I was lucky to run into a startup called Veer. They talked about the launch and creation of the first product, earplugs with a volume control, and even answered my questions about the anatomy of the ears, the design of the earplugs, the difference between the left and right ear.

All photos were taken from a pre-sale sample, everything is more accurate for the final one.

What is your product about?

Veer earplugs are designed for people who are disturbed by ambient noise. Primarily for those who work in open spaces and cannot concentrate due to sound pollution.

Unlike headphones with active noise reduction, Veer does not need to be charged and can be washed with soap. Some people have a headache from active noise reduction, and even without electronics it will be much cheaper.

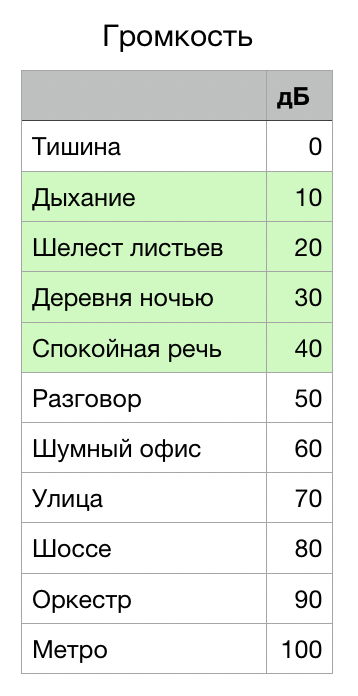

The earplugs have a built-in volume control, the sound can be changed from 5 to 40 dBA. Unlike conventional foam or silicone earplugs, the Veer does not need to be pulled out to hear better, just twist the outer shell.

Earplugs will be able to drown out some sounds completely, loud ones will become quieter. This will reduce the deafening noise of the subway to street level.

How did the idea come about?

It's always noisy in our office: 3D printers are working, people are walking, a kettle is boiling, scooters are rolling, phones are ringing, someone is sawing, milling, blowing a compressor. For those who do not work with their hands at this moment, it is difficult to concentrate on tasks: you are constantly distracted, then by force of will you return yourself to the flow, it is exhausting. Many at River wore regular drugstore earplugs, but they were not very office-friendly:

- Every time you need to talk or listen, you have to take out the earplugs and then insert them again. It is unpleasant.

- Foam or silicone earplugs often have a shell effect. Sometimes it's annoying.

Some brainstorm came up with an idea to make the perfect earplugs for the office. When they began to investigate, it turned out that the idea was not new. At that time, several products with similar positioning were presented on Kickstarter. None of the products from Kickstarter have been sold yet - often crowdfunding projects remain dreams - and we took on the project.

In general, earplugs are made up of two components: a body and a silicone ear pad. I will tell you in order.

What did you do before?

River is an incubator for gadget startups. We develop b2c gadgets that solve old problems in new, better ways, from idea to mass production.

Veer earplugs are the first product that we have brought to the start of mass production. Another product, a toothbrush with three heads, was brought to the finalization of the construct, a saxophone, on which it is easy to learn to play - until a strong-willed decision to postpone, and about 15 potential products were also killed at various stages. Now, in parallel with production, we are developing several concepts for new products. A total of 12 people work on the products.

Chapter 1: corpus design

What did you decide in the first place?

We immediately mutually decided that Veer should drown at least 40 dB in order to completely drown out a quiet conversation next to you. I want them not to have to be charged, removed to talk to people, and they also have to look cool. From this and began to make a start.

The first idea was to make 2 modes: everything is heard / nothing is heard. We began to simulate, we realized that with the same efforts it is possible to make 3-4 modes in order to drown out not so much and hear what is happening out of the way.

At first, it turned out to drown out only 25 dB

The body of the first prototype was made of a metal cylinder 1 cm in diameter. A filter was used inside: a regulator and 4 round plates with holes in different places were printed on a 3d printer. The plates were located one above the other and closed the holes one after the other.

It was planned that it would be possible to make 4 modes due to the gradual imposition of each of the plates, but in fact there were only 2 modes: open / closed. In the intermediate versions, there was no difference, they were always drowned out to the maximum.

