What is common between a cycling suit and shark skin, and between a rose petal and a plastic bag? At first glance, there seems to be no commonality, but all these dissimilar objects can be combined in terms of the properties of their surfaces. Many objects created by man in one way or another repeat the properties of surfaces found in nature. However, the manufacturing process of such an object is largely limited by the properties of the material underlying it. Structurally, metals and polymers differ in many respects from biomaterials; therefore, it is extremely difficult to imitate their properties. Nevertheless, scientists from the University of Iowa (USA) decided to use the microstructure of the rose petal as inspiration for transforming the metal, which greatly changes its properties. How exactly the metal was changed,what was done for this and how did the petals of the noble flower help in this? We will find answers to these questions in the report of scientists. Go.

Basis of research

In nature, nothing happens just like that. The same principle applies to various kinds of surfaces that we can find in nature. Representatives of flora and fauna for hundreds of thousands of years have undergone all kinds of changes necessary to adapt to habitat conditions.

Phyllocrania paradoxa, Nautilus pompilius, Cataglyphis bombycina.

Thanks to evolution, someone acquired the ability to become virtually invisible to enemies (mimicry in the mantis Phyllocrania paradoxa , which looks like a dried leaf), someone acquired durable armor (the shell in the mollusk Nautilus pompilius ), and someone learned to survive even in the most adverse conditions (high reflectivity of the body of ants Cataglyphis bombycinaliving in the Sahara Desert), etc.

Each of the above adaptation examples is a consequence of structural features and surface properties. It is logical that scientists would be happy to apply such unique characteristics in our world, but this is extremely difficult. The process of reconstructing the properties of biomaterials is called biomimicry, and it is often associated with the processing of a material in a chemical or physical way, which allows it to change its structure to some extent. For example, etching is used to create ultra- or superhydrophobic surfaces on solid materials, which requires aggressive reagents and expensive equipment, not to mention trained and experienced specialists.

