How do layouts, prototypes of cases for radio electronic equipment differ from each other, and what are all these prototypes for in general? Formlab version.

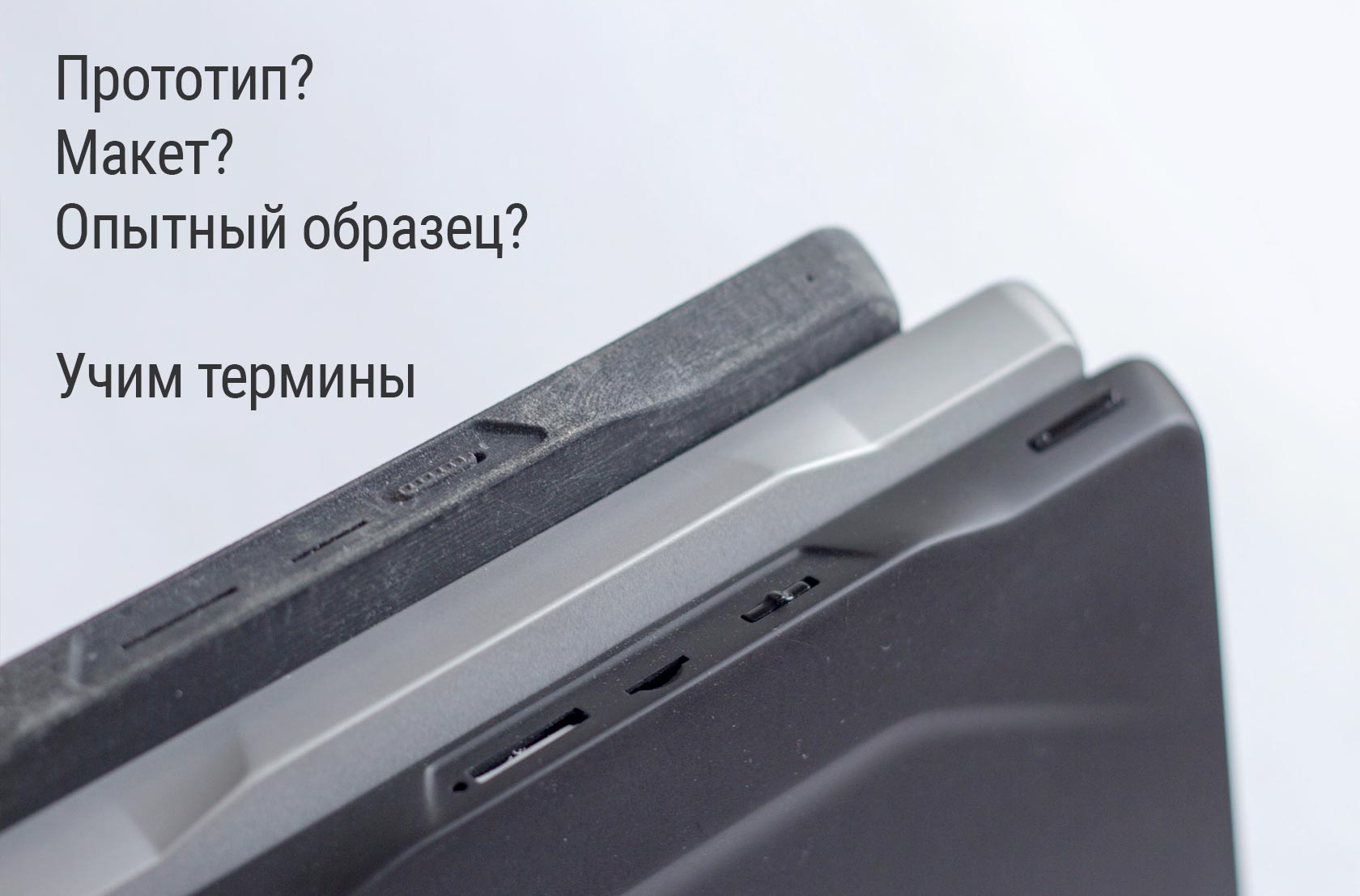

Layout

A model (fr. Maquette - scale model, Italian macchietta, diminutive of macchia) - a model of an object in a reduced scale or in full size, usually devoid of the functionality of the represented object. Designed to represent an object. Used in cases where the presentation of the original object is unreasonably expensive, impossible or simply impractical.Wikipedia Geometrical characteristics of the

layout only approach the serial product. It is made using non-serial, non-production technologies and almost anything (including plasticine