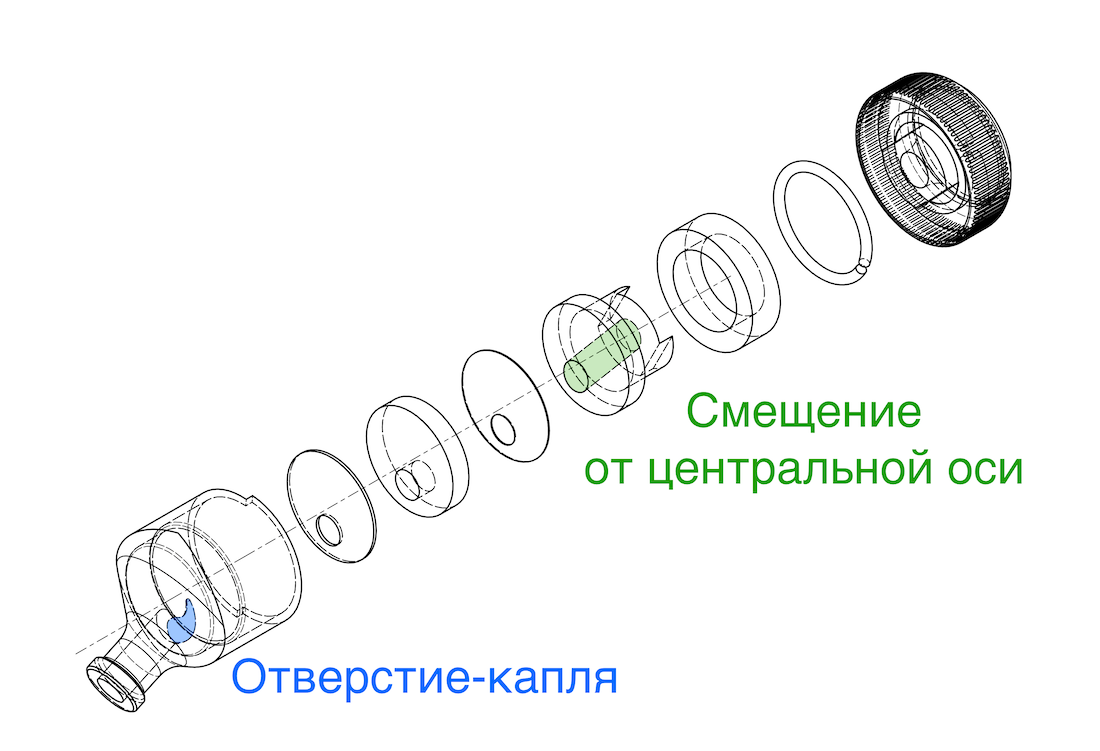

In the next iteration, we decided to try playing with the size of the holes. A foam rubber damper was placed on the bottom of the cylinder, 3 holes were made in the cylinder in a circle, and the body was 3D printed. The hole in the body itself was slightly offset and we could put different holes when turning. The prototype drowned out only 25 dB.

How was noise reduction measured?

To measure the level of noise reduction, we molded an artificial ear from silicone and made an imitation of an ear canal from plasticine. This design was attached to a conventional sound level meter. We measured the level of white noise without an earplug and with an earplug in the silicone ear. This design does not show the frequency spectrum, does not show the frequency response, but shows the overall noise level.

How did you increase the damping?

When they began to actively study how passive soundproofed systems are created, they learned that to achieve a high level of noise reduction, mass is needed. They began to think how to increase the mass of the earplug, while leaving the body compact. The very first prototypes were made of plastic, its mass was not enough at all, and after a week we switched to heavy brass, the regulator from it was inserted into a plastic case. This really made it possible to reflect more sound, noise reduction became from 40 to 50 dB, and the size was reduced several times. As a result, we switched to aluminum, it turned out to be not so heavy, but sufficient for good absorption.

Naturally, we ran into a problem: when closed, the earplugs created a shell effect in the ear, an unpleasant buzz appeared - this is resonance due to the design feature. In the open position, they hissed and drowned out too much, 10-15 dB, although we planned a maximum of 5 dB. Then the idea came to make a smooth volume control so that the user himself could adjust the level that is comfortable for himself.

In total, at this stage we closed the question with the desired noise reduction level. It was necessary to get rid of muffling in the open mode, the effect of a shell in the closed mode and figure out how to regulate the sound smoothly.

To get rid of unnecessary jamming in open mode, we placed a confuser in the case - a funnel that amplifies the sound. Outside, a metal mesh was added to the funnel, thus removing resonance. The grid removed harsh percussive sounds and reduced the Q of the resonance channel. As a result, my ear stopped hissing when open and buzzing when closed.

