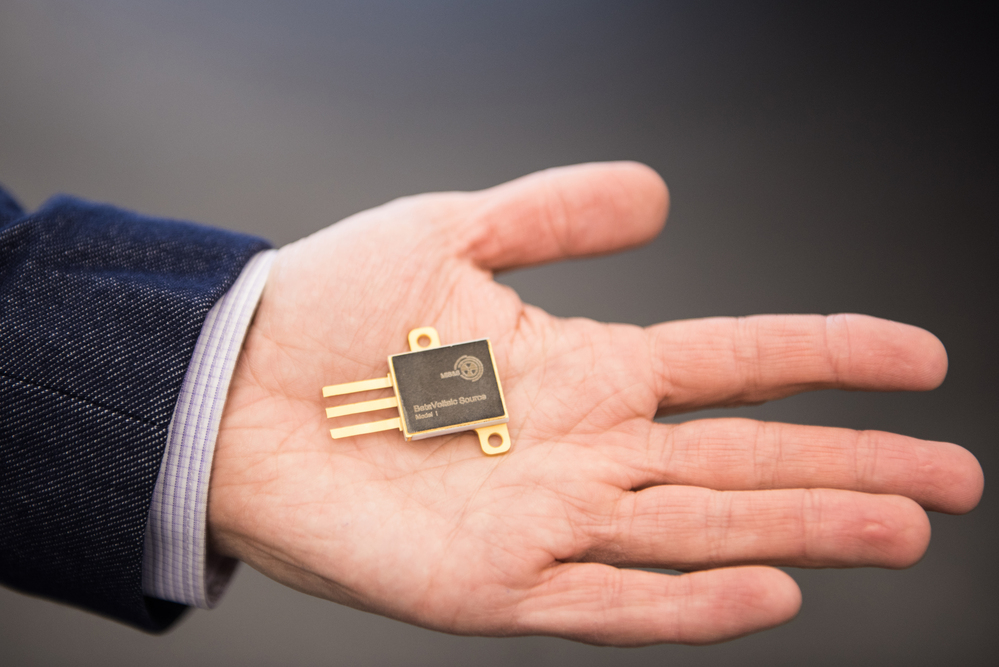

A few days ago we published the news that the American startup Nano Diamond Battery presented a working prototype of a beta galvanic battery that can last for thousands of years. The startup promises working batteries at the end of this year.

As it turned out, domestic scientists have a similar development. Specialists from NIITU MISIS in early August this year demonstrated their own prototype of a battery, the design of which is based on a microchannel bulk structure of a nickel beta-galvanic cell. Its service life is about 20 years.

The peculiarity of the structure is that the radioactive element is deposited on both sides of the planar pn junction. This makes it possible to simplify the manufacturing technology of the element, plus control the reverse current. Thanks to microchannels, the effective conversion area of beta radiation is increased by 14 times, which means that the current also increases.

According to representatives of the university, the element can be used in several modes: an emergency power source or a temperature sensor in devices that operate at extreme temperatures in hard-to-reach places, including mountains, water or even space.

Not a single radioactivity

And scientists of the NIITU "MISIS" have developed thermochemical cells that convert heat into electrical energy. Batteries of this type are small. This allows them to be made wearable by placing them on clothing.

Well, the generated energy can be used to power various mobile devices. According to scientists, thermoelectricity is one of the most promising areas of energy. However, there is a problem - the output power is too low.

Experts have found a way to solve this problem - in the design of batteries, metal oxide electrodes are used based on hollow nickel microspheres and an aqueous electrolyte. This solution makes it possible to increase the current by lowering the internal resistance of the element.

The open circuit voltage can in this case reach 0.2 V at an electrode temperature of up to 85 degrees Celsius. The power of such an element is 10-20 times higher compared to analogues. Well, the use of an aqueous electrolyte allows you to reduce the cost of production and increase the safety of the system.

Scientists announced that they were able to achieve a record for aqueous electrolytes, a hypothetical coefficient of thermoelectric sensitivity of 4.5 mV / K.

In the near future, domestic scientists are going to increase the output power by optimizing the composition of the electrodes and improving the overall design of the thermocell.