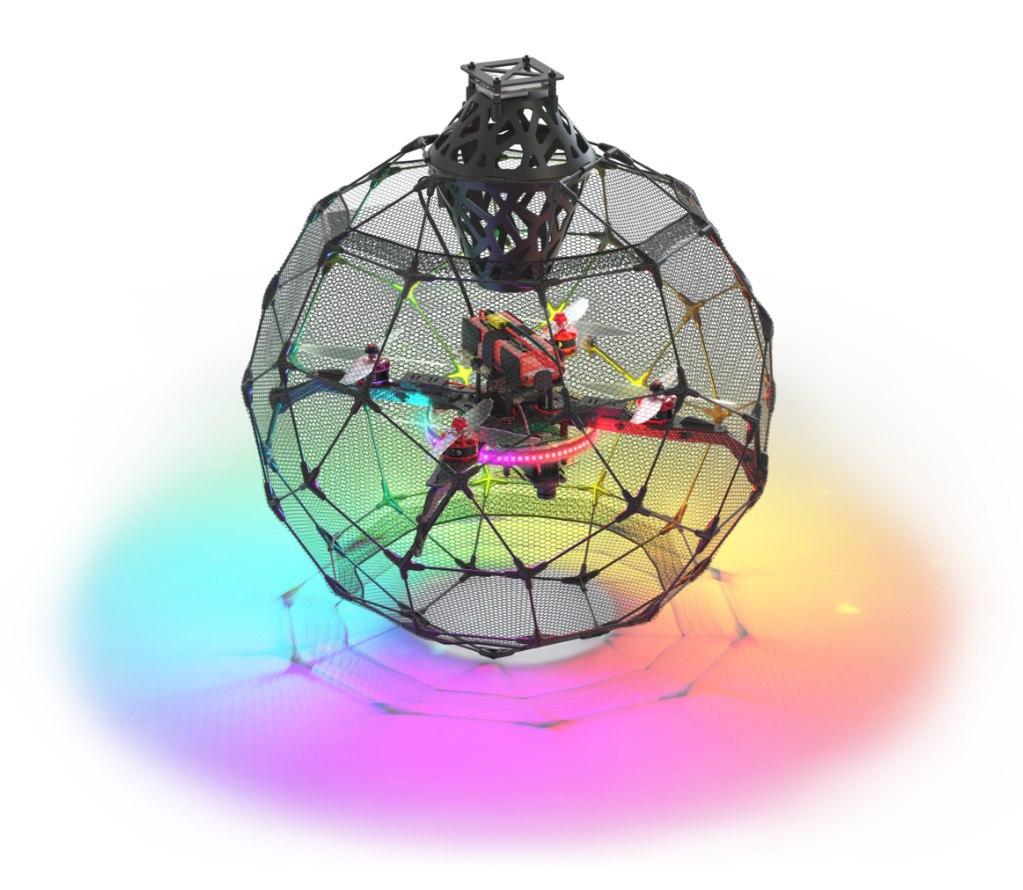

Very controversial, very unusual, very strange, but it works! At the intersection of architecture, collaborative robotics and unmanned aerial vehicles. Introducing: Tensodrone ™.

Tensodrone (Tensodron) - unmanned aerial vehicle (UAV) of a multi-rotor type of a new design with protection against collisions, made on the principle of tensegrity. This approach improves impact resistance with less weight by combining the protective cage with the structural frame design.

The project is a vivid example of the interaction of various teams of the NTI Competence Center in the direction of "Technologies of Robotics and Mechatronics Components" on the basis of the Innopolis University.

Drones are falling

Source

Just because they fly. Control systems, motors, sensors, autopilots, on-board computers and software - the developers try to do all this as reliably as possible, but the risk of crashing the copter remains. And if this is a prototype, then immediately you need to make several (pieces or dozens?) For debugging. In addition to internal factors, obviously, external factors remain: wind, passive obstacles, active influence.

Hardly anyone will argue, the drones fall, collide, overturn.

