Top 3D Shop welcomes you! Today we are talking about the technologies of mechanical and optical scanning in three dimensions. We introduce you to the principles of operation and areas of application of CMM - coordinate measuring machines. We compare different equipment. Learn more from the article.

Introduction

Source: aberlink.com

Coordinate Measuring Machines (CMMs) are instruments for precise contact measurements of objects. The devices operate using special sensors (probes) that determine the position of points on the surface of objects.

The movement of the measuring head can be controlled by a computer or an operator. The coordinate measuring machine determines the position of the sensor by changing its position, in comparison with the original position along the XYZ axes. For work in hard-to-reach areas, the CMM changes the angle of the sensor as it moves.

Source: starrapid.com

Timeline of CMM creation

1950s of the XX century. The Scottish Ferranti Company presented the world with the first prototype of a 2-axis measuring machine. The device was designed to meet the challenges of the military industry.

1960s of the XX century. The Italian company DEA creates 3-axis CMMs.

1970s of the XX century. The advent of computer-controlled devices.

1980s of the XX century. Browne & Sharpe develops the first digitally controlled commercial vehicle.

Industry pioneers Browne & Sharpe and DEA are now part of the Swedish holding Hexagon AB .

Mechanical measurements

Manual CMMs

Source: directindustry.com

Portable handheld CMMs are mobile and can be used anywhere in your production. Most devices are wireless, so they can work in hard-to-reach areas. The devices are designed for high-precision measurements of parts of complex geometric shapes: with complex edges, holes, recesses, etc. Using the equipment, GD&T analyzes (shapes, sizes and tolerances) and control comparisons of finished samples with basic digital models are carried out.

Source: directindustry.com Hand

-held CMMs do not require special training as the equipment does not require complex setup and calibration. The use of such devices together with other devices for editing and digitizing expands the functionality and scope of the equipment.

Horizontal arm CMMs

Source: metrology.news

In cases where you need free access to the part from different sides, CMMs with a horizontal arm are used. The device operates on a heavy platform, which ensures that the object remains stationary during measurements. The design is designed to protect users from injury and objects from deformation.

Among contact measuring instruments, horizontal arm coordinate measuring machines are the fastest to solve problems in the field of automated metrological control.

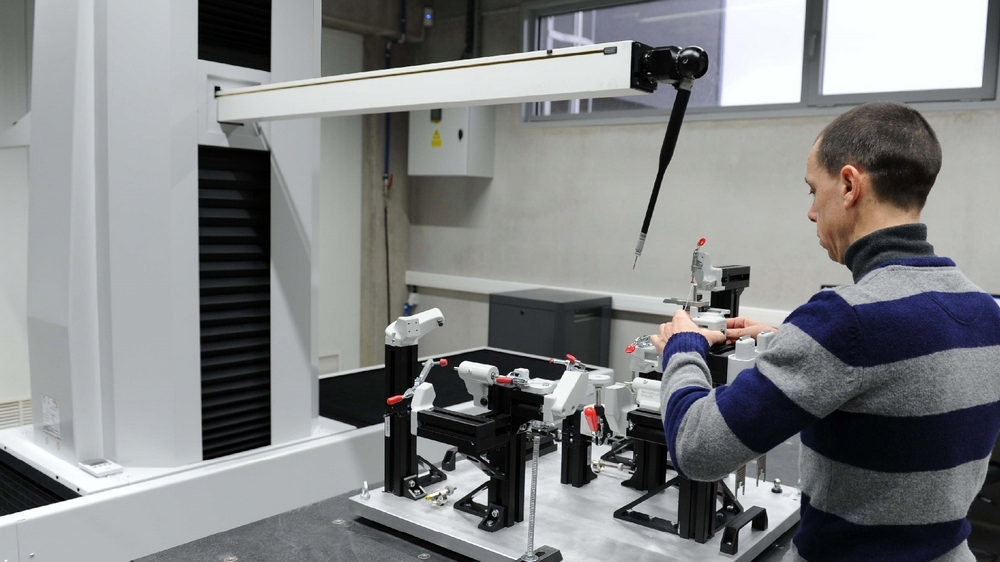

Bridge CMM

Source: metrology.news

Bridge CMMs are designed specifically for high precision and challenging measurements. They digitize depressions and holes with very small diameters. Design features of devices:

- heavy, usually granite base;

- vibration isolation system;

- rigid structure to exclude various types of damage;

- a range of interchangeable styli, probes and probes for accurate measurements and comparison of the finished part with the basic programming model.