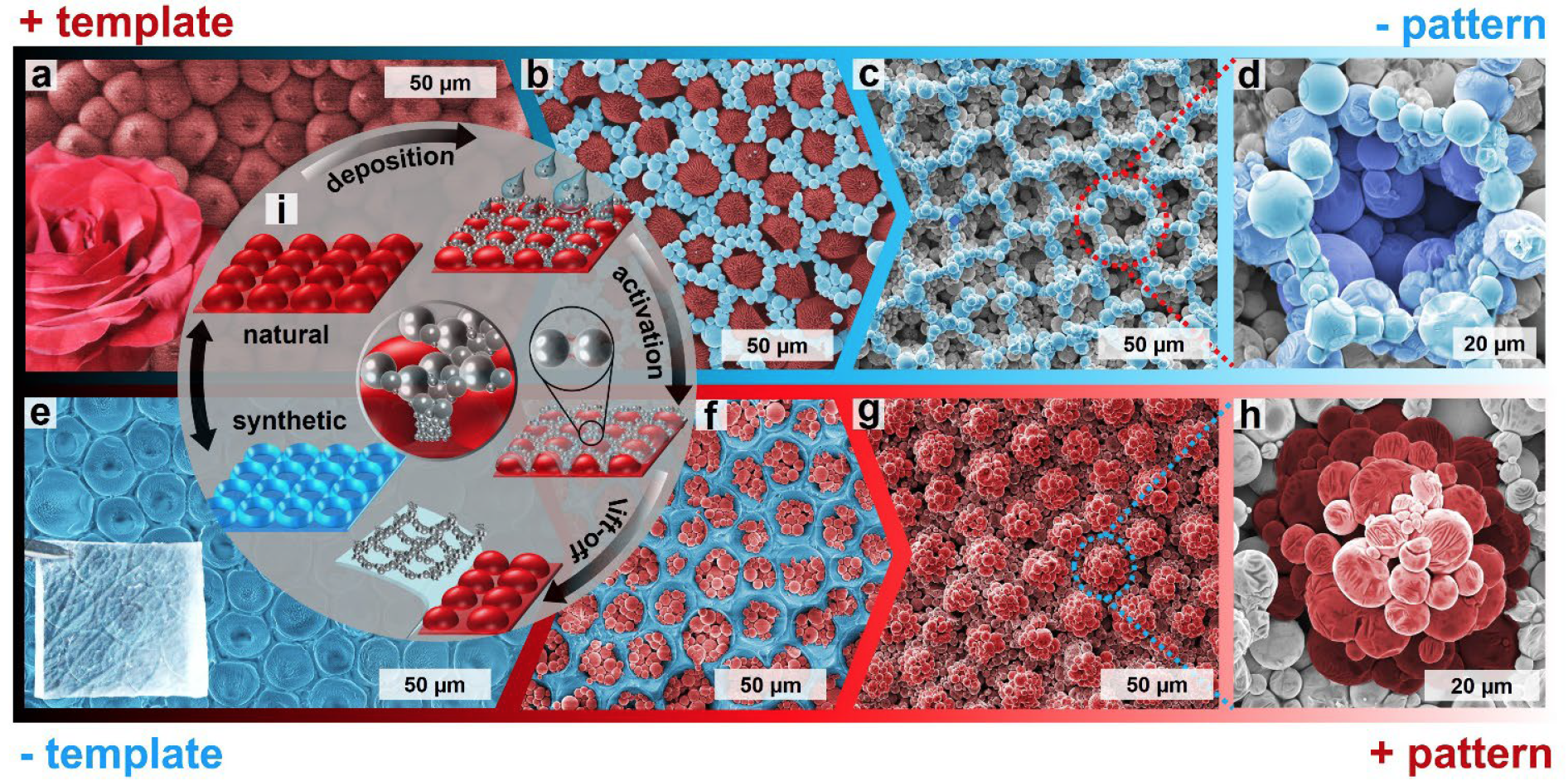

In recent years, the process of supercooling metal particles has become very popular. Polydispersed soft particles ( core-shell * ) of supercooled liquid metal (ULMCS) suspended in a solvent make it possible to achieve dense packing and self-sorting of particles into multiscale surface textures, such as those of rose petals ( 1a - 1b ).

Particle core-shell * - a particle, the core and shell of which differ in composition, morphology and functional purpose.

Image # 1

After precipitation and solvent evaporation, soft particles tend to form random close packing (RCP) structures and get stuck at a packing ratio ∅ = 0.64. The packing factor is determined by the ratio ∅ = NV 0 / V, where N is the number of particles; V 0 - the volume of the particle; V is the total volume.

Moreover, given the existence of multiscale structures and channels on the surface of the rose ( 1a ), these particles will undergo a self-filtration process, which is facilitated by the self-assembly of capillaries. After drying and reaching a pendulum state, the particles will eventually self-fix and get stuck in the cracks of the surface textures ( 1b ).

Jamming occurs when the size of the interparticle cavity, the concentration of the suspension and the size of the particles satisfy the following relationship:

where R is the radius of the capillary; r is the particle radius; n is the number of particles.

This equation predicts the size ( r ) or number ( n ) of particles needed to get stuck for a given depression size ( R ).

Jamming also ensures that the deposited ULMCS particles are mechanically stabilized and therefore can be sintered * into conformal networks of the desired surface template ( 1c - 1d ).

Sintering * is the process of creating porous and solid materials from small powdery or dusty particles by increasing temperature and / or pressure.The application of cold chemical sintering and the bonding and curing of trapped ULMCS particles results in a hardened structure that can be removed from the rose petal (or similar soft base material) without damaging it. This process is also compatible with synthetic, heat-sensitive and soft motifs * such as PDMS (polydimethylsiloxane / (C 2 H 6 OSi) n ) ( 1e ).

Motive * is a short sequence of nucleotides or amino acids that changes little during evolution.When inverse biomimetic structures are applied to elastomeric materials on which ULCMS particles are packed and chemically sintered, an exact replica of the natural pattern is realized ( 1f - 1h ).

Thus, biomimetic solid metal structures can be fabricated without heating through the use of autonomous processes such as capillary sealing, disruption of kinetics (hypothermia), and self-assembly / self-sorting of particles.

Research results

Polydisperse metal particles ULMCS (51% In + 32.5% Bi + 16.5% Sn) were synthesized using the SLICE method (separation of liquids into complex particles from shearing liquids into complex particles ).

The SLICE process can produce particles <10 nm, but to improve self-filtration and ease of characterization, this study decided to use larger sizes (μm) and higher polydispersity. The particles used in this study had a diameter of 2.71 ± 1.58 µm, therefore, the predicted packing factor was about ∅ = 0.70.

