In this article, we will talk about optimizing quality control processes using 3D scanning , about the design and principles of operation of metrological 3D scanners . Using real examples, we will show the effectiveness of the use of equipment for solving various problems. After reading the review, it will be easier for you to navigate among the large number of models on the market and determine the criteria for choosing the right device.

Introduction

Every year the industry produces more advanced devices and devices. Machine parts often have a complex geometric shape and are in close interaction with each other. In order to ensure the well-coordinated operation of the mechanisms, it is necessary to match the shapes, sizes, assembly accuracy and other parameters. Quality control in mechanical engineering was carried out using various technologies, including using coordinate measuring machines (CMM). However, scanning is by far the most efficient way in terms of the ability to capture data for measurements and the speed of information processing.

Capabilities of 3D scanners

Source: solutionix.com

3D scanners deal not only with flat surfaces, but also with difficult areas: corners between edges and edges, indentations, holes. An important advantage of the devices is a non-contact method of operation, which allows scanning from a distance, in hard-to-reach places.

After making the changes, the information is transmitted on-line to a computer, where the software compares the received data and the specified parameters and demonstrates deviations: size discrepancies, cracks, traces of deformation and corrosion, and other changes.

Areas of use

Source: sastrarobotics.com

Digital measurement is a highly technological process that has several important advantages over other verification methods. The only disadvantage of the technology is the high price of the equipment. In large industries, with a quick payback, the use of 3D scanners is economically justified. Let's consider some examples:

- large-scale production of parts and devices with mandatory input and output quality inspections;

- small-scale production of objects of complex geometry, which is impossible without constant quality control.

Situations when other technologies cannot be applied:

- work with objects made of specific materials, deformable by the contact method of determining the parameters;

- measurement of electronic parts at risk of damage from static electricity;

- repeated measurements of objects that are physically absent can also be made on a previously taken digital copy.

Purpose of use

Source: www.capture3d.com

Control at different production stages

Incoming inspection of materials and parts is necessary at any enterprise. For large-scale production, sample lots are inspected. However, this requires a large number of controllers, which entails an increase in the price of the product.

The use of 3D scanners automates the workflow, eliminates errors associated with the "human factor", allows you to switch from selective quality control to continuous quality control, increases the speed of verification several times compared to manual labor.

Analysis of the location of parts relative to each other

In a product consisting of several parts, it is important to monitor the correct arrangement of the elements in relation to each other. Scanning technology easily fixes the position of objects in space and transmits information to a computer monitor.

Checking the geometry of large objects

A number of large objects such as construction machinery, marine and air transport require regular testing of the hull geometry. The process is lengthy and requires a search for specialists with the necessary qualifications and experience. Metrological 3D scanners easily cope with the digitization of large-sized objects, guarantee high measurement accuracy and save companies' time and financial resources.

Checking the geometry of small objects

Sometimes measuring small objects is more difficult than measuring large ones. 3D scanners successfully measure to a few microns, regardless of the size of the parts. Deviations in shape and size from the base model are highlighted in the program, which makes it easy to notice and eliminate them.

Equipment selection

Source: tool-maker.net

There are dozens of models of metrological scanners on the modern digital equipment market. The choice of the device begins with identifying the range of tasks set by the production. Here are some parameters that need to be considered and compared with the key goals:

1. Workspace

It is quite clear that large-sized objects require devices with a large work area. Please note that the size of the work area is in inverse proportion to the resolution. By choosing a device with an excessive scan area, the user may find insufficient accuracy and resolution.

2. Data Accuracy

Obviously, in aircraft construction and the production of other critical parts, the highest available accuracy is required.

In reverse engineering of consumer goods, products without complex mechanics, as well as when used in the creation of works of art, souvenirs, in the development of computer games, such accuracy will not find application, for these purposes it makes no sense to overpay tens and hundreds of times for a scanner.

3. Speed of operation

This parameter includes the time of calibration and direct scan. For high volume production, where 3D scanning is used for quality control that involves tens of measurements per minute, high speed is a significant feature. Small batch fabrication and reverse engineering are less demanding on instrument speed.

4. Software

We recommend giving preference to scanners that work with proprietary highly specialized software. The software required for processing scans, if it is not included in the kit, may require significant additional financial investments.

5. Price

Choosing a 3D scanner, you must independently or with the help of a qualified specialist correlate the user's tasks and the capabilities of the device. There is no point in overpaying for unnecessary features. In this case, it is important that the device has the required set of parameters that are guaranteed to give the required result. It is important to predict the payback period of the equipment.