You can try to avoid this, you can prepare for it. What's better? It's up to the developer, user and legislator.

I am in favor of using both approaches together. But in this article, we will focus on how to avoid the consequences of a fall or collision of a UAV.

Protective structures

The most straightforward approach to avoid the consequences of a fall or collision of a UAV is a protective cage and other protective structures. There are two tasks here - to protect the drone from damage and to protect the environment where the drone operates and the people in it from the drone.

The basic version of the design, which is more likely to protect people from the drone, is the propeller guard.

AR.Drone 2.0 drone with propeller guards. Source

There are also fun origami-inspired solutions with foldable flexible propeller guards (and even frame designs) developed by Professor Dario Floreano's team at EPFL.

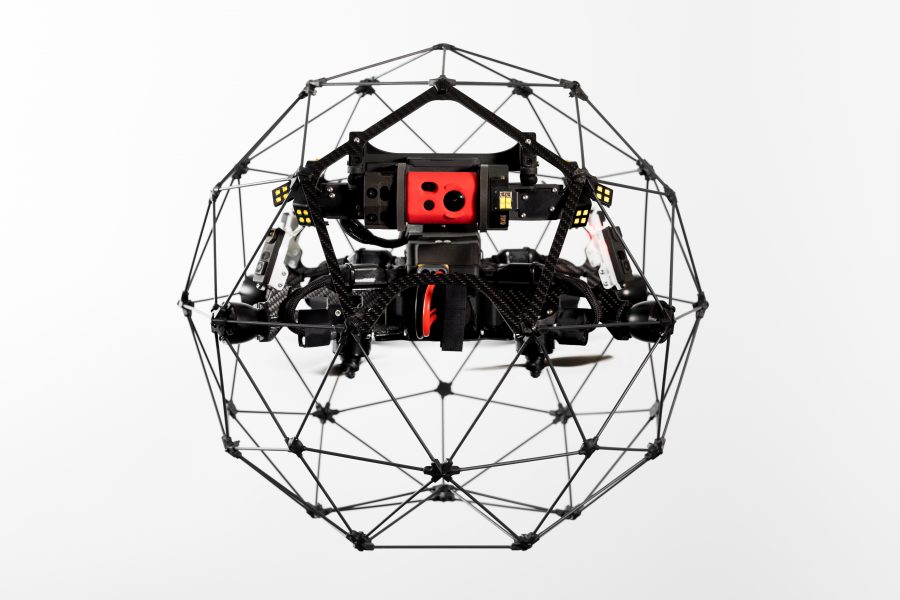

The prevailing design for protecting the drone itself (and at the same time people from it) is a protective cage. The quadcopter itself is inside the cage.

DroneClover from the Russian COEX The

Russian company COEX makes drones for training purposes, which by default have propeller guards and, optionally, a protective cage.

Drone Flyability ELIOS

Swiss (Switzerland - capital dronostroeniya?) Flyability company - produces perhaps the most commercially successful copter ELIOS with a protective cage for performing inspections inside premises. The originality of the design consists in attaching the protective cage to the frame of the copter on a movable suspension with the possibility of stabilization.

Drone Dronistics

EPFL's Dronistics startup (Switzerland again, from the Dario Floreano group) offers a drone with a foldable cage for the safe delivery of goods.

Still break

The disadvantage of such drones is the increase in the weight of the structure - you need to carry with you a protective cage and attachments to the UAV. The desire to reduce the weight of the protective structure leads to a decrease in its strength.

Drones with variable geometry

Another direction related to the idea of a rugged drone (and not only) is folding drones and drones with variable geometry (foldable and morphing). This refers to the ability of the drone to change its geometry in flight. Foldable structures are made in order to avoid damage to the drone (for example, the drone can "cringe" before impact), and the drone can, for example, be folded to a compact size for flight through narrow windows.

You may have seen a cool variable geometry drone video from Switzerland (yes, ETH + EPFL + UZH again). This idea is also interesting and close to us, I will tell you why later.