These soft deformable ULMCS, as expected, form denser structures than the random close packing observed with hard spheres (∅ = 0.64). The densification is likely due to the change in shape under the action of capillary pressure and autonomous dimensional ordering, which increases the densification. However, these processes can be disrupted by external stresses during particle settling.

To investigate the effect of the deposition process on packing density, the scientists conducted several cycles with varying degrees of applied shear stress (F s ). The particles were applied to biological templates (rose petals) and removed with copper tape, creating a biomimetic metallic structure, albeit with a reverse relief.

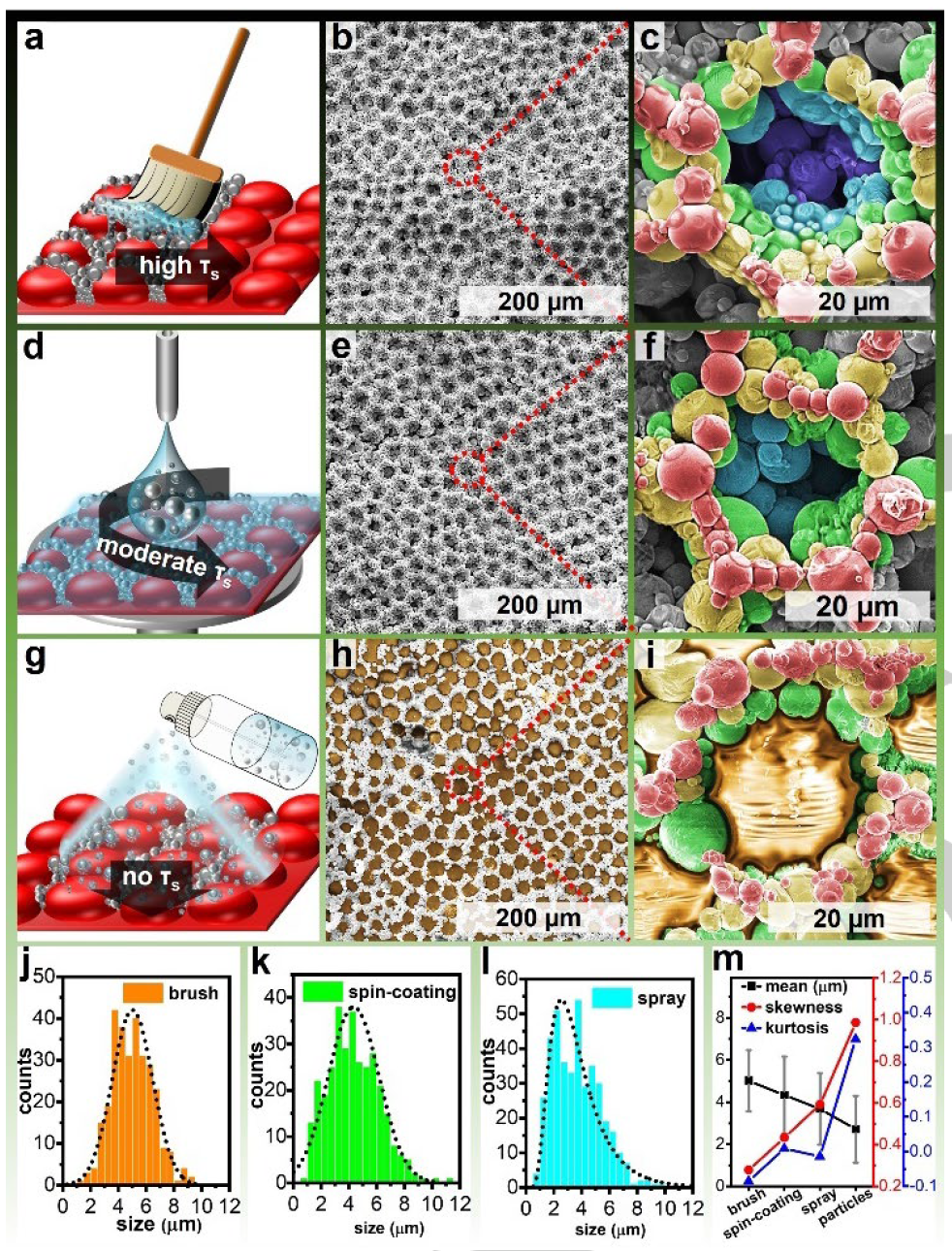

Image No. 2

In images 2a, 2d and 2g schematically illustrate various methods for deposition in the range of low values of F (application by brush) to high F (centrifugation) and without F (sputtering). The spray method provides a minimum amount of F since the particles are deposited perpendicular to the petal surface.