How does stepless control work?

It was obvious that for smooth adjustment it was necessary to change the round shape of individual holes to one cone-shaped one. As a result, the cone was pulled out, turned, and a drop was obtained.

We made the first prototype with a confuser, mesh and drop. The confuser was first cast - there was no way to bend it from a solid material. In subsequent iterations, the correct diameter was selected and the confuser was made of aluminum.

Everything was ok, except for one thing - it was hard to turn the regulator. At the same time, they began testing new ear pads, with which, as it seemed to us, there should be no problems.

Chapter 2: ear pad design and main quest

Let's talk about the attachment. What stages of development did you go through?

With the help of a nozzle, the mechanism is fixed on the ear, adjusts to the peculiarities of the anatomy, while it should not scroll when we change the volume.

Hydraulic? Unreliable

The first crazy idea was to make a hydraulic nozzle. The idea was to take the shape of the ear canal. They cast a bag from silicone and poured liquid into it. Once the pouch broke in the ear of a leading engineer. We decided to abandon this idea due to the complexity of the implementation, probably temporarily.

With membranes? Uncomfortable

While we were exploring the world of earplugs, we came across a cone-shaped ear pads with membranes used in military aviation. We prototyped a similar one with 15 membranes. It turned out very uncomfortable - the thin tip rested against the ear membrane. They abandoned the conical shape, but decided to keep the membranes and made the shape of a cylinder.

First, we developed a 3D model. Based on the model, an injection mold was printed on a 3D printer. To quickly prototype the ear pads, silicone was manually poured into the mold with a syringe.

Thin membranes did not spill, because air got inside and bubbles formed. They figured out what to evacuate - to place a mold with silicone in a vacuum container, and a pump pumps out air through the gating channels. Some prototypes were evacuated in a pickle jar.

The ear pads were cast, but to achieve the desired level of noise reduction and comfort with such a spiral is not.

Classic vacuum + spiral? Uncomfortable again

Then we thought, why not use the familiar one-dome bombs on vacuum headphones at the base of the ear pads. As an independent option, bombs drown out badly, because it was necessary to plug the channel in order to achieve the required noise suppression, and not just cover it. We thought that if we combine them with our spiral, it might turn out interesting.

We made ear pads with a bombon at the entrance to the ear canal and with a spiral that overlaps it, and received a high level of noise reduction.

We started testing for convenience within the team, about half liked it. We decided to test it on a potential target audience - we handed out prototypes to friends and interested ones from telegram channels, because our ears, used to dozens of tests, have already ceased to feel discomfort, and we really wanted to finally get something worthwhile.

We were already in anticipation and even made the final renders for the site, but in the end we screwed up with these ear pads. For most testers, after a long stay, their ears began to itch. We analyzed the reviews and the design, realized that the sharp edges of the spiral irritate the skin. As a result, they abandoned the spiral shape and began testing further.