Drone with variable geometry

Tensegrity

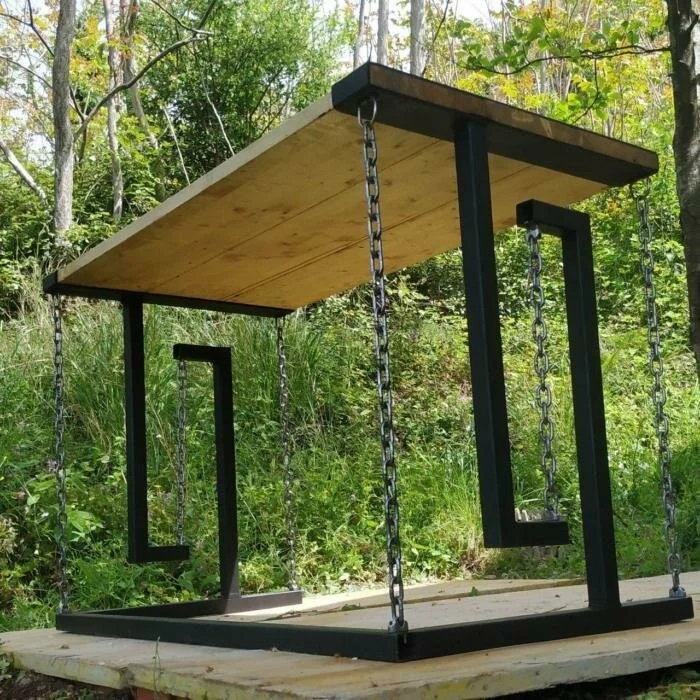

Tensegrity table. The source of

Tensegrity is the ability of framing structures to exploit the interactions of compressive solid elements with tensile constituents so that each element operates with maximum efficiency and economy ( Wiki ). The term is relatively new, appeared in the 1960s. The table in the picture above stands (or hangs) without legs precisely due to the principle of tensegrity.

There are many modern applications of this approach in architecture, from where it appeared, primarily in the design of bridges.

The world's largest Tensegrity bridge, Australia. A source

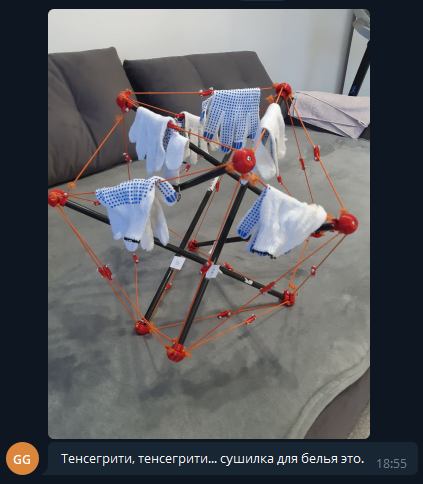

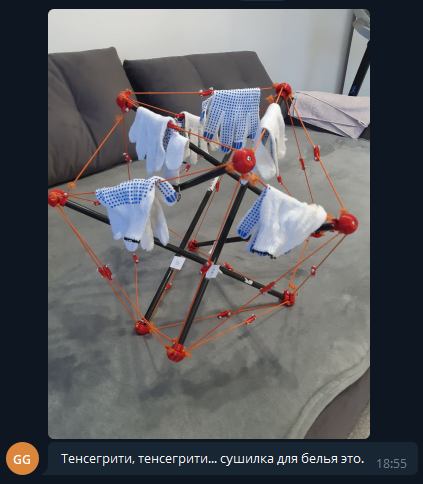

Alternative uses :)

Tensegrity in Robotics

One of the oldest areas of robotics - industrial manipulators - is now experiencing a new stage in its development, associated with the so-called. collaborative robotics. In the speech of specialists in this field, two terms can be heard with great frequency - stiffness and compliance.

In industrial robotics, the term compliance refers to flexibility and compliance. A non-compliant, stiff robot is a device that works no matter what external forces are acting on it. The robot's end effector will follow exactly the same path every time. On the other hand, the end-effector of a compliant robot can move along different trajectories to complete a task and apply different forces to the object. For example, a robot can grab an egg without crushing it. Controlled rigidity is at the heart of collaborative robotics.