Direct brushing ( 2a ) causes low F values on the particle suspension during deposition, resulting in thick (> 10 μm), multi-layer (> 7 layers) patterns ( 2b - 2c ). This method is the easiest to implement, but not the most suitable, since it requires direct human participation, which scientists would like to avoid.

Centrifugation sedimentation at 1000 rpm (2d ) allows for a more controllable and reproducible process, since the deposition rate, and hence the F s value , can be fixed. However, this method cuts off the outermost layer of deposited particles, resulting in slightly thinner films (<10 μm, ~ 4-5 layers; 2e - 2f ) compared to brushed films.

Surprisingly, centrifugation provides slightly better self-filtration, as shown by the offline sizing on the top layer of the raised structure (marked in red at 2c and 2f ).

But the spraying ( 2g) gives much thinner films (~ 3 layers) with significant defects / delamination ( 2h - 2i ). This may be due to problems with pumping fairly dense metal particles from the hand spray system, which will tend to deposit fewer and fewer particles. The deposition of larger particles in the spray solution can also contribute to low concentration and size selectivity, hence the formation of thinner films.

In the case of granular material, self-filtration can result in better packing into surface features, resulting in more conformal packing at different size scales. Self-filtration manifests itself in the particle size distribution in the uppermost layer of entrained particles.

Comparing the particle size distribution of the pre-prepared particles with those that are deposited most deeply in the crevices of the rose petals (i.e., represent the uppermost layer of the metal structure), a significant shift is observed. In the polydisperse initial suspension, a large positive asymmetry coefficient is observed, while in the deposited particles, larger particles are filtered off ( 2j - 2m ).

Fitting a Gaussian to the particle size distribution of the uppermost layer showed that when using a brush, the particles will be the largest (~ 5 μm), followed by centrifugation (~ 4 μm) and sputtering (~ 3 μm).

A deeper analysis of the three methods of particle sedimentation showed that it is centrifugation that is most suitable, despite the small relative asymmetry. In the case of other methods, a number of problems were observed: low capillary packing in the case of spraying; good packaging, but poor scalability in the case of using a brush.

Regarding the choice of the method of particle deposition on the rose petal (i.e. the method of replicating its microstructures with metal particles), it was also necessary to assess the degree of coincidence of the structures of the original and the mold. The comparison showed that all the elements obtained from the red rose were of average size in the following order: brush> centrifugation> spray. However, in all cases, the sizes of the structural elements were quite similar to each other (20 μm), i.e. in this aspect, any of the methods can be used.

