When I was little, my father had a VAZ-2101 car. It is not the coolest car, but it did its job properly and always looked great. The reason for this was that her father was courting her. Therefore, I have always believed that a cheap or old car can look much better than an expensive one only due to its neatness. Dust on any surface causes not only aesthetic disappointment in the style of Prometheus (because no matter how long you remove it, this process will have to be repeated over and over again), but also negatively affects the performance of some objects (coolers in computers, for example), and human health. does not strengthen. And if we are talking about dust on the surfaces in the apartment, then there are plenty of funds to eliminate it.But if this is the surface of an Earth satellite? Scientists from the University of Colorado at Boulder (USA) have developed a technique for removing dust from the lunar surface. Who is hindered by the dust on the Moon, how did scientists decide to get rid of it, and how effective is their method? We will find answers to these questions in the report of scientists. Go.

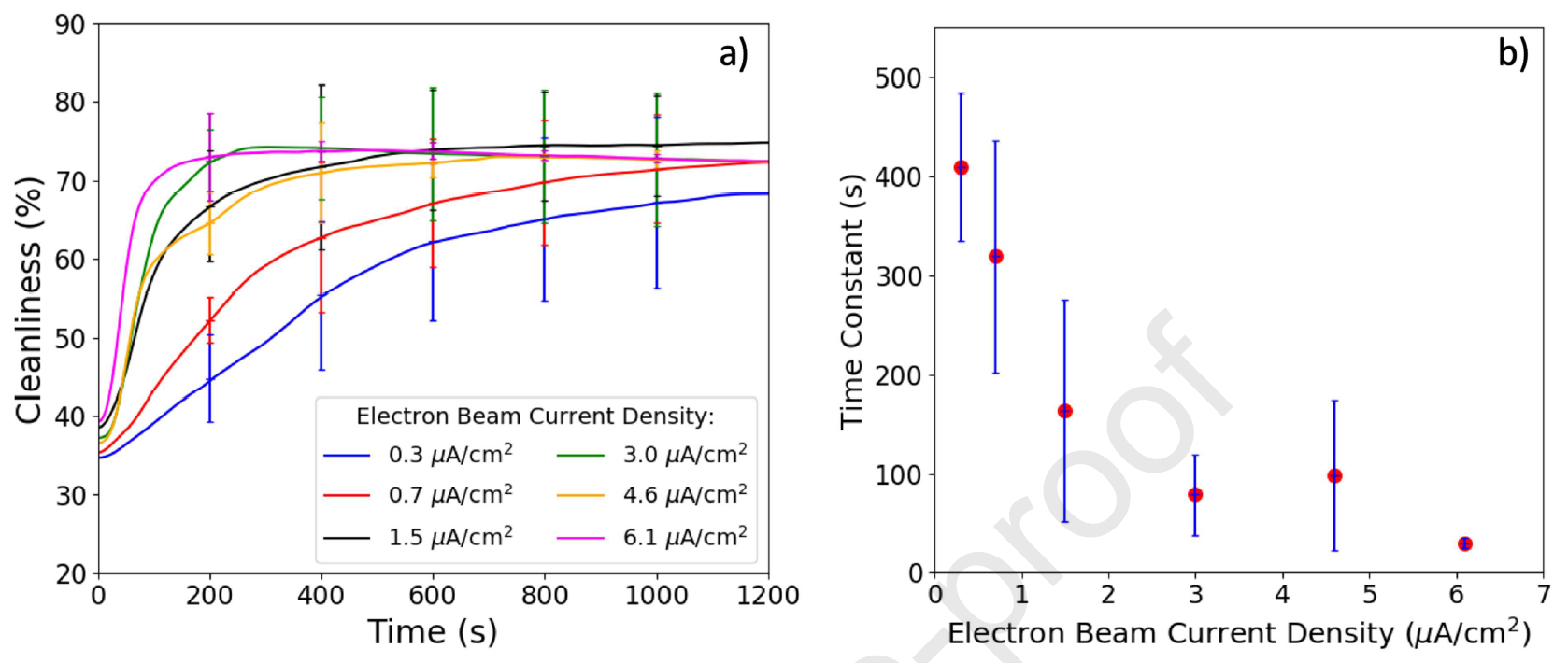

Basis of research

The lunar surface is a nightmare for allergy sufferers and cleanliness lovers. All jokes aside, the surface of our satellite is covered with a layer of regolith * .