( — 3D- , ), —

. , , ( Elta)

— , . , , . 3D- ANISOPRINT

. . “”

Of course, there is no rigid division into layouts and prototypes. There are also compromise options. Here is a 3D printed model of an air recirculator in which the electronics were placed.

Air recirculator "Armed" - "hybrid" model and prototype

Prototype

Prototyping (English prototyping from ancient Greek πρῶτος - first and τύπος - imprint, imprint; prototype) is a quick "rough" implementation of the basic functionality of a future product / product, for analyzing the operation of the system as a whole. At the stage of prototyping, a working system is created with little effort (possibly ineffective, with errors and not fully). During prototyping, a more detailed picture of the system design is visible. But it is not necessarily performed using the same technologies as the system itself.Wikipedia

The prototype is also produced using non-serial technologies. Its task is to be as similar as possible to a serial product and (as far as possible) to repeat its physical characteristics. Once again: as far as possible, that is, how it will turn out, because the prototype can be made with the same 3D printing.

Printed and milled mouse prototype

But sometimes it may not be printed.

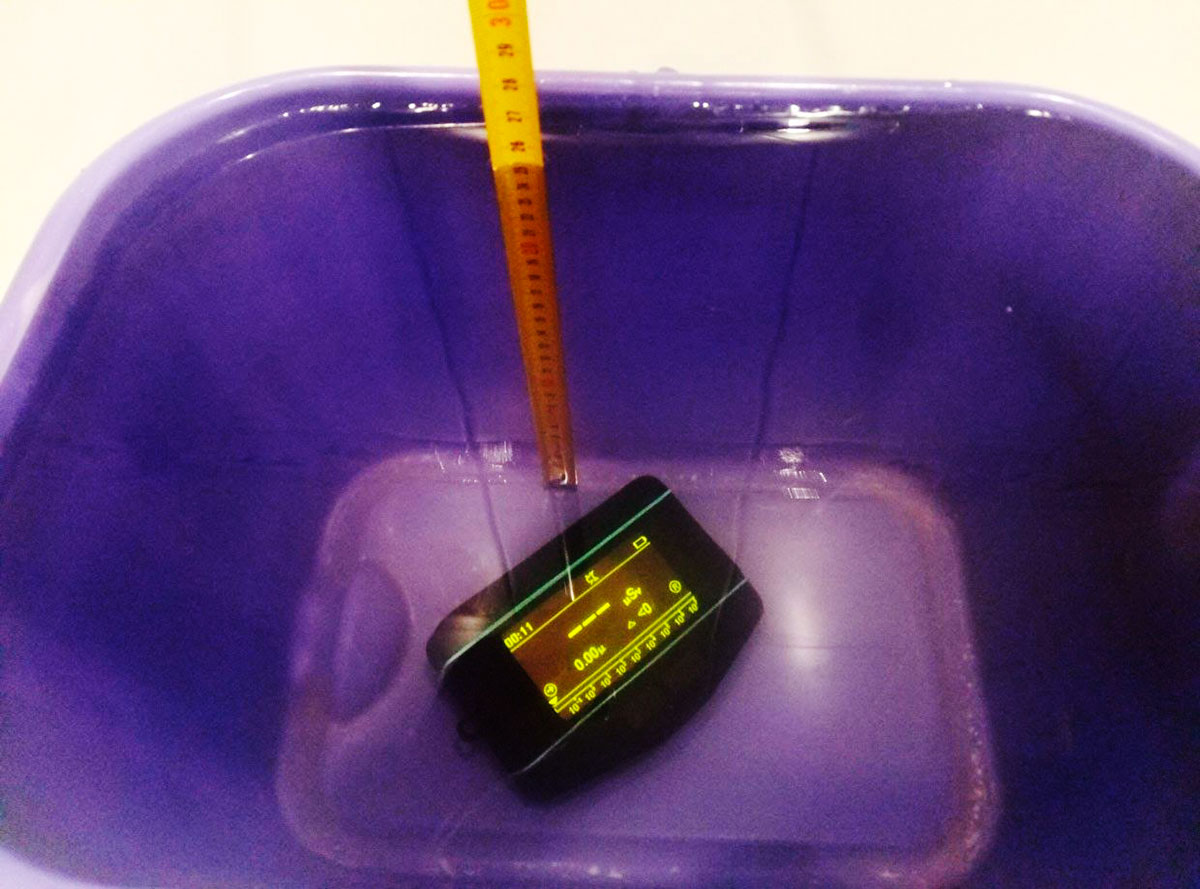

Exception to the rule: a prototype made by milling ABS plastic is laid in a bucket of water (and works). Zyablik dosimeter-radiometer , IP67

But usually you don't need to put a prototype in a bucket of water to check its water resistance.

The dimensions of the prototype already exactly match the dimensions of the future device (the color and texture of the surface also correspond). Electronic components can already be placed in the housing.

Prototypes router

prototype incubator for culture "Inseptor"