The ideas for using tensegrity in robotics come from collaborative and “soft” robotics. Tensegrity structures are lightweight, impact-resistant and make it possible to control their rigidity (compliance) and configuration (shape).

The most famous example of the application of tensegrity in robotics is NASA's Super Ball Bot, a foldable ground robot, which was planned to be used to study planetary surfaces. Thanks to the spherical structure of cables and ropes, the robot can withstand a fall from a great height when it is dropped onto the planet from a spacecraft. Once on the surface, the robot can roll in any direction by controlling the lengths of the cables and / or rods.

IEEE Spectrum Video on NASA SUPERball v2

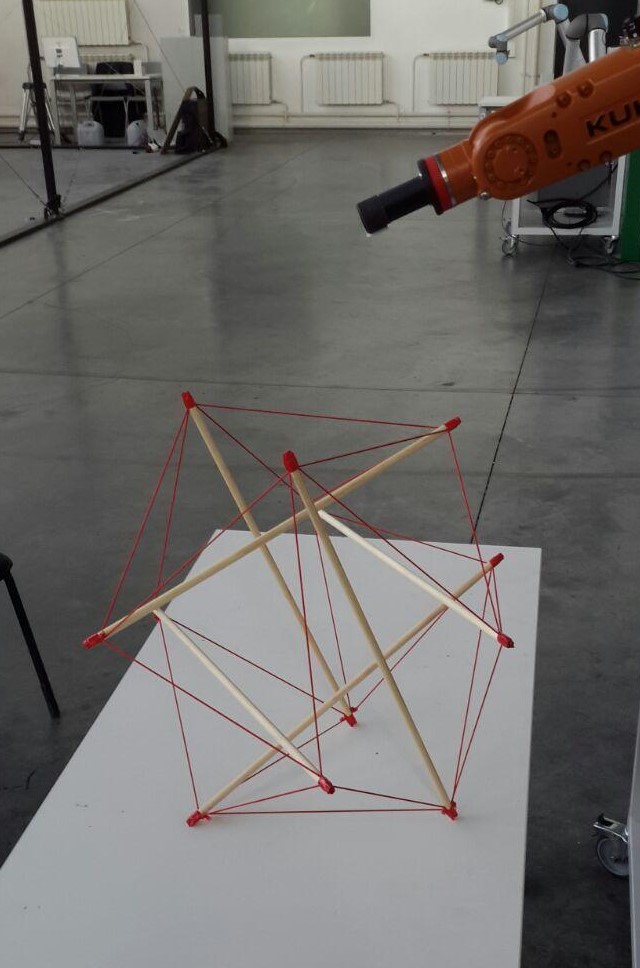

Tensegrity robots at Innopolis University

At UI, we develop a mathematical apparatus for modeling, designing and controlling robotic systems with stress-coupled structures with variable stiffness (this is Tensegrity). This is a fundamental work that can be found in a wide variety of robots, such as tensegrity manipulators or walking robots.

Tensegrity manipulator and graduate and research fellow of UI Oleg Balakhnov

Oleg was the first to start prototyping tensegrity robots with us - first from wooden sticks and rubber bands. The photo of the construction of sushi sticks, perhaps, also keeps the history of chats.

Tensegrity Vibrobot

-

-

Synergistic effect

You probably got it already

I have a drone, I have tensegrity. Ugh! (Tensodrone)

Once in our garage I passed by an eye-catching strange design:

I asked: "What is this?" I was told: "an unkillable structure - drop it, but it does not break."

I broke (actually just shriveled - changed shape because the rubber bands were loose and misaligned). But we need such a design for drones! And we started an adventurous experiment.