Two versions: static work platform and movable bridge, or static bridge and movable platform.

Portal CMM

Source: directindustry.com

Gantry CMMs measure large objects. The devices themselves are also large. The guides are made of rigid materials that are resistant to temperature changes and deformation. The open design type simplifies the work: installation, direct measurement and movement of parts.

Optical 3D scanning

Laser 3D scanning

Source: 3d-scantech.com

Laser 3D scanners are representatives of another technology for measuring objects. One of the key differences between probe and laser measurements is the ability to shape objects. Mechanical scanning does not give an idea of the shape of objects. When digitizing objects with a laser scanner, a point cloud is created, on the basis of which the software forms a three-dimensional detailed and high-precision model.

Source: whatech.com

Laser scanning is a non-contact technology, therefore it is widely used for remote quality control when working with fragile and easily deformable objects. Since lasers are sources of coherent light, 3D laser scanners are virtually unaffected by fluctuations in environmental conditions.

Scanning with structured illumination

Source: 1zu1prototypen.com

Optical 3D scanners based on structured illumination technology are usually more affordable than laser devices. A light grid is directed to the scanned object, the cameras fix the shape of the light projection and calculate the coordinates of each point. Based on the information received, the software builds a digital model.

Source: 1zu1prototypen.com

Despite the fact that 3D scanners using this technology are inferior in accuracy to laser ones, they have a number of advantages:

- affordable price;

- ease of use;

- safe digitization of living things (including people).

Source: 1zu1prototypen.com

When it is necessary to scan hard-to-reach areas, for example, canals and holes, scanners with structured illumination are supplemented with hand-held measuring instruments.

Multisensor devices

Source: interestingengineering.com

By combining contact and non-contact measurement technologies, multisensor equipment incorporates the strengths of each method:

- possibility of high-precision measurements in hard-to-reach places - advantages of CMM;

- high speed of work and more information received are the advantages of optical scanners.

The design of such devices is a 3D scanner equipped with an additional probe with a sensor.

Source: metrology.news

The construction of multisensor machines does not have strict standards, so they can differ from different manufacturers and depending on the purpose.

Robotic coordinate measuring machines

Source: metrology.news Robots are becoming the

best solution for automation of measurements. The devices operate regardless of environmental conditions, always with the same high accuracy, without fatigue and days off. Robots replace people in hazardous and hazardous environments. They work with large and small objects.

A CMM, optical scanner, probe and other control devices can act as a sensor. Today's experience of use proves that any metrological measurement is available with robotic CMMs.