Prototype remouta irrigation system IRRIOT

Prototype

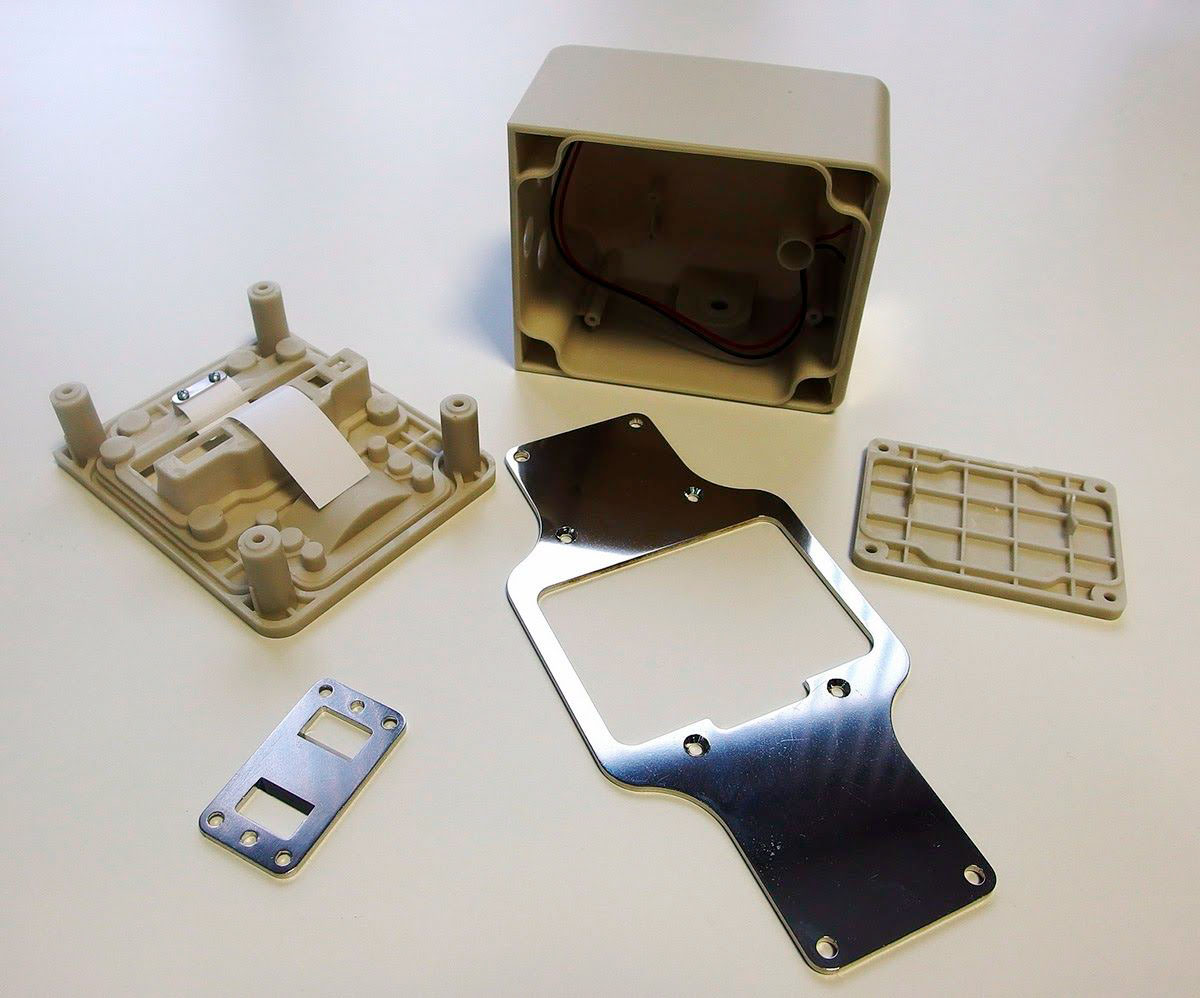

A sample of products made during the development work on the newly developed working design and technological documentation for verification by testing the compliance of its parameters and characteristics with the specified technical requirements and the correctness of technical solutions, as well as for making a decision on the possibility of putting into production and (or) use by appointment.GOST R 53736-2009: Electronic products

The next stage is a prototype . It is still produced using non-serial technologies, but its task is to be similar in everything to a serial product. The prototype should be as close as possible in physical and geometric properties to the serial product. It is understood that it has the same weight, the same dimensions, the same color, the same properties like radio transparency as the device from the series.

A prototype of a wall-mounted electric boiler

"Filling" of a prototype may be such.

A prototype of an electronic door lock

Test batch

A test batch (or trial batch ) can then be made . A test batch is a prototype that is made in a small batch . That is, the technologies remain non-serial, the properties of the device are as close as possible to a serial product. Details of the Zyablik dosimeter-radiometer . Test batch Microterminal for entering the results of medical research ( leukocyte counter ). Test batch, circulation - 125 pieces

Golden sample

Next is the golden sample. This is, relatively speaking, the first generation of a product that is made using serial technologies, on a "combat" mold, but it may have drawbacks that need to be corrected during serial production. From the same (or the next) batch of products, an

