Batteries were once heavy and awkward objects that produced ridiculously low power for their size and weight. Fortunately, technology has improved over time, and in 2020 we have great high-power lithium-polymer batteries that deliver as much power as your mobile project needs. However, there are a few things to keep in mind when using them - so I suggest you read a beginner's guide on how to properly use LiPo in your project.

So many types!

The first commercial lithium-ion batteries entered the market in 1991 and over the past 30 years we have seen rapid progress. As a result, we have many different technologies and types of batteries, divided by the type of design and materials used. In order to properly handle batteries, it is important to know which type you got your hands on, and it is very important to pay attention to this.

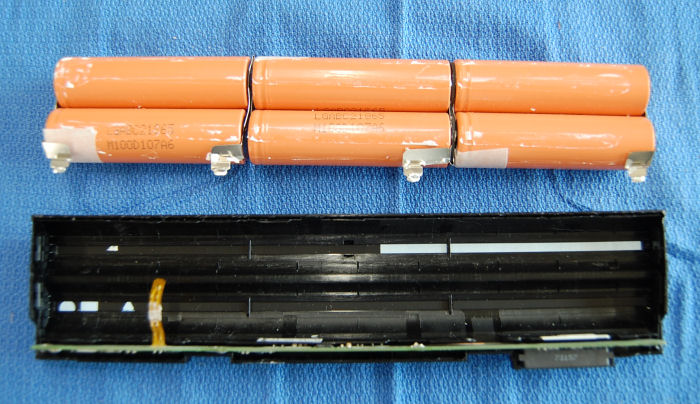

Lithium-ion 18650 cells from a laptop. Kits like this are usually spot-welded with nickel strips.

Typically, lithium-ion, or Li-ion batteries are called the entire technology of rechargeable lithium batteries as a whole, however, this is often the name for traditional cells with a cylindrical metal body. One option is the highly respected 18650, however there are many options and sizes. Their sturdy hulls have made them popular for use in vehicles, as they experience significant physical stress.

Lithium Polymer, or Li-Po, refers to lithium-ion batteries that use a polymer electrolyte instead of a liquid one. Thanks to this, they can be made in the form of containers of various shapes. This flexibility makes them useful for applications such as smartphones and tablets that require a large capacity and flat battery. They are also often used in radio-controlled models, since their low weight gives a significant advantage to flying vehicles.

Lithium polymer packaged batteries for use in radio controlled models.

Lithium-HV, or high voltage lithium batteries, are lithium polymer batteries that use a special silicon-graphene additive on the positive terminal so that they are not damaged by high voltage. If you charge most lithium batteries to a voltage higher than 4.2 V, they will significantly lose capacity, and their life will be noticeably reduced. Using this additive, cells can be charged up to 4.32 V without such negative consequences. Increasing the voltage gives about a 10% increase in energy density compared to conventional lithium polymer batteries.

Lithium iron phosphate batteries , or LiFePO 4, use slightly modified chemistry, so they can endure more charge / discharge cycles at the expense of a slightly lower energy capacity. They perform best in the 3.0V to 3.65V range, rather than the 3.0-4.2 range typical of standard lithium ion chemistry. This and the very flat discharge curve makes them ideal for replacing 12V lead batteries in many cases, and instead of the original six cells, four are used. They are usually more stable, less susceptible to self-discharge and loss of capacity over time.

Respect boundaries

A mistake can lead to unpleasant results

Compared to most types of batteries, lithium cells do not tolerate abuse. Discharging below the lower limit leads to the formation of copper dendrites, due to which their capacity decreases and a short circuit can occur. Overcharging can damage the anode by lithium deposits, which can form lithium dendrites, often resulting in a short circuit or self-sustaining heat-generating reaction - the battery begins to smoke and burn. Also, each element in the group must be maintained at the same voltage level as all its neighbors so that the elements do not degrade too quickly.