Cases using measuring equipment

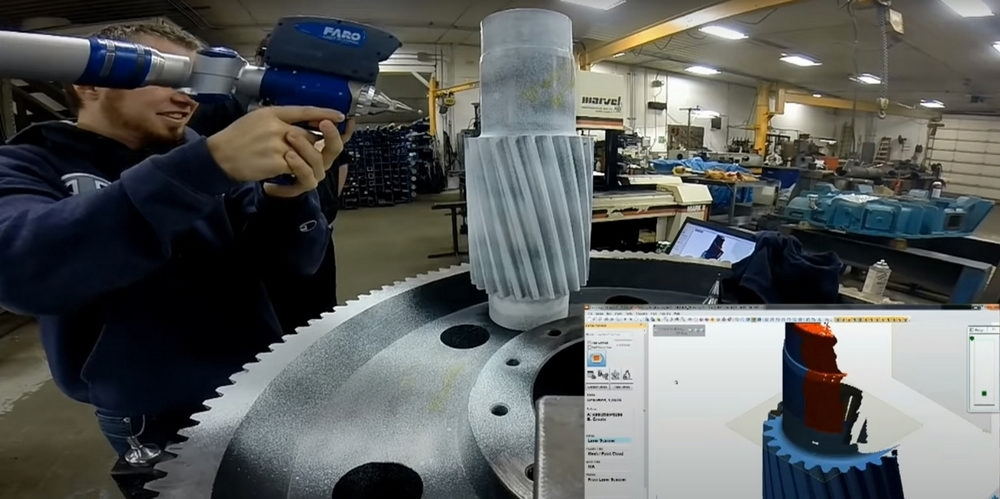

Gear digitizing for retrofitting, DeWys Engineering

Source: youtu.be The

company was faced with the task of reconstructing a failed large cast gear from the gearbox. For the solution, a robotic 8-axis multisensor center Faro Platinum Arm LLP V3 was used, equipped with the functions of mechanical and laser 3D scanning. After digitizing and inspecting the part's holes, the data was collected and processed in Geomagic Design X software . The created model was sent to Soildworks for further processing, then DeWys Engineering specialists prepared a file with a guide for creating a copy of a gear on a hobbing machine.

Quality control of large batches, Computer Aided Technology

Source: cati.com

Bob Renella, the company's manager, shared that the company regularly carried out quality control of large batches of parts. In this regard, he was faced with the task of optimizing processes: reducing time costs without losing the verification accuracy. The usual technologies did not suit the company any more: an operator was involved in checking every detail, there was a loss of time and quality.

Computer Aided Technology found itself in the conditions of choice:

- Buy an additional test machine and bring in a new workforce for service.

- Engage third parties to carry out some of the checks, which will increase costs and, possibly, the quality of measurements.

- Invest in more advanced equipment.

Source: creaform3d.com The

guide settled on the last version. As a result of the acquisition of the kit: the wireless Creaform HandyProbe and the two - chamber C-Track, the company received a number of advantages:

- The mobile scanner allowed the operator to work at any part of the enterprise, which saved the time and effort that was spent on transporting consignments to the place of inspection.

- The size of the parts to be checked is no longer limited by the capabilities of the old test machine.

By combining Creaform HandyProbe and INNOVMETRIC 's PolyWorks Inspector software solution , operator work has become much easier. Now the specialist acts according to the algorithm proposed by the software in real time.

Inspection of 10m shaft arm with ScanTech TrackScan and TrackProbe light pen in 15 minutes

Source: 3d-scantech.com

When the excavator is operating, heavy loads are applied to the bucket arm, as a result of which the bucket shaft bushings wear out intensively. An increase in the diameter of the bucket shaft hole leads to an increase in the shaft runout in the lever hole, which subsequently entails a breakdown of the equipment. Accordingly, regular inspection of the arm hole size prevents equipment failure. Buying CMMs to solve this problem is expensive and impractical, since such machines are installed permanently, and the transportation of large-sized parts to the CMM installation site entails additional time and financial costs.

Source: 3d-scantech.com

It took 15 minutes to digitize, process the results and control the quality of the 10-meter arm right on site. The specialists used the ScanTech TrackScan 3D scanner, created in partnership with the Norwegian manufacturer Metronor. The scanner works without markers, complete with a TrackProbe light pen, makes high-precision measurements of holes of any depth and radius.

Outcome

Source: creaform3d.com

Requirements for product quality, in the face of tough competition between manufacturers, are constantly growing. Accordingly, the production needs are growing to optimize quality control processes: increasing speed and accuracy, and reducing costs. The market demands professional equipment: 3D scanners and CMMs, easy to use, ready to use, solving specific problems of various industries.

To create products that meet the high requirements of consumers, maintain a competitive position, suppliers of goods and services need to timely invest in modern equipment.

Order control and measurement and 3D scanning devices in Top 3D Shop - the largest integrator and supplier of digital production equipment on the Russian market.