Regolith * - residual soil, which is the result of cosmic weathering of rock on the surface of the Moon (and not only).Regolith particles can rise upward both from human activity and due to natural processes. They easily stick to any surface (moon rovers, spacesuits, optical lenses, etc.). But this is not the worst, because they can damage the objects on which they settle. For example, spacesuits suffer from the abrasiveness of moon dust; laser retroreflectors on the lunar surface show a decrease in light reflectance over time; heat sinks and thermal control surfaces (TCS from thermal control surfaces ) show degradation in their performance; solar panels covered with dust give lower power output, etc. And a person who breathed in moon dust can face extremely serious health problems.

This video examines the impact of moon dust on Apollo 17 mission participant Gene Cernan.

All of the above reasons have led to the fact that lunar dust is considered one of the main technical problems for future studies of the lunar surface by humans and robots.

Several dust suppression technologies have been studied and developed over the past decades. These methods can be divided into four categories (links lead to some of the research in these areas): hydraulic, mechanical, electrodynamic, and passive.

Hydraulic methods include the use of jets of liquid, foam and compressed gases to remove dust from surfaces. ( Lunar Dust Degradation Effects and Removal / Prevention Concepts )

Mechanical methods use brushes (such as nylon bristles) or vibrating mechanisms to clean up dust. This technique was used during the Apollo program. ( Evaluation of Brushing as a Lunar Dust Mitigation Strategy for Thermal Control Surfaces ) The

electrodynamic dust shield is currently considered one of the most advanced methods of dealing with moon dust. The basic idea is to apply an oscillating high voltage to electrodes embedded under the surface of the equipment to remove dust. It is expected that this method will be more effective in the lunar environment, since the lunar dust is charged with solar wind plasma, solar radiation and / or triboelectric effects. (Practical performance of an electrostatic cleaning system for removal oflunar dust from optical elements utilizing electrostatic traveling wave )

In passive methods, surfaces are modified (for example, by ion implantation) to reduce the adhesion of dust to a given surface. ( Evaluation of Surface Modification as a Lunar Dust Mitigation Strategy for Thermal Control Surfaces )

Naturally, each of the above methods has its own advantages and disadvantages. The choice of a particular technique depends on the characteristics of the dust itself, the properties of the surfaces and the conditions of use of the technique.

Scientists believe that the best results can be achieved by hybridizing these methods. In their research, they present a new method of using an electron beam to charge dust particles (<25 microns in diameter) to bounce off surfaces as a result of electrostatic forces.