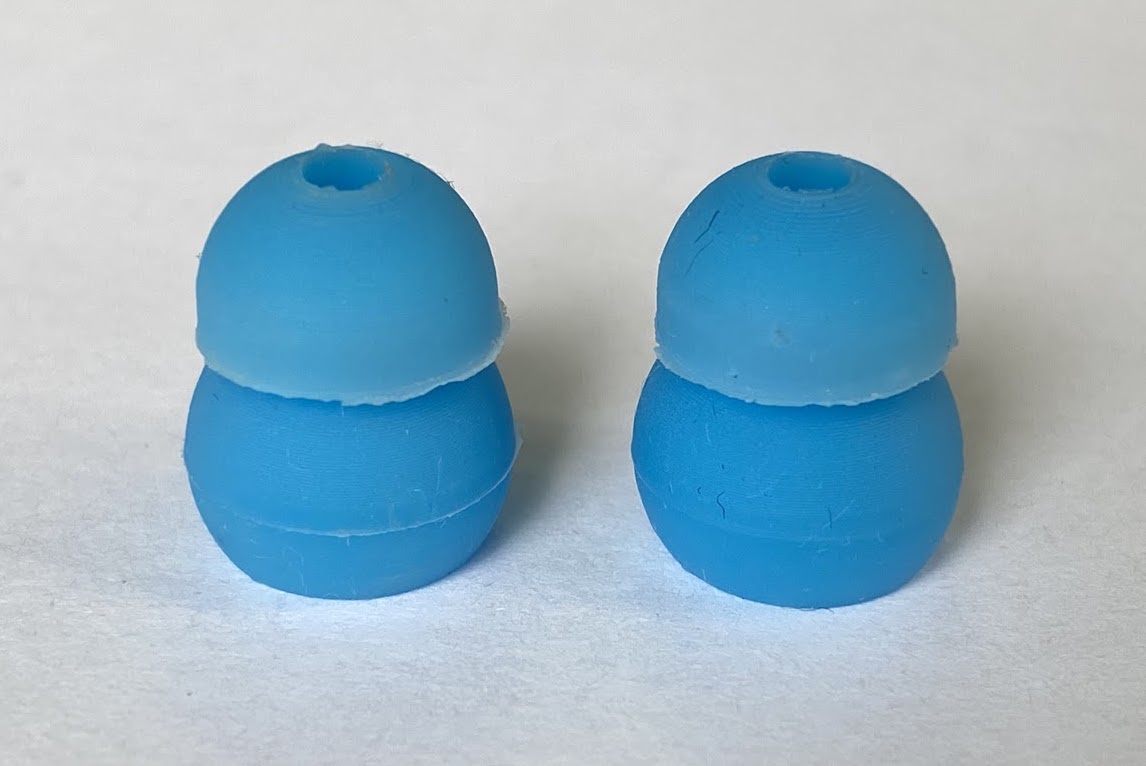

Double dome with two bombs? Does not hold in the ear

We continued to adhere to the idea that both the channel itself and the entrance to it should be blocked. After a dozen iterations, we made a two-dome ear cushion with two bombs.

Simple two-domes existed on the market, but they were more like a hemisphere than a bomb, and, in our tests, a bomb with more rounded inward edges was easier to get out of the ear due to the vacuum created inside the channel.

In 3 days we drew earplugs and a shape, printed a shape, molded an ear cushion. Distributed to testers of the previous version, the results were again controversial. 2 spheres were uncomfortably pushed in and did not drown out very well, but they easily got out and jumped out of the ears by themselves. Due to the fact that the ear canal is curved and the ear cushion is straight, the vacuum was broken and the shape of the sphere was broken. We had planned that the ear cushion would adjust to the curve, but this did not happen.

All this time, we have been actively studying research about the shape of the ear canals, and the results have put us in a mild disorder. It turned out that people have completely different ears, even in one person the shape of the canals in different ears may differ.

It began to seem that making one comfortable and well-damping ear pads for millions of people was something of a fantasy.

Anatomically curved ear cushion. The final.

After all the experiments, we made an anatomically curved ear cushion. It finally turned out to be the final version of our experiments. It was not possible to produce it immediately, for the first couple of weeks it was torn when removed from the mold.

The final version shows a high level of damping, it sits comfortably in the ear all day, but you first need to adjust the earplugs for yourself. We almost unanimously accepted the difficulty of the first use, because the comfort of long-term wear is obviously more important than the difficulty of the first use.

Sacrificed the convenience of first donning for a level of muffling

If you don't figure it out, stick the earplugs into yourself, a miracle will not happen - in 80% of cases it will be inconvenient or inoperative. To be fun, you first need to choose the right size: on tests it turned out that 95% of people have a left channel smaller than the right one, so it is worth using a smaller ear cushion for it.

Then you need to find the right angle in relation to the body so that the ear cushion fits correctly into the ear canal. To make it clearer, we recorded a video instruction.

After the release of the first batch, we will return to the question and hope to come up with a pneumatic super-plug that has never been seen before, but for now we are putting four sizes in boxes, installation instructions and hope that no one will draw conclusions about the product without reading the instructions (ha).

Chapter 3: production

Where to find suppliers?

We are looking for an alibab. We send them requests, they respond, we choose those who are suitable. We have a person in our team who is responsible for purchases, he communicates with the Chinese in English.

What do you order in China?

The ear pads are cast in China, they are prepared according to our models. For example, according to our first tech. To the task, the mold connectors should not fall on the domes of the ear cushions so that they do not have a seam (domes are two hemispheres that make up the ear cushion). The Chinese said ok, and then after 2 weeks it turned out that this would not work. We found an alternative, made it so that there was only one connector on one lower dome.

Back in China, they ordered cases for carrying earplugs. We make small cases for ear pads already in Russia, it turned out to be faster and not more expensive.