Tensegrity Survival Test Video

A tougher test

Squishy robotics — , - , ,

Squishy robotics — , - , ,

Adventure

Sergey approves of the adventurous experiment. Jeff Bezos is also

Sergei Savin - a senior researcher, associate professor, a serious scientist with a Ph.D. at 25 years old and many rated publications. He is one of the founding fathers of Tensegrity Robotics at UI and has received several grants for the development of Tensegrity in Robotics.

Igor is considering an idea

Dmitry, Oleg and Haney collect the first tencodron (it looks like something). Dmitry DevittGigaFlopsis- a researcher and graduate student of the University and the one who applied the most modern technologies - carbon tubes and kevlar threads, 3D-printing with carbon and soft plastic, implemented everything and made it fly.

The process of assembling the Ura tensodron

. happened!

Flies!

Dmitry is also the first actor after the tensodron in the epic videos of his flights. Rate:

A game of two actors starring themselves. Video by DeluuusiOn

More about prototype construction

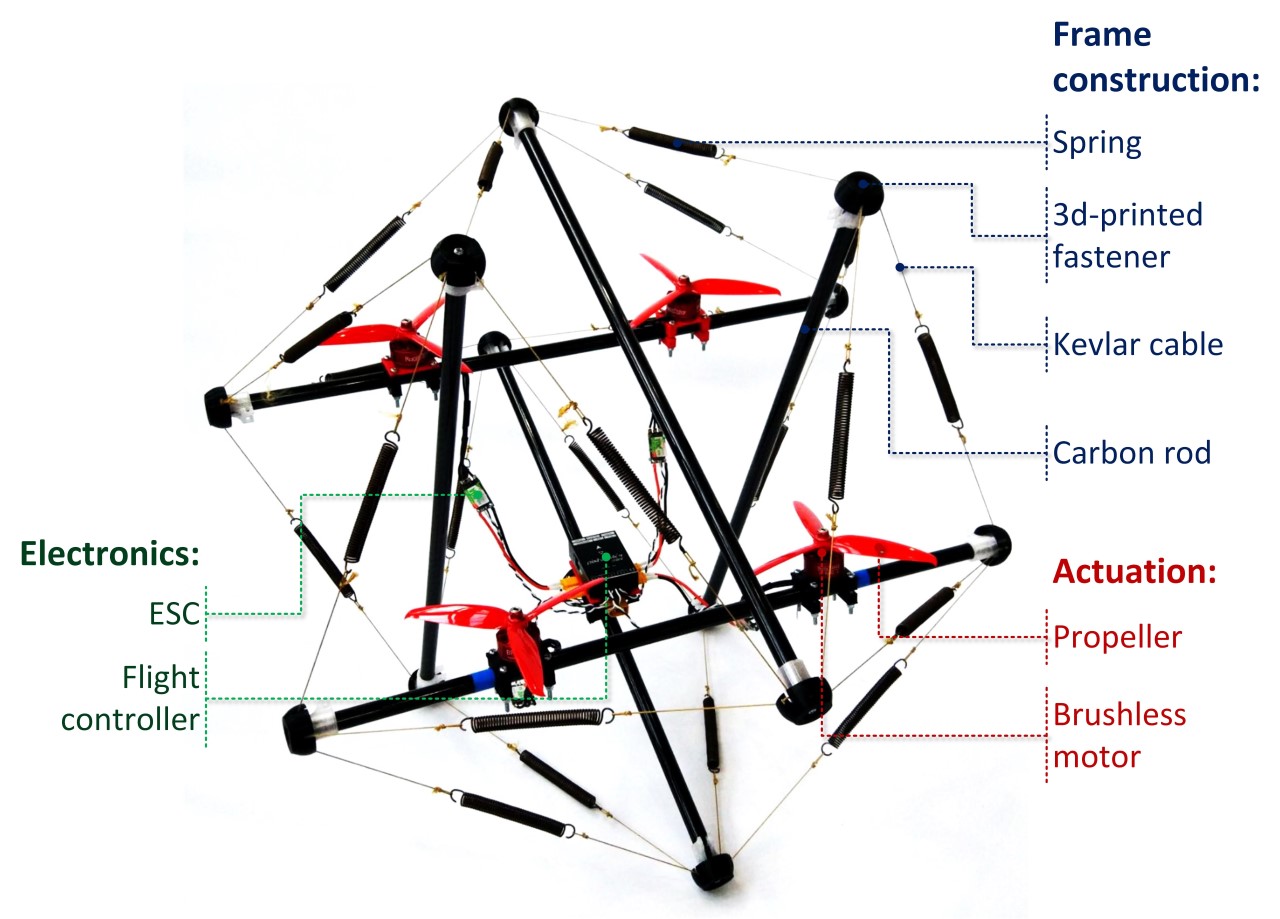

The design of the first prototype drone turned out as follows:

The design of the prototype of the Innopolis University tensodron

The basic six-rod design of Tensegrity was used. Unlike rigid quadcopters, we have two pairs of propeller motors mounted on different beams. Also, none of them is rigidly connected to the autopilot, which is located on the lower beam.

The onboard electronics and electromechanical components of the drone prototype include:

- Autopilot CUAV Pixhawk v5 mini;

- 3s 1400mAh battery;

- Racerstar REV35 35A BLheliS 3-6S ESC Regulator;

- Racerstar Racing Edition BR2205 2300KV motors;

- IMU sensors MPU9250.

The cables are made of Kevlar fiber with custom springs. The rods are made from carbon fiber tubes. End caps and other small parts are 3D printed.

Management problems

The main control problem compared to a conventional hard drone is vibrations, which, firstly, are larger in amplitude, and secondly, they are different for the controller and different engines, because they are installed on different beams (although this can also be a plus - vibration isolation).

Early Tensodron Suspension Tests: Vibration (sorry for the vertical video)

Early tests of the tensodron in flight: vibration

We are not alone

, .

( ), , Imperial College London:

, : — .

.. , , , .

, , :