Preparing for experiments

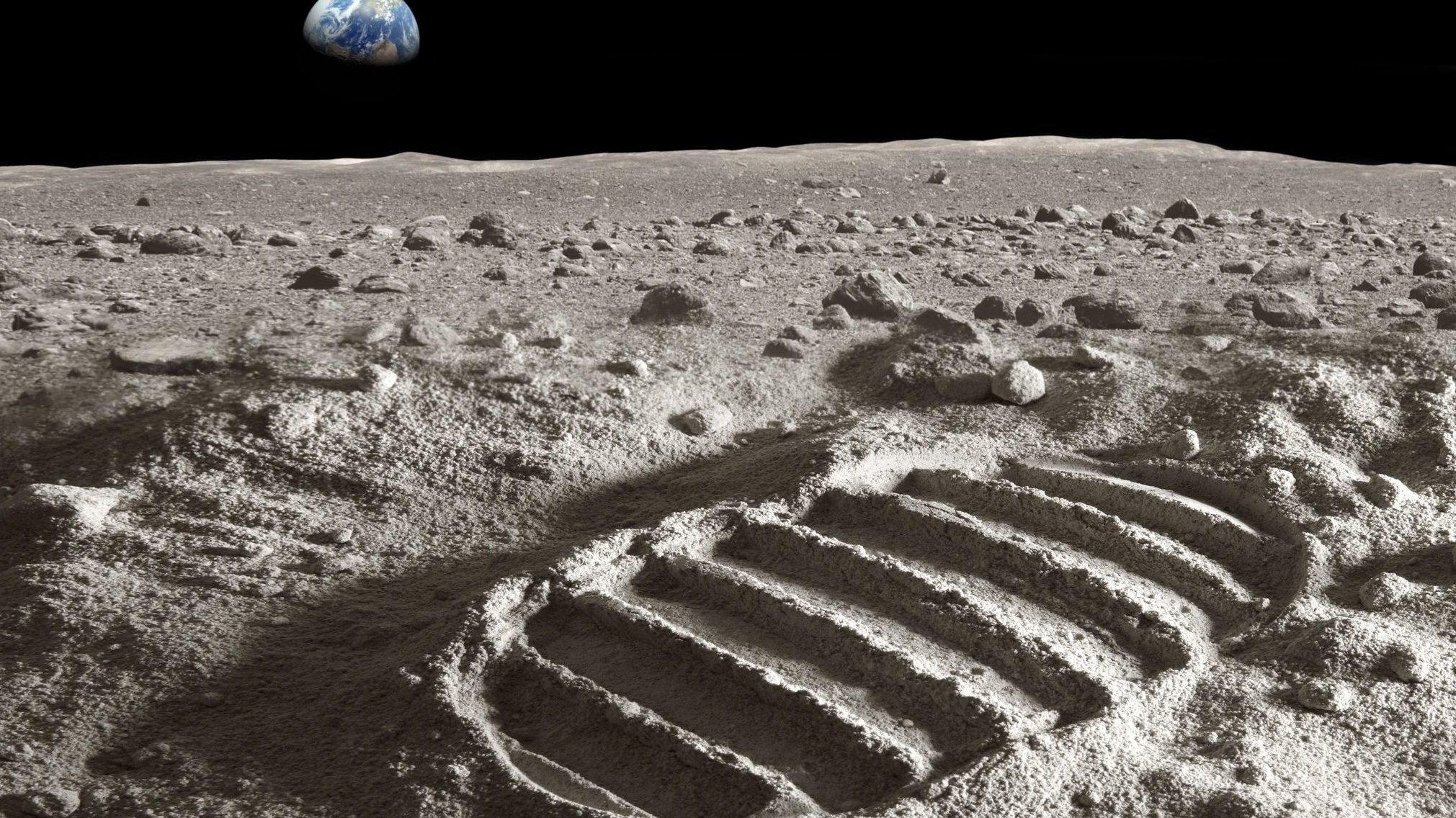

Image # 1

First of all, it should be noted that dusty surfaces have a unique feature of the formation of microcavities between dust particles. As seen in diagram 1aWhen electrons or photons pass through a small gap and hit the blue surface of the dust particles below the surface of the upper layer, secondary electrons or photoelectrons are emitted. Some of these emitted electrons are absorbed inside the microcavity and impose negative charges on the surrounding dust particles (red areas in the diagram). An extremely large electric field is generated across the cavity due to its small size (on the order of microns), which leads to the accumulation of significant negative charges on the surrounding particles. As a result, the repulsive force between these negatively charged particles is large enough to surpass the particle-to-particle or particle-to-surface cohesion and gravity. Consequently, dust particles are released. Practical experiments have shownthat dust particles of the same size with a diameter of up to 60 µm or aggregates with a diameter of up to 140 µm can be released from surfaces under the influence of an electron beam of 120 eV.

Based on these data, the scientists decided to conduct a series of experiments to determine the optimal characteristics of the electron beam to effectively remove dust from surfaces.

The experiments were carried out in a vacuum chamber 50 cm in diameter and 28 cm in height ( 1b ). Simulator lunar particles JSC-1A ( p ~ 2.9h10 3 kg / m 3 ; diameter <25 microns) was applied to the test specimen (2.5 x 5 cm) attached to the substrate. The substrate was attached to a shaft rotated so that the surface of the substrate was at a 45 ° angle to the horizontal line.

The entire surface of the sample was approximately uniformly illuminated by an electron beam emitted by a hot filament (filament) with a negative bias installed in the upper part of the chamber at a height of about 20 cm above the surface of the sample. Under vacuum conditions, the emitted electrons create space charge effects that limit the beam current emitted from the filament. To achieve higher beam currents, a low-density plasma was created by supplying low-pressure argon (~ 0.2 mTorr), ionized by an electron beam.

The beam current density on the sample surface was measured with a Langmuir disk probe. And the dust released from the surface was recorded by a high-speed camera (2000 frames per second).