What are you doing in Russia?

We make aluminum bodies and regulator rings in Russia. We found only 2 factories that had the right equipment and expertise. At first, the bodies were made on robotic machines - a metal hand intercepted the aluminum cube several times and perfectly cut the desired shape perfectly.

It turned out that the equipment breaks down when it starts running continuously. That is, the machine can make 5 pieces, but it cannot stand on the stream. The body holds the collet clamp, into which the robotic arm inserted the workpiece. The equipment broke down during mass production because the metal dust from the machining was clogged inside the clamp. Because of this, the clamp did not grip the body tightly, the body flew out, the machine broke.

The new tooling is installed on the milling table. The operator places 12 workpieces in the cradle and clamps them. The tool that grinds the part was designed and manufactured specifically for our case. This is a cutter, its profile follows the contour of the body nose.

What do you produce yourself?

We do all the internal parts ourselves: dampers, sides of the ring, nets for the regulator ring. We ourselves anodize the cases, assemble the earplugs, test them before sending them to the level of noise reduction and the ease of turning the wheel.

Chapter 4: test drive

The history of production turned out to be interesting: many iterations, hopeless situations, failed first tests, production difficulties. Let's see what happened in the end: a test copy arrived and I used it for a couple of weeks.

Fitting

As we learned, the shape of the ear canal is a very individual thing, even the left one may differ from the right one, therefore, first you have to adjust the earplugs for yourself. I looked at the instructions, but set them up a little differently: I inserted them in the default position, and then twisted them a little so that they would sit comfortably in my ear. At first it is incomprehensible and the sensations are strange, and then you start to feel the structure of the channel. After that, the main part can be rotated so that the external volume control fits correctly on the ear and is convenient to twist.

If inserted incorrectly, there will be several disadvantages.

- You will not be able to adjust the volume normally, it will fall out of your ear due to rotation.

- Will not isolate noise as it should

- It will be just uncomfortable and may fall out by itself.

If you can change the volume and the earplugs do not fall out, then everything is ok.

Noise isolation

The most important feature: the volume can be adjusted. If you turn the shiny twist halfway, then the sound will begin to flow into the ear, you can communicate with people as usual. The overall volume is still slightly lower, but not much, like in the first airpods, when you are not listening to music. Between maximum isolation and audibility, smooth adjustment, can be adjusted as desired.

With full noise cancellation, the sound still hits, but it becomes much quieter. It seemed to me that the sound is optimal: on the one hand, you do not feel isolated, the highest and lowest sounds still reach, but the noise became really quieter. At a construction site, this will not save, but the neighbor with the drill has become quieter. Self-isolation, renovation, you know.

As a result, the sound does not disappear, but it becomes pleasantly quieter.

Appearance

Looks good on the ear. I like the grid, the volume control shines metallic, in the end it is harmonious. Because of the mesh, they look like they have a built-in "retro" microphone.

Comfort

If you insert the earphone correctly, then there is no discomfort, over time it does not accumulate. The fact that the earphone is not very easy to insert is compensated by the fact that it does not need to be removed to talk to people.

You can sit in them all day, the sensations are normal, but I plan to wear them from time to time:

- When I go to work on the subway. The noise of the car is quieter, but people can be heard if someone wants to get out.

- In the evening in the office, when everyone starts to work a little less and talk a little more.

- When the child started to play actively at home, and I work remotely.

Form and hygiene

The shape of the caps is more complex than in conventional headphones. At first, the headphones pulled out quite a lot of earwax, but literally after a couple of times it became clean. A couple of conclusions:

- it is better to wash them from time to time, dirt can accumulate inside the ear pads,

- you should not let other people try to "listen" to ear pads, you risk getting a portion of someone else's dirt.

There are no external differences between the left and right earphones. This is a little strange, because each ear has its own fit, and it's easy to get confused. According to statistics, the left ear cushion is almost always smaller, you can distinguish it by its size.

Outcome

It was not so easy to make earplugs, difficulties were at every step, but Veer managed to achieve a good result: the earplugs are beautiful, the sounds are quieter in them, you can safely use it in the office and at home, it will become easier to ride the subway.

If you became interested in how a startup will get to sales, then subscribe to the Veer telegram channel : now there is a small storm with suppliers, new technology for the production of cases, the first reviews of the test batch. If you like the earplugs, then you can pre-order on the Veer website , according to the plan, sales will begin in September.