Examples of 3D scanners for metrological quality control

Let's start our acquaintance with the presentation of the Russian model - RangeVision Pro. The device is officially approved as a measuring device by the Federal Agency for Technical Regulation and Metrology.

Basic information about RangeVision Pro

Source: top3dshop.ru

The device is designed as a universal measuring device for small and large objects with sizes from 30 to 1000 mm. Three working zones and a set of interchangeable lenses allow the scanner to digitize jewelry and car body parts with equal accuracy.

Measurement accuracy is ensured by structured illumination technology, 6-megapixel cameras and original software solutions.

RangeVision software allows you to stitch together image elements, fill in empty areas and align images. The program includes basic functions for checking geometry and taking measurements. The output file format is supported by all popular CAD and virtual modeling systems. Software updates are freely available.

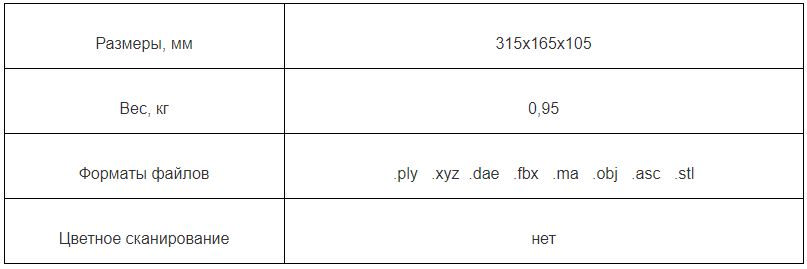

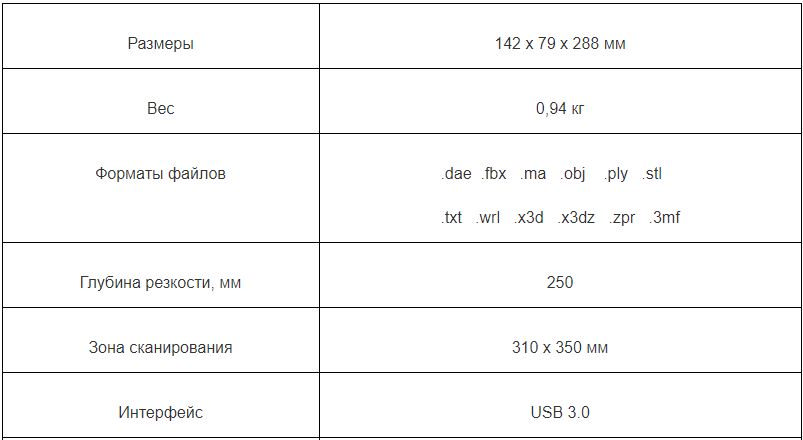

RangeVision Pro Features

Examples of using a 3D scanner in various fields

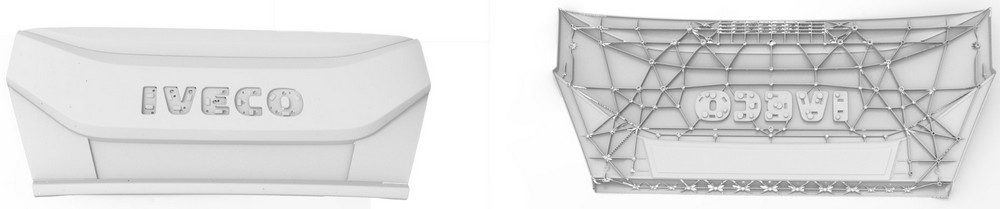

Quality inspection at Dolsatech

Source: rangevision.com

Italian partner of Iveco and Porsche, Dolsatech received base parts from the PRC that required quality control. The usual incoming inspection system could not cope with a large flow of products and did not have the opportunity to test objects of non-standard geometry.

A RangeVision PRO 3D scanner was used to optimize the process. Current measurement technologies involved the transportation and storage of control samples in dedicated areas. The mobility of the Russian scanner made it possible to reduce logistics costs.

Source: rangevision.com

With the use of a scanner, there was no need to move lots of goods for measurements. RangeVision PRO works in workshops and warehouses - in any convenient place.

In this case, a three-dimensional model of a part with a size of 1700 mm * 720 mm was created. Stickers were glued to the part, which made it possible to automatically assemble individual images into a single 3D model. The information was processed by the proprietary ScanCenter software supplied with the scanner.