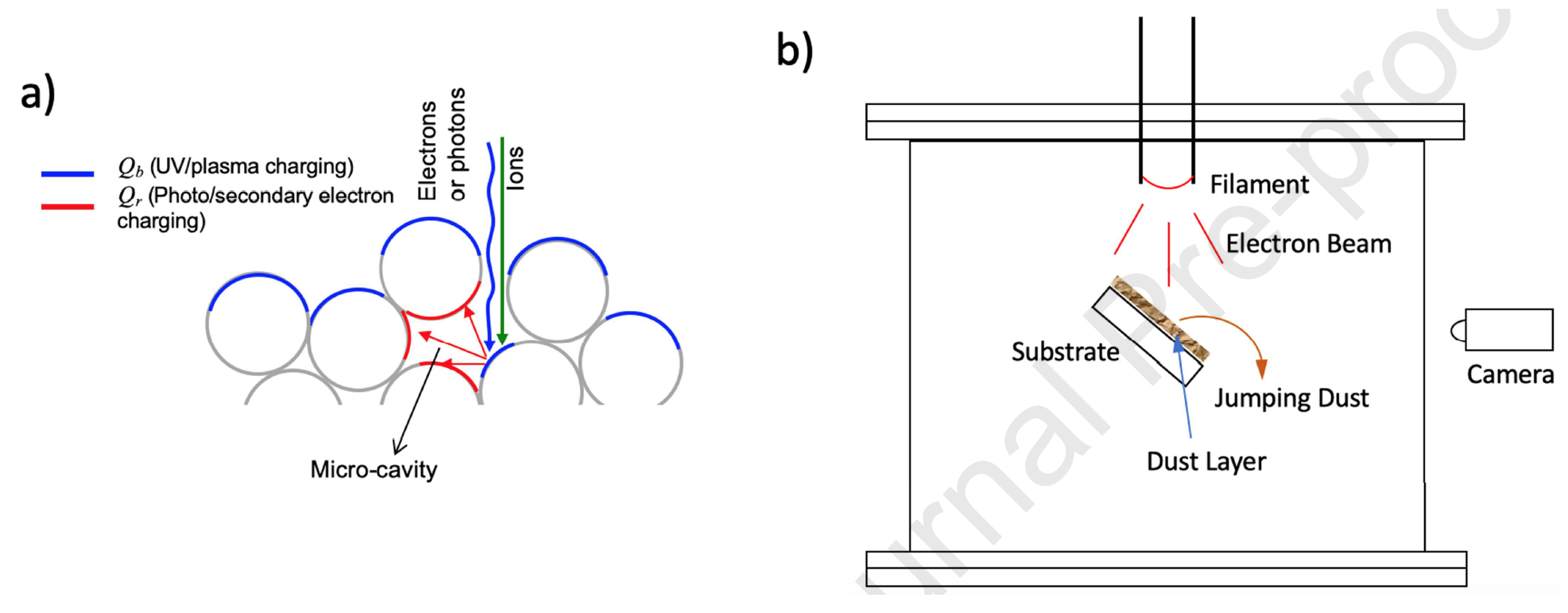

Image No. 2

Image # 2 (left) shows that a large flux of dust particles bounces off the glass surface as a result of exposure to an electron beam (230 eV; 1.5 μA / cm 2 ).

A video camera (but not a high-speed one) was used to record the initial cleanliness of the surface and its changes during the dust collection process. The camera's gamma correction was set to 1 by calibrating against the brightness obtained from the images. Image # 2 (right) shows images of the glass surface before and after the release process.

Surface cleanliness determines how dusty the surface of the test piece is (the lower the cleanliness, the higher the dustiness). In these experiments, purity (C) was determined in accordance with the formula:

C = (L s - L d ) / (L c - L d )where L s is the average brightness of the pixels of the entire surface of the sample; L c - average brightness of pixels of a clean surface (no dust); L d - average brightness of pixels on a surface completely covered with dust.

To achieve a controlled and constant deposition of dust on the test sample, it was necessary to perform the following three-step procedure:

- load the lunar particle simulator onto a sieve (mesh size: 25 microns);

- knock on the sieve so that particles of the required size fall on the sample and form an even layer;

- record images and analyze the brightness of the sample surface to determine the initial surface cleanliness using the above equation;

It is important to note that dust particles do not always form a uniform layer on the sample surface. In some areas, due to adhesion between the particles, several layers of dust are formed. Thus, the surface finish also depends on the thickness of the dust layer.