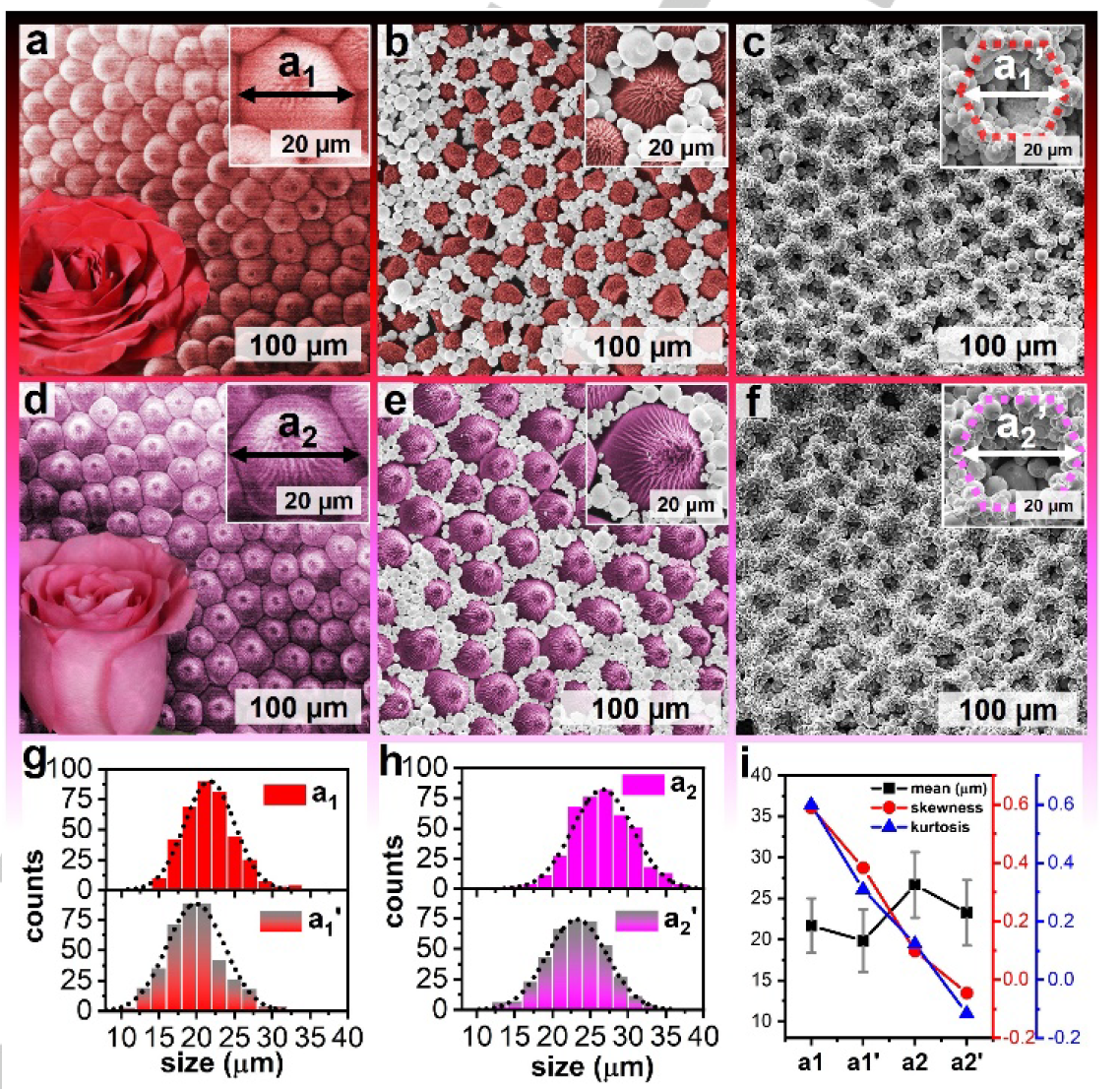

Image №3

Next, the scientists began a full assessment of the characteristics of BIOMAP ( BIOmimetic MetAl Patterning ), i.e. biomimicric metal system.

During practical experiments, two types of closely related roses were used:

- ( 1) a1 = 21.68 ± 3.32 (3);

- Peace ( 2) a2 = 26.63 ± 4.00 (3b);

Application by centrifugation of the same initial suspension to similarly prepared petals was performed in order to capture the differences in these templates.

As a result of the application of particles by centrifugation on rose 1, patterns were obtained with a hotel element diameter a 1 '= 19.85 ± 3.82 μm ( 3b - 3c ), which is ~ 2 μm deviation from the original pattern. The difference of 10% can be caused by deformation of the surface features of the petals under the action of capillary pressure and / or the weight of the deposited particles.

For rose 2, the average size of the pattern elements of the applied particles was a 2 '= 23.23 ± 3.98 μm ( 3e - 3f), i.e. the deviation from the original was about 3 microns. These differences are also recorded as shifts in the average Gaussian values of the obtained histograms ( 3g - 3h ).

The shape of the distributed particles of the petals and BIOMAP surfaces are very similar, which indicates good replication. However, skewness and kurtosis confirm that the above-described subtle changes (deviations) are systematic errors (3i).

Naturally, it should be noted that all the resulting BIOMAP patterns (marked with "-") are inverse to the original (rose petals, marked with "+"), albeit with a high degree of replication. To obtain the same pattern as on the petal, first it is necessary to replicate using the PDMS elastomer, and then from this "impression" to make a copy using BIOMAP. Roughly speaking, to get identical (non-mirrored) prints of a rose petal, you need to perform the procedure twice (those who are familiar with cooking know how to remove a cake from a mold using two dishes).