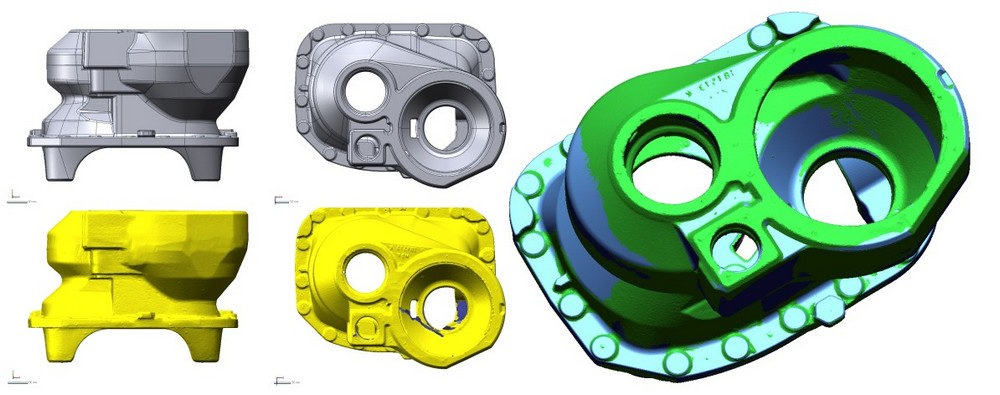

Quality inspection at INKAY TECHNOLOGY

Source: rangevision.com

INKAY TECHNOLOGY SRL from Italy was tasked with verifying that the dimensions of the body cast part of the base model saved in the CAD file were correct. Taking into account the non-standard geometry of the object, it was decided to abandon the usual technologies and use the RangeVision 3D scanner.

The work was performed in 3 stages:

- Created scans of the outer part of the body using markers for automatic image stitching.

- To scan the inside, the body was divided into 2 parts, each of which was digitized separately.

- We sewed all the images into a single model.

Source: rangevision.com

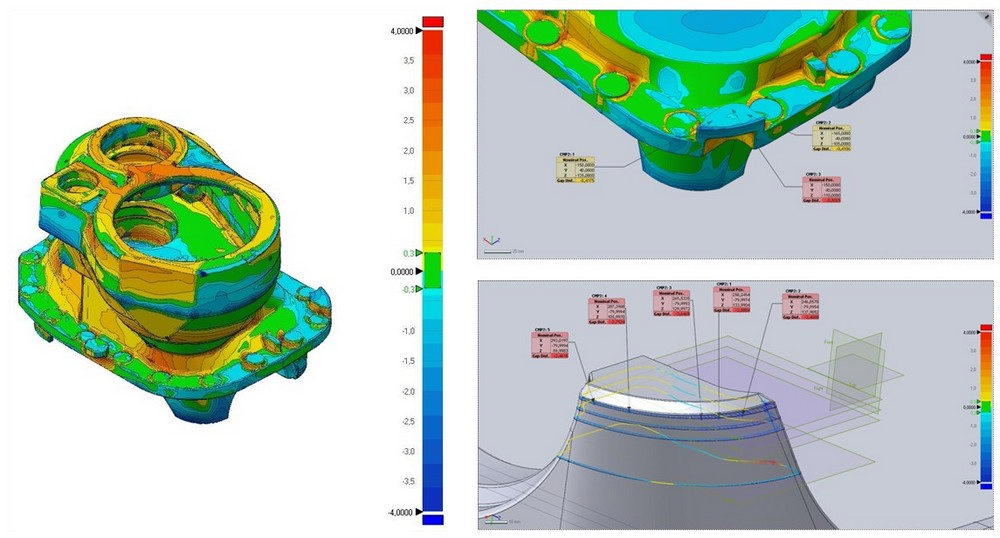

Quality inspection at the Krasnoye Sormovo plant

Source: rangevision.com

As we mentioned above, 3D scanning is justified not only in high volume production environments. Often the equipment is effectively used for piece production of parts. In the shipbuilding industry, cast components with complex geometry are used, the quality control of which is difficult and time-consuming. Therefore, the use of 3D equipment in the industry is becoming more common.

The Krasnoye Sormovo plant specialists chose RangeVision to inspect the quality of the variable pitch propeller hub.

Part height - 70 cm, diameter - 80 cm.

Source: rangevision.com

Before starting work, stickers were glued to the object to automate the stitching of the picture. The RangeVision PRO 3D scanner was moved around the hub, taking pictures from different sides. A 3D model was assembled from the 100 images obtained. The stl file was combined with the basic design model in the GOM Inspect software to determine the deviations. The work, as a result of which the specialists received an accurate report on the conformity of the finished product to the base model, took several hours.

ScanTech PRINCE775

Source: www.3d-scantech.com

Portable hand-held laser 3D scanner ScanTech PRINCE 775 operates on the basis of 2 cameras with LED backlight. There are 2 operating modes available to users:

- In BLUE mode, the blue laser is active; this mode is used to obtain high-detail models;

- RED mode with a red laser is turned on when high speed digitizing is a priority.