After the experimental setup was ready, several tests were carried out to determine the optimal parameters of the current density and energy of the electron beam. The cleaning efficiency was tested on different surface materials and with different thickness of the initial dust layer.

Experimental results

The first step was to check the current density and beam energy on a sample of a spacesuit covered with JSC-1A dust with an average layer thickness (C = 37.5%). The resulting beam current density varied from 0.3 to 6.1 mA / cm 2 . The beam energy was set at ~ 230 eV, which gives relatively high secondary electron emission for most materials.

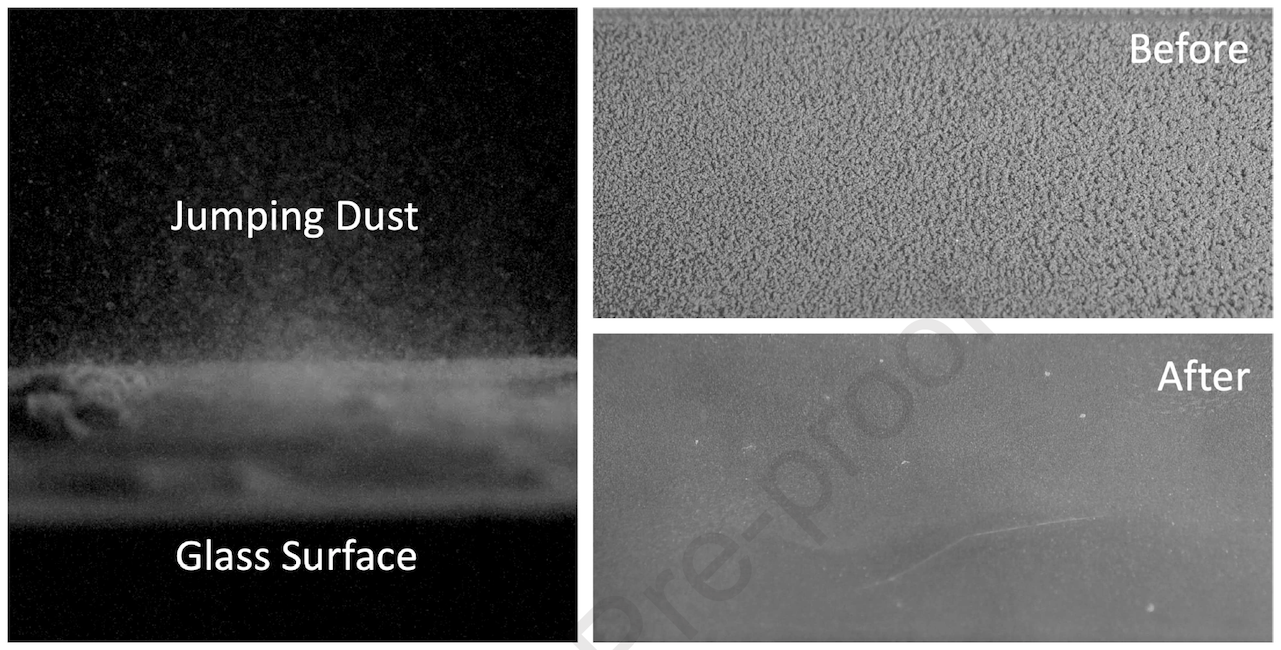

Image # 3

Graph 3a shows the cleaning process as a function of time. The maximum purity reached ~ 75% for all beam current densities. The time constant (defined as the time it takes for the purity to rise to 1-1 / e ≈ 63.2% between the initial and final values) of the purification process decreases as the current density increases ( 3b). The time constant tends to reach a plateau of ~ 100 seconds at a current density of 1.5 to 3 mA / cm 2 .

The rate of decrease in the time constant for cleaning from dust approximately corresponds to the rate of increase in the current density of the electron beam, since the charging time of dust particles is inversely proportional to the current density. Higher current density results in shorter charging times and therefore faster dust collection. When the charging process is faster than the movement of the dust, the discharge rate is limited by the movement of the dust and reaches a plateau.

The energy dependence of the beam was checked in the range from 60 to 400 eV. It was found that the threshold energy for starting the cleaning process is ~ 80 eV, which is the minimum energy of incident electrons to generate enough secondary electrons to create a significant microcavity charging effect.