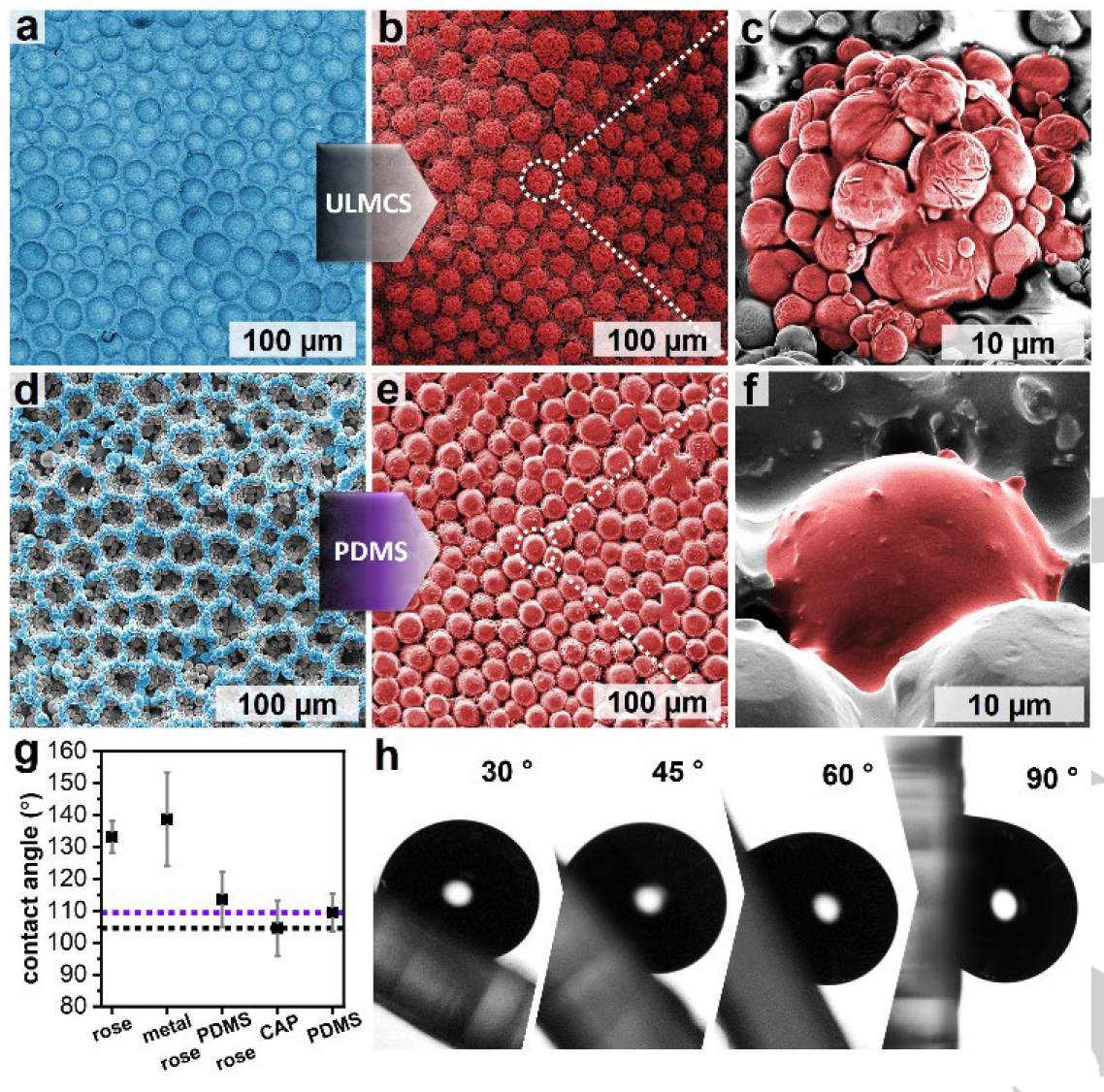

Image # 4

The images above demonstrate the BIOMAP's degree of precision in creating a synthetic rose pattern. First, a primary / draft (-) template is made by accurately impressing the PDMS from the surface of the rose petal ( 4a). The PDMS mold is then filled with ULMCS particles, which are then sintered with CUPACT and the samples are removed ( 4b - 4c ). The result is a final sample of (+) ULMCS, albeit with larger gaps between surface features compared to the rose flower ( 3a ), due to the retention of sphericity of the particles after CUPACT.