As a result of scanning, a point cloud is created, which is processed using the ScanTech software solution. The finished image is displayed on the screen of the working device.

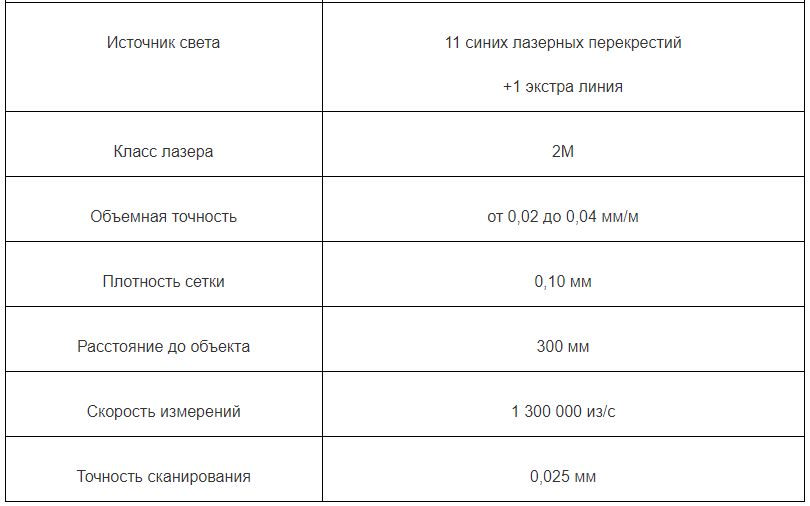

Scanner specifications

Using PRINCE 775

The main field of application of the scanner is the digitization of large objects, such as parts of ships, cars, industrial installations. The device can also work with small objects such as jewelry.

ScanTech PRINCE 775 applications:

- reverse engineering;

- Industrial Design;

- quality inspection;

- creation of computer games and 3D films;

- and in many other areas.

Source: www.3d-scantech.com

An example of using a PRINCE hand-held scanner in a set with MSCAN - the use of two devices increases the efficiency of the process, due to the features of the equipment.

The first device provides high accuracy and detail, the second helps to study large-sized objects using photogrammetry.

Source: www.3d-scantech.com

Digitizing Airbus A350 Parts Using Kit: MSCAN + PRINCE. The pair has proven to be excellent in solving quality inspection tasks quickly.

Source: www.3d-scantech.com

Digitization made it possible to create a three-dimensional model of the impeller, since it was impossible to accurately measure it in other ways.

Creaform HandySCAN Black Elite

Source: creaform3d.com

Let's get acquainted with the versatile compact HandySCAN Black Elite - a professional metrological 3D scanner from Creaform. The device is suitable for most users, including those who do not have practical skills in working with such equipment. Despite its ease of use, the scanner guarantees high-precision models, even when digitizing large objects of complex geometry.

Scanner specifications

Applications of Creaform HandySCAN Black

The device is designed for professional use in various fields. HandySCAN Black does a great job with tasks such as:

- incoming and outgoing quality control in production;

- reverse engineering;

- pipeline inspection;

- digitization of objects for any purpose.

The scanner is easy to use: to get started, you need to establish a connection with a laptop and select a program. In the process of digitizing, you can pause, study the intermediate results and continue working.

Creaform MetraScan 750 | Elite

Source: industryarena.com

Another handheld metrology scanner that produces highly accurate models even for large objects.

MetraScan 750 | Elite Specifications

MetraScan 750 | Elite Applications

The instrument is widely used in architecture, power engineering, reverse engineering and metrological control.

Solutionix C500

Source: psarta.com

Solutionix 500 - compact color 3D scanner. The mobile device is placed on any level surface.

The design is based on a turntable and two cameras with a resolution of 5 megapixels each. The rotation of the platform allows cameras to capture the subject from different angles. The high operating speed and ease of use ensure the excellent performance of the equipment.

Technical characteristics of Solutionix 500

Solutionix C500 scope

Thanks to its compact size and the ability to quickly and accurately scan in color, the device is in demand in many areas, for example:

- in dentistry;

- jewelry industry;

- in education;

- to solve reverse engineering problems in various fields.

conclusions

The use of metrological 3D scanners improves the quality of products and reduces their cost by saving time and resources, and minimizing rejects. Automation of production processes, through the inclusion of 3D scanning technology, increases the efficiency of the enterprise and its competitive position in the market.

For a professional 3D metrology scanner, contact Top 3D Shop . Technical specialists will help you choose the equipment that is optimal for solving your problems, with the most suitable ratio of price and functionality.