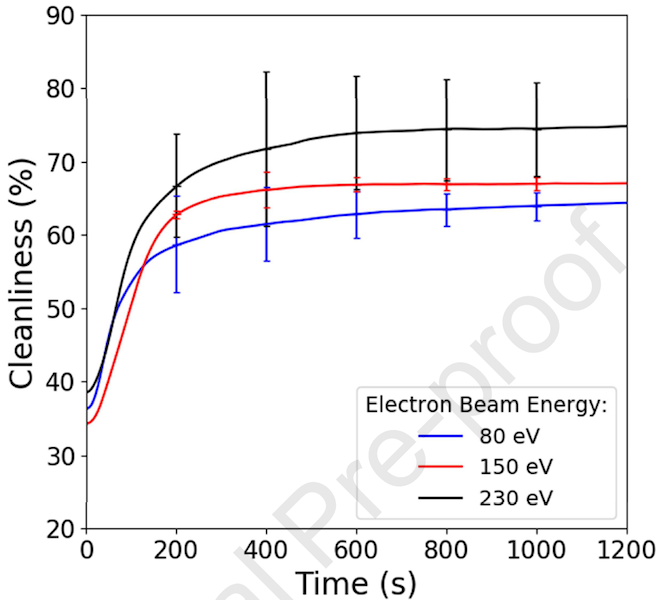

Image # 4 The

graph above demonstrates cleaning processes with beam energies of 80, 150 and 230 eV. As can be seen from the graph, the degree of purity increases with increasing beam energy. However, at 400 eV, the dust was practically not removed. This is due to the fact that the yield of secondary electrons increases to a maximum value, but then decreases with an increase in the energy of primary electrons. From this it follows that such a maximum in the case of a lunar dust simulator is reached at 230 eV.

As a result, it was found that the optimal performance of the system for better dust removal is an energy of 230 eV and a minimum current density of 1.5 to 3 mA / cm 2 .

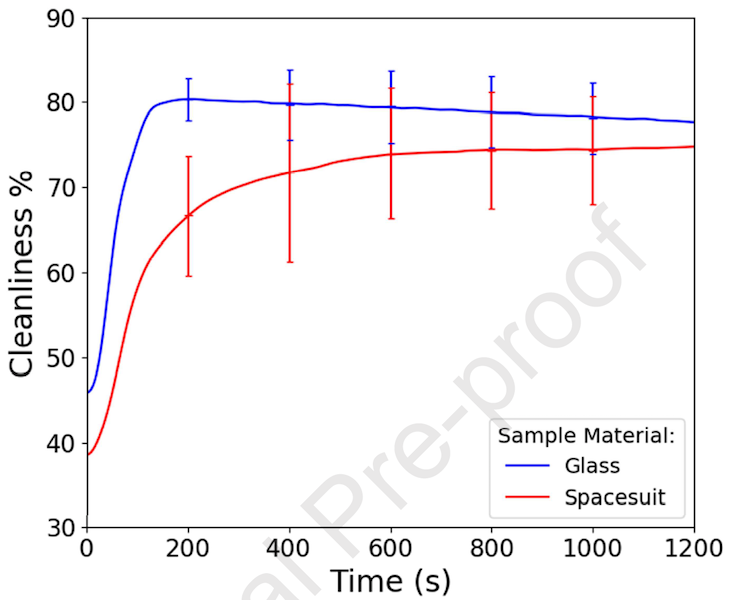

Image No. 5

To confirm the correctness of the selected parameters (230 eV and 1.5 mA / cm 2 ), tests were carried out using a sample of a spacesuit and a sample from a glass plate. As can be seen from the graph above, the change in the purity of both materials follows the same trend.