Despite the limitations in creating a completely continuous smooth surface, this method demonstrates the closest analogue of a rose surface ( 4b), created using the principles of physical chemistry and chemical kinetics. In addition to the new surface texture, it is also clear that a metal (-) embossed copy of the petal surface can be used as a mold to create an elastomeric analog of a rose petal, since capillary forces will prevent the viscous uncrosslinked elastomer from penetrating through the pore network.

To test this theory, metal (-) elements were filled with PDMS ( 4d ), after which a raised (+) pattern similar to a rose petal ( 4e - 4f ) was obtained .

When metal was used to obtain a copy, deviations in the dimensions of the resulting elements from the original were observed by about 10%. But in the case where metal was used as a mold for creating PDMS elements, significant changes in dimensions were not observed.

Despite all the differences between the copies and the original, the wetting values * of the original surface and the replica are quite similar (comparison of hydrophobicity at 4g ).

Wetting * - the interaction of a liquid and the surface of a solid or other liquid.The rose petal was ultrahydrophobic with an average contact angle of 133.1 ± 5.0 °, while the biomimetic copy, (+) ULMCS ( 4b ) sample , gave an average contact angle of * 138.7 ± 14.7 °. The PDMS replica showed a smaller contact angle.

Wetting angle (contact angle) * - the angle between the tangent drawn to the liquid surface and the solid surface. This parameter determines the intermolecular interaction of particles of the surface of a solid with a liquid.Non-textured sintered CUPACT particles (CAP at 4g ) and PDMS particles were used as a control group during the analysis (dashed line at 4g ).

The droplets on the non-textured surfaces of the sintered particles, slowly diffusing into the porous surface, exhibit temporary hydrophobicity. Presumably, this slight hydrophobicity observed on the layer of sintered particles is due to the presence of the substantial methyl-terminated surface ligand used to stabilize the ULCMS.

To further compare wetting between biomimetic and natural samples, the droplets located in the BIOMAP pattern were tilted ( 4b) to simulate the petal effect. As expected, droplets adhere to the surface, albeit with a large contact angle hysteresis as the angle of inclination increases ( 4h and video below).

Demonstration of the wetting properties of a rose petal and a metal replica.

For a more detailed acquaintance with the nuances of the study, I recommend that you look into the report of scientists and additional materials to it.

Epilogue

In this work, scientists were able to make a biomimetic metal pattern based on a soft substrate (i.e. a rose petal). The manufactured elements completely imitate the biosimilar both in structure and in the properties of wetting, albeit with small deviations, artifacts of the BIOMAP processing method and asymmetry in the properties of the material.

If we simplify the entire study to one sentence, then scientists were able to make an impression of a rose petal from metal particles. The resulting replica has the same properties as the original. Particular attention should be paid to the hydrophobicity of the developed material, which was previously achieved by much more complex and costly methods.

The created structure has the strength and durability of metal and the hydrophobicity of a delicate rose petal. This hybridization of properties makes it possible to create various variants of materials, expanding the range of their applications. According to scientists, their development can be used in a variety of industries, from medicine (replication of nanometric structures to further replace damaged parts) to the aviation industry (processing aircraft wings to reduce icing during flight).

Be that as it may, nature has once again shown that it is an almost inexhaustible source of inspiration not only for artists creating picturesque landscapes, but also for scientists who invent incredible devices and systems.

Thanks for your attention, stay curious and have a good work week, guys. :)

A bit of advertising

Thank you for staying with us. Do you like our articles? Want to see more interesting content? Support us by placing an order or recommending to friends, cloud VPS for developers from $ 4.99 , a unique analogue of entry-level servers that we have invented for you: The Whole Truth About VPS (KVM) E5-2697 v3 (6 Cores) 10GB DDR4 480GB SSD 1Gbps from $ 19 or how to divide the server correctly? (options available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Is Dell R730xd 2x cheaper in Equinix Tier IV data center in Amsterdam? Only we have 2 x Intel TetraDeca-Core Xeon 2x E5-2697v3 2.6GHz 14C 64GB DDR4 4x960GB SSD 1Gbps 100 TV from $ 199 in the Netherlands!Dell R420 - 2x E5-2430 2.2Ghz 6C 128GB DDR3 2x960GB SSD 1Gbps 100TB - From $ 99! Read about How to build the infrastructure of bldg. class with Dell R730xd E5-2650 v4 servers at a cost of 9000 euros for a penny?