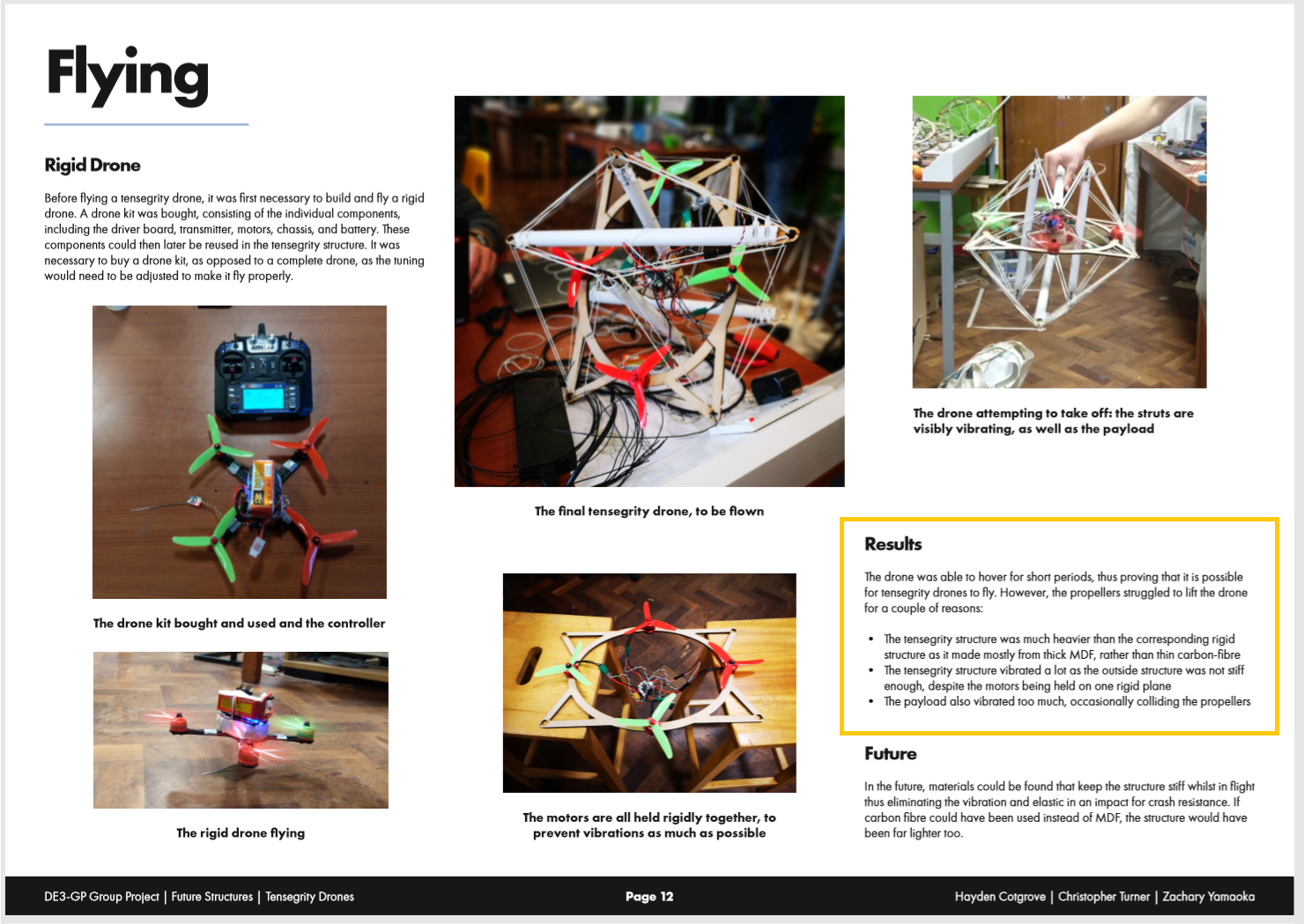

Hayden Cotgrove, Christopher Turner, Zachary Yamaoka Tensegrity Drones.

-, . -, — -, -, . , , .

. , Hayden Cotgrove, Christopher Turner, Zachary Yamaoka:

( ), , Imperial College London:

, : — .

.. , , , .

, , :

Hayden Cotgrove, Christopher Turner, Zachary Yamaoka Tensegrity Drones.

-, . -, — -, -, . , , .

. , Hayden Cotgrove, Christopher Turner, Zachary Yamaoka:

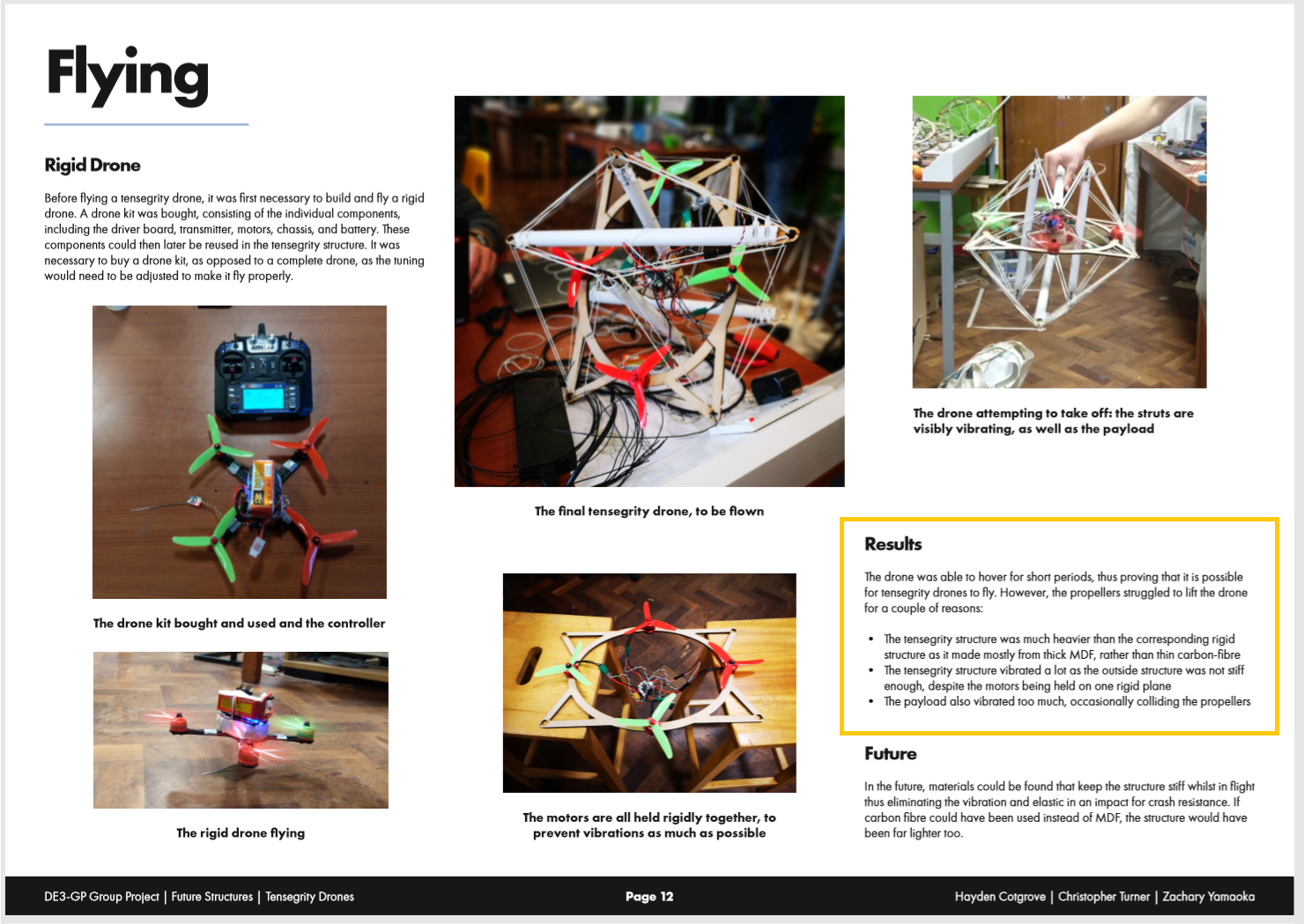

Results

The drone was able to hover for short periods, thus proving that it is possible for tensegrity drones to fly. However, the propellers struggled to lift the drone for a couple of reasons:

- The tensegrity structure was much heavier than the corresponding rigid structure as it made mostly from thick MDF, rather than thin carbon-fibre

- The tensegrity structure vibrated a lot as the outside structure was not stiff enough, despite the motors being held on one rigid plane

- The payload also vibrated too much, occasionally colliding the propellers

We solve these problems from two sides - by improving the design to reduce vibrations during flight and developing control and state estimation algorithms in order to suppress vibrations and better control, including taking into account additional data from IMU sensors on the beams and a dynamic model of tensegrity structure.

Falling to the floor followed by takeoff, indoors (without installation)

Some more test videos

, , . , .. .

( )

( )

What's next?

Research

There is still a lot of interesting things ahead:

Application

Now this thing flies by itself on a given mission (including GPS on the street, and indoors - we will use visual odometry). For us, further application for inspection of premises is obvious.

Except for low-level control and shape, the tensodron is a regular drone, we integrate our motion planning algorithms into it for autonomous exploration and obstacle avoidance.

An example of performing an automatic inspection. Master's project by Victor Massague, our alumnus and in the near future, hopefully an employee from Barcelona

And again research

The potential of the Tensegrity drone design is much greater than a simple drone.

Remember the Foldable Drone from the video above? What about SUPERball ?

So, if you actively change the lengths of the rods or the tension of the cables of the tensegrity drone, you can control its configuration (or, more simply, the shape)!

It turns out Foldable Morphing Tensodrone. We are actively conducting research in this area.

Innopolis University Variable Geometry Tensodron (Concept)

The use of Tensegrity for an aircraft opens up new research challenges. The design prototype already shows that the idea works and can be used to protect the UAV.