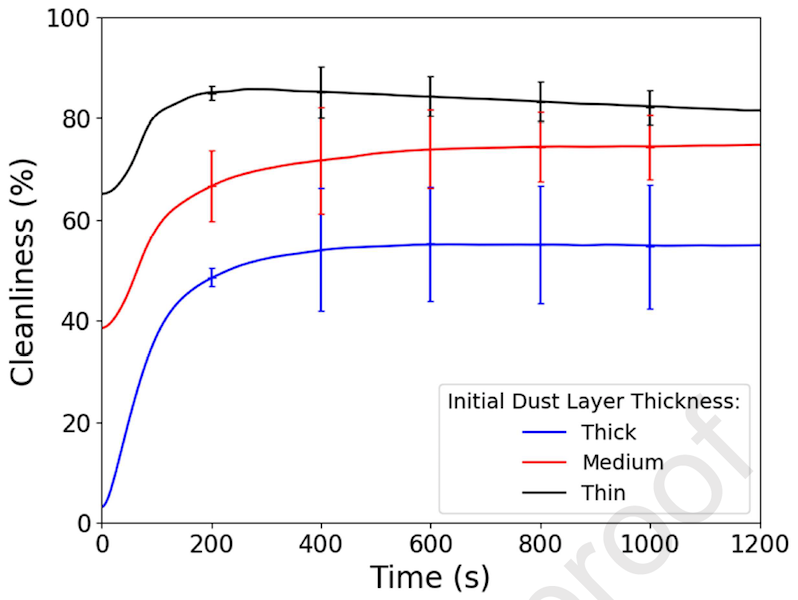

In addition to the parameters of the electron beam itself, it was also necessary to analyze the effect of the thickness of the dust layer on the operation of the system. During the tests, the layer thicknesses in terms of the level of purity were: 5%, 40% and 65%.

Image No. 6

The degree of purity unambiguously depends on the initial thickness of the dust layer: the thinner the layer, the higher the purity will be (up to ~ 85%). A possible explanation is that in a thicker layer, the dust particles below the topmost layer are more compact due to gravity, resulting in greater cohesion forces between the particles. However, on the lunar surface, according to scientists, this effect will be much weaker than in laboratory conditions on Earth, due to reduced gravity. You can also use a hybrid dust removal method, i.e. remove the thick layer with a brush or vibrations, and remove the remaining thin layer using the electron beam method.

Taken together, the above results clearly indicate that surfaces covered with a medium to thin layer of dust can be successfully cleaned (to 75-85% purity levels) by means of an electron beam in a relatively short period of time (less than 1 minute). It is also worth noting that the accumulation of charge on surfaces exposed to the electron beam did not lead to electrostatic discharge in any of the tests performed.

For a more detailed acquaintance with the nuances of the study, I recommend that you look into the report of scientists .

Epilogue

Nobody can say for sure when the process of colonization of the Moon will begin. But scientists are doing their best to solve all kinds of problems that might face future colonists.

In this work, the issue of lunar dust was considered, persistently sticking and damaging everything that falls into her eyes (figuratively speaking, of course). The cleaning method is quite simple and consists in using an electron beam that charges dust particles, which leads to their separation from each other and from the surface.

According to the authors of this development, their cleaning option is much better than the one that is currently being actively developed at NASA (namely, the introduction of a network of special electrodes into spacesuits), at least for the price and ease of manufacture.

Perhaps someday lunar settlers, after a long day on the lunar beds, will enter the premises through a special airlock, in which an electron-beam "shower" will be installed, which will cleanse them of dust. The scientists themselves do not intend to stop there, because the degree of purity obtained in the course of the experiments was only 85%. To achieve higher performance, the system needs to be improved so that it can cope with the residual dust layer consisting of extremely small particles. Also, scientists intend to consider the possibility of using short-wave ultraviolet radiation in their development.

Friday off-top:

, .

, .

Thanks for your attention, stay curious and have a great weekend, guys! :)

A bit of advertising

Thank you for staying with us. Do you like our articles? Want to see more interesting content? Support us by placing an order or recommending to friends, cloud VPS for developers from $ 4.99 , a unique analogue of entry-level servers that we have invented for you: The Whole Truth About VPS (KVM) E5-2697 v3 (6 Cores) 10GB DDR4 480GB SSD 1Gbps from $ 19 or how to divide the server correctly? (options available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Is Dell R730xd 2x cheaper in Equinix Tier IV data center in Amsterdam? Only we have 2 x Intel TetraDeca-Core Xeon 2x E5-2697v3 2.6GHz 14C 64GB DDR4 4x960GB SSD 1Gbps 100 TV from $ 199 in the Netherlands!Dell R420 - 2x E5-2430 2.2Ghz 6C 128GB DDR3 2x960GB SSD 1Gbps 100TB - From $ 99! Read about How to build the infrastructure of bldg. class with Dell R730xd E5-2650 v4 servers at a cost of 9000 euros for a penny?