Security alarm control unit "Supply" ”. The so called golden sample

! The difference between a prototype and a test batch: if a prototype unit can be milled, then it is too expensive for a test batch, therefore, for example, polyurethane is molded into silicone molds.

Conclusion

- So, we can have a mock-up that can be made from anything; a prototype that looks like a final product, but is manufactured using non-serial technologies; there is a prototype, as much as possible, similar to a serial product, including inside; a test batch - the production of several dozen prototypes and, finally, a golden sample - the first products made using serial technologies, but having drawbacks that will be corrected later.

The best resolution table is here .

Serial sample of the voltage stabilizer for gas boilers "Teplocom"

By the way, the stabilizer in the Formlab case was launched almost into space not so long ago. And nothing, returned safe and sound:

What else to read?

Russian instrument making: we turned your design on our fingers

How to design a case for a device. A complete guide

How not to miss a budget for serial production of hulls: 20 examples from the practice of an engineering design bureau

How not to miss a budget for mass production of hulls-2: prices for small-scale plastic molding We

“prepare” a prototype correctly. Prototyping technologies for the case

How to independently calculate the price of a device case in a couple of minutes

Industrial design for business: minimize costs, save on unnecessary, invest in the main thing

Industrial design for business, part 2: design instead of marketing or make a product that will sell itself