It is important not to charge lithium cells too quickly. The ambient temperature also greatly affects battery performance. Lithium batteries don't like freezing temperatures, especially when fully charged. They cannot be charged in freezing temperatures. Because lithium metal can deposit on the negative electrode, which can damage the cell or cause a short circuit. In principle, they can be charged down to -5 ° C, but this must be done very slowly. In addition, batteries can be damaged if charged at temperatures above 45 ° C.

If you go beyond the specified limits, at best, you simply kill the battery, at worst it will catch fire and explode. In addition, these elements are susceptible to swelling, gas evolution, and generally do not seem very convenient to work with. It may seem like it is too difficult to deal with them. Fortunately, modern electronics has learned to cope with their problems. The correct equipment and precautions will ensure that lithium batteries can be used safely and efficiently. However, everyone who works with them must understand the potential dangers. Bob Baddeley published an excellent article on this topic last November .

Working with batteries

In the case of using individual cells or their groups, for example, when using LiPo batteries in radio-controlled models, it is enough just to use a special charger for lithium batteries. When charging, you need to connect the wires to check the balancing [allow you to measure the voltage on each of the elements separately / approx. transl.], especially if the battery is completely discharged. The best battery efficiency can be achieved when using smart chargers (especially in cases with LiFePO 4 and high voltage cells). Make sure you have a way to stop the battery from draining if the voltage drops too low - be it a warning light, beep, or just an automatic shutdown.

These modules are great for integrating lithium batteries into a prototype.

If your device requires an integrated battery, special protection and charge boards are suitable for you. There are ready-made modules and integrated circuits that allow you to easily monitor the operation of lithium-ion batteries. In principle, there are many of them - from those that simply break the circuit when the voltage drops, to complex solutions for charging and protection. Companies like Adafruit sell modules that are great for beginner electronics hobbyists looking to integrate a convenient battery charging and monitoring solution without having to design boards themselves. However, there are open source solutions that will be easy to integrate into your own board in the future.

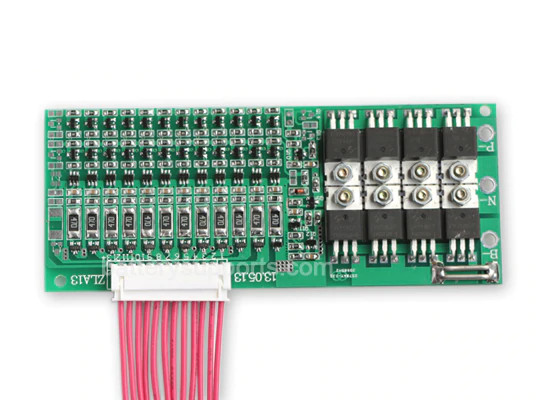

(BMS) 12 , 60 .

For larger projects with self-assembled batteries, Battery Management Systems (BMS) are well suited. The BMS is not really that much different from the security chip, it is simply designed for larger tasks. BMS is commonly used for batteries with a dozen or more cells and is often used in projects such as e-bikes and other vehicles. BMS is soldered directly to the batteries, and is connected to each cell separately [to a group of cells connected in parallel / approx. transl.]. Its task is to balance the elements, limit the discharge current for safety, control the charging process. Experienced battery assemblers often integrate the BMS into the body or casing of the battery itself, leaving only the connector outside. This allows the user to simply add the finished battery to their project,without worrying about protection.

If your project needs special environmental resistance, you will also need to monitor the battery temperature. Keeping track of the temperature of the cells, especially while charging, is a great way to protect your battery from damage. The best chips and BMS have temperature tracking function. At this level of assembly, you will already be making the battery yourself, inserting thermocouples into the right places during assembly. For batteries producing high currents, temperatures must be monitored without fail. Almost all e-bikes and electric vehicles have equipment to monitor the temperature of batteries and control systems.

Outcome

Lithium-ion batteries can be dangerous, but when used correctly, they are safe enough for most projects. The key is to use the right equipment to make sure you stay within the voltage and temperature ranges, or else disaster can happen. Hope this guide will help you in your search for information on including lithium batteries in your project.

See also:

- " Solar charger for lithium battery "

- " We place a point on Li: Do I need a lithium battery drill? "

- “ Solar power plant on the balcony. Personal experience "