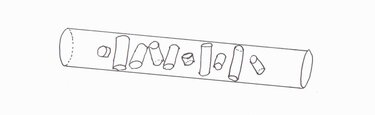

A straight-through boiler can be imagined as a long, compactly coiled tube, streamlined by a flame, into which water is pumped. This type of boiler has a number of advantages:

- Allows to create steam of higher pressure with less mass and small boiler volume.

- Due to the fact that there is not much carrier in the tube, such a boiler is considered safer (a large amount of energy is not stored).

- Quick exit to the mode, since you do not need to warm up a large amount of water.

For easy understanding, the operation of such a boiler can be represented in a simplified form:

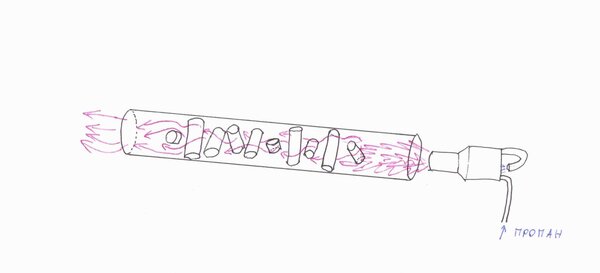

Creating a once-through boiler

And, of course, I wanted to make a direct-flow boiler.

Having picked up long stainless tubes of different sections, I welded them together in such a way that the section gradually increased. Then, all this 8-meter "intestine" was compactly rolled up and packed into the motorcycle frame. The outer walls, which are supposed to hold the flame and direct it in the right direction, were made of simple tin. The pump that pumps water (carrier) was made from a gas closer, which usually holds the hoods and trunks of cars. Structurally, a "closer" is a finished product. I only needed to weld the water inlet and outlet and attach a valve that would not let the pumped water back in. The pump was movably attached with one part to the frame, and the second to the crank on the wheel shaft. Using a flexible high-pressure hose (brake hose from a car), pressurized water was pumped into the boiler,and was taken from a separate tank located above the pump. The burner was made according to the type of "roofing", such workers heat roofing material on the roofs of buildings. To make the percentage of flow around the tubes greater, I installed two burners at once.

Outcome

Trials of a steam motorcycle equipped with a once-through boiler went wrong from the start. The very first problem was the lack of "initial" pressure in the boiler. I had to turn the wheel with my hands so that the pump sent a certain amount of water into the pipeline. But, when I opened the throttle handle (by supplying steam to the engine), the steam pressure instantly dropped, not having time to spin the wheel. The solution was not found immediately. A small air receiver was made after the pump. It worked like a spring for water. Stored compression energy from the pump and gave it back when the pump was at a dead point or in the suction phase of feed water.

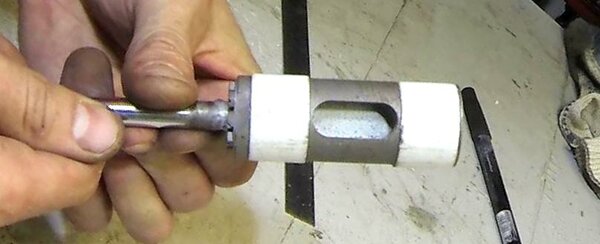

The engine is running! But it worked for about 10 seconds. Spool valvejammed. When disassembling the engine, no problems were identified. Putting it back together and running it again, I ran into the same problem. It turned out to be coming and going by itself. After studying this problem, an error was found in the calculations of thermal expansion. Initially, the spool was a solid piece of fluoroplastic, but it turned out to have a very high coefficient of thermal expansion (22) and when heated it expanded so much that it jammed to death in the body.

After detailed and careful calculations of thermal expansion, a steel spool fitted with PTFE rings, 2 mm wide, was machined.

Since the body is made of aluminum and the spool is made of steel, the difference in thermal expansion has been reduced to almost zero.

A new test showed that the spool works just fine and without any issues. The suspended wheel was spinning, water was being pumped in, the direct-flow boiler was working. It's time for a ride. But then a new problem arose. I could not drive it more than a few meters. Again, I was confused. It still worked! At idle, everything is debugged! What else is wrong?

After a long analysis of other similar steam apparatus,

I realized that my boiler was too small (the length of the heated tube), as a result of this, with an increase in productivity, the water simply did not have time to evaporate and flew out along with the steam into the engine. From this effect, the efficiency of the entire installation disappears, since the expansion of water is too little or does not occur at all. Increasing the length of the boiler tube is no longer an easy task. But my grief did not end there either.

During the next tests, I tortured the device, forcing it to work, but the condition of the engine began to deteriorate sharply and at some point it jammed. This time, just cooling it down with snow didn't help. A major bulkhead was needed again. The autopsy results showed that all the fluoroplastic rings melted and even the aluminum piston expanded so much from heating that it began to lift the cylinder. And that turned out to be a fatal problem. The fact is that at a high flow rate, this boiler did not have time to produce the required amount of steam, and at a low flow rate, it created steam of such energy that the entire engine simply went out of order. And no wonder. After all, the boiler outlet tubes were red-hot. That is, the steam reached temperatures of the order of 600-700 * C. As we know, fluoroplastic decomposes at 400 * C. For me, this was the "last straw"!I already wanted to get a workable motorcycle, and I was mired in some endless problems!

Almost everything in the boiler had to be redone. And at that moment I realized that, despite the indisputable advantages of a once-through boiler, this product is not very simple and requires delicate calculation, additional control equipment, and the pump consumed not a small part of the rotational energy. There was a clear understanding that if I were making a classic boiler, then none of these problems would simply arise!

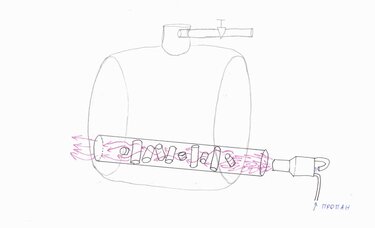

Classic boiler

After all those endless problems with a direct-flow boiler, creating a classic one, I was just, one might say, resting. As I said above, this is just an iron barrel into which the firebox is embedded. It was possible not to think at all about the temperature of the steam, because with excess pressure, the safety valve works and releases the excess, reducing the temperature of the water and maintaining the pressure within the specified limits. There was no need to create the initial rotation of the wheel to build up the initial pressure. Steam for the "start" was ready immediately and even stored in excess. All that was required was to come up with an efficient firebox. But here I had to think carefully, because we don't have much space.

Manufacturing

At the metal reception, I found some kind of receiver or a propane cylinder with a wall thickness of 3-4 mm, so the dimensions of the boiler were already fixed.

If you bother a lot with a massive and efficient firebox, then there will be little room for the water itself (the carrier). If the furnace is too small, then we will not have enough energy for a more or less satisfactory cruising speed, and the process of heating the boiler itself will take too long.

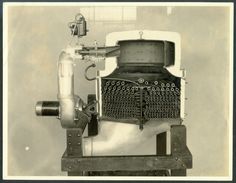

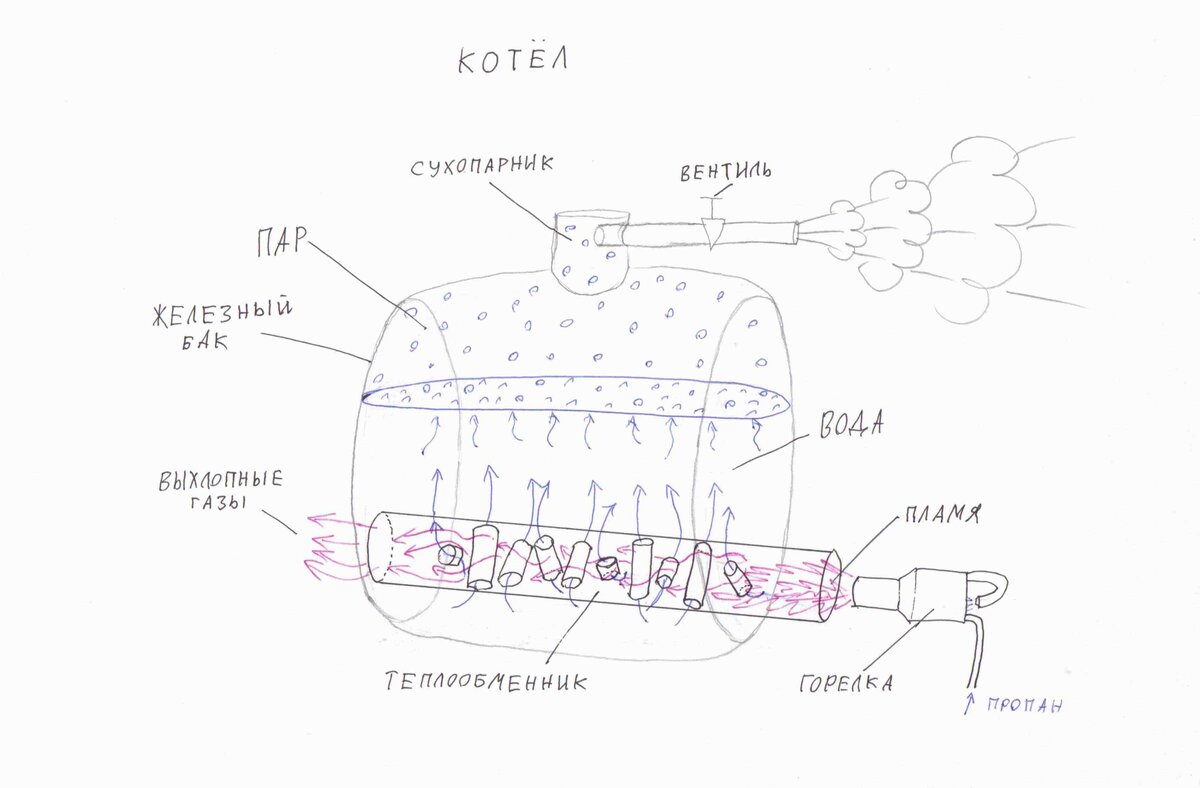

And here's what I came up with. The firebox will be subjected to squeezing by enormous pressure, so it was decided to make it simple, through and round. An ordinary pipe of 100 mm went under this. To increase the efficiency of our firebox ( heat exchanger ), 12 transverse through pipes were cut in.

I found this to be very beneficial, as they would flow around the flames and exhaust gases at right angles,

and the water inside them would circulate under the natural convection effect. This will keep the maximum volume of water in the boiler, and for us this is the power reserve. And, as a bonus, such a firebox was easy to cut into the tank. It was only necessary to make two holes at both edges.

To control the pressure, I installed a small pressure gauge. It is not necessary to control the temperature of the carrier, since it is directly related to pressure and clearly does not go beyond the critical mark (400 * C). I decided to make the pressure in the boiler like that of real steam locomotives - 16 bar.

The safety valve is set to 18 bar. Now it remains to press it... This is a kind of strength test. The boiler is filled to the top with water and increased pressure is pumped. At first, I did this with a pump from a closer, left over from the previous boiler system, but compressing such a pump at a pressure of more than 20 bar turned out to be not an easy task (it is very good that we can now abandon such a unit, because it took a lot of power on itself) ... It turned out that it is most convenient to pressurize with a carbon dioxide fire extinguisher. With them, I easily created a pressure in the boiler of 25 bar (this was the maximum of my pressure gauge) and, after waiting a few minutes, proceeded to adjust the safety valve.

Outcome

The boiler turned out to be great. Even the pressure of 25 bar was nothing to him. It didn't even start crunching. The safety valve (used from the compressors) worked clearly, although it dropped the pressure from 18 to 9. This one is not very profitable for us, but it will only work when you cannot keep track of the pressure yourself. So, it is better not to bring it to its operation. It will be a senseless waste of resources.

Flame

Now we need to resolve the issue with fire. Of course, it would be nice and pleasant to heat such a motorcycle with wood. This is a retrospective into the past, steampunk, classicism, but, as I said, we have very little space for this, because our firebox is a little more than an elbow. Of course, you can fit a cap of coal there, but this is not even enough to just warm up the boiler. Here I had to retreat from romance and make a gas burner. It is actually a very efficient, powerful and convenient fuel. The gas is liquid, so it is easy to store it, it is easy to feed it into the burner and it immediately goes under pressure, which allows creating a high-speed hot flow in the furnace, thereby improving the heat exchange process (no blowing is required).

Manufacturing

At the metal reception I found excellent, small-sized, stainless steel tanks. Judging by their shape and blue color, these are oxygen tanks from some kind of passenger plane. I assembled several such tanks into a battery and connected them with gas supply and refueling lines. The volume of each tank is about 1.7 liters, which means that it will be possible to carry more than 5 liters of fuel with you. liquid gas. Agree, not a bad supply of energy.

With the burner, he did not become wise and simply copied the system from the Soviet gasoline blowtorch. I must explain something here. The blowtorch is designed in such a way that the gasoline first enters a certain cavity, where it must evaporate and, already in the form of vapors, is released into the combustion zone. And the flame of the burner heats this very "evaporation" chamber. We will need the same. Imagine what would happen if liquid gas starts flying out of such a burner ... The process of gas evaporation is relatively long, and, in addition, it is also accompanied by a cryogenic effect. The flame from such a burner will be long, ineffective, not economical and even fire hazardous.

Experiment (Fig. A) Flame from an unheated burner (Fig. B) Correct mode, heated burner

Therefore, gas should be supplied to our burner smoothly so that it has time to warm up.

The boiler tests went like clockwork. I filled in about 35 liters of water, brought the burner to full power and waited. After 14 minutes, the water boiled, and the pressure slowly began to rise. After about the same time, the boiler was 16 bar.

I used a simple water ball valve to control the steam, which handled both temperature and pressure perfectly. They use the same fluoroplastic, so I think there won't be any problems.

For fun, I decided to turn the tap on full and look at our energy. A jet of steam reached the neighboring garages and created the noise of a rocket taking off. At the same time, I felt the force of jet thrust, I even had to hold the boiler so that it would not start flying all over the street. I was very pleased!

A huge amount of energy is stored in a boiler of this type. By venting steam for 5 seconds through the ½ ”hole, the boiler pressure dropped by only half. The fact is that with decreasing pressure, the boiling point of water also shifts. That is, the water begins to boil without heating, just from a decrease in pressure. This effect will work until the water temperature drops to 100 * C. This is good news for us. This means that it will be possible to drive for a long time even with the burner off.

But there is also one effect that is not entirely clear to me. With the active release of steam at a pressure of less than 5 bar, water begins to fly out. I assumed that it boils so intensely that in its frantic seething it reaches the dryand the steam caught by the stream flies out. For the experiment, I drained some of the water, leaving it at 20%. The effect of course decreased, but still remained. Does the water bounce 30-40cm in the boiler? To be honest, I haven't figured it out yet. Such is the small mystery.

Anyway! The functionality is ready, it's time to assemble our device!

Style

During the construction of our unusual motorcycle, many "pundits" advised me to make a closed water system. That is, so that steam does not fly out of the engine into the street, but gets into the condenser (cooler) and the resulting water is pumped back into the boiler using a small pump. This is a very good idea, I myself have been thinking about it all the time. But the goal of our project is not to travel around the world on wood, but to consider the technology of the century before last, overcome the engineering challenge and enjoy the work of a real steam engine. Well, what is a steam engine without this legendary "chug-chug". In addition, I would like to watch the escaping steam, it will tell a lot about the modes occurring inside the engine. Finally, I just find it very beautiful when there are puffs of steam from the locomotive, especially if they are illuminated by the sun. Steam locomotive romanceso to speak. But, in spite of all this, for the image, I decided to make a capacitor, so that it would be seen about our manners, and just for the style.

Most of the various homemade products are in the style of "Mad Max" or "Post-apocalyptic world". Yes, that's the easiest way. You don't really need to do anything. Rusty pieces of iron, welded wrenches, some hanging rags and the style is ready. But this simplicity, or so to speak "lazy style" in our world is very much. I wanted to do something small, cute and beautiful. Make "candy", so to speak. And since we have ancient steam technology, Steampunk suggests itself .

Steampunk is a fictional world. The way it would become if humanity had not invented electricity, internal combustion engines and other technologies and only steam energy existed.

Of course, I'm not a designer, but when assembling a motorcycle, some things still came to mind.

Steam motorcycle test

The "garage" tests of the fully finished steam motorcycle, equipped with a classic boiler design, went surprisingly smoothly. While I was building it, in the comments to the videos, people recommended a lot of correct and smart things. Along the way, I used some of them and in the end they showed themselves great. So, for example, when the engine is heated with steam, a lot of water condenses in it, which blocks the piston and can lead to a water hammer. People suggested making a small threaded hole with which it would be possible to release steam and drain condensed water, thereby quickly heating it. Then, drown it with a cog and calmly go straight away.

Surprisingly, the very first attempt to ride a fully finished motorcycle went without any problems. As the saying goes, "I sat down and went." Having driven a little in front of the garage, I realized that this is not enough for me and I want more. Of course, in order to measure all the parameters, see weak points, feel and understand this apparatus, a straight, empty, endless track is needed. Therefore, I had to take the motorcycle out of town and calmly deal with all this.

About the tests:

Overall, I am very pleased with the results. They even exceeded my expectations. Seeing how similar steam motorcycles ride all over the world, our baby turned out to be far from last.

Conclusion

When I thought about building this steam motorcycle, I reasoned like this: I’ll make it, somehow it will pass it all and, having satisfied all my engineering interests, I’ll put it at home opposite the sofa as an aesthetic element, forever. But no! Now, on the contrary, it haunts me. I want to study him, modernize, remake and break his own records, I want to determine his maximum, to understand everything he is capable of! Of course, within the framework of this concept.

The first thing to start with is to remake the steam switching system to the classic one. I wondered what the difference would be. And yet, during subsequent tests, you will need to "play" with the settings. Achieve maximum speed by choosing the most correct advance of the steam inlet. Also, I want to experiment with different types of fuel.

Apparently a big upgrade is coming. So, if our "steam locomotive" was going to retire and sit out somewhere in a museum, then I will greatly disappoint him! He still has a long, difficult, but most interesting future ahead of him!

More details about the creation and testing in the video materials:

Steam energy surrendered!

Great idea or fiasco? We deal with a direct-flow boiler

Creation of a locomotive whistle, assembly of the apparatus

Steam